Evaluation of the Asphalt Binder Quality Tester (2022)

Chapter: Appendix A - Overview of the ABQT Device

APPENDIX A

Overview of the ABQT Device

A.1 Supply Chain Background

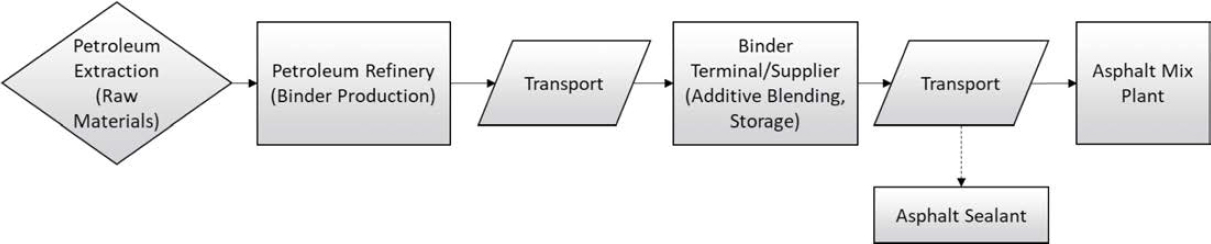

Asphalt binder is a viscous liquid or semisolid petroleum by-product used to bind aggregate together in the production of the asphalt mix. Binder is produced at crude oil refineries and then transferred to terminal facilities where binder suppliers may blend additives and store the binder temporarily. Asphalt binder may travel through multiple blending terminals along the supply chain depending on the properties required for the final use. After blending, suppliers transfer binder to asphalt mix plants where it is stored on site for use in asphalt mix production. In some cases, mix plants may further modify the binder. Figure A-1 depicts the asphalt binder supply chain. Some asphalt binder is also used by contractors who add additional emulsifying agents as asphalt sealant, which is used either to fill cracks in asphalt concrete or to create covers in parking lots; however, this application was not considered as part of this study.

A.2 Binder Quality Overview

In 1987, the U.S. Congress established the Strategic Highway Research Program aimed at improving the performance, durability, and safety of the nation’s highways. One product of the 5-year, $150 million program was Superpave (an acronym for Superior Performing Asphalt Pavements). Superpave was designed to develop testing methods and identify specifications for pavement materials used in roadway construction across the country. Superpave was introduced for state government use in 1992 when FHWA then assumed responsibility for further development of the program.

Three components make up the Superpave method:

- Asphalt binder specification system;

- Asphalt mix design and analysis system based on tests that measure performance factors such as fatigue, cracking, permanent deformation, thermal cracking, aging, and water sensitivity; and

- Mix analysis tests and performance prediction models.

The first component of Superpave was the asphalt binder grading system, or the performance grading system. This system characterizes all PG binders based on fundamental engineering parameters, climatic factors, the impact of traffic conditions, and aging control. It was a major improvement over previous systems of asphalt binder grading.

The quality of the binder used in asphalt mixes is an important factor in the performance and longevity of the asphalt. States have quality assurance (QA) protocols in place to make sure that the binder has the required properties and is the correct PG binder. QA consists of two main

components—quality control (QC) and acceptance. QA, QC, and acceptance are defined in TRB’s Glossary of Highway Quality Assurance Terms as follows:

- Quality Assurance. All those planned and systematic actions necessary to provide confidence that a product or facility will perform satisfactorily in service.

- Quality Control. Those QA actions and considerations necessary to assess and adjust production and construction processes to control the level of quality being produced in the end product. QC is typically performed by contractors or binder suppliers.

- Acceptance. The process of deciding, through inspection, whether to accept or reject a product, including what pay factor to apply. In the case of binder, the pay factor may be a percentage penalty for binder that does not meet the standard specifications. Acceptance testing is typically performed by binder suppliers and the road owner or highway authority.

Testing is used at key points along the supply chain to ensure that a binder meets the required PG specifications for a project. Testing protocols are commonly employed at two stages in the supply chain:

- Binder Suppliers. Binder suppliers may conduct QC tests in the formulation process to ensure that they have the required properties when blending additives. These tests are conducted at the supplier’s discretion and are typically not mandated by regulation. Binder suppliers are also required to take samples at frequencies that vary by state. Suppliers are then required to either conduct acceptance testing with on-site equipment and submit the results to owner agencies or submit samples to agency testing labs to conduct the acceptance tests.

- Asphalt Mix Plants. Most states have QA requirements for asphalt mix plants to ensure that the appropriate binder is being used each day on each project. In most cases, asphalt mix plants do not conduct on-site testing but have operators take samples according to state regulations and submit them to owner agencies for acceptance testing.

A.3 ABQT Background

In most states, inspectors periodically visit supplier and contractor sites to collect samples of binder for QC testing and acceptance testing. However, most states do not have sufficient testing capacity, which has two important effects. First, most states do not test every sample they collect. Second, the lag time between a sample being drawn and being tested is long.

The result of these effects is that problems may not be identified until well after the asphalt mix is placed or may be missed altogether, leading to road quality problems at a later date. In most cases, states levy penalties when they discover binder quality issues if the issue is not severe enough to justify removing and replacing the mix. In rare circumstances, roads must be repaved to mitigate quality issues, which can be costly to both the contractor and the users of the roadway.

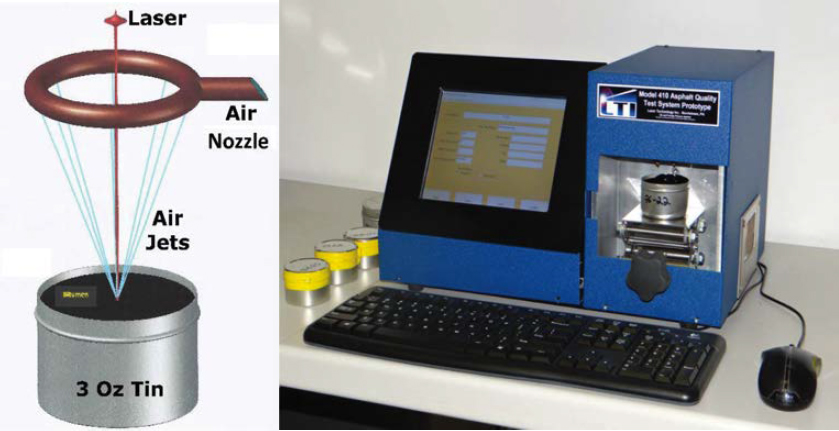

To address some of the challenges related to QA of binders, FHWA and Laser Tech, Inc. (LTI) of Norristown, Pennsylvania, worked together under a Cooperative Research and Development Agreement (CRADA) to develop the Asphalt Binder Quality Tester (ABQT), pictured in Figure A-2.

The ABQT is a testing device that can provide QC test results in minutes. This device is smaller than most other existing asphalt binder testing equipment and requires less complicated calibration, making it more portable than most binder rheological testing equipment. The ABQT is also easy to use; the test requires only a 3-ounce tin of asphalt binder that must be conditioned to 25°C (77°F). The ABQT uses an air jet to produce a 20-second load on the asphalt binder sample and then allows a 70-second recovery time. A laser deflectometer in the ABQT measures the resulting deflection and recovery of the sample over this 90-second period. Deflection and recovery are important properties of a binder because the elastic and plastic deformation of the binder under load has a major impact on rutting and the durability of the asphalt. FHWA also developed an Artificial Neural Network (ANN) model in the ABQT. The ANN model incorporates test data from known binders meeting the Superpave PGs and uses the deflection and recovery curve measured over the 90-second test period to predict the PG of the asphalt binder sample. Furthermore, the ABQT was tested to compare the percentage recovery of the sample to the percentage recovery of the Multi-Stress Creep-Recover (MSCR) test, and the results from the two tests were very similar, indicating that the recovery results from the ABQT relate to the recovery of asphalt binders. The ABQT can detect the PG of softer binders used in Recycled Asphalt Pavement (RAP) mixes and modified PG plus graded binders.

Although these results show that the ABQT is useful for conducting quick QC tests, the ABQT does not provide data that other tests do not. The test is also only conducted on unaged binders, so it does not provide data on the impacts of aging on the binder properties. Because of these limitations, there may not be a strong push to have it replace current acceptance testing procedures.

Five state DOTs had evaluated the ABQT device on asphalt binder sampled in their states and found that the device predicted the PGs with 98% accuracy. Contractors using the ABQT can also add new PGs to the ANN model to improve its prediction accuracy and train the model to recognize new grades.

Figure A-2. The ABQT.