Construction Strategies and Techniques for Planned Bridge Replacements in Complex Scenarios (2025)

Chapter: 4 Case Examples

CHAPTER 4

Case Examples

This chapter presents case study examples from six DOTs (California, Colorado, Massachusetts, Texas, Washington State, and Wisconsin) that illustrate in more detail strategies, decision-making, and project delivery processes that DOTs use for complex bridge replacement scenarios. The case examples show that each complex bridge replacement scenario has unique challenges and characteristics and that there is no standardized process for strategy selection. However, the case examples also illustrate successful strategies for DOTs under certain conditions, depending on the options available to each DOT. Innovative construction techniques such as ABC and alternative PDMs have been identified as strategies utilized for complex bridge replacements. The case examples for successful projects emphasize collaborative decision-making and early communication with stakeholders.

Responses from the survey and the literature review were used to identify DOTs that indicated the use of unique strategies or methods, DOTs with guidelines and/or experience with different replacement strategies or PDMs, and DOTs with unique buy-in strategies for complex bridge replacement projects. Table 4-1 indicates the DOT practices highlighted in the examples, with a particular aspect of decision-making for complex bridge replacement scenarios. Then, among these DOTs, respondents willing to participate in a case study were identified, ensuring all four AASHTO regions were represented.

One representative from each DOT was identified based on DOT input, and a virtual interview was conducted with that individual. Each DOT representative was asked the same set of questions. Their answers were compiled to develop case examples, which the interviewees later reviewed and revised, if necessary. The list of questions is provided in Appendix C.

California DOT

Strategy Selection Process for Complex Projects

California Department of Transportation (Caltrans) can use all typical bridge replacement delivery strategies and project delivery and procurement methods. In order to guide the procurement method selection, Caltrans has an Alternative Procurement Guide to compare the appropriateness of PDMs (Caltrans 2008) (Figure 4-1). This document has two main categories: construction methods (e.g., ABC methods, lateral slide, prefabricated bridge elements and systems, and so on) and delivery methods (e.g., D-B-B, D-B, CM/GC, PDB, and so on). The guide indicates that there is no one-size-fits-all project delivery system suitable for all projects. Instead, Caltrans focuses on a process for selecting an appropriate project delivery system, which is based on each project’s unique characteristics and specific criteria for success. While many of these criteria can be objectively measured, some important aspects are subjective and vary based on individual perspectives. The guide also notes that the decision-making process for project

Table 4-1. Highlighted practices in the case study examples.

| DOT | ||||||

|---|---|---|---|---|---|---|

| Practice | California | Colorado | Massachusetts | Texas | Washington State | Wisconsin |

| Use of various construction strategies or PDMs | X | X | X | X | X | X |

| Guidelines for decision-making/experience with different replacement strategies | X | X | X | X | X | X |

| Unique buy-in strategies | X | X | X | |||

delivery should be collaborative, involving a team approach. The mentioned project delivery tool is designed to guide this process, fostering meaningful discussions and ensuring a shared understanding of the rationale behind the chosen project delivery system.

Each strategy is assessed and scored based on its applicability to the project’s stage in the development process and other specific criteria. The process ensures that project selection is systematic and guided by clearly defined criteria, helping to standardize decision-making across different projects. The document facilitates a structured dialogue and shared understanding among stakeholders regarding selecting appropriate PDMs.

Critical Factors for Strategy Selection

Caltrans acknowledges that selecting the right project delivery system or construction method for complex bridge replacements is challenging because of the unique characteristics of each project, such as time constraints, specific location attributes, project geolocation, risk, cost, schedule, and innovative planning. Additionally, the availability and competence of contractors play a crucial role in determining the project approach. This is especially the case for ABC projects, which require precise coordination and are heavily influenced by site-specific factors like average daily traffic and environmental conditions. Caltrans has an ABC manual designed to serve as a guideline for planners and engineers, offering a fundamental understanding of various ABC methods (Caltrans 2021a). It aims to assist in selecting appropriate ABC methods for specific projects and promotes the adoption of these methods in bridge construction projects. The manual includes prefabricated bridge element checklists, lateral slide checklists, SPMT move

checklists, and guidance on the implementation of ultra-high-performance concrete (UHPC) along with ultra-high-performance concrete (UHPC) checklists.

The availability of ACMs, such as D-B and CM/GC, necessitates early project evaluation to determine the most beneficial delivery method. Caltrans employs various assessment tools, including the Caltrans project delivery selection tool developed in 2008, the Project Delivery Selection Matrix (PDSM) developed by the Colorado DOT and the University of Colorado, and practical experience in choosing the appropriate delivery method. D-B-B, D-B, and CM/GC methods are all considered. Districts identify and nominate potential projects, which are then assessed by the CM/GC Program under the Office of Innovative Design and Delivery in the Division of Design. Once an assessment is completed and a delivery method is selected, the project is presented to the Caltrans Alternative Contracting Steering Committee, which includes Caltrans headquarters management and FHWA, for approval. For federally funded projects approved for CM/GC, the Caltrans project manager must inform the FHWA transportation engineer assigned to their district to discuss FHWA’s involvement. Optimal CM/GC projects typically involve high technical complexity, significant risk management needs, complex phasing, schedule acceleration, a requirement for Caltrans to maintain design control, phased funding, non-standard design types, and budget constraints necessitating cost certainty in construction (Caltrans 2021b).

The DOT emphasizes a collaborative team approach in the decision-making process, in which various project aspects are evaluated, including both objective and subjective criteria. This involves detailed discussions and assessments early in the project’s life cycle, particularly for high-risk projects. Using evaluations that include quantifications and scoring of different project delivery options, an appropriate method is selected, often involving innovative approaches such as PDB or ABC.

Suitability of Project Delivery and Procurement Methods

Following the four-step approach to project delivery decision-making, the team identifies an alternative delivery method, and the project is presented to the Caltrans Alternative Contracting Steering Committee for the final decision. Caltrans emphasizes the importance of a structured approach to support the decision-making process. This structured approach ensures that every project phase, from initial design to construction, is executed with thorough oversight and is aligned with strategic goals.

For instance, projects like the single-span ABC bridge at Jacoby Creek in Northern California illustrate the application of this approach. The project involved a lateral slide construction method to minimize disruption, chosen due to specific site conditions and the need to avoid lengthy highway closures. Similarly, complex multi-span projects in high-traffic areas might opt for a CM/GC method or PDB (Caltrans 2024), depending on the risk assessment and project specifications. PDB was authorized in California by Senate Bill No. 146 (https://leginfo.legislature.ca.gov/faces/billNavClient.xhtml?bill_id=202320240SB146).

Caltrans also points to legislative developments, such as the introduction of California Senate Bill No. 991 (https://leginfo.legislature.ca.gov/faces/billNavClient.xhtml?bill_id=202120220SB991, which expands the use of PDB in the public sector, providing further flexibility and enabling local agencies to employ these methods more broadly.

Overall, choosing a PDM at Caltrans is a dynamic and carefully considered decision. It incorporates extensive planning, stakeholder engagement, and adherence to regulatory and environmental standards, ensuring that each project’s unique demands are met efficiently and effectively.

Successful Strategies for Buy-In and Communication

Caltrans acknowledges the complexities of gaining stakeholder buy-in for alternative PDMs, especially for non-traditional or complex projects like ABC. From the agency’s experience, the following strategies have been successful:

- Innovation Goals: For complex projects, developing, proposing, tracking challenges, and quantifying the benefits of innovations are essential during the preconstruction phase. This process includes proposing criteria to evaluate suggestions and select improvements that will offer the most value in cost, schedule, and quality.

- Leveraging Established Processes: Contractors and engineers within the state are comfortable with the D-B-B process because of its historical use and their familiarity with it. Introducing new methods, such as PDB, presents a time-consuming and costly learning curve, necessitating clear communication and a justified rationale for the shift. Therefore, Caltrans focuses on a unique project’s specific needs and requirements to ensure efficient communication.

- Early and Comprehensive Communication: Effective communication is critical, particularly early in the project’s life cycle during the environmental study and feasibility stages. Caltrans emphasizes the importance of initiating communication channels early, particularly when dealing with complicated projects in congested and/or environmentally sensitive areas. Ensuring all stakeholders, including environmental officials, are involved from the outset is crucial to addressing potential issues arising from project activities.

- Addressing Environmental Concerns: Projects that might affect sensitive environmental areas require careful handling. For instance, activities like pile driving in areas with aquatic life must be communicated to and coordinated with environmental authorities to mitigate impacts. The key is to avoid significant disruptions and ensure compliance with environmental regulations, which often involves securing various permits and adjusting project specifications to minimize ecological impact.

- Stakeholder Engagement: Engaging all relevant stakeholders from the beginning ensures that everyone’s concerns are addressed. This approach helps manage expectations and facilitate smoother project execution. It is not just about meeting project timelines and budgets but also about respecting and preserving the environmental and social context of the project area.

- Practical Adjustments Based on Feedback: Feedback mechanisms are crucial. For instance, adjustments need to be made if the construction method could potentially harm local wildlife or disrupt the ecosystem. This could mean changing the construction methodology or even the physical attributes of the project, such as the length of girders, to ensure minimal impact on a creek and surrounding environments.

Caltrans uses these strategies to navigate the complexities of implementing new and innovative project delivery and construction methods, ensuring that each project meets technical specifications and gains the necessary support and approval from all stakeholders involved.

Challenges and Planned Changes for Strategy Selection

Caltrans acknowledges the significant challenges involved in selecting the appropriate bridge replacement strategy, emphasizing the complexity of the factors considered:

- Time, Budget, and Environmental Constraints: These are consistently primary concerns throughout the initial stages of project planning and execution. Each meeting and discussion needs to address these foundational elements comprehensively.

- Public Awareness and Community Impact: For projects in densely populated areas like San Francisco or Los Angeles, managing public perception and the direct impact on local residents and businesses is critical. Strategies such as extensive public outreach and clear

- communication about project timelines and detours are vital, especially in projects like the 21st Avenue Bridge superstructure replacement project in downtown Sacramento, where extensive public interaction and a rapid construction timeline (99 hours) were crucial.

- Economic Considerations: The direct and indirect costs associated with bridge replacements are significant. Direct costs include materials and labor, while indirect costs encompass impacts on commuters and local businesses due to construction-related disruptions. These economic factors often dictate the strategy chosen.

- Improved Work Zone Safety: Reducing the risk of conflict between construction activities and the traveling public is one of Caltrans’s priorities. This is accomplished by separating traffic from the work zone and/or reducing the amount of time that traffic is exposed to construction activities. ABC is one of the examples that aligns with the Caltrans Strategic Plan, the Project Delivery Strategic Direction, and the Division of Engineering Services (DES) Strategic Direction. By implementing ABC in California, Caltrans supports the FHWA Every Day Counts initiative to deploy innovations that shorten the project delivery process, enhance roadway safety, and reduce traffic congestion.

Caltrans continually updates its guidelines based on experience gained from completed projects. This adaptive approach allows the agency to refine strategies and apply improvements in real time, ensuring that project delivery remains efficient and effective. Three current practices have been helpful for strategy selection and implementation:

- Flexibility in Project Delivery: Caltrans has developed a range of tools and guidelines to support various PDMs, ensuring that the DOT can adapt to the specific needs of each project. This flexibility allows the DOT to utilize both traditional methods and innovative techniques like ABC, depending on the project’s requirements.

- Innovative Project Delivery Incentives: Caltrans provides incentives for the use of innovative methods such as ABC by offering incentives for reduced on-site construction time, which can significantly decrease overall costs and disruption. These incentives are structured to encourage contractors to adopt more efficient construction practices.

- Support for Innovation Across Districts: Each district within Caltrans has its own set of innovation goals that are supported by the central agency to ensure that advancements in construction and project management are implemented effectively across all regions.

These challenges highlight Caltrans’s approach to project management, which balances technical requirements, economic impact, community relations, and environmental considerations. This holistic strategy ensures that each bridge replacement project meets engineering standards and aligns with broader state goals and local community needs.

Experience Gained

- Adaptable Project Delivery Selection: Caltrans recognizes that no single project delivery system fits all projects. Therefore, it utilizes an Alternative Procurement Guide to assess and select the most appropriate methods based on unique project characteristics.

- Critical Factors Considered: Factors such as time constraints, site-specific conditions, and contractor competence are crucial in determining suitable construction and delivery methods, especially for ABC projects.

- Collaborative Decision-Making: The decision-making process involves a collaborative team approach, incorporating both objective and subjective criteria to ensure comprehensive evaluations and stakeholder buy-in.

- Early and Comprehensive Communication: Caltrans reports that effective communication with stakeholders, including environmental authorities, early in the project’s life cycle is critical for addressing potential issues and gaining support for innovative methods.

- Legislative Support: Legislative developments, such as California Senate Bill No. 991, provide flexibility to Caltrans by extending the use of PDB, facilitating more efficient project delivery.

- Structured Approach: A structured approach ensures thorough oversight and alignment with strategic goals, from initial design to construction, enhancing project efficiency and effectiveness.

- Stakeholder Engagement: Engaging all relevant stakeholders from the beginning helps address concerns, manage expectations, and facilitate smoother project execution.

- Environmental Considerations: Projects affecting sensitive environmental areas require careful handling and compliance with regulations to mitigate ecological impacts.

- Feedback Mechanisms: Practical adjustments based on feedback ensure that construction methods are adapted to minimize environmental and community impacts.

- Ongoing Adaptation: Caltrans continually updates guidelines based on experience gained from completed projects, refining strategies to ensure efficient and effective project execution.

Colorado DOT

Strategy Selection Process for Complex Projects

Colorado DOT’s (CDOT’s) process accounts for design and situational complexities, such as heavy traffic areas or projects requiring coordination with multiple agencies. All bridge replacement projects undergo a thorough evaluation through the Structure Selection Report (Colorado DOT 2023), included as Appendix 2A of the Bridge Design Manual, which assesses the need for accelerated delivery or specialized construction techniques based on the project’s complexity. Following this evaluation, CDOT determines the appropriate delivery method—either D-B or regular D-B-B—tailored to address the specific complexities of each project. Additionally, the state maintains process documents for the Alternative Delivery Program, including guidelines on considering accelerated construction techniques for all projects. The Alternative Delivery Program offers owners support in several key areas:

- It helps enhance their understanding of different PDMs, specifically D-B (Colorado DOT 2016) and CM/GC (Colorado DOT 2015).

- It provides tools for evaluating and selecting the most suitable delivery method for their projects, utilizing resources like the Project Delivery Selection Workshop Summary Template (Colorado DOT 2024).

- It offers guidance on managing projects that utilize these alternative delivery methods effectively.

These documents are kept separate to provide clear and specific guidance.

The structure selection report checklist serves as a quality assurance tool for the structure selection process within CDOT. It details the necessary components and information that must be included in the report. Key elements of the checklist include:

- Site description and design features (information on existing structures, vicinity maps, impacts on ROW, traffic detours, constructability and construction phasing, utilities, geotechnical and hydraulics summaries, environmental concerns, and roadway design features including cross-sections and vertical and horizontal alignments);

- Structural design criteria (specifications for design, loads—including collision, earthquake—deck drainage, aesthetic requirements, and provisions for possible future widenings);

- Structure selection (criteria for selecting the structure, rehabilitation alternatives, inspection summaries, load testing requirements, and various alternatives for structure layout, vertical and horizontal clearances, skew, span configurations, superstructure, concrete and steel girders, deck drains, substructure, abutments, piers, and walls); and

- Additional considerations (constructability and construction phasing details, ABC design, maintenance and durability considerations, corrosive resistance, a summary of structure type evaluation, and construction costs, including alternatives).

The staff bridge unit leader or a designated proxy must sign the checklist before submitting Final Inspection Report (FIR) documents to the region. This ensures that all findings, recommendations, and design deviations from the CDOT structural standards and design criteria are properly documented and approved. This structured approach ensures thorough documentation and verification at each step of the structure selection process.

Critical Factors for Strategy Selection

Regarding site-related factors considered for selection of a bridge replacement strategy, CDOT evaluates various site characteristics to determine the most appropriate strategy. For areas with tight right-of-way or other significant restrictions, CDOT often consults with the contractor for innovative solutions that minimize impact on the traveling public. When faced with increased risks or uncertainties, such as unfamiliar construction techniques, CDOT may opt for a D-B approach. This method allows CDOT to share risks more effectively between the owner and the contractor, leveraging the contractor’s expertise throughout the design process.

Furthermore, CDOT acknowledges the complexities of managing daily traffic and other known risks. However, the D-B delivery method becomes advantageous in scenarios with extensive site constraints or significant budgetary limitations, especially in large interchange projects. It consolidates various project elements into a single contract, facilitating streamlined execution and completion.

For structure-related factors, the choice of structure type and construction method heavily depends on the specific project requirements and the existing experience within CDOT’s team. For instance, if geometry or required construction methods, such as accelerated techniques, present a scenario with which CDOT is less familiar (such as a slide-in bridge move), CDOT may opt to collaborate with external contractors who specialize in these areas. This collaboration is crucial for building the project’s internal expertise and ensuring the its success. Similarly, a D-B approach, such as precast segmental bridges, is preferable for segmental construction, which CDOT may not have undertaken in recent decades. Thus CDOT can share the responsibility for design and construction risks with the contractor, leveraging the contractor’s expertise to manage unfamiliar or complex challenges.

Moreover, when CDOT encounters a bridge type that has not been constructed before or is discussing newer construction methods that CDOT staff are not yet skilled in, CDOT might again turn to the D-B model. This method is beneficial for larger projects (which can fit under complex scenarios), in which the complexity and scale necessitate bringing together skills and expertise that might not be readily available in-house. However, CDOT can manage design and construction internally or with minimal external support for more minor or singular bridge projects.

Direct and indirect costs are always considered when determining cost factors, but they are not the sole drivers of CDOT’s decision-making. Funding constraints often play a more significant role, especially in large projects that might benefit from being broken down into manageable parts under a D-B framework. This method facilitates funding allocation per package and allows for innovative solutions like P3s, which are particularly useful in large-scale infrastructure projects where funding and financing flexibility are crucial.

In conclusion, whether to go with a D-B approach or to manage the project in-house depends on the challenges the bridge type presents, the construction methods involved, and CDOT’s

current capabilities. This strategic decision-making ensures that CDOT effectively manages risks and capitalizes on the strengths of available construction and design methodologies.

Suitability of Project Delivery and Procurement Methods

CDOT primarily considers the construction delivery methods when selecting strategies for bridge replacement. For instance, if the project decision involves dealing with cast-in-place segmental bridges, CDOT might opt for a D-B approach depending on material type and availability, which are usually not major determinants. However, if the project involves materials such as T1 steel, which CDOT has not used recently, it will likely engage a design consultant to ensure the project’s success. This approach helps CDOT determine the best construction method, especially when it faces unknown risks or needs specialized construction techniques like slide-in bridges.

For larger projects or those involving complex elements like segmental bridges, CDOT tends to lean toward D-B. This method allows CDOT to consolidate and manage various project risks more effectively by collaborating closely with contractors who bring in the necessary expertise. If a project involves significant unknowns or specific risks related to construction methods, such as precast or cast-in-place segmental structures, bringing on a contractor early in the process can be advantageous. This strategy helps CDOT leverage external expertise to address potential challenges head-on. By evaluating the risks involved and the resources available, whether in-house or through external consultants, CDOT ensures that each bridge replacement strategy is robustly planned and executed, focusing on managing complexities effectively.

Successful Strategies for Buy-In and Communication

CDOT has successfully gained legislative buy-in for the D-B approach, particularly for larger projects. This method allows CDOT to manage significant projects comprehensively, streamlining the process and minimizing disruption to the public. CDOT highlights that the known costs and the ability to implement solutions rapidly make D-B appealing to legislators, especially when the projects involve crucial corridors or complex interchanges that require substantial funding and have high visibility.

From CDOT’s experience, continuous and effective communication with stakeholders is essential. Even after initially securing buy-in, maintaining open lines of communication is critical to managing expectations and keeping all parties informed throughout the project’s duration. CDOT emphasizes that even if early communications are well-received, the public and legislators may need regular updates to feel reassured about the project’s progress and impact.

The effectiveness of these communications is often measured by the volume of public and legislative feedback CDOT receives. A decrease in complaints typically indicates successful expectations management and project execution. Moreover, staying on schedule and transparently managing any arising issues are crucial for maintaining trust and confidence among stakeholders and the broader public.

In summary, CDOT finds that ongoing, clear communication is critical in securing and maintaining support from legislators and the public, with feedback serving as a primary metric for gauging the success of its outreach and engagement strategies.

Challenges and Planned Changes for Strategy Selection

CDOT is satisfied with its current strategy selection process for complex bridge replacement projects. It effectively identifies and assesses all risks and challenges associated with each project

and bridge. This thorough understanding allows CDOT to make informed decisions regarding the most suitable delivery method and bridge type for specific scenarios. CDOT feels that the existing processes are functioning well and achieving the desired outcomes.

Research Needs

Looking toward the future, CDOT acknowledges the importance of continuous improvement and the potential benefits of integrating new research and information. CDOT would benefit from insights into innovative construction methodologies, emerging technologies, and advanced materials to further enhance its strategy selection process. Additionally, updated data on environmental impact assessments and cost-benefit analyses (specifically analyses that compare the economic effectiveness of alternative delivery methods) could further refine its approach to selecting strategies for bridge replacement in complex situations. This information would support CDOT in maintaining its commitment to safety, efficiency, and sustainability in infrastructure development.

Experience Gained

The key experiences reported by CDOT in this case example are summarized as follows:

- Comprehensive Evaluation and Tailored Approaches: CDOT’s process involves thorough evaluations using the Structure Selection Report to determine the need for specialized construction techniques based on each project’s complexity. This ensures that the chosen delivery method, whether D-B or D-B-B, is perfectly suited to addressing the project’s specific challenges.

- Leveraging the Alternative Delivery Program: CDOT enhances project outcomes by utilizing its Alternative Delivery Program, which helps the agency understand different PDMs and provides tools for selecting the most suitable method. This program supports the effective management of projects employing alternative delivery methods.

- Effective Stakeholder Communication: Continuous and clear communication has proved essential for maintaining stakeholder support and legislative buy-in, particularly for larger projects. CDOT measures the effectiveness of communications by monitoring feedback and complaints from the public and legislators, using these metrics to adjust project management strategies accordingly.

- Adaptability in Financial Planning: Addressing funding constraints is pivotal. CDOT often opts for D-B methods for larger projects to streamline funding and execution. This approach allows for innovative financing solutions, such as public-private partnerships, facilitating manageable funding and project delivery segments.

- Continuous Improvement Through Research and Innovation: Looking forward, CDOT emphasizes the importance of integrating innovative construction methodologies, technologies, and updated data analyses. This ongoing commitment to innovation and improvement ensures the sustainability and efficiency of future infrastructure projects and maintains safety and effectiveness in complex bridge replacements.

Massachusetts DOT

Strategy Selection Process for Complex Projects

The Massachusetts DOT (MassDOT) does not have a formal written process for selecting strategies for bridge replacement in complex scenarios. However, MassDOT utilizes its project review process for D-B suitability for bridge replacement projects (Appendix B, Figure B-1) and

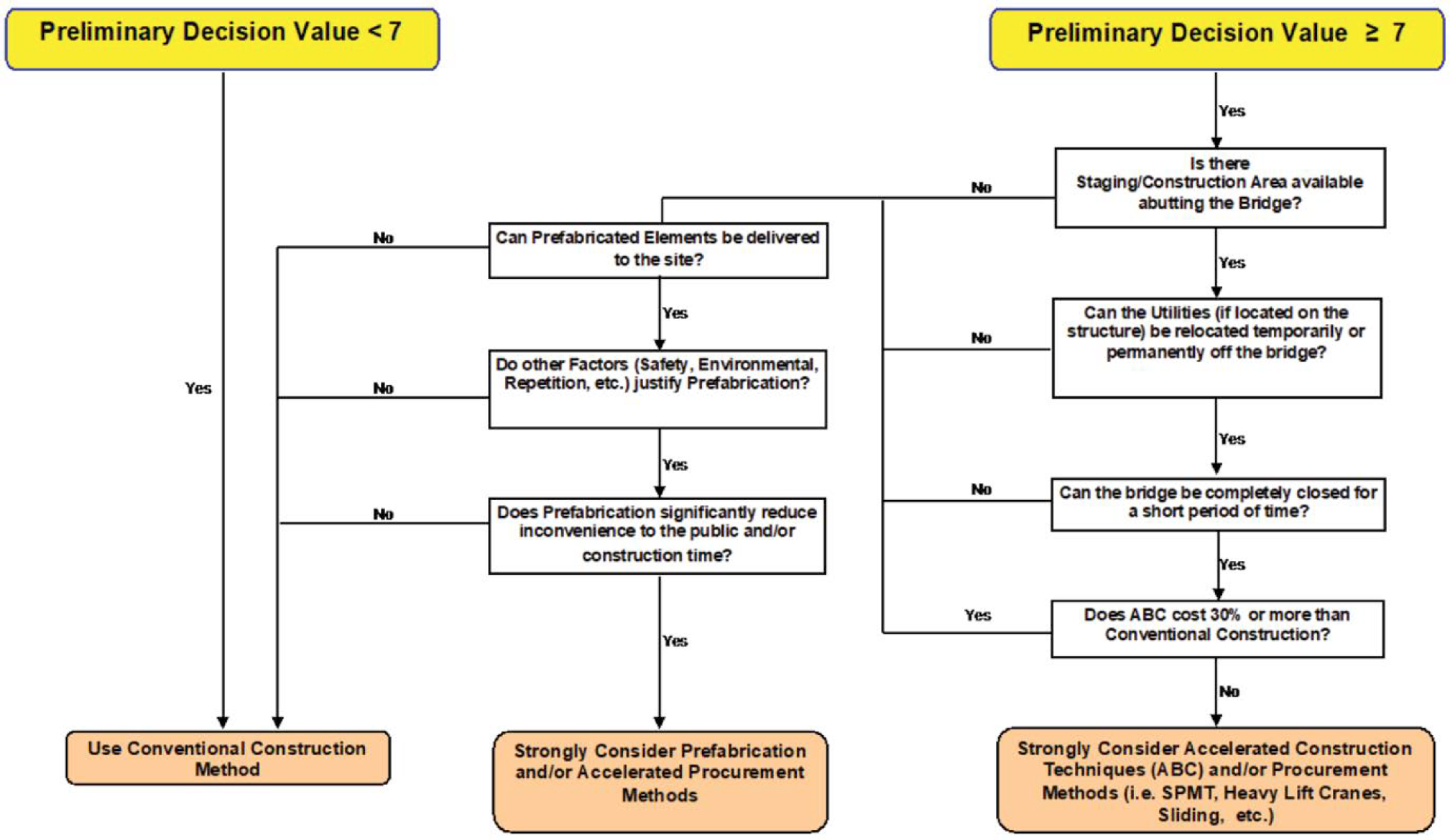

has a chapter on preliminary engineering guidelines in the MassDOT LRFD Bridge Manual (MassDOT 2013). To assist designers in selecting an appropriate construction method for bridge projects, a decision flowchart (Figure 4-2) has been developed for use during the preliminary engineering decision-making phase. To effectively utilize this flowchart, MassDOT staff must first evaluate certain factors to compute a Preliminary Decision Value (Figure 4-3). Average daily traffic (ADT), detour length, the road’s functional classification, whether it is an emergency replacement, or whether the bridge is over an active and busy railroad or navigation channel or on an evacuation route all factor into the preliminary decision value calculation. This value then guides the decision-making process, as referenced in the flowchart. The specific steps to calculate this value are part of a defined procedure that must be followed before consulting the flowchart.

Two critical factors primarily drive decision-making:

- Dollar Value: Financial considerations heavily influence the selection of project strategies, particularly in determining whether a project is pursued through a D-B approach.

- Project Complexity: The complexity of a project, especially in terms of its location and the technical challenges involved, also plays a significant role in strategy selection. Complex projects typically involve intricate design and construction demands, such as those encountered in intersection projects or major structures over rivers.

MassDOT typically employs a D-B strategy for complex projects. This approach is characterized by:

- Preliminary Concept Development: A consultant initially develops a design concept for highway and bridge components.

- Proposal and Execution by Design-Build Team: The design-build team is provided with these preliminary concepts, which serve as the base technical concept. The team is then expected to refine, elaborate, and propose alternative technical solutions encompassing highway and bridge elements.

- Continuous Oversight and Review: The consultant who developed the initial concept also reviews the proposals submitted by the design-build team. MassDOT maintains a design-build section specializing in bridges, which oversees the entire process.

Current complex scenarios that MassDOT is working on include multiple intersection designs that require coordinated approaches or significant structures over rivers (e.g., over the Merrimack River north of Boston) with geographic and structural challenges. Such projects affect surrounding structures because of traffic control and other factors.

As documented in MassDOT’s bridge manual (MassDOT 2013), the standard design process follows a systematic approach from preliminary planning to project completion once a project decision is made. This structured approach ensures consistency and thoroughness in handling complex bridge replacement projects. MassDOT’s approach to selecting strategies for complex bridge replacements is adaptive and responsive. It focuses heavily on each project’s financial implications and inherent complexities. This flexible yet structured approach allows MassDOT to effectively address the unique challenges posed by complex bridge replacement projects.

Critical Factors for Strategy Selection

MassDOT weighs various critical factors when considering complex bridge replacement scenarios, beginning with traffic considerations. The AADT is a key factor influencing construction method selection, particularly when projects require intricate traffic management solutions. The potential impact on traffic flow, especially on routes vital for emergency services or those with heavy commuter usage, is also a significant determinant in deciding the construction strategy. Larger structures with high AADT tend to be more suitable for D-B contracting than D-B-B.

Environmental and community impacts play a pivotal role in project planning. The feasibility of detour routes and their effect on local communities are carefully assessed, with longer detours or those passing through residential areas significantly influencing construction methods. The presence of protected lands, such as parks or agricultural zones, can limit construction options, often necessitating legislative approval before proceeding.

Design and safety requirements are integral to the decision-making process. Designs incorporate Complete Streets provisions to ensure accommodation for multiple modes of transport, including pedestrians and cyclists. Historical accident data and existing safety issues are considered to guide construction methodology. The potential impact on critical disaster evacuation routes is another essential factor that is considered to maintain functionality during and after construction.

Ecological considerations are addressed with strict compliance with environmental regulations, especially concerning impacts on wildlife habitats and water quality at stream crossings. The focus on minimizing land acquisition and using existing rights-of-way helps reduce environmental and community impacts.

The selection of construction methodology, including choices between D-B and D-B-B, depends on several factors, such as balancing speed, cost, and impact to optimize project outcomes.

Structural considerations also dictate the construction method; the bridge’s size and type, such as the requirement for single-phase construction for truss bridges, are crucial elements.

Construction management factors, including material type and availability, influence the choice of construction method, considering delivery times and logistical feasibility. Seasonal considerations also affect construction activities, with decisions influenced by weather conditions and daylight availability.

Economic and financial considerations are fundamental to project planning. Project cost and funding constraints are critically assessed. High-cost projects require robust funding from various sources, including toll revenues and federal aid when suitable. The availability of these sources is vital, especially when federal funds have restrictions on their use.

Project execution strategies, such as the contract period, significantly affect public perception. Efficient execution is essential to prevent negative sentiment and public dissatisfaction. Accelerated construction techniques, such as prefabricated units and slide-in bridge construction, are selected based on their potential to minimize traffic disruptions and accelerate completion times.

In conclusion, MassDOT’s approach to complex bridge replacements involves a thorough evaluation of structural, economic, managerial, and ecological factors. This comprehensive assessment ensures that all potential impacts are carefully considered and mitigated, aiming for optimal project success and minimal disruption to the public and environment.

Suitability of Project Delivery and Procurement Methods

MassDOT provided insights into how different conditions might influence the choice of project delivery or procurement methods for bridge replacements.

- Accelerated Construction and D-B: One notable example is the Fast 14 project (FHWA 2012). MassDOT utilized prefabricated bridge units to expedite the construction of 14 bridges over 14 weekends, an undertaking that could have taken years to complete with traditional methods. This approach was feasible due to the existing substructures’ adequate condition and capacity to support new load requirements. This strategy is particularly effective in high-traffic areas where minimizing disruption is crucial.

- Temporary Bypass: MassDOT employs a phased approach in scenarios requiring complete bridge replacements on dual-divided highways or interstates with sufficient space in the median to build a bridge. This approach involves constructing a new bridge in the median, shifting traffic to this new structure, and subsequently demolishing and replacing the original bridge. Depending on the complexity and size of the project, this method can be executed via either D-B-B or D-B. This method efficiently minimizes disruption and maximizes the use of available space.

- Slide-In Bridge Construction: Slide-in bridge construction is considered for other projects when conventional methods are unsuitable. This method involves constructing a new bridge adjacent to the old one, diverting traffic to the new structure. Subsequently, the old one is demolished, and then the new bridge is slid into the old bridge’s original position. The choice to undertake this technique is based on specific site constraints and the geometric particulars of the existing bridge.

MassDOT notes that each project is unique and requires a tailored approach, particularly considering factors like right-of-way restrictions, land usage, and ownership. Innovative and accelerated construction techniques are often necessary to navigate these challenges effectively.

MassDOT emphasizes that the choice of construction and procurement methods depends heavily on each project’s specific conditions and constraints, necessitating a flexible and context-sensitive approach.

Successful Strategies for Buy-In and Communication

MassDOT has found that the most effective way to gain buy-in from stakeholders on innovative techniques and strategies is through demonstrable success. The Fast 14 project serves as a prime example. MassDOT’s first large-scale accelerated construction project met initially with skepticism regarding its feasibility and impact on traffic. However, through committed leadership and robust communication strategies, the project proved to be successful.

Early in the project, MassDOT engaged directly with mayors, councilors, and other local officials in the affected cities, conducting informational meetings to outline the project’s scope and to address traffic management concerns. These efforts were supported by a dedicated project website that provided ongoing updates and information, which further helped build trust and transparency.

As the project progressed and stakeholders observed MassDOT delivering on its promises, the initial skepticism became strong support. The successful execution of the Fast 14 project alleviated doubts and sparked inquiries from other communities interested in similar rapid bridge replacement projects.

From the project’s onset, MassDOT conducts scoping meetings involving consultants and various stakeholders, including community representatives and MassDOT’s internal teams—highway, district, bridge, right-of-way, environmental, hydraulics, and Complete Streets staff. These meetings aim to comprehensively explain all project parameters, anticipate potential challenges, and incorporate local concerns and desires into the planning process.

Decisions about employing accelerated construction methods or other strategies are made early for significant projects, particularly on interstates, guided by prior experience and detailed project scoping. This approach ensures that by the time projects are ready for execution, there is a clear, agreed-upon strategy that rarely undergoes significant changes, even when handed over to design-build teams.

Remote collaboration tools like virtual meetings have proved effective, allowing broader participation from community leaders such as Department of Public Works (DPW) directors or town managers. These virtual engagements have fostered active involvement, gathered essential input, refined project details, and ensured comprehensive stakeholder engagement and support from inception to completion.

In summary, MassDOT’s strategy for securing stakeholder buy-in on innovative bridge construction projects relies heavily on demonstrating success, engaging stakeholders early and continuously, and employing a collaborative approach that integrates feedback into all stages of project planning and execution.

Challenges and Planned Changes for Strategy Selection

MassDOT’s current processes have proved effective, and while the DOT has no significant changes planned, there is a focus on continual improvement. Learning from each major project allows for incremental improvements rather than wholesale changes. This approach helps refine strategies and address any pitfalls encountered along the way. The experience gained over the years, including from successful initiatives like the Fast 14 project, underscores the effectiveness of this strategy. With a solid foundation and widespread buy-in, MassDOT is committed to fine-tuning its processes through ongoing adjustments and learning from each project, ensuring the continual enhancement of its operations.

Research Needs

MassDOT does not currently identify any gaps in its knowledge that would necessitate additional research. However, the agency remains attentive to industry developments and innovations. As active members of the local Precast/Prestressed Concrete Institute (PCI) technical committee, MassDOT staff are committed to incorporating innovative ideas and industry-wide improvements in design, construction, fabrication, or materials as they emerge. The organization maintains a stance of continual improvement, focusing on adopting relevant advancements and keeping abreast of global trends in the field. This initiative-taking approach ensures that MassDOT integrates the latest industry practices into its operations.

Experience Gained

The key experiences reported by MassDOT in this case example are summarized as follows:

- Project Review Process: MassDOT utilizes a project review process and a decision flowchart for selecting appropriate construction methods, ensuring a systematic approach during the preliminary engineering decision-making phase.

- Critical Factors for Strategy Selection: Key factors such as average daily traffic, detour lengths, and environmental impacts significantly influence the selection of construction methods.

- D-B Strategy for Complex Projects: MassDOT typically employs a D-B strategy for complex projects, characterized by preliminary concept development, proposal execution by the design-build team, and continuous oversight and review.

- Traffic and Environmental Considerations: Detailed assessment of traffic impacts, community effects, and environmental justice issues guides construction methodology selection.

- Safety and Design Requirements: Designs incorporate Complete Streets provisions, historical accident data, and safety considerations to ensure comprehensive project planning.

- Innovative Construction Techniques: MassDOT employs innovative techniques such as slide-in bridge construction and temporary bypass methods to minimize disruption and optimize project outcomes.

- Stakeholder Engagement and Communication: Early and continuous engagement with stakeholders, including local officials and community representatives, fosters support and ensures alignment with project goals.

- Proven Success: Demonstrating success in previous projects, such as the Fast 14 project, helps gain stakeholder buy-in and support for innovative techniques.

- Continual Improvement: MassDOT focuses on continual improvement, learning from each project to refine strategies and address challenges incrementally.

- Industry Engagement: Active participation in industry technical committees ensures that MassDOT stays updated with innovative ideas and industry-wide improvements, integrating relevant advancements into the DOT’s operations.

Texas DOT

Strategy Selection Process for Complex Projects

The Texas Department of Transportation (TxDOT) manages a broad spectrum of bridge-related projects encompassing the construction of new bridges and the replacement, rehabilitation, repair, and maintenance of existing bridges across public highways, roads, and streets. TxDOT’s bridge projects can be on-system, forming part of the state highway system and directly overseen by TxDOT, or off-system, managed under local government authority but still receiving oversight

and funding from TxDOT. Depending on the nature of the route, funding for these projects can come from a mix of federal, state, and local sources.

TxDOT explains that its process for selecting a suitable bridge replacement strategy typically involves initial consultations with the district to understand the main objectives and constraints of the project. This process does not have a formal structure. It relies heavily on collaborative efforts with district representatives to identify the needs and limitations at a local level. For local projects, funding considerations also play a significant role, as much of the funding originates from TxDOT, even if the agency is not directly involved in the design or other aspects of the project. The district often takes the lead, with TxDOT maintaining an interest due to its financial contribution.

Communication is critical in establishing project constraints and objectives early on to develop a solution that aligns with everyone’s interests. Although TxDOT does not follow a strict formal process, the Project Development Section utilizes the Texas Bridge Project Development Manual (Texas DOT 2023) as a guiding document, especially during the preliminary design phase, which includes considerations for environmental constraints and locational factors. This approach ensures flexibility and adaptability in handling various project demands, focusing more on practical and collaborative problem-solving than adhering to a rigid protocol.

Texas’s Bridge Project Development Manual offers detailed guidance and establishes consistent procedures and policies for the administration and development of bridge-related projects. Topics include bridge programming and funding, advanced planning, bridge plan review processes, and bridge project development reference information. The manual serves as an essential resource for professionals involved in planning, funding, and implementing bridge construction and replacement projects, ensuring that all phases are conducted effectively and in accordance with standardized practices.

Challenges and Planned Changes for Strategy Selection

TxDOT acknowledges the complexities of selecting appropriate strategies for bridge replacements, especially when funding and jurisdictional differences affect the available options. A key challenge highlighted is navigating funding constraints, where certain funds are applicable only to specific parts of a project, like a city or local structure. This situation necessitates carefully assessing funding eligibility and availability to find solutions and develop the project accordingly.

These financial and regulatory variations often dictate the strategies that can be implemented, affecting how projects are approached. Flexibility within strategic planning processes is needed to respond to these variations and challenges. TxDOT pointed out that while ABC techniques are highly beneficial, not every aspect of a project may require or be suited for ABC methods. This insight leads to a broader strategy of selective application, ensuring that ABC is used where it provides the most benefit, thereby optimizing resources and maximizing efficiency.

In conclusion, while TxDOT faces challenges similar to those in other states, its ability to adapt and modify its approach based on the specific circumstances of each project plays a crucial role in overcoming these obstacles. The ongoing evaluation and potential adaptation of its strategic selection processes reflect a dynamic infrastructure management and development approach.

Critical Factors for Strategy Selection

In selecting strategies for complex bridge replacement scenarios, TxDOT considers traffic ADT and detour length as the most critical site-related factors for strategy selection. Urban areas typically focus on traffic flow impacts, whereas rural areas prioritize detour implications due to longer possible reroutes. This distinction is crucial, particularly in remote areas with scarce alternative routes that make even minor projects critical in maintaining connectivity.

TxDOT also leverages ABC techniques, especially in less trafficked or remote locations to minimize disruption. This approach is facilitated by the use of standardized, pre-decked bridge components such as slab beams and box beams, which expedite construction and reduce on-site activity duration. However, these components often come with limitations regarding span length and durability, so careful planning and equipment considerations are needed during the installation process.

Regarding construction management, factors like material type, availability, quality, and contractual strategy significantly influence project execution. Texas benefits from a robust supply network, allowing flexibility in material selection. Contractual strategies often incorporate incentives or disincentives and A+B type bidding to ensure efficiency and cost-effectiveness in complex projects.

In terms of cost considerations, direct costs generally dominate decision-making processes, although life-cycle costs are considered, particularly in terms of maintenance and durability to optimize long-term value.

Suitability of Project Delivery and Procurement Methods

TxDOT has extensively utilized ABC strategies to address various bridge replacement scenarios efficiently. The state DOT possesses a comprehensive library of standardized bridge designs that facilitate quick construction, particularly when project timelines are constrained. These designs predominantly feature simple, single-span systems conducive to precasting almost all structural elements. This standardization has allowed TxDOT to gain experience and proficiency in ABC methods.

The state DOT emphasizes that not all project parts necessarily require the ABC approach. TxDOT collaborates closely with district offices and other stakeholders to identify specific project segments that critically need expedited construction. Focusing ABC techniques on these critical areas enhances efficiency while effectively managing costs.

This selective application of ABC allows for critical time savings on crucial project components without necessitating a full-scale ABC implementation across the entire project. Thus, resource allocation is optimized, and overall expenses are reduced. This strategic approach underscores TxDOT’s commitment to flexibility and cost-effectiveness in managing bridge construction and replacement challenges.

Successful Strategies for Buy-In and Communication

TxDOT emphasizes that transparent and thorough communication has been pivotal in gaining buy-in from legislators and other stakeholders for various bridge replacement strategies. TxDOT highlights the effectiveness of being up front about the benefits and drawbacks of each approach as a crucial factor in stakeholder engagement.

The process typically begins with comprehensive discussions with the district to identify all pertinent issues, constraints, and objectives. TxDOT ensures that all parties understand the benefits and potential challenges by explaining the rationale behind each chosen strategy and its expected outcomes. For instance, in projects requiring temporary road closures, TxDOT communicates the trade-offs between short-term inconvenience and long-term benefits, helping to manage expectations and maintain community support.

Additionally, TxDOT utilizes tools such as dedicated project websites to disseminate information and updates about ongoing construction activities, including the “My35” website (www.my35.org), which provides details about construction along Interstate 35. Although the

effectiveness of these websites can be challenging to gauge directly, they serve as a valuable resource for keeping the public and stakeholders informed.

Overall, TxDOT’s approach centers on proactive communication, setting clear expectations and demonstrating how each strategy aligns with the broader goals of the project and the community’s needs. This method has proved effective in minimizing complaints and easing the process of stakeholder engagement, reflecting a robust and well-considered approach to infrastructure development.

Experience Gained

The key experiences reported by TxDOT in this case example are summarized as follows:

- Flexible Strategy Selection Process: TxDOT emphasizes flexibility and collaboration with district representatives to identify project needs and constraints, focusing on practical problem-solving rather than on adhering to a rigid protocol.

- Guiding Documentation: Texas’s Bridge Project Development Manual provides detailed guidance and standardized procedures, ensuring consistent and effective project administration and development.

- Critical Site-Related Factors: Key factors influencing strategy selection include ADT and detour length, with urban areas focusing on traffic flow impacts and rural areas prioritizing detour implications.

- ABC Techniques: TxDOT leverages ABC techniques, especially in low-traffic areas or remote locations. These techniques use standardized pre-decked bridge components to expedite construction and reduce on-site activity duration.

- Material and Contractual Considerations: Material availability, quality, and contractual strategies, such as incentives or disincentives and A+B type bidding, play a significant role in project execution and efficiency.

- Cost Considerations: While direct costs dominate decision-making, life-cycle costs are also considered to optimize long-term value, particularly in terms of maintenance and durability.

- Selective Application of ABC: Not all project parts require ABC. TxDOT focuses ABC techniques on critical areas, enhancing efficiency and managing costs effectively.

- Transparent Communication: Proactive and thorough communication with stakeholders, including legislators and the public, is crucial for gaining buy-in and managing expectations, highlighting the benefits and trade-offs of each approach.

- Public Information Tools: Tools such as dedicated project websites (e.g., the My35 website) provide valuable resources for keeping the public informed about ongoing construction activities and updates.

- Navigating Funding Constraints: Addressing funding constraints and jurisdictional differences requires careful assessment of funding eligibility and availability, necessitating flexibility in strategic planning.

- Adaptability and Continuous Improvement: TxDOT’s ability to adapt and modify its approach based on specific project circumstances plays a crucial role in overcoming challenges, reflecting a dynamic and responsive infrastructure management strategy.

Washington State DOT

Strategy Selection Process for Complex Projects

The decision-making process for selecting bridge replacement strategies in complex scenarios is primarily managed by project engineer offices (PEOs) spread across the state of Washington, guided by regional administrators. These offices determine whether to proceed with D-B-B

approaches, employ consultants, or opt for D-B projects based on cost, schedule, expertise, and the project’s specific needs.

The strategy selection process for each project is dynamic and unique, not bound by rigid, one-size-fits-all policy and guidelines. Many factors, including financial considerations, risk assessments, available expertise, and project timelines, influence the selection process. For instance, the choice between in-house expertise or consultants is often a result of the availability of the workforce and the ability to meet project deadlines.

Legislative changes in 2015 approved the use of D-B for projects with contract costs of $2 million or greater (DBM 1-2.1). WSDOT’s Design-Build Manual (DBM) (Washington State DOT 2021), a crucial resource managed by the construction office, is a comprehensive guide for project selection, development, and administration via D-B project delivery. This manual outlines the processes and procedures for procuring and managing D-B contracts. A deep understanding of the DBM is beneficial and vital for effectively managing D-B contracts. It is continuously updated to incorporate lessons learned, adapt to evolving industry practices, and align with federal and state laws. WSDOT actively encourages feedback through a suggestion log, welcoming comments and ideas for further manual enhancement. The DBM is updated based on feedback from subject matter experts within WSDOT.

Not every project is suitable for the D-B PDM because of the considerable time and resources required to execute a D-B procurement process effectively. WSDOT uses a formal PDM Selection Guidance (PDMSG) to determine the most appropriate PDM for each project (Washington State DOT 2021). This process involves careful scoping and scheduling, setting clear project goals, assessing staffing and resource needs, and conducting an initial risk assessment. The PDMSG identifies several key characteristics of a D-B project, including the ability to expedite project delivery, achieve cost-efficient solutions through innovation, and require that funding, project scope, and performance expectations be defined and set in advance. Additionally, it necessitates substantial resources for advancing preliminary design, managing a comprehensive procurement process, and overseeing project implementation, which may include the co-location of teams. Effective D-B projects depend on a clear understanding and proper allocation of project risks between WSDOT and the D-B contractor. These factors and comparisons to traditional D-B-B characteristics guide the selection of the best PDM.

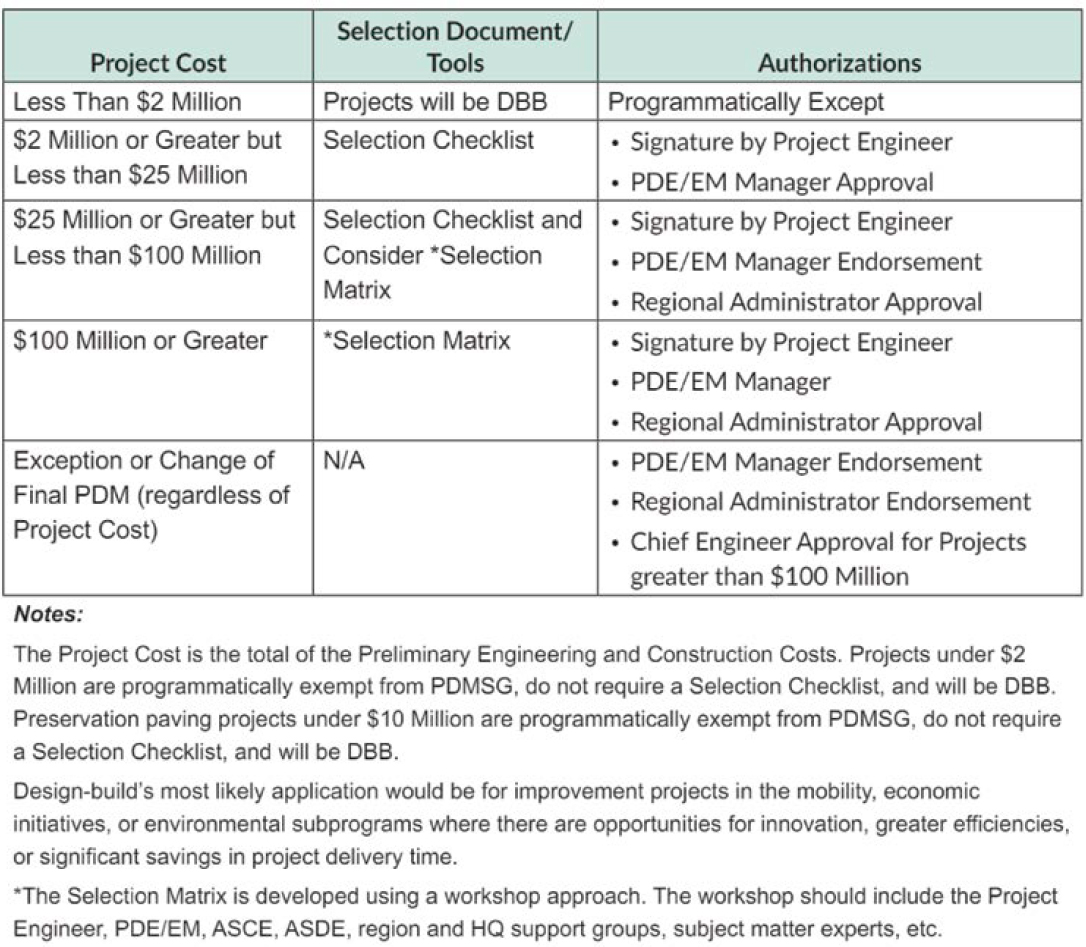

Project cost thresholds also determine the PDM (Figure 4-4). For example, projects under $2 million will be D-B-B, and projects exceeding certain cost limits may automatically be designated D-B to manage the increased complexity and financial stakes.

WSDOT’s approach is to maintain strong ownership over the specifications and standards applied across state projects, which are reviewed and updated regularly with input from internal experts and external industry groups. This collaborative review process frequently occurs to keep standards current and comprehensive, accommodating the diverse and complex nature of bridge replacement projects.

Critical Factors for Strategy Selection

WSDOT’s strategy for selecting bridge replacement methods is influenced by multiple factors, and they are analyzed on a case-by-case basis. As previously noted, these factors include the project size, cost, availability of in-house expertise, project timelines, and associated risks. Projects are classified as either regular or mega based on the cost of the project. Washington State Standard Specifications, which apply to D-B-B and D-B projects, are updated annually to reflect current industry practices. The WSDOT/AGC (Associated General Contractors) subcommittee and pavement teams are crucial in reviewing these specifications. They discuss the need for updates

and ensure that WSDOT remains a strong owner focused on maintaining up-to-date standards. The DBM is managed by an internal WSDOT group that meets every six weeks and includes experts from various fields such as structures, roadway, electrical, utilities, permits, environmental, hydraulics, and public relations. This group incorporates industry feedback and updates the DBM annually. The D-B group comprises 100+ internal WSDOT employees maintaining the DBM updated to the latest industry standards and best practices.

Suitability of Project Delivery and Procurement Methods

WSDOT does not identify a specific PDM that fits a certain scenario but rather emphasizes the importance of the process followed under state DOT guidance documents.

Challenges and Planned Changes for Strategy Selection

WSDOT introduced two pilot projects with progressive design build (PDB), expanding its range of alternative delivery methods. While PDB has been added to WSDOT’s toolkit to enhance project delivery, it is still too early to evaluate its effectiveness. As the pilot projects progress, WSDOT will continue to monitor and assess the outcomes to determine the viability of PDB for future projects.

One of the significant challenges WSDOT faces in selecting bridge replacement strategies revolves around maintaining high-quality standards. In the D-B-B approach, WSDOT retains considerable control over product quality. However, the D-B method often leads to challenges

such as contractor pushback, particularly when project specifications are not explicitly detailed in the DBM. For instance, WSDOT has experienced situations in which contractors dispute the necessity of material submittals not clearly outlined in the manual. This lack of clarity can undermine WSDOT’s position, necessitating contract negotiations. To address these issues, WSDOT focuses on being a “strong owner” by actively updating the DBM based on real-world experiences and feedback, strengthening the quality control/quality assurance processes, and ensuring the guidelines are comprehensive and enforceable. This ongoing refinement helps mitigate challenges and improve the overall effectiveness of bridge replacement projects.

Research Needs

WSDOT relies on a broad spectrum of guidelines, research, and documents to support its bridge replacement program, referencing comprehensive resources from several authoritative bodies. The key references include NHI (National Highway Institute), AASHTO (American Association of State Highway and Transportation Officials), PCI (Precast/Prestressed Concrete Institute), ACI (American Concrete Institute), AISI (American Iron and Steel Institute), APA (American Plywood Association), ASCE (American Society of Civil Engineers), CRSI (Concrete Reinforcing Steel Institute), IBC (International Building Code), NDS (National Design Specification), PCA (Portland Cement Association), and NCHRP (National Cooperative Highway Research Program).

WSDOT places significant emphasis on the guidelines from FHWA (Federal Highway Administration), considering them alongside NHI and AASHTO as top-tier resources for developing its own manuals and guidelines. AASHTO’s construction manual and resources from the American Welding Society are particularly important for ensuring compliance with industry standards. WSDOT finds practical examples for designing bridge elements useful and advocates for making such resources more publicly accessible to enhance transparency and knowledge sharing.

Experience Gained

The key experiences reported by WSDOT in this case example are summarized as follows:

- Flexible Strategy Selection: WSDOT emphasizes a dynamic and flexible approach to selecting bridge replacement strategies, considering each project’s unique factors such as cost, schedule, and specific needs.

- Comprehensive Guidelines: The Design-Build Manual is a crucial resource that is regularly updated based on feedback from various stakeholders, ensuring the guidelines remain relevant and reflect best practices.

- Collaborative Review Process: WSDOT maintains strong ownership over specifications and standards, involving internal experts and external industry groups in a collaborative review process to keep standards current and comprehensive.

- PDM Selection: WSDOT uses a formal PDM Selection Guidance (PDMSG) to determine the most appropriate delivery method for each project, considering project size, cost, in-house expertise availability, timelines, and risks.

- Emphasis on Quality Control: To address challenges in maintaining high-quality standards, particularly in the D-B method, WSDOT focuses on being a “strong owner” by actively updating the DBM and strengthening quality control and assurance processes.

- Pilot Projects for Innovation: WSDOT has introduced pilot projects, such as for PDB, to expand its range of alternative delivery methods and continues to monitor and assess their outcomes to determine future viability.

Wisconsin DOT

Strategy Selection Process for Complex Projects

At the Wisconsin Department of Transportation (WisDOT), the dialogue regarding complex bridge replacement projects primarily starts at the regional level, especially on the roadway side, where project constraints such as time, environmental factors, and traffic maintenance are significant considerations.

In many instances, roadway personnel develop initial concepts, such as implementing a temporary bypass, or suggest employing ABC techniques to expedite the project. This often results in a collaborative (although sometimes roadway-led) dialogue between the structures and roadway designers. To facilitate this process, WisDOT’s Bureau of Structures has developed an ABC chapter (Chapter 7) within the WisDOT Bridge Manual to provide guidance and outline potential ABC options. This chapter includes application criteria for usage, design considerations, details, or steps, as applicable, for the ABC technologies currently used by WisDOT.

WisDOT defines its mission with ABC as to lead in creating and managing a safe and efficient transportation system, with a core value focused on continuous improvement (Wisconsin DOT 2020). This involves seeking innovative and forward-thinking strategies to enhance the services provided and evaluating their effectiveness. Consistent with these principles, WisDOT incorporates ABC methods to advance the efficiency of the transportation system. ABC aligns with the department’s goals by enabling quicker bridge construction, thereby minimizing disruption for travelers and potentially reducing project costs. This approach not only shortens construction timelines but also contributes to safer project sites and lessens the impact on the public, reflecting WisDOT’s commitment to enhancing infrastructure while serving the community effectively.

WisDOT adheres to the FHWA Every Day Counts initiative, which focuses on expediting project delivery, increasing roadway safety, and protecting the environment. Among the key accelerating technologies highlighted by FHWA are prefabricated bridge elements and systems (PBES) and geosynthetic reinforced soil – integrated bridge systems (GRS-IBS). These technologies are detailed in the sections of the ABC chapter of WisDOT’s Bridge Manual—namely, Prefabricated Bridge Elements, Geosynthetic Reinforced Soil – Integrated Bridge Systems (GRS-IBS), Self-Propelled Modular Transporters (SPMTs), and Lateral Sliding. WisDOT has successfully implemented GRS-IBS and Prefabricated Bridge Elements, continually seeking innovative technologies to enhance construction efficiency and minimize traffic disruption.

Using these guidelines, the final decisions are frequently influenced or directed by the roadway teams based on various project-specific requirements. Project-specific requirements are assessed and clarified through communication to arrive at the final decisions. In practice, the use of ABC, particularly precast components, has been more prescriptive than voluntary. For instance, during a significant project extending from Madison to the Illinois state line on the Interstate, WisDOT required the use of precast piers for six structures in a corridor to standardize details and to encourage the use of ABC methods.

However, the anticipated voluntary adoption of precast technologies has not been as successful as hoped. Traditional methods that utilize existing workforce and equipment over subcontracting may be preferred, even when precast options are available.

The experience indicates complexities and real-world challenges of integrating innovative construction methods into traditional infrastructure projects, highlighting both the collaborative efforts and the limitations faced by the DOT in using innovative technologies.

Critical Factors for Strategy Selection

As for the site- or location-related factors or characteristics, the primary concerns for bridge construction projects are AADT and detour out-of-distance travel. The priority is often the volume of traffic affected by the construction—whether it involves rerouting a few cars or thousands—and the feasibility of detour routes available. These two factors are intricately linked and critically assessed when planning construction closures and selecting the associated bridge replacement strategy. Additionally, WisDOT’s standard PDM has been D-B-B, but the DOT is currently exploring and gaining experience with D-B projects, having completed one bridge and started another under this method.

Construction management considerations at WisDOT vary significantly depending on the specifics of the project site and its context. Typically, complex projects are perceived primarily as large interchange construction, such as the Zoo Interchange project in the Milwaukee area, while other DOTs may consider challenges in more remote locations where logistical constraints exist as a complex scenario, even if the structures themselves are not as complex.

In terms of construction materials and methods, WisDOT typically utilizes concrete prestressed girders or cast-in-place concrete slabs for the majority of its bridges. For larger structures, the decision between using steel versus concrete girders is sometimes influenced by factors such as material availability and delivery times. The choice of construction material and method depends greatly on the project’s requirements and situational demands.

Furthermore, the construction season and project duration are crucial factors due to the distinct winter season in Wisconsin, which can complicate or halt construction activities. These elements are typically prioritized in planning, as they significantly affect the feasibility and timing of construction projects at WisDOT.

Regarding the cost factors, direct, indirect, and asset life-cycle costs are all considered, but direct cost may be more influential in strategy selection since, for example, using SPMTs may make sense in many situations but come with a high price tag. Also, factors such as high cost or high traffic are very interrelated and decisions such as material selection for life-cycle cost considerations are already included in the process. Therefore, while direct cost might be the main driver at times, all cost factors are included and considered in various stages of strategy selection and design.

Suitability of Project Delivery and Procurement Methods

WisDOT has found that innovative construction techniques and ABC methods have been effective in various projects. However, there has been limited adoption by contractors in traditional D-B-B contracts. This might change as WisDOT explores more D-B and ACMs, which could incentivize contractors to adopt innovative techniques when they perceive a direct benefit.

In the D-B-B framework, WisDOT specifies the timelines, which differs from the D-B approach in which contractors have more flexibility to choose their methods and potentially gain benefits from faster and more efficient practices. For instance, in a significant project in the Milwaukee area, a contractor chose to use precast piers for sign structures instead of the specified cast-in-place method. This decision, prompted by the project’s scale and time limits, proved to be successful.

Additionally, WisDOT has successfully implemented the lateral slide technique in a project on which the contractor utilized two different methods within the same project, learning and improving from one application to the next. Despite these successes, WisDOT has not observed

more common use of ABC techniques. This ongoing experience underscores the potential and challenges of integrating more advanced construction methods within WisDOT’s projects.

Successful Strategies for Buy-In and Communication

WisDOT has successfully gained stakeholder buy-in for innovative bridge replacement techniques through demonstration pilot projects, particularly with regional partners involved in roadway engineering. A notable example includes using SPMTs to expedite bridge replacement. Initially, there was a proposal to close a bridge for three months to accommodate the SPMT. WisDOT’s Bureau of Structures advocated for a shorter closure of only a couple of weeks, noting that the additional costs involved with using SPMTs should provide a shorter construction.

Furthermore, WisDOT is leveraging its pilot D-B projects to display the benefits of this approach to stakeholders, including the legislature, by highlighting the time savings achieved compared to traditional D-B-B projects. For instance, a specific project is to be completed two years earlier than it would have been under the conventional approach.

Communication and engagement with local communities play a critical role in building trust and securing buy-in for future projects. WisDOT places a high value on this aspect, focusing on engaging with local communities and providing comprehensive information through platforms like dedicated websites. This approach is designed to ensure that a broad range of stakeholders, defined differently across projects, understand the benefits and necessities of innovative construction methods and technologies, thereby fostering a sense of reassurance and value among them.

Challenges and Planned Changes for Strategy Selection

WisDOT identifies the availability of alternative contracting methodologies as one of the primary challenges in selecting strategies for complex bridge replacement projects. Constraints imposed by state statutes significantly limit the flexibility to use potentially more efficient approaches like PDB, which currently are not permissible under state law.

Financial resources, while crucial, are generally viewed as a surmountable challenge, because WisDOT’s adaptable approach ensures that necessary funding can be found if a particular method proves essential for a project. For instance, techniques such as using SPMTs or implementing temporary bypasses are feasible solutions that can be employed, when they are suitable for a certain situation.

Environmental constraints may also pose significant challenges. Often, projects encounter regulatory conflicts, such as environmental protection requirements from the Department of Natural Resources, which might restrict certain activities. For example, protected species like mussels in a project area can prohibit specific construction practices or hinder the timeline of a project or contractor operations. A bigger challenge is when contradictory conflicts occur for a project.

WisDOT’s most significant potential change is the pilot projects it is doing for alternative contracting. WisDOT is interested in exploring alternative contracting options and being able to include them in its toolbox.

Research Needs

WisDOT sees value in research on additional technologies to help mitigate future or potential issues.

Experience Gained

The key experiences reported by WisDOT in this case example are summarized as follows:

- Collaborative Decision-Making: The selection of bridge replacement strategies involves a collaborative dialogue between roadway and structures teams, often initiated by roadway personnel. This collaboration ensures that project constraints and goals are comprehensively considered.