Evaluation of Post-Consumer Recycled Plastics in Asphalt Mixtures via the Dry Process (2025)

Chapter: 2 Literature Review

CHAPTER 2

Literature Review

A comprehensive literature review was conducted on the use of recycled plastics in asphalt binders and mixtures. This review was built upon the previous literature review efforts conducted at the National Center for Asphalt Technology (NCAT) (Yin et al., 2020a), which included over 150 research reports, journal articles, trade publications, newsletter and magazine articles, technical guidance, and personal email communications. There is likely further literature available on this topic in languages other than English and Spanish, but these sources were not included in this literature review.

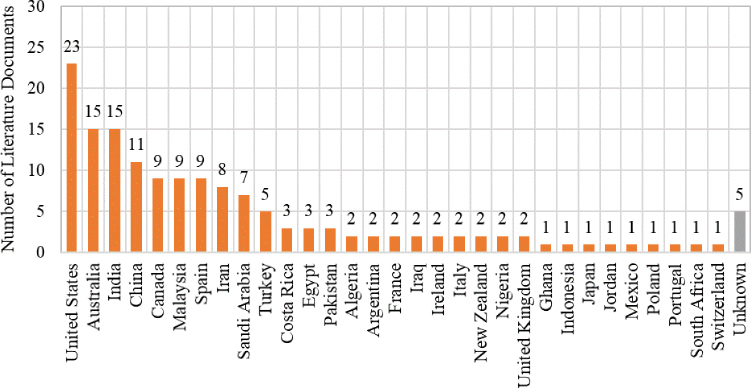

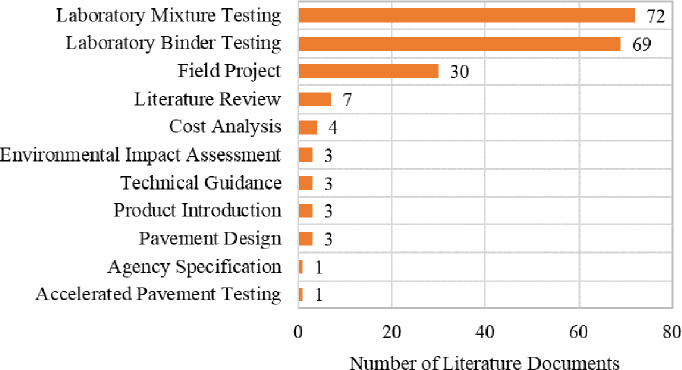

Figure 2 through Figure 6 present the classification of literature documents based on year of publication, place of publication (i.e., country of the first author), type of recycled plastics used, method of incorporating recycled plastics into asphalt, and scope of the study. (Note that some documents fall under multiple classifications within certain categories.) Approximately 73% of the literature was published from 2011 to 2021 (Figure 2). The six countries with the most literature documents were the United States, India, Australia, China, Malaysia, and Canada (Figure 3). Polyethylene (PE), including linear low-density polyethylene (LLDPE), LDPE, and HDPE, is the most studied type of recycled plastic for use in asphalt, followed by polyethylene terephthalate (PET) and polypropylene (PP), respectively (Figure 4). In roughly 50% of the literature, recycled plastics had been added into the asphalt binder via the wet process (including Novophalt and Polyphalt), and approximately 32% used the dry process of adding recycled plastics into the mixture; only a few studies reported the use of asphalt-plastic emulsion and plastic synthetic binders for adding recycled plastics (Figure 5). Over 85% of the literature focused on laboratory testing or field projects, or both, of RPM asphalt binders and mixtures (Figure 6). The remaining studies provided literature reviews, cost analyses, pavement designs, production information, accelerated pavement testing, technical guidelines, environmental impact assessments, or agency specifications.

The following sections present a summary of literature review findings and knowledge gaps organized by topic. For each document included in the literature review, a summary table and synthesis are provided in Appendix A of this report.

2.1 Availability and Sourcing of Recycled Plastics

2.1.1 Summary of Findings

According to the EPA, approximately 35.7 million tons of waste plastics was generated in 2018, which accounted for 12.2% of municipal solid waste (MSW) generation (approximately 292 million tons) (EPA, 2021). Figure 7 presents a breakdown of plastics by type in MSW based on EPA data in 2017. As shown, PP is the most common type of MSW plastic at 32.1%, followed by PE at 29.2%. Other major types of MSW plastic include PET, polystyrene (PS), and PVC.

Note: PU = polyurethane.

Source: Adapted from DuBois et al. (2020) and used with permission from The Dow Chemical Company. Note: PETE is an alternate abbreviation for polyethylene terephthalate.

Although plastics exist in all major MSW categories, the containers and packaging category holds the most plastic tonnage, encompassing items such as bags, sacks, and wraps; other packaging; PET bottles and jars; HDPE natural (i.e., white translucent) bottles; and other containers. Among the MSW plastics generated in 2018, only 3.1 million tons was recycled (corresponding to a recycling rate of 8.7%), 5.6 million tons was combusted with energy recovery, and the rest was landfilled. As shown in Figure 8, the tonnage of recycled MSW plastics has increased steadily over the last four decades, with 20,000 tons in 1980 and 3.1 million tons in 2018. The recycling rate of MSW plastics also showed a steady increase over the same period, reaching a record high of 9.0% in 2015. This recycling rate varies significantly across plastic types. Based on the data provided by the Association of Plastic Recyclers, PET bottles and jars, as well as HDPE natural bottles, had a significantly high recycling rate of approximately 30% in 2018 (EPA, 2020).

Plastic recycling starts with the collection of PCR plastics and PIR plastics, which are also known as manufacturing waste plastics. PCR plastics are used consumer items that have completed their life cycle, often referred to as a “dirty” plastic stream due to contamination with other non-plastic materials. PCR plastics are typically collected by local recycling programs and processed at centralized recycling facilities for end-of-life recycling applications. PIR plastics, on the other hand, are generated by manufacturers and processors in the original extrusion or molding process. Because PIR plastics have not entered the consumer market, they are free from post-consumer contaminants and are considered a “clean” plastic stream from a polymer compositional standpoint, requiring significantly less processing effort for recycling than PCR plastics.

In general, the recycling process for PCR plastics includes collecting, sorting, shredding, washing, decontamination, resizing, identification, and compounding. The process starts with sorting the collected PCR plastics according to plastic type. Sorting can be done manually or with automated machines equipped with technology for recognizing and sorting plastics. After being sorted into different plastic types, the PCR plastics are processed through a series of shredders to create plastic flakes. The shredded plastic pieces are then washed to remove dirt and contaminants that can be separated in water due to density differences. In some cases, chemicals, detergents, disinfectants, or other products are added to the water to improve the efficiency of cleaning and separation. Because PCR plastics can contain chemical or biological contaminants, standards have been established to regulate the reuse of PCR plastics that may have been in contact with food. Therefore, an additional step may be added to the decontamination process after washing to ensure these standards are met (Kolek, 2001).

Once the plastic flakes have been resized and decontaminated, they are identified and separated based on their properties. Separation properties typically include density, air classification,

Source: Data from EPA (2021).

melting point, and color. In many cases, the plastics are then compounded into a new form, most commonly pellets. Other processes directly pelletize without producing flakes as a first step.

The cost of post-processed PCR plastics is highly dependent on the recycling process; the more processing that is required, the higher the cost. The price of post-processed PCR plastics on the market can vary from $50 to $1,500 per ton. The upper end of this range is for prime-quality, high-end packaging applications where recycled content is desired. It remains unknown if this level of quality is necessary for asphalt pavements.

Specific gravity, melting temperature, and particle size are the three most common properties of recycled plastics reported for asphalt applications in the literature. When recycled plastics are added via the wet process, specific gravity plays an important role in the phase separation tendency of RPM asphalt binders, among other factors that affect the microstructure and compatibility of the asphalt-plastic system. For the dry process, the incorporation of recycled plastics affects the volumetrics of RPM asphalt mixtures due to the large difference in specific gravity between recycled plastics and aggregates. Melting temperature is another important property that determines how recycled plastics should be added to asphalt. In general, recycled plastics with a low melting temperature (i.e., below 160°C) are suitable for use in the wet process, while most types of recycled plastics can be used in the dry process (except PVC due to safety concerns of hazardous chlorine-based dioxin emissions). The particle size of recycled plastics is also important since it affects the rate of heat transfer, influencing the ability of recycled plastics to be melted and blended into asphalt binders for the wet process. In the dry process, particle size can affect the shape and phase of the plastic and change how it interacts with the binder and aggregate during mixing.

In addition to specific gravity, melting temperature, and particle size, other important properties of recycled plastics for asphalt applications, especially those added via the wet process, include melt flow index (MFI), degree of crystallinity, and ash content. MFI is a measure of the mass of the plastic sample that is extruded through a capillary at a certain temperature and force. The standard test method for measuring MFI is ASTM D1238. MFI indicates the flow properties and molecular characteristics of different recycled plastics on a relative basis. For example, a lower MFI value suggests higher melt viscosity and the presence of longer polymer chains or greater polymer branching (Shenoy et al., 1983). Testing for MFI with different load weights can also provide information on the molecular weight distribution of the recycled plastic sample (Bremner and Rudin, 1990).

The degree of crystallinity indicates the fraction of ordered molecules and molecular chains in the recycled plastic sample, typically ranging between 10% and 80% (Bassett, 1981). Differential scanning calorimetry (DSC) is the most common test method for measuring the degree of crystallinity, but other analytical techniques—such as X-ray diffraction, infrared spectroscopy, and nuclear magnetic resonance—can also be used. Recycled plastics with a high degree of crystallinity are generally not desired for asphalt modification because the resultant RPM asphalt binders are brittle, have poor low-temperature relaxation properties, and are susceptible to premature surface cracking. Finally, ash content should be considered because it indicates the content of inorganic residues in the recycled plastic sample. These inorganic residues are contaminants that could appear in antiblock agents, fillers, reinforcements, catalyst residues, or pigments, among others (Ranta-Korpi et al., 2014). Recycled plastics with a low ash content are preferred for use in asphalt binders and mixtures.

An ongoing research study at RMIT University in Melbourne, Australia, provided recommendations for the selection of recycled plastics for asphalt applications (Guppy and Giustozzi, 2021). As shown in Figure 9a, the selection criteria included blendability, purity, storage stability, solubility, processability or easy QC test, polarity, organics contamination, and screening for “risky” additives. For each evaluation criterion, the corresponding laboratory test or analysis method

Source: Adapted from Guppy and Giustozzi (2021), sourced with permission.

Note: BFRs = brominated flame retardants.

was provided. Figure 9b shows an example of the evaluation results for different types of virgin and recycled plastics. Although these evaluation criteria appear reasonable, their robustness, effectiveness, and practicality for implementation are yet to be determined.

2.1.2 Knowledge Gaps

There are currently no robust specifications available on the source, recycling process, and properties of recycled plastics for use in asphalt. Although the use of many different types of

recycled plastics has been reported in the literature, the source and properties of the plastic materials studied were not characterized and reported consistently. Some of the recycled plastics used in asphalt research had undergone a systematic recycling process that included collection, sorting, washing, resizing, identification, and compounding. As a result, these post-processed recycled plastics typically consisted of polymer resins with a high degree of consistency and cleanliness. However, unprocessed or partially processed recycled plastics were also added to asphalt binders or mixtures. In these cases, the recycled plastics typically consisted of a mix of different polymer resins and non-plastic contaminants in unknown proportions. Because each component of the unprocessed or partially processed recycled plastics has different physicochemical properties, they may yield RPM asphalt binders and mixtures with inconsistent quality characteristics and performance properties. Thus, future studies are needed that specify the finished product source or overall polymer composition (e.g., PE-rich or PE/PP 3:1) and the recycling process of plastics for use in asphalt binders and mixtures.

Further research is needed to evaluate whether compositional and contaminant differences in PIR and PCR plastics could significantly affect the performance properties of RPM mixtures, and, if so, what criteria should be used in the specification.

2.2 Methods of Incorporating Recycled Plastics

2.2.1 Summary of Findings

There are essentially two methods of incorporating recycled plastics in asphalt: the wet process and the dry process. In the wet process, recycled plastics are added to the asphalt binder as a polymer modifier or an asphalt replacement (in some cases, erroneously referred to as asphalt extenders). This requires mechanical mixing to achieve and maintain a homogeneous modified binder blend. Recycled plastics with a low melting point, such as LLDPE, LDPE, and HDPE, are typically suitable for this process. For the wet process, the dosage of recycled plastics commonly reported in the literature varies from approximately 1% to 12% by weight of asphalt binder. This dosage corresponds to about 1 to 12 lb. of recycled plastics in a ton of asphalt mixture.

In the dry process, recycled plastics are added directly into the mixture as an aggregate replacement, mixture modifier, binder modifier, or any combination of these. The aggregate replacement approach is commonly used with recycled plastics with a high melting point (i.e., above the typical production temperature of asphalt mixtures), such as PP, PET, PS, and polycarbonate. The mixture modifier approach appears to be applicable to most types of recycled plastics (e.g., PE, PP, PET, PP, PS, and others), except for PVC due to concerns about hazardous chlorine-based dioxin emissions. Several studies claimed that when recycled plastics with melting points below the mixture production temperature (e.g., LLDPE, LDPE, and HDPE) were added via the dry process, the plastics melted upon mixing with the hot aggregates and produced plastic-coated aggregates, which improved the physical and surface characteristics. According to asphalt contractors in France, when LDPE was added into the asphalt mixture via the dry process, part of the plastics coated the aggregate particles, while the rest was dispersed in the asphalt mortar phase. For the dry process, the dosage of recycled plastics commonly reported varies from approximately 0.2% to 6.0% by weight of aggregate, corresponding to about 4 to 120 lb. of recycled plastics per ton of asphalt mixture. The equipment commonly used for feeding fibers into a continuous-mix plant is well suited for feeding pelletized recycled plastics for the dry process.

Some studies suggest that the wet process may offer economic advantages for recycling plastics compared to traditional polymer-modified binders, since recycled plastics often cost less than commonly used asphalt polymers. However, there are handling challenges with the wet process due to the potential for separation of the plastic in the binder. This may require continuous agitation of the plastic-modified binder, the addition of a stabilizing or compatibilization agent, or

that the plastic-modified binder be used immediately after blending. The dry process has lower addition costs, but the interactions of the plastics with the binder and aggregates are not well understood. One study noted that the wet process has greater potential than the dry process due to its advantages in structural performance, environmental impact, safety, and life-cycle cost (Lin et al., 2020).

2.2.2 Knowledge Gaps

Although wet and dry processes have both been used for incorporating recycling plastics in asphalt, guidelines are needed to further define the details of each method. For the wet process, information is needed to determine whether each type of recycled plastic will act as an asphalt modifier or asphalt replacement. The asphalt pavement industry has a long history of using modified asphalt binders to enhance the performance of asphalt pavements. Asphalt modifiers include polymer or non-polymer additives that improve certain performance properties of asphalt binders. Recycled plastics such as PE and PP are plastomeric polymers, thus they fall into the category of asphalt modifiers. Asphalt replacement, on the other hand, refers to additives that substitute for a portion of asphalt binder without necessarily providing performance improvement. The intent of these additives is mainly to reduce the amount of asphalt binder in the mixture and consequently provide an economic benefit by lowering material costs. A few proprietary recycled-plastic products claim to replace, rather than modify, asphalt binder.

For the dry process, recycled plastics are not added to the binder but instead are added directly into the drum or pug mill at the hot-mix plant. In this process, recycled plastics could act as asphalt modifiers, asphalt replacement, aggregate coating, aggregate replacement, or any combination of these. The asphalt modifier and asphalt replacement approaches are similar to the wet process in principle. However, because high-shear blending is not used and because of short mixing times, it is unlikely that recycled plastics will fully dissolve into the asphalt binder. As a result, recycled plastics may behave as a multiphase system in which some of the plastic melts and becomes part of the asphalt binder or mortar, some may coat the aggregate, and some may remain solid as part of the aggregate matrix. The aggregate replacement approach is considered applicable for recycled plastics that have a melting temperature above the production temperature of asphalt mixtures. In this approach, the role of recycled plastics is to contribute to the aggregate structure by replacing a portion of the fine or medium-sized aggregate particles without disrupting shear strength. Given the different roles of recycled plastics in asphalt mixtures, a closer examination of the aggregate coating concept and the aggregate replacement approach is needed. For the dry process, research is also needed to assess the dispersion of recycled plastics within the mixture for both lab- and plant-produced samples. The degree of dispersion will affect the consistency and performance properties of RPM asphalt mixtures.

Finally, the terminology of the dosage of recycled plastics needs to be standardized for reporting purposes. The project team suggests describing the dosage of recycled plastics by weight of asphalt binder for the wet process and by weight of aggregate for the dry process.

2.3 Laboratory Binder Characterization

2.3.1 Summary of Findings

Most of the studies evaluating the impact of recycled plastics on asphalt binder performance reported findings in terms of penetration, softening point, viscosity, ductility, or performance grade. In a limited number of studies, multiple stress creep recovery (MSCR) and dynamic shear rheometer (DSR) frequency sweep tests were conducted for binder performance characterization. The consistent finding across these studies was that the use of recycled plastics for asphalt

modification reduced penetration, ductility, and creep compliance (Jnr), and it increased the softening point, viscosity, and high-temperature performance grade of asphalt binder. Therefore, asphalt binders modified with recycled plastics should exhibit better rutting resistance than their equivalent unmodified counterparts. Few studies examined the effect of recycled plastics on asphalt binder properties related to fatigue or low-temperature cracking susceptibility. These studies generally reported that the addition of recycled plastics improved fatigue and low-temperature resistance when a third additive [such as transpolyoctenamer (TPOR), SBS, reactive elastomeric terpolymer (RET), crumb rubber, or waste vegetable oils] was used for the modification.

A limited number of studies performed analytical evaluations of asphalt binders modified with recycled plastics. From these studies, tests such as DSC, modulated DSC, thermogravimetric analysis (TGA), and derivative thermogravimetry were used to characterize thermal properties, while Fourier transform infrared spectroscopy (FTIR) and scanning electron microscope tests were used to characterize chemical properties. Regarding thermal characterization, the consistent finding was that blending temperatures in the range of 170°C to 200°C would not be detrimental to the incorporation of recycled plastics in asphalt binders. As for chemical characterization, some studies reported that recycled plastics interacted with the asphalt binders through physical processes, while others highlighted the development of chemical interactions.

The inherent incompatibility in terms of phase separation between recycled plastics and asphalt binders was another topic often evaluated in the “wet process” literature. This incompatibility can be attributed to differences in density and solubility parameters between the two individual components. An important attribute for polymer-modified asphalt is its ability to maintain integrity and homogeneity during storage, handling, and mixture production. Phase separation refers to the tendency of polymers to separate from the asphalt binder under static, heated storage conditions. The evaluation of phase separation typically requires storage stability testing (ASTM D7173) of modified binders followed by softening point, viscosity, and rheological testing of the top-third versus bottom-third cigar-tube samples, sometimes in conjunction with fluorescence microscopy analysis.

The literature consistently reported that producing a homogenous and storage-stable binder blend is difficult because the plastic-modified binder is very susceptible to phase separation. To overcome this issue, several researchers incorporated a third component in the binder blends to act as a stabilizing agent or a compatibilizer. Stabilizers and compatibilizers identified as potentially effective include ethylene-vinyl acetate, maleic anhydride grafted LLDPE, nanosilica, organic montmorillonite, polyphosphoric acid, RET, SBS, crumb rubber, TPOR, waste vegetable oils, and sulfur. Low-level chlorination and maleation of PE were also found to be effective in improving its compatibility with asphalt binder, but the chlorination process could also lead to issues with hazardous chloride-based dioxin emissions. Among these potential stabilizers and compatibilizers, the use of elastomeric polymers can enhance the performance grade and elasticity of RPM asphalt binders. Finally, one study reported that PE was insoluble in solvents commonly used in the chromatography and spectroscopy characterization techniques for polymers and asphalt binders (Yin et al., 2020b), which further complicated the chemical characterization of asphalt binders containing recycled plastics and made solvent extraction and recovery infeasible.

2.3.2 Knowledge Gaps

Due to differences in viscosity and density between recycled plastics and asphalt binders, as well as incompatibilities originating from differences in solubility parameters, RPM binders are prone to phase separation and, therefore, exhibit poor storage stability. Although existing studies have identified steric stabilizers or compatibilizers that can improve storage stability,

some resultant RPM binders still tend to exhibit phase separation after long-term storage and thus have a limited shelf life. Therefore, research on compatibilization of recycled plastics to improve the stability of RPM asphalt binders is needed. In addition to the incorporation of a steric stabilizer or compatibilizer, appropriate chemical modification of recycled plastics to facilitate the formulation of polymeric materials with varying degrees of crystallinity and polarity could be another approach to mitigate the phase separation of RPM asphalt binders. Future research is also needed to evaluate the consistency of RPM asphalt binders. Fluorescence microscopy can be used to visualize the morphology and dispersion of recycled plastics in asphalt binders. RPM asphalt binders with a uniform distribution of small-size plastic polymer particles are typically desired from a stability perspective.

Existing studies generally agree that the addition of recycled plastics stiffens the asphalt binder, as indicated by increased softening point and viscosity, as well as reduced penetration and ductility. This stiffening effect is expected to enhance the shear resistance of RPM asphalt binders at high temperatures and contribute to the improved rutting performance of asphalt pavements. However, this same stiffening effect could also adversely impact the intermediate-temperature fatigue resistance and low-temperature cracking resistance of RPM asphalt binders due to increased embrittlement and reduced relaxation properties. Durability-related cracking has become the primary form of distress governing the service life of asphalt pavements in the United States.

While some studies evaluated the effect of recycled plastics on fatigue [based on the DSR parameter |G*|sin(δ)] and low-temperature performance grade and relaxation parameters of asphalt binders, more research should focus on damage resistance testing to assess these materials. These tests can rank binders based on ultimate failure parameters instead of stiffness and modulus. Examples of new asphalt binder performance test methods include the linear amplitude sweep (LAS) per AASHTO T 391; binder yield energy test per AASHTO TP 123, Method B; and the asphalt binder cracking device (ABCD) test (Kim, 2007).

Another research need is to evaluate the applicability of laboratory asphalt binder tests used in the United States with RPM asphalt binders, since modifications to current test methods may be needed to accommodate the non-homogeneity of some RPM asphalt binders. Future research efforts also need to assess the chemical compatibility between recycled plastics and other additives used in asphalt binders, such as warm-mix asphalt additives, antistrip agents, and recycling agents. If there are incompatibility issues, the resultant RPM asphalt binders and mixtures will not perform as well as anticipated and could cause premature pavement failures. Finally, certain types of recycled plastics may be insoluble in solvents commonly used for the extraction and recovery of asphalt binders and those used in chromatography and spectroscopy characterization techniques for polymers and asphalt binders. As a result, alternative solvents and testing technologies are needed to accommodate the appropriate characterization of asphalt binders containing recycled plastics.

2.4 Laboratory Mixture Characterization

2.4.1 Summary of Findings

Earlier studies evaluating the effect of recycled plastics on asphalt mixtures were limited to Marshall properties. Most of those studies reported an increase in Marshall stability with the addition of plastics. Recent studies have incorporated additional mixture characterization tests, such as wheel tracking tests, indirect tensile strength (ITS), Dynamic Modulus (E*), various fatigue tests, and others. Most research studies found that adding recycled plastics improved rutting resistance and mixture stiffness. However, conclusions varied regarding the impact on

fatigue resistance, moisture susceptibility, and ITS. The varied findings may be attributed to the different types of plastics used, the method of introduction (wet or dry), as well as differences in sample preparation, different test methods, and different test temperatures. Several studies from India employing the dry process claimed that the improvement in mixture rutting resistance could primarily be attributed to coating aggregates with plastics. This coating increased internal friction within the aggregate structure. These studies also suggested that plastic-coated aggregates exhibited improved toughness, abrasion resistance, bond strength, and reduced asphalt absorption.

2.4.2 Knowledge Gaps

The impact of recycled plastics on the cracking resistance of asphalt mixtures remains unclear. Relatively few studies have evaluated cracking resistance using test methods that are popular in the United States. Considering that the interpretation of fatigue test results can be influenced by mixture stiffness and strain levels, which are dependent on pavement structure, load magnitudes, and temperature, it is not appropriate to make generalized conclusions about the impact of recycled plastics on fatigue cracking from different studies. There is limited research on the evaluation of low-temperature cracking properties. Additionally, there is little published information on the effect of aging on mixtures containing recycled plastics. Since most studies found that adding recycled plastics increased the stiffness of asphalt mixtures, a potential value-added application of RPM asphalt mixtures could be as a high-modulus layer in perpetual pavements. Further investigation of this idea through laboratory testing and pavement design analysis may be warranted to determine whether high-modulus RPM mixtures could be used to reduce pavement design thickness or help design against bottom-up fatigue cracking.

If volumetric properties are to be used as part of mix design or quality assurance (QA) testing for RPM asphalt mixtures, particularly those using recycled plastics as aggregate replacement, further investigation is required to determine the influence of the significant differences in specific gravities between the plastic material and natural aggregates, which affect the appropriate criteria for air voids, voids in mineral aggregate, and voids filled with asphalt. Finally, research is needed to assess the impact of recycled plastics on the texture characteristics of asphalt mixtures, since this will influence the skid resistance, tire-pavement noise, and rolling resistance of asphalt pavements.

2.5 Plant Operations

2.5.1 Summary of Findings

Many of the existing studies that documented asphalt plant operations were related to the production of Novophalt. To overcome the phase separation of Novophalt binders during storage, a mobile, high-shear blending unit was developed to accommodate the on-site formulation of PE-modified binders at asphalt plants during production. Equipped with agitation and mixing tanks, the Novophalt blending unit ensured the homogeneity of asphalt binder until it was mixed with aggregates. Field experience indicated that the Novophalt blending unit was not difficult to set up and could be completed within hours. During production, the blending unit was typically attached to the asphalt plant, with one hose connected to the asphalt intake line and the other connected to a return line. No additional plant modifications were required, besides the blending unit, to produce Novophalt mixtures. Since the Novophalt binders could be directly pumped into the plant for mixing with aggregates without the need for transportation and storage, phase separation was not critical for this approach.

However, plant-blending would be challenging on a larger scale because portable blending units with high-shear mixers are expensive, and it would be difficult to schedule a limited number of units to serve numerous projects. Furthermore, certification of plant-blended RPM asphalt binders for acceptance would be challenging given the susceptibility of these binders to phase separate and the risk associated with the time required to get the binder to a lab and tested. Other than the Novophalt projects, no other studies involving field projects were found that used a portable blending unit.

Rather than using a mobile, high-shear blending unit at the asphalt plant, certain field studies that employed the wet process for adding recycled plastics have accomplished the blending at a terminal. Terminal-blended RPM asphalt binders need to exhibit superior stability to prevent phase separation during transportation and storage at the asphalt plant. Given that phase separation poses a significant challenge when incorporating recycled plastics via the wet process, QA testing of terminal-blended RPM asphalt binders should include the storage stability test, and the QA samples should be taken periodically from the asphalt tank and tested. One benefit of the terminal blending approach is the minimal need for major plant modifications to produce RPM asphalt mixtures, aside from installing a mechanically agitated storage tank if one is not already available. Using agitated storage tanks would help eliminate the phase separation issue, but they are not widely available among asphalt contractors. In one study that used a recycled PE-modified binder, the authors recommended increasing the mixing and compaction temperature by between 5°C and 10°C. The authors also recommended minimizing the time between binder production and mixture production, which could be solved by using a mobile, modified binder manufacturing unit.

For the dry process, the literature identified two points of introduction: the cold-feed conveyor and the RAP conveyor (or RAP inlet). However, the former is not recommended due to safety concerns. The temperature of gases inside the drum can reach 760°C (1,400°F), exceeding the flash point of virtually all types of recycled plastics. As recycled plastics enter and travel inside the drum, they could reach their flash point and ignite upon contact with the burner flame, causing fires—or even explosions—within the mixing drum or baghouse. Therefore, recycled plastics should be introduced through the RAP conveyor to prevent direct contact with the burner flame during the mix production process.

To verify the consistent dosage of recycled plastics added into the asphalt mixture during production, existing feeder systems used for fibers and other dry additives appear to be suitable for pelletized recycled plastics. These systems offer electronic weighing systems with interlocked controls to adjust the feed as the plant production rate changes. Calibrating the feeder is required to achieve the desired dosage rate of the plastics.

One study concluded that using the dry process for adding PS would not increase the production costs of asphalt mixtures since the process does not require significant plant modifications. This conclusion was based on a life-cycle assessment (LCA) performed on mixtures with and without PS.

2.5.2 Knowledge Gaps

A question that still needs to be answered is whether recycled plastics with a low melting point can be added to a mixing drum so that the plastics uniformly coat aggregate particles as part of a dry-process mixing approach. If so, does the mixing time need to be extended and the mixing temperature need to be increased to account for the viscosity of recycled plastics? Furthermore, there is a plant operation concern that recycled plastics could be picked up in the gas stream and carried to the baghouse, where they could blind the filter bags, jeopardizing the operational efficiency of the baghouse and increasing the chance of a baghouse fire.

A recent Austroads report indicated that the higher viscosity of plastic-modified binders is likely to reduce the overall mixture workability and compactability (Remtulla and Halligan, 2021). Although increasing the mix production temperature could overcome this issue, this is not recommended because it will increase emissions and energy consumption associated with plant production as well as increase the paving crew’s exposure to fumes. Instead, strategies such as using a softer asphalt binder or using warm-mix asphalt (WMA) additives should be considered, but their effectiveness is yet to be evaluated. The same Austroads report also provided recommendations to asphalt contractors regarding the production of RPM asphalt mixtures, including how to receive the recycled plastics, verify that the supplied materials are the correct types of plastics, stockpile the recycled plastics in the correct location, manage stockpiles to ensure traceability of product, and avoid product contamination and damage.

2.6 Construction

2.6.1 Summary of Findings

One study examined the construction of asphalt mixtures modified with recycled plastics and their effects on mixture properties (Serfass et al., 1992). The study claimed that high-modulus asphalt mixtures produced with PE modification were difficult to compact due to increased binder viscosity and mixture stiffness; thus, heavy rollers were required for construction to achieve adequate in-place density. Communications with asphalt contractors in France indicated that the compaction of PE-modified asphalt mixtures was temperature sensitive; for the most part, field compaction was not an issue if it could be completed before the asphalt mat temperature dropped below the crystallization temperature of PE. Another report identified various potential challenges associated with the use of recycled plastics for road construction, such as health and safety concerns, generation of microplastics, reuse of polymer-modified binders, plastic compatibility, and storage stability (Lin et al., 2020). The study indicated that the release of microplastics in a plastic road could be prevented by heating waste plastics to the correct temperatures and adhering to QC standards.

2.6.2 Knowledge Gaps

The workability and compactability of asphalt mixtures are important factors in ensuring optimal performance of asphalt pavements, and these qualities depend on the viscosity of asphalt binder, aggregate gradation, and asphalt binder content, among other factors. Because recycled plastics will affect the viscosity of the asphalt binder when added via the wet process, and possibly the aggregate gradation when added via the dry process, they are likely to affect the workability and compactability of RPM asphalt mixtures. Adding higher dosages of recycled plastics could cause a sharp viscosity increase. Research is needed to assess the significance of this impact. In the United States, WMA additives are now widely used as compaction aids to help achieve proper in-place density during construction. Studies are needed to evaluate the compatibility between recycled plastics and WMA additives and their combined effects on the compactability of RPM asphalt mixtures. A key question that needs to be answered is whether WMA additives can be used with recycled plastics while reducing mixture production temperatures to levels desired for future emission targets. Since some plastics have a melting point within the temperature range used for WMA compaction, the phase change could negatively affect compactability. Field projects are needed to adapt current construction practices to accommodate recycled plastics, provide an indication of operational costs for incorporating RPM, and provide early indications of the impact on a pavement’s service life to assess the costs and benefits related to long-term pavement sustainability.

2.7 Health and Safety

2.7.1 Summary of Findings

The literature review identified two potential health and safety concerns regarding the use of recycled plastics in asphalt: (1) leaching of toxic components during processing of recycled plastics, and (2) the generation of chlorine-based gases and dioxin from PVC during mixture production and construction. One laboratory study evaluated the leachability of hazard chemicals and toxic fumes (e.g., toluene, benzene, as well as aliphatic, cyclic, and aromatic hydrocarbons) generated by asphalt binders modified with three proprietary plastic products but found no detectable adverse effects from the recycled plastics (White, 2019). However, literature references do caution against the use of chlorinated polymers, such as PVC (Willis et al., 2020).

2.7.2 Knowledge Gaps

There are significant health and safety uncertainties surrounding the occupational exposure of asphalt workers to hazardous air pollutants (HAPs) emitted during the heating of recycled plastics during the production and construction of RPM asphalt mixtures. Recycled plastics, particularly PCR plastics, often contain chemical additives from the manufacturing process, along with contaminants and deleterious materials. Certain recycled plastics can release HAPs, including polycyclic aromatic hydrocarbons (PAHs) and volatile organic compounds (VOCs), when subjected to elevated temperatures (Chin and Damen, 2019). Therefore, further research is needed to evaluate the health effects of occupational exposure to HAPs during the production and construction of asphalt mixtures that contain recycled plastics.

In addition to traditional HAPs, the potential presence of contaminants of emerging concern, per- and polyfluoroalkyl substances (PFAS), raises additional health and safety concerns regarding the use of certain types of recycled plastics in asphalt. These plastics are primarily limited to polytetrafluoroethylene and other fluorinated polymers, and their usage has declined substantially in recent years. PFAS are synthetic organofluoride chemical compounds considered as persistent organic pollutants with a serum elimination half-life of four to five years (Hogue, 2019). Although short-term exposure to a low level of PFAS is not likely to cause adverse health effects, the accumulation of these substances in humans over time could lead to adverse health outcomes such as hypercholesterolemia, ulcerative colitis, thyroid disease, cancer, and pregnancy-induced hypertension and preeclampsia (EPA, 2020). Therefore, future work is needed to evaluate the health and safety effects of worker exposure to PFAS in recycled plastics.

Finally, as previously discussed in the section on plant operations, the dry process of adding recycled plastics has safety concerns from a plant operating standpoint. Further field evaluation is needed at asphalt plants to ensure that recycled plastics would not have direct contact with the burner flame inside the drum, since direct contact could cause fires and explosions as well as jeopardize the operational efficiency of the filter bags and cause a fire in the baghouse.

2.8 Environmental Impact

2.8.1 Summary of Findings

The literature review suggested that the recycling of waste plastics in asphalt pavements could provide significant environmental benefits, such as preservation of limited natural resources, reduction of energy consumption, reduction of disposed and discarded solid wastes, and reduction of carbon dioxide (CO2), sulfur dioxide (SO2), and nitrogen oxide (NO) emissions. However, these

claims were not quantified. An LCA showed a reduced environmental impact associated with the utilization of RPM-modified binders and mixtures for pavement applications. The production of recycled-plastic pellets was found to contribute significantly to the potential environmental impact, primarily due to the energy-intensive pelletization process. However, a key input of an LCA is the impact of an additive on the pavement’s service life, which is unknown for recycled plastics. In addition, the use of recycled plastics in asphalt has raised several environmental concerns, including the release of microplastics, jeopardizing the future recyclability of asphalt mixtures containing recycled plastics.

2.8.2 Knowledge Gaps

Asphalt pavement stands as one of the most recyclable materials in the United States. According to the latest asphalt pavement industry survey conducted by NAPA, more than 93% of asphalt pavements reclaimed in 2022 found reuse in new pavements, with the remaining 7% repurposed in other civil engineering applications (Williams et al., 2024). The recyclability of asphalt pavements must be maintained with the incorporation of any recycled materials, including recycled plastics. However, it remains unknown whether RPM asphalt mixtures can be successfully recycled upon completion of their service lives. The aging of RPM mixtures is not well documented by existing literature and warrants further research.

The potential release of microplastics and nanoplastics is a major environmental concern, namely from the weathering of in-service asphalt pavements containing recycled plastics and the milling of asphalt pavements after they have reached the end of their service lives. High-crystallinity plastics tend to break into small particles upon impact, and these small plastic particles are often known as microplastics and nanoplastics (Chin and Damen, 2019). Conversely, lower-density plastics, which appear to have greater potential for use in asphalt pavements, may not be as susceptible to degradation.

According to the U.S. National Oceanic and Atmospheric Administration and the Parliament of Australia, microplastics are plastic fragments measuring greater than 50 μm and less than 5 mm in length (Lin et al., 2020). Although the definition of nanoplastics remains under debate, this term typically refers to very small plastic particles with an upper size of 100 to 1,000 nm (Gigault et al., 2018). Beyond posing a major threat to marine life, microplastics and nanoplastics can adversely impact plant growth, earthworms, and human health. Implementing ventilation and water-spray controls on asphalt pavement milling machines for silica dust management might mitigate the release of microplastics and nanoplastics from pavement milling operations. Although technical guidance suggests that the release of microplastics can be prevented in a plastic-modified road when the waste plastics are heated to the correct temperatures and QC standards are strictly followed (Lin et al., 2020), the effectiveness of this strategy has yet to be determined.

Leaching of harmful materials and pollutants—such as phthalates, bisphenol A (BPA), and microplastics—from asphalt pavements made with RPM asphalt mixtures poses a significant environmental concern. The potential release of microplastics from a pavement containing recycled plastics may be a greater concern for the dry process given the potential for a higher content of recycled plastics with this method. Phthalates and BPA are two types of manmade chemicals used in many common plastic products, especially PET plastic bottles. There is scientific evidence that phthalates and BPA may cause a variety of health issues for humans and animals, such as hormonal and developmental problems (National Institute of Environmental Health Sciences, 2018; 2020). Therefore, there is a need to evaluate the leaching of phthalates and BPA from asphalt mixtures modified with recycled PET, as well as the leaching of microplastics and nanoplastics from other types of RPM asphalt mixtures.

When recycled plastics are incorporated via the wet process, the resulting RPM asphalt binder will likely exhibit higher viscosity compared to the base binder. Consequently, higher production and construction temperatures may be necessary to ensure adequate workability and compactability of the mixture (although the temperatures are generally comparable to those of traditional polymer-modified asphalt mixtures). The elevated temperatures will increase the emissions of PAHs, VOCs, total organic compounds, and objectionable odors, which have an adverse impact on the environment and increase the occupational exposure of asphalt workers to HAPs. Therefore, emissions monitoring and analysis are needed at asphalt plants and paving sites that use RPM asphalt mixtures. Finally, LCA studies are useful tools to holistically assess the impacts of pavement systems on humans and the environment, as well as identify potential unintended negative consequences (Harvey et al., 2014). Thus, research efforts should be devoted to establishing upstream LCA data for asphalt pavements that contain recycled plastics and comparing their environmental impacts and sustainability benefits against other potential recycling applications for waste plastics. For example, FHWA has conducted a research study on the LCA of asphalt pavements with recycled plastics (Rangelov et al., 2021).

2.9 Field Projects

2.9.1 Summary of Findings

Over 200 field projects using recycled plastics in asphalt pavements were identified in literature references. There were reportedly additional projects constructed in France between the mid-1980s and mid-1990s, but they were not identified in this review due to a lack of published records in English. Most of the field projects identified in this literature review were constructed using Novophalt in more than a dozen countries between the late 1980s and the early 2000s. Novophalt projects included city streets, county roads, minor and principal arterials, interstates, and airports. Limited field performance data suggest that Novophalt pavement sections performed well, especially in terms of rutting performance, although one study reported more cracking compared to pavement sections that used unmodified and SBS-modified binders. In 1993, a Novophalt test section constructed on FHWA’s accelerated loading facility had the best rutting performance among all test sections included in the study (Stuart et al., 2000).

India has reported over 15 years of experience recycling waste plastics in asphalt pavements, in total placing more than 2,500 km of roads. Although several studies reported successful outcomes when using plastic-modified mixtures, field performance data for these pavement sections was not documented. More recently, numerous demonstration projects using proprietary products made of recycled plastics were constructed in Australia, Canada, China, Colombia, Indonesia, Mexico, the Netherlands, New Zealand, South Africa, the United Kingdom, and the United States. Most of these projects are only a few years old, so the long-term durability of these pavements has yet to be determined.

Table 1 provides a list of constructed and upcoming trial projects with asphalt mixtures containing recycled plastics in the United States since 2018. The first “dry plastic” trial project was constructed on the campus of the University of California in San Diego using a proprietary recycled-plastic product from MacRebur. Since then, trial projects have been constructed following both dry and wet processes for introducing recycled plastics into the asphalt mixture. The dry process typically uses 0.5% to 1.0% of recycled PE by weight of the aggregate or mixture; in contrast, the wet process uses up to 2% recycled PE by weight of the binder (and a polymer, if needed), and the asphalt binder is modified to meet a performance grade specified for the trial project. Seven trial projects have been constructed, and two upcoming trials are being planned in Missouri and Pennsylvania.

Table 1. List of recent field projects of RPM asphalt mixtures in the United States.

| Location | Project Type | Project Size | Type of Plastics Used | Quantity of Plastics Used | Process | Year Constructed | Notes |

|---|---|---|---|---|---|---|---|

| UC San Diego, CA | Local road | Unknown | LDPE/LLDPE | Unknown | Dry | 2018 | One mix with a MacRebur product |

| Dow’s Facility Freeport, TX | Private roads | 2,600 ft of roads | LLDPE | 1,686 lb. of recycled LLDPE | Wet | 2019 | PG 70-22 modified with LLDPE & ELVALOY RET |

| Dow Sabine River Works, TX | Private roads | 3,480 yd2 | LLDPE | 1,830 lb. of recycled LLDPE | Wet | 2020 | PG 76-22 modified with LLDPE & ELVALOY RET |

| Multiple locations in MI | Four county roads and two parking lots | 5.5 lane miles and 30,500 yd2 of parking area | PIR PE & mixed thermoplastic polymers | 10,400 lb. of recycled PE | Wet | 2019 | PG 64-28P with recycled PE & ELVALOY RET |

| Cincinnati Technology Center, OH | Parking lot | 2,885 yd2 of parking area | LDPE/LLDPE | 4,290 lb. of recycled PE (71,000 retail bags) | Dry | 2020 | One mix using generic recycled PE at 0.5% by weight of aggregate |

| Howe Street, Racine, WI | Local road | 450 ft long by 17 ft wide | LDPE/LLDPE | 990 lb. of recycled PE | Dry | 2020 | One mix using generic recycled PE at 0.5% by weight of aggregate and one control |

| NCAT Test Track, AL | Accelerated testing | Two 200-ft test sections | LDPE/LLDPE | Unknown | Wet and dry | 2021 | Wet process: PG 64-22 modified with 1% recycled PE & 1.75% ELVALOY RET |

| Dry process: 0.5% recycled PE by weight of aggregate | |||||||

| Stadium Blvd., University of Missouri, MO | Local street | 2 miles of roads | LLDPE | 10 tons of recycled PE | Wet and dry | Upcoming | One mix with 0.9% ELVALOY RET & 0.5% recycled PE by weight of mix and one control with 0.5% recycled PE |

| Ridley Creek State Park Roadway, PA | Local road | Two quarter-mile roadway sections | Unknown | Unknown | Unknown | Upcoming | One section with recycled PE and one control |

2.9.2 Knowledge Gaps

Although numerous field projects using RPM asphalt mixtures have been constructed, the long-term pavement performance data for many of these projects is not available. Such performance data is crucial to quantify the impact of recycled plastics on the service life of asphalt pavements. This information also provides critical input for the life-cycle cost analysis of RPM asphalt mixtures. Therefore, future research should establish a pavement performance database for RPM asphalt mixtures, covering field projects with different pavement ages, roadway classifications, traffic levels, climate regions, and underlying pavement structures. To enhance the value of the database, field performance data should be collected and analyzed in a consistent and objective manner, preferably following the guidelines of federal or state highway agencies.

2.10 Other Potential Civil Engineering Applications

2.10.1 Summary of Findings

Recycling waste plastics in construction materials has been considered to support sustainable development. Waste plastics are used as fillers and aggregate in concrete, especially in lightweight concrete, since waste plastics have lower density than most natural materials (Choi et al., 2005). Shredded waste from plastic bags can serve as fibers in concrete to improve energy

absorption capacity and increase resistance to impact for concrete pavement and barrier applications (Jain et al., 2021). Waste plastics can also be used as aggregates in the base and subbase, and they have been used to make recycled-plastic strips for improving pavement stiffness and bearing capacity (Benson et al., 1994; Jha et al., 2014). Additionally, waste plastics are incorporated in glass-fiber reinforced composites for manufacturing railway sleepers, benches, decks, fencing, sheeting, garden products, footpaths, components for bridges, and pipes (Bajracharya et al., 2014).

2.10.2 Knowledge Gaps

In addition to asphalt pavements, research continues to explore uses for recycled plastics in other civil engineering applications. For example, because of their low density, recycled plastics could potentially be used as alternative lightweight backfill materials for embankments and landscape projects. Furthermore, the aggregate replacement approach may also be applicable to aggregate base courses, potentially allowing for the use of more recycled plastics if they provide adequate structural support under traffic and are not susceptible to the leaching of microplastics, nanoplastics, and other deleterious materials. Similarly, recycled plastics could be used to replace aggregates and fillers for cold asphalt recycling and Portland cement concrete applications.