Infusing Advanced Manufacturing into Undergraduate Engineering Education (2023)

Chapter: 5 Engineering Education for a Changing Future

5

Engineering Education for a Changing Future

Engineering and manufacturing are changing rapidly. The impetus for this report, a view that undergraduate engineering education must change to prepare students for new engineering and manufacturing landscapes, will persist and may increase as the fields continue to change.

Many of the technologies represented by “advanced manufacturing” have yet not reached mature roles in the manufacturing industry, but their trajectory, momentum, and promise are palpable. They build on components that have huge markets with expanding scope and declining price: computers, microelectronics, sensors, internet communications and services, artificial intelligence platforms, open-source software, virtual reality visualizations, digital representations of final parts and the processes to produce them, and many more. Advanced manufacturing generates innovations in two ways: in existing manufacturing techniques, equipment, and software, and in novel manufacturing approaches, tools, and processes.

This report makes recommendations for improving undergraduate education in advanced manufacturing given the state of today’s advanced manufacturing technologies and their propagation in education and industry. This chapter looks a bit farther ahead to anticipate changes in advanced manufacturing and thus new expectations for undergraduate education.

Undergraduate education programs can prepare graduates in several ways for changes to engineering during their careers. Faculty and professional organizations are discussing ways to meet future needs, and some

engineering programs are making changes accordingly. Doubtless the suggestions developed in this chapter have occurred to many and are being addressed by some:

- Develop an engineering ecosystem for teaching and learning;

- Anticipate likely evolutions of advanced manufacturing; and

- Produce graduates who are sufficiently digitally proficient to function in a complex digital environment.

The chapter concludes with a vision for the engineering ecosystem.

DEVELOP AN ENGINEERING ECOSYSTEM FOR TEACHING AND LEARNING

In pursuing its study, the committee was struck by the speed and excitement of change in manufacturing and the need for those innovations to be diffused rapidly through a large and diverse engineering community. Innovation is outpacing teaching and learning.

Because an undergraduate degree does not cover all a student needs to know to be a practicing engineer, graduates must know how to learn on the job, both because the job requires knowledge and skills that are not covered by an undergraduate program and because the nature of the job will change over time. Most undergraduate programs require students to learn some things on their own. For example, many first-year mechanical engineering students are expected to master an interactive solid-modeling application on their own, using video tutorials and optional assistance from a teaching assistant (admittedly, some students will have achieved mastery in high school or earlier). Problem sets can stretch to require students to learn new mathematics or techniques. And design courses can require learning about new materials or vendor offerings.

A design engineer needs to know the opportunities and limitations of the manufacturing services available to her. Traditional factory machinery is usually introduced in engineering education programs, but new equipment and processes—such as in advanced manufacturing—will require the designer to learn both basics and details. While some of this information will be covered by instruction manuals or online training, ultimately the designer will need to ask questions and take advice from the engineers or technicians in the factory, seeking facts, ideas, and suggestions.

Engineering educators are rightly calling for training students to “learn to learn” or to become “lifelong learners.” How can education techniques and the rest of the engineering community help? The committee offers the following suggestions:

- Challenge students with a capstone design that requires materials or techniques that they have not encountered. Assess the manufacturability and cost of a project. Find information on the internet. Better yet, find an expert.

- Recruit engineering alumni to critique student designs one on one using online collaboration tool. “Curate” alumni according to their expertise, to make it easy for students to find assistance.

- Would-be employers might also offer online critiquing by their experts. It is a way to evaluate and recruit a student while also helping the student.

- Vendors of advanced manufacturing equipment and software publish tutorials, specifications, manuals, and application notes on the network. By banding together (perhaps through a trade association) they can build a federated, curated database so students can easily find information from different vendors of similar products.

- The various manufacturing institutes (e.g., Manufacturing Innovation Institutes, Manufacturing Extension Partnerships) could play a bigger role in teaching and learning, both for undergraduates and for engineers later in their careers, brokering connections between teachers and learners, especially mixing different types of industries and educational institutions.

- Encourage technical conferences and trade associations to make papers and presentations available for free online. For example, USENIX (the Advanced Computing Systems Association) makes proceedings of all conferences, symposia, and workshops since 1993 freely accessible online.1 The manufacturing institutes could host and curate repositories of research papers and educational materials.

___________________

1 USENIX, “Homepage,” https://www.usenix.org, accessed October 4, 2022.

ANTICIPATE LIKELY EVOLUTIONS OF ADVANCED MANUFACTURING

Advanced manufacturing is not mature: every day brings reports of new devices, new materials, new structures, new demonstrations, and new applications. Many of these are not yet ready for routine use; some may be usable only for making prototypes; and only a few are ready for production. Despite rapid developments and improvements, the fundamental techniques emerging in advanced manufacturing, especially in additive manufacturing, digital control, and robotics, and their influence on engineering design, seem certain to endure. A comprehensive undergraduate education that covers these fundamentals will make it easier for an engineer to adapt to evolving changes, such as:

- New additive manufacturing methods, many of which are modest derivatives of those already introduced. Increased emphasis on working volume, speed, and cost.

- New materials. Additive manufacturing can combine multiple materials to make a single part. Sintering from powder beds has demonstrated alloys with new combinations or concentrations of materials; some have unequaled strength. And extruded materials can be combined, much the way a resin and its hardener are sprayed for insulation and coatings.

- New composite, multilayer, and multimaterial capabilities. Additive techniques can build multilayer structures or patterned layouts of different materials (e.g., tiling). Composite improvements include affordable out-of-autoclave resin systems and environmentally sustainable layup materials and solvents.

- New structures. Additive manufacturing can build parts with voids or channels, such as used for cooling (e.g., turbine blades, heat exchangers) or for conveying fluids in a network to implement control or mixing systems. New kinds of fixturing or sacrificial support structures for additive manufacturing may emerge.

- Robotic manipulation. Robots large and small have demonstrated additive techniques, such as forming concrete foundations and walls, or welding. Automation improvements include autonomous robotic training and system-of-system coordination.

- Greater dependence on modeling and simulation and the use of artificial intelligence analysis for engineering design, manufacturing process modeling, sequencing, and automation.

Other emerging technologies may not yet be visible on the horizon, but seem inevitable; for example,

- Volume additive manufacturing. Today’s additive machines work for low-volume parts; surely some higher-volume designs will emerge. But for what additive technologies and materials? With how much flexibility in part type?

- Factory automation. Build a near-net-shape using laser sintering, remove it, transport it to a computer numerical control (CNC) mill to create the final shape, then maybe to another machine to measure it. A simple extension of “flexible manufacturing” techniques, extended, for example, with a robot to grip the sintered part. This is a simple example; more complex and customized configurations are sure to be developed. What machines will be linked in a typical automated “advanced manufacturing factory?” Will small-scale robots be the key to flexibility to handle different part shapes? What about assembly?

- Automated metrology in manufacturing to validate parts and assemblies in real time during processing, perhaps adjusting a manufacturing process accordingly.

- Data integration to connect information in design and manufacturing systems to a complete product life cycle, including engineering, manufacturing, component supply, operation, and sustainment.

Of course, not all of these futures can be covered in undergraduate education, no matter how forward-looking, but some may trigger additional educational coverage. For example, the legacy portfolio of materials (a dozen kinds of aluminum and steel) will be inadequate for additive manufacturing opportunities. Engineers will have to have greater knowledge of, and participation in, the development, characterization, testing, and applications of materials, many of which will be new.

Applied research will be important in evolving advanced manufacturing. U.S. funding and pursuit of applied research in academia appear to be growing. The National Science Foundation’s (NSF’s) new Directorate for Technology, Innovation and Partnerships (TIP) is one recent example

(see Recommendation 4.5) and some universities are increasing emphasis on applied research and on the opportunities it offers to engage students and contribute to their education. While U.S. activities are much less fully developed than the German system exemplified by the Fraunhofer institutes, advanced manufacturing and engineering students will benefit from the growth of applied research.

ENSURE SUFFICIENT DIGITAL PROFICIENCY FOR GRADUATES TO FUNCTION IN A COMPLEX DIGITAL ENVIRONMENT

Engineering design and manufacturing depend on digital representations of designs, processes, and results. Designers use software to create digital models of their designs, which ultimately feed manufacturing processes such as CNC or three-dimensional (3D) printing.

The term “digital thread” is apt for describing the passage of digital representations in the paths from design to manufacturing: intervening steps may involve software to analyze and adjust a design for performance properties, manufacturability, cost reduction, and so forth. Software may be able to simulate the design’s operation to determine that it will work correctly as well as extract characteristics of the design such as cost, producibility, weight, and thermal performance. The digital path is also accompanied by additional steps and annotations, for example, to incorporate changes, record the results of design or requirements reviews of the project, or develop and check fixtures needed during manufacturing. The path may also lead, via digital networks, to vendors or customers who perform specialized analyses or check that a design will mate properly to an assembly of parts produced by others.

The digital thread is not new,2 but the concept and implementations are now being widely adopted and implemented in the defense industrial base and its supply chains. The growth of the digital thread is due in part to design and manufacturing processes and equipment that increasingly

___________________

2 Computers have long been used as digital design aids, for example, to record the schematic circuit diagram of a new computer design and simulate the new circuit. In the 1960s, it was common for designers to develop ad hoc design and simulation software for these tasks. They also wrote software to transform the circuit diagram into a series of wiring steps to build the circuit. The simulator and the circuit could then be executed step by step to ensure that behavior of the circuit (as wired!) matched the simulation. The hardware and the custom software with its data thus represented a limited form of digital twin.

create or consume digital specifications, and in part to a growing ecosystem of software and vendors (including system integrators) that offer software products to operationalize the concepts. The availability and widespread use of computer-aided design (CAD) software were the nuclei of the digital thread. CAD models can be transformed (sometimes requiring human guidance) into digital data to drive manufacturing equipment such as CNC mills and 3D printers. They can also be used to visualize and inspect parts and assemblies, for example, to present a virtual reality “walkthrough” of an airplane’s interior.

Digital Twins

A digital twin is a computer model (or “virtual representation”) of a physical asset or process, often encompassing its entire life cycle (see Box 5-1). It is valuable because creative and analytic work on the asset can be done using computers and software tools (the “virtual environment”) before the asset is built. A solid model of an asset created with CAD software may be part of the asset’s digital twin, which may also include test data, simulation scripts, predicted operating parameters, and more. When the asset is realized, as-built measurements may augment the model, as may measurements of operating parameters and their evolution over time as the asset ages. Maintenance events and design upgrades, such as block upgrades of military equipment, can be recorded. A twin can record both real-time measurements of the physical asset and data computed by simulation. It can also include manufacturing twins that can predict build staffing, tool counts, factory space, potential bottlenecks, and capital requirements.

Digital twins to drive modeling and simulation of various product behaviors and capabilities in aerospace or commercial markets are typically created early in product development cycles and validated during product testing and validation. In some aerospace products, these cycles can be as long as 20 years because of extensive structural and flight-testing requirements. In the future, modeling and simulation of digital twins are envisioned to eventually reduce product testing and validation requirements, manufacturing risk, and overall product development cost and span.

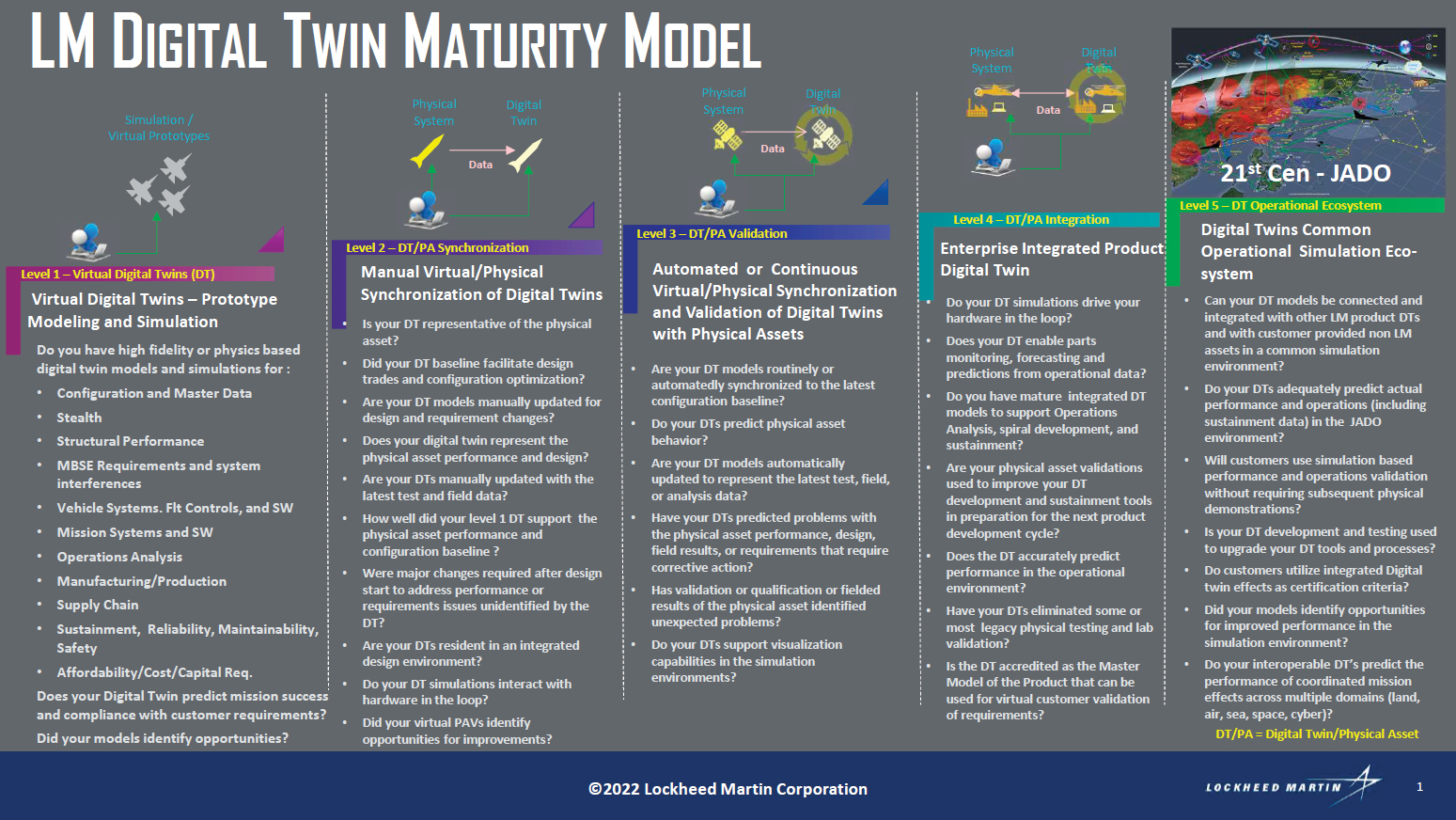

Lockheed Martin sees digital twin models increasing in size and scope as a product is developed, manufactured, and operated (see Figure 5-1). Level 1 digital twins of various product capabilities aim to increase initial product maturity (reduce program risk) prior to engineering release. Levels 2 and 3

SOURCE: Lockheed Martin, “Visualizing the Digital Thread = Digital Twins at Lockheed Martin,” https://www.lockheedmartin.com/en-us/news/features/2021/visualizing-the-digital-thread-and-digital-twins.html, accessed October 4, 2022.

use product testing to feed and enhance the digital twins, leading to Level 4 digital twins that accurately represent the physical assets and can be used to validate requirements to customers. Level 5 twins are capable of engaging other twins either from Lockheed Martin or provided by the customer in a common digital ecosystem for mission planning and customer accreditation. The more mature the digital twins, the fewer disruptions during the product development cycle, thus reducing manufacturing costs and span times.

Digital twins can be very simple, or complex comprehensive models of large products. In practice, they are often realized as a set of separate but related digital models. For example, at Lockheed Martin, there is no single twin to represent the extraordinarily complex F-35 fighter jet, but subsystems may have their own twins (e.g., for fuel, radar, engine, hydraulics). Models may be simple at the outset but grow in fidelity and complexity as a design progresses, and more accurate analysis is required to ensure that it meets performance targets. Building complex models that are consistent with other, related models and are sufficiently accurate models of reality can be very difficult.

Modeling and Simulation

Most engineering disciplines today are fully engaged with digital methods and the digital threads that link them into engineering processes from design to realization, whether expressed as a collection of related data and tools or as a digital twin. Software tools are available to build and modify models, to run simulations, and to do various kinds of design analysis. An engineering design team may need to use many different software tools, data formats, and vendor services to develop the digital picture of a design.

Modeling and simulation are introduced in undergraduate education, often through simple examples or linkages or crankshafts in MATLAB.3 Solid models are augmented with models of motion for joints, bearings, and the like. Visualizations of simulations show the results of motion of the moving parts.

Modeling and simulation are the power behind digital twins—and they can become very complex. The fidelity of the virtual models and simulations is what makes the virtual twin valuable to the product’s development and deployment. Finite element models using tools such as NASTRAN4

___________________

3 MATLAB (matrix laboratory) is a multi-paradigm numerical computing environment and proprietary programming language developed by MathWorks.

4 NASTRAN is a finite element analysis program and is the industry standard for basic types of analysis for aerospace structures (e.g., linear, elastic, static, and dynamic analyses).

or Abacus verify structure design loads, which can be validated by testing actual structures. Aircraft designs may involve computational fluid dynamics models to assess loads, flight dynamics, and other performance factors. Custom models might be built, for example, to cover fueling operations or effects of component failures. Models in these separate domains can become very complex, and ensuring that the multiple models are consistent is very challenging.

There are no tools for building comprehensive models; each project or business must decide on an appropriate level of modeling fidelity and on the tools and practices to build, validate, and exploit its models. Different tools are usually needed for different domains, such as hydraulic, electrical, structural, and control. Current lack of sufficiently sophisticated tools and techniques for modeling and simulation are among the principal limitations of the “dream” of digital twins.

Digital Data Management and Infrastructure

For small teams or simple designs, the complexity of the associated digital data files is modest. But as project complexity grows, so do teams, the variety of software tools, and the number of design collaborators, contributing to challenges in the management of the quantity and variety of digital data files. It is easy to lose data, or discover that information saved no longer works with the latest version of a software tool or that a remote collaborator is providing data in a noncompatible format. This situation is commonplace for software engineers, for whom producing a single software product may require the exact management of several thousand digital files of source code, software tools of varying provenance and version, test data, bug reports, scripts to drive the software “tool chain” that compiles, assembles, and tests the software, and so on. Software tools and practices have evolved to manage project data for large teams.

Every engineer will need to appreciate the challenge of managing dozens of file formats and hundreds or thousands of files. Working for a small company on small projects, a designer may not face data management challenges. Until, that is, a customer returns two years later and asks for a small revision to a product; this is when the designer discovers that he’s lost some data or that the data no longer work with current software tools. Larger companies with large projects that may span decades devote considerable engineering and information technology resources to designing, curating, and maintaining the digital infrastructure required for their work. They approach

managing digital data as a problem in “systems engineering”—engineering the systems their company uses to do its work.

Undergraduates can begin to glimpse and cope with digital data management in a variety of ways; for example,

- Design courses and practicums to exhibit and use digital techniques, with as much fidelity as possible to those used in manufacturing. Do not overlook the problems of scaling up project size or timeline.

- Practice collaborations that exchange digital information, both off- and online. For example, two metal parts that must mate share an “interface” that can be represented digitally. Another example is a team of design engineers and one of manufacturing experts working collaboratively on a single project, with their respective views and tools.

- Practice using digital data management tools such as GitHub,5 even with small teams. To glimpse the challenges posed by large digital datasets, ask a student to make a small change to an existing, large project represented only by its digital repository.

- Techniques for modeling engineering processes and products, of the sort used in digital twins, could be covered and practiced in engineering programs. MATLAB examples can introduce modeling and simulation, but asking students to make a small modification to a large-scale model can build an appreciation of the difficulty of modeling with the scale and precision required by digital twins.

- Expose all engineers to the cyberphysical techniques used in process automation (including factory automation) involving sensing (the Industrial Internet of Things) and digital control. Small, programmable, flexibly deployed robots are good candidates for practicum projects in this area.

- Encourage engineers to become deeply skilled in computer science or informatics. Skills beyond computer literacy or “computational thinking”6 are needed. Offerings labeled “CS+X” (where CS = computer science and X = engineering) are appropriate.

This report recommends incremental changes to existing undergraduate engineering programs and practice in the hope that they can be implemented relatively easily and quickly. We have presented a few cases of exemplary

___________________

5 GitHub, “Homepage,” https://github.com, accessed October 4, 2022.

6 P.S. Wang, 2016, From Computing to Computational Thinking, Boca Raton, FL: CRC Press.

practice where such changes have been made; doubtless, there are many more examples, and still more engineering schools that are planning or implementing changes.

Many educational institutions are already rolling out changes that will strengthen the treatment of manufacturing and advanced manufacturing. NSF’s TIP directorate can develop programs that will also help. And DoD, especially through its Manufacturing Innovation Institutes, has mechanisms to spur action. Government can play large and urgent roles in strengthening undergraduate education of advanced manufacturing.

Harder to predict than changes in engineering and manufacturing are changes in student interest and engagement. Some academics attribute the rise in science, technology, engineering, and mathematics (STEM) bachelor’s degrees to interest in computer science, inspired by new consumer products and startups. Can national security and defense also attract engineers to contribute to stability in an increasingly unstable world? Perhaps the challenges of sustainability and of mitigating and adapting to climate change will inspire a new wave of engineers. A major role for industry is to inspire every new wave by showcasing its huge assortment of exciting innovations, including advanced manufacturing.

In the introduction to this report, the committee sketched a vision of a collaborative, interdisciplinary engineering future: a culture of engineers—both academic and industrial—who continuously embrace advanced manufacturing innovations and ramifications, such as in new materials and design opportunities, and who work together to couple design and manufacturing in an engineering ecosystem. The vision is not a monoculture: it must accommodate differences among academic institutions, among businesses, and among engineers. Academic engineering will recognize manufacturing as an integral, essential element of engineering, and will grow its ability to innovate in all aspects of engineering. Students will engage in the real-world engineering ecosystem, where manufacturing is the route to impact.

This page intentionally left blank.