Options for a National Plan for Smart Manufacturing (2024)

Chapter: 2 The Value and State of Smart Manufacturing in the United States

2

The Value and State of Smart Manufacturing in the United States

DEFINING SMART MANUFACTURING

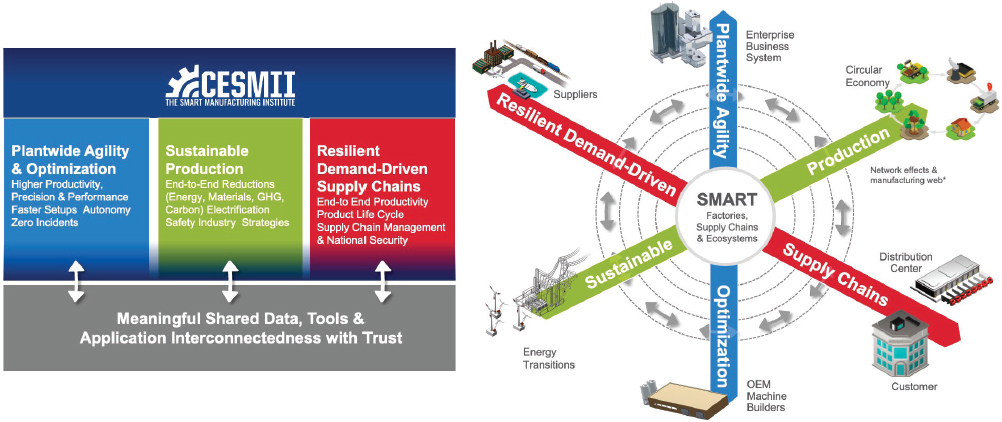

The National Academies of Sciences, Engineering, and Medicine committee sees smart manufacturing as the scaled integration of networked data with plantwide optimization; physical and sustainable production; and resilient, demand-driven supply chains, as depicted in Figure 2-1.1 At the center, integration is internally focused within every factory and externally extended throughout all interfactory operations, supply chains, and resource ecosystems. The gray circles indicate an industry that is networked with trusted data interconnectedness at every level—sensor to machine or device, operation, line operation, factory, interfactory, supply chain, and ecosystem. Broadly accessible core information and operational modeling and simulation capabilities are developed through a facilitated community source and market approach for contribution and validation; sharing through standardized approaches; and low-barrier accessibility to small, medium, and large enterprises.

Smart manufacturing can also be viewed beyond technology and operations as the strategic investment in people, technology, and practice that enables manufacturers to extract significantly increased value from their existing assets and

___________________

1 The original version appeared in a Time magazine informational cover in 2010 as an article by Sujeet Chand (Chief Technology Officer, Rockwell Automation) and Jim Davis (Vice Provost, University of California, Los Angeles), titled “What Is Smart Manufacturing?” The graphic was used extensively by the Smart Manufacturing Leadership Coalition through 2015. Jim Davis updated the graphic in 2022 for the Clean Energy Smart Manufacturing Innovation Institute to reflect a decade of industry and smart manufacturing evolution.

SOURCE: Courtesy of CESMII, a program at the University of California, Los Angeles. Original Artwork Copyright © 2010 Rockwell Automation, Inc.

resources, at network scale, using digitalization to empower more effective workers, factories, and supply chains. Through sensing, contextualization, and modeling of data to produce actionable information, smart manufacturing enables manufacturers to visualize “what” is going on; develop insights into “why” an operation is behaving a certain way; use predictive modeling to forecast “when” to expect certain behaviors; and determine “how” to control the manufacturing process through optimized actions (through human interaction or through automation and automated systems). These what, why, when, and how aspects of a smart manufacturing solution are the smart manufacturing building blocks of data and information that must be collected and processed.

As a general statement, smart manufacturing defines the digital transformation of the U.S. manufacturing industry for proactive management, automation and autonomous operation of assets, line and factory operations, supply chains, and ecosystems. Smart manufacturing both enables and derives maximum value with scaled industry adoption and industry’s ability to execute on industry-wide strategies, with the objectives of increasing productivity (use less, waste less), precision (drive specification, greater accuracy, and quality), resilience, and performance (manage human and physical resources for better, faster, cheaper, and more flexible operations) at all levels of manufacturing (see Figure 2-2b). Smart manufacturing is among the key enablers of environmental sustainability given the basic strategies of (1) making products that have less harmful environmental impact; (2) using new physical technologies that employ resources in different ways; (3) removing and repurposing harmful emissions; and (4) measuring, controlling, managing, and optimizing industry operations to maximize the use of resources, recycle and manage a circular economy, and enable industry-wide strategies.

EXAMPLES OF TECHNOLOGIES SHAPING SMART MANUFACTURING

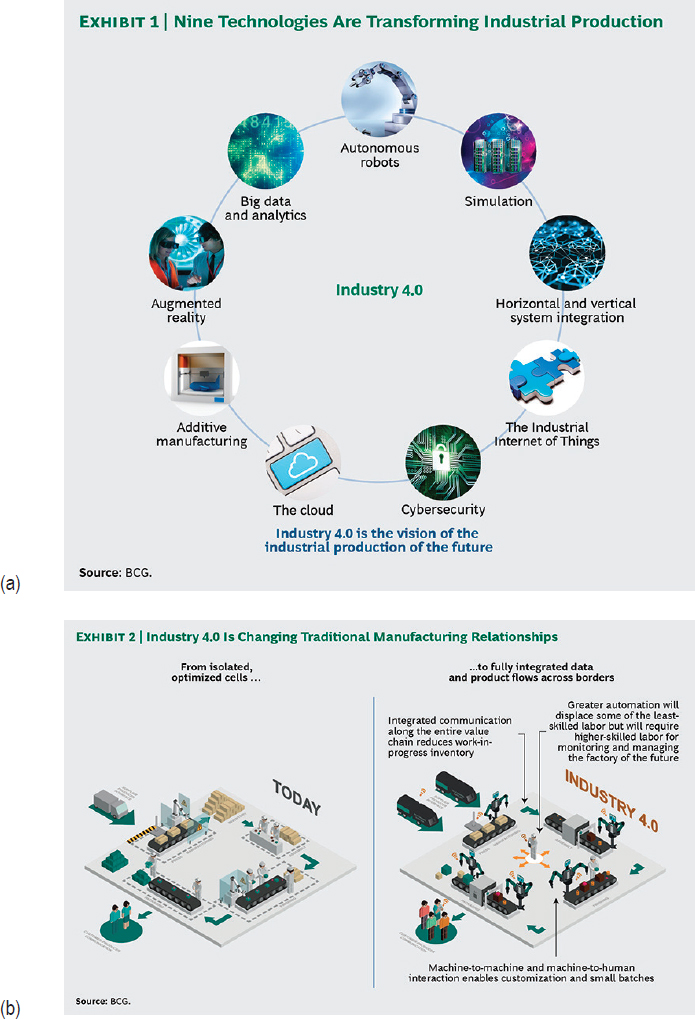

There is a wide range of technologies that underpin smart manufacturing (see Figure 2-2a). Many of these technologies are also driving the transformation to smart systems in other sectors (e.g., consumer products, energy, and transportation). Some of the technologies include the following:

- Internet of Things (IoT): This describes the network of physical objects—“things”—that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the Internet. When applied to the industrial sector (e.g., manufacturing), IoT is referred to as industrial IoT (or IIoT).2

___________________

2 S.A. Gillis, “What Is Internet of Things (IoT)?” https://internetofthingsagenda.techtarget.com/definition/Internet-of-Things-IoT, accessed November 13, 2023.

SOURCE: M. Rüßmann, M. Lorenz, P. Gerbert, M. Waldner, P. Engel, M. Harnisch, and J. Justus, 2015, “Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries,” Boston Consulting Group (BCG), https://www.bcg.com/publications/2015/engineered_products_project_business_industry_4_future_productivity_growth_manufacturing_industries.

- Big data: This is a field that treats ways to analyze, systematically extract information from, or otherwise deal with data sets that are too large or complex to be dealt with by traditional data-processing techniques. A major source of big data is IoT.3

- Cloud computing: This is a model for enabling ubiquitous, convenient, on-demand network access to a shared pool of configurable computing resources (e.g., networks, servers, storage, applications, and services) that can be provisioned and released rapidly with minimal management effort or service provider interaction.4

- Artificial intelligence (AI) and machine learning (ML): AI is a broad field encapsulating a variety of techniques that enable computers (and machines in general) to mimic human intelligence. AI applications include computer vision, speech recognition, some forms of robotics, and other topics. ML is a subset of AI that enables computers to learn from experience (data). Deep learning is a special and very powerful type of ML that enables computers to perform complex learning tasks (e.g., image recognition) when provided with a lot of data.5

- Cybersecurity: This is the protection of operational technology (OT), computer systems, and networks from the theft of or damage to their hardware, software, or electronic data, as well as from the disruption or misdirection of the services they provide.6

- Robotics: This is an interdisciplinary field that integrates computer science and engineering. Robotics involves design, construction, operation, and use of robots. The goal of robotics is to design machines that can assist humans.7

- Simulation, visualization, and immersion methods: These are tools that help humans to interact digitally with physical objects. They can be used for many purposes, including verification and validation, optimization, and remote control. Some noteworthy technologies8 in this category include the following:

___________________

3 A.K. Kordon, 2020, Applying Data Science, Basel, Switzerland: Springer Nature Switzerland, https://doi.org/10.1007/978-3-030-36375-8.

4 H.B. Rebah and H.B. Sta, 2018, “Cloud Computing: Potential Risks and Security Approaches,” Pp. 69–78 in Lecture Notes of the ICST Institute for Computer Sciences, Social Informatics and Telecommunications Engineering, T.F. Bissyande and O. Sie, eds., https://doi.org/10.1007/978-3-319-66742-3_7.

5 C. Okwudire, 2022, “Lecture 2: Introduction to Smart Manufacturing Systems (Cont’d),” https://www.coursehero.com/file/138912109/Lecture-1-2-Introduction-to-Smart-Manufacturing-Systems-Contd.pdf.

6 D. Schatz, R. Bashroush, and J. Wall, 2017, “Towards a More Representative Definition of Cyber Security,” Journal of Digital Forensics, Security and Law 12(2):Article 8.

7 University of Piscosoft, 2021, “Robotics,” https://piscosoft0.blogspot.com/2021/01.

8 Unless otherwise indicated with a citation, the definitions listed here and elsewhere in the report are the committee’s own.

-

- Digital twin: This is a digital replica (model) of a physical object. It is usually connected with the physical product (e.g., through data sharing).

- Augmented reality: This is an interactive experience of a real-world environment where the objects that reside in the real world are enhanced by computer-generated perceptual information, sometimes across multiple sensory modalities, including visual, auditory, haptic, somatosensory, and olfactory.9

- Virtual reality (VR): This is a simulated immersive experience that realistically captures the real world (or a made-up world). It is usually achieved using VR goggles and controllers.

RELATIONSHIP OF SMART MANUFACTURING TO INDUSTRY 4.0, ADVANCED MANUFACTURING, AND SIMILAR EFFORTS AROUND THE GLOBE

Data and Humans

Smart manufacturing fundamentally is about what gains are possible when the right data are available in the right formats, at the right times, and in the right places wherever needed throughout the entire enterprise to apply the best machine or human actions to make the best product with the least amount of energy and resources. In the United States, smart manufacturing started and evolved independently of “Industrie 4.0” in Germany.10 Both started in the mid-2000s as Smart Plant in the United States and Smart Factory in Germany. The term “Industry 4.0” was the result of rebranding. “Smart manufacturing” was the result of simplifying a longer title of smart (predictive, preventive, and proactive), zero-incident, zero-emissions manufacturing. Differences between the two arose with differences in focus and evolution. Smart manufacturing started from the perspective of the process industry (chemicals, oil and gas, materials) and evolved to encompass discrete parts manufacturing. “Industrie 4.0” started from discrete parts manufacturing, which has remained a dominant continuing focus. Smart manufacturing evolved to emphasize energy consumption, environmental sustainability, and safety. IoT was a term that came into wide use after smart manufacturing and Industry 4.0. IoT, which addressed the scaled networking of devices, sensors, data, and people, became viewed as an underpinning layer of capability for both. Smart manufacturing

___________________

9 P. Cipresso, I.A. Giglioli, R. Chicchi, and G. Riva, 2011, “The Past, Present, and Future of Virtual and Augmented Reality Research: A Network and Cluster Analysis of the Literature,” Frontiers in Psychology 9:2086, https://doi.org/10.3389/fpsyg.2018.02086.

10 J. Davis, 2022, “The 15th Anniversary of Smart Manufacturing,” https://www.cesmii.org/the-15th-anniversary-of-smart-manufacturing.

has embraced the central role of humans in high-performing enterprises from its start, while “Industry 5.0” has recently been introduced to emphasize the critical importance of even greater synergies and interactions between humans and machines.

Operational Technology and Information Technology Convergences

The beginnings of smart manufacturing can be traced back to the 1960s, 1970s, and 1980s and the OT elements associated with “digitization,” manufacturing’s transition to digital controllers, and the first surge of AI and “expert systems.” The Internet and cyberinfrastructure took off in the early 2000s and were needed to truly motivate comprehensive, scalable U.S. strategies. There were also timely convergences with dramatically increased data management and computing capabilities, rapid expansion of modular and multiscale modeling, the advent of enterprise resource planning (ERP), and the building interest in enterprise key performance indicators. Manufacturing interest ramped up, motivated by how these primary infrastructure ingredients could be used with real-time data about resources, operations, and quality at scale. Interests focused on new business and operational capabilities for making products, dealing with safety, and addressing environmental sustainability. Smart manufacturing became the term that pulled these ingredients together into scaled capabilities for all levels of manufacturing operations.

There is no doubt that the early digitization (transition from analog to digital data) of the industry, the Internet, information communication technology, cyberinfrastructure, cloud, ubiquitous computing and data management, high-performance computing, ERP systems, and AI/ML have all been necessary information technology (IT) developments for smart manufacturing to progress. Smart manufacturing depends on additional convergences, generally called OT/IT convergences, that reflect the key technology and practice ingredients that define how to scale and the pace of change for smart manufacturing:

- Automation, autonomy, and robotics that address zero setup to changes and are autonomously responsive to changing conditions.

- Consistently shared data, models, and tools curated and developed for shared application needs within industry segments while using industry-wide infrastructure, tools, and practices within the United States, including a national transformative data infrastructure.

- Distributed technology and user interface simplification, with complexity managed with data-centered modeling and workflow.

- Increased use of cloud-native applications to democratize information management for operations. Although real-time control processes are likely to continue to take place on premises, the use of the cloud for information

- management applications is especially useful for small and medium-sized businesses by reducing the number of on-premises IT assets and the corresponding need for internal IT support resources.

- Security, zero trust, and interconnected opportunity as different aspects of the same architecture that need to be addressed together.

- Process control for continuous and batch material processes is seeing greater integration with machining and three-dimensional (3D) printing in discrete parts manufacturing that uses logic/workflow control. Similarly, logic/workflow control is seeing integration with the management and control of continuous and batch processes.

- The evolution of smart manufacturing and AI technologies, which includes optical character recognition and natural language processing for interfacing with people; feature acoustic, vibration, and image recognition; and the recent advances using large generative AI models and high-performance computing to securely blend private and public data.

One big challenge is that IIoT technology companies are under intense market pressure to focus on “first to market” over security, thereby passing on risk to final consumers. The aggregated vulnerability assumed by consumers has created a significant national concern.11 The Cyberspace Solarium Commission’s call for action urges companies to shift from a “first to market” mentality to a “secure to market” manufacturing ecosystem to enable a secure IT/OT convergence.12

Artificial Intelligence at Scale

Smart manufacturing and AI have evolved together over 50 years such that today they are integrated concepts that continue to evolve and that are expected to be pervasive with dramatic impact. Smart manufacturing with AI refers operationally to software systems that can recognize (what), assess (why), simulate and predict (explain), and optimize situations, operating conditions, and material properties for human and machine action (how).

___________________

11 Cybersecurity Manufacturing Innovation Institute (CyManII), 2022, Cybersecurity Manufacturing Roadmap 2022—Public Version 8 B. The Digital Transformation, https://cymanii.org/wp-content/uploads/2022/05/CyManII-Cybersecurity-Manufacturing-Roadmap-2022-Public-Version-Final.pdf.

12 A. King and M. Gallagher, 2020, United States of American Cyberspace Solarium Commission Report, U.S. Cyberspace Solarium Commission, March, https://www.solarium.gov/report.

Machine Learning

ML, generally seen as a subset of AI, refers to algorithms that use prior data to identify current state, predict future state, or discover hidden causalities and opportunities with the goal of improving productivity, precision, and performance. Recent advances in AI using large generative AI models and high-performance computing can be used to blend private company data with public data (including 3D models, video, documents, and simulation data) securely. These techniques are combined with traditional ML. Output data can be used by smart manufacturing AI systems to “learn and improve” over time with use. These AI functions are widely applied for production objectives that include operational control and management, diagnostics, quality assurance, equipment and operational health monitoring, and production optimization from factory to supply chain to ecosystem.13

AI notably plays important roles with chain of custody for cross factory, supply chain, and ecosystem items of interest such as materials, energy, emissions, carbon, contamination, and defect tracing. There are also the AI systems that support various stages of the manufacturing process, including human–computer interfacing; validating and verifying data; selecting data and models; managing contracts; exchanging data within and between companies; and enhancing security, privacy, and protection of confidential information. Finally, AI is expected to offer key network capabilities to learn, categorize, and scale data accumulated throughout the industry from years of experience and provide opportunities to derive new insights for continuous improvement of factory operations and products. This is the AI for enabling scaled network effects with the ability to search, discover, access, and use widely distributed, networked, industry resources, including data sets, models, tools, training, application playbooks, and market opportunities. As AI moves from research to mainstream tools, engineering will be as important as the research breakthroughs.14

Many of the most important real-world impacts will occur after deciding how to employ existing AI algorithms and systems, some more than a decade old. Adoption of AI in manufacturing will also require development of new AI tools and algorithms. The integration challenge is immense. Harnessing data, hardening and packaging algorithms for field implementation, and adapting AI software to legacy equipment and rigid organizations all require time, effort, patience, a skilled workforce, and resources. Integrating AI often necessitates overcoming substantial organizational and cultural barriers, and it demands top-down leadership. For this to work, a manufacturing architecture is needed that securely retrieves, translates,

___________________

13 National Institute of Standards and Technology (NIST), 2022, Towards Resilient Manufacturing Ecosystems Through Artificial Intelligence—Symposium Report, https://nvlpubs.nist.gov/nistpubs/ams/NIST.AMS.100-47.pdf.

14 Ibid.

transforms, and stores data so that data-centered modeling and AI applications can mature and progress through dashboards, human-in-the-loop, control, automated, and autonomous operations.15

Smart Manufacturing and Business Structure

The early work on AI and ML also set in motion the view that data are key resources with considerably more value when separated from functional and physical operation handcuffs. The need for ingestion, contextualization, and orchestration of the data and the know-how to use them became core to smart manufacturing. There was also early recognition that the manufacturing industry was data rich but “right data” poor because of compartmentalization. Compartmentalization is a catch-all term describing the vertical design of physical operations; the transactional (not operational) interfacing with interprocess, -factory, -company, and –supply chain operations; and the business structures and market drivers that have reinforced them.

Compartmentalization—as result of vertical optimization, software systems developed for individual function often with independent architectures, standards that isolate operational layers, business structures designed for individual operations, and business policies designed to isolate the use of data—has promoted and continues to promote a large legacy of software applications in which data are trapped in a software function. This legacy practice guarantees a precise but implicit contextualization of the data. It also ensures that the data cannot be easily reused and effectively prevents scaled use, making digital transformation more difficult and stalling the impact potential of smart manufacturing. This has also led to “reinventing” cyber and physical systems in isolation for many similar applications. This reinventing the “wheel” is extraordinarily pervasive.16

Finding: There is a legacy of software applications today in which data are trapped in a software function preventing full implementation of smart manufacturing.

Smart manufacturing is therefore not separable from manufacturing’s business structure and necessarily encompasses aligning business and market drivers for the use of data. The rising importance of chief digital officers in companies underscores the growing recognition of fusing data from a variety of sources to create a holistic

___________________

15 Ibid.

16 J. Davis, H. Malkani, J. Dyck, P. Korambath, and J. Wise, 2020, “Cyberinfrastructure for the Democratization of Smart Manufacturing,” In Smart Manufacturing: Concepts and Methods, M. Soroush, M. Baldea, and T.F. Edgar, eds., Elsevier.

picture of the manufacturing value chain. IT leadership is now an important part of the decision-making process for manufacturing projects in many companies, assessing the security, scalability, and maintainability of new technology and workflows. Not surprisingly, there is increasing interest in “as-a-service” business models on the plant floor that have long been popular in the office environment.

Compartmentalization as a general descriptor of manufacturing’s business structure is fundamentally counter to AI and data-centered approaches since they draw value and power from access to as much of the right data as possible. Changing business structures to value and take broad advantage of data (i.e., digitalization defined by smart manufacturing) becomes essential. Smart manufacturing, by definition, raises the prospects of cyber and redefined manufacturing as the integration of equally required physical and cyber processes that together extend from the factory floor to the supply chain. For the physical side, there are the material and energy supply chains, workflow, material transformations, and operational orchestration within and across factories. With the understanding that there are many challenges yet to overcome (e.g., legal, intellectual property, security), to be discussed in Chapter 3, one can anticipate equally valuable “data supply chains,” cyber and IT “workflows,” inter- and intrafactory data transformations, and operational orchestration of data and models throughout the industry ecosystem. Safety and resilience on the physical side are analogous to security, privacy, track and trace, and trade secret protection on the cyber side.

Finding: Compartmentalization of manufacturing’s business structure is fundamentally counter to AI and data-centered approaches in smart manufacturing.

Smart Manufacturing and a Next-Generation, Data-Savvy Workforce

Smart manufacturing defines a journey of change in the workforce. Manual, repetitive, and high-precision tasks will give way to automated and autonomous operations as they become cost-effective. Machine interfaces will improve human–machine interactions so that humans can take on tasks of greater creativity, complexity, and innovation. Humans will use smart manufacturing to build greater depth and breadth of domain understanding and insight that can be implemented to further improve and scale operations. A typical smart manufacturing implementation requires integrated expertise with the domain, modeling, data, instrumentation, and OT and IT infrastructure. As more smart manufacturing is implemented within the industrial base, the workforce must keep pace. New job roles will emerge, and many existing manufacturing roles in production, engineering, quality, and leadership will require new competencies to keep pace with the smart manufacturing adoption. Without upskilling the existing workforce, manufacturers are less likely to unleash the power of smart manufacturing. The rise in demand for

data- and technology-savvy talent in manufacturing is in fierce competition with many other industries also seeking to attract talent. The result is an imperative for the manufacturing sector to connect the value of the work with an individual worker’s contextual role within a manufacturing enterprise toward sustainability, national security, society, and economic prosperity. As an example and according to the April 2023 study by McKinsey titled “Cracking the Code on Digital Talent,” meaningful work was in the top three reasons for individuals to accept a job or stay with an employer for those defined as digital talent (i.e., cloud engineers, data scientists, product managers, software-as-a-service administrators, and software engineers).17 The manufacturing industry is rich in meaningful work and should be leveraged to ensure that the talent is attracted and retained for overall smart manufacturing success. Any nation’s smart manufacturing plan would need to take into account the heavy reliance on engaged, educated, and trained humans in optimizing and leveraging smart manufacturing technology, data and systems, and business practices to their fullest benefit and potential. Without the trained and engaged workforce, the risk for stagnation is high. According to a survey of manufacturing companies performed by the Clean Energy Smart Manufacturing Innovation Institute (CESMII) and SME18 the number one challenge encountered while pursuing a smart manufacturing strategy is a lack of skilled talent (59 percent of respondents). This challenge was greater than overcoming the cost of implementation and complexity of integration, which indicates that even when the technology challenges are solved, the well-documented talent challenges in the United States from early career to those retiring will erode and impede the ultimate potential progress.

Finding: Even when the technology challenges are solved, heavy reliance on engaged, educated, and trained humans in optimizing and leveraging smart manufacturing technology exists.

To be sure, smart manufacturing is taking advantage of technology to scale capability industry-wide; to increase productivity, precision, and performance as end-to-end horizontal industry-wide improvements; and to address industry-wide collaboration on national challenges and opportunities. At its core, however, smart manufacturing is human-centered. People are key to the data, the innovation, the engineering, and the sustainment of the machine- or human-centered mechanisms for taking action to improve operations and products. People are also at the center

___________________

17 T. Horst, K. Kuhn, S. Madner, P. Roche, and C. Seiler, 2023, “Cracking the Code on Digital Talent,” McKinsey & Company, April, https://www.mckinsey.com/industries/technology-media-and-telecommunications/our-insights/cracking-the-code-on-digital-talent.

18 Clean Energy Smart Manufacturing Innovation Institute (CESMII), 2022, “2022 Smart Manufacturing Market Survey,” https://www.cesmii.org/smart-manufacturing-sustainability-study.

of building and sustaining the mechanisms for new operational data that feed a virtuous industry research and development (R&D) cycle that supports continued competitiveness, market share, and national leadership of the industry. Ultimately, the contributions of individual manufacturers enable broad, new industry-wide capabilities that provide productivity benefits that are returned to the contributing companies. Accompanying opportunities for researching new methods provide opportunities for founding new businesses to deliver solutions to manufacturers. To be successful, the industry would need to continue to build technical and business trust to scale capabilities. Trust is a key human-centered factor that depends on the trained and data-savvy workforce. Trust is key to ensuring that the technical advancements and personnel advancements are simultaneously addressed at pace to accelerate smart manufacturing adoption, or one will hold back the other. The recommendations in this report reflect addressing smart manufacturing technology, practice, business, infrastructure, and talent together.

CURRENT STATE OF SMART MANUFACTURING IN THE UNITED STATES AND THE WORLD

Global Race

Fifty years of manufacturing digitization have made it far easier to conduct business in a distributed fashion. The digitization of the existing business structures is now giving way to the digital transformation of the manufacturing industry into a networked industry defined by smart manufacturing. New digital thread ecosystems create opportunities to increase U.S. global competitiveness and enhance supply chain network resilience. However, with this exponential increase in connectivity, there is an exponential increase in exploitable weaknesses, leaving manufacturers vulnerable to massive consequences if their OT boundary detection systems fail. In the current state of the art, these digital threads are a patchwork of architectures with incomplete security that creates additional complexity and costs for many manufacturers. Furthermore, interconnecting variable architectures with varying security creates additional attack surfaces at the interfaces if not managed. In order to have a competitive advantage in the global race, the United States needs to secure smart manufacturing. The current approach of hardening systems insufficiently and working to prevent human-induced flaws is not enough.19 The recently released National Cybersecurity Strategy20 highlights the need to protect

___________________

19 CyManII, 2022, Cybersecurity Manufacturing Roadmap 2022—Public Version 8 B. The Digital Transformation, https://cymanii.org/wp-content/uploads/2022/05/CyManII-Cybersecurity-Manufacturing-Roadmap-2022-Public-Version-Final.pdf.

20 White House, 2023, National Cybersecurity Strategy, National-Cybersecurity-Strategy-2023.pdf.

critical infrastructure and harden defenses. Uplifts needed in cybersecurity include manufacturers throughout the value chain as smart manufacturing better connects data flows. Methodologies such as the Cybersecurity Maturity Model Certification programs are a beginning, but work is required to ensure robust implementation and understanding.21

More efforts around devising the future of robust, resilient, energy efficient, and decarbonized smart manufacturing systems, which extend beyond the current world of insecure technologies to new systems of architectures that will exponentially increase the United States’ ability to resist cyberattacks, are needed. Manufacturing innovation institutes such as the Cybersecurity Manufacturing Innovation Institute (CyManII) and Manufacturing x Digital’s (MxD’s) Center for Cybersecurity in Manufacturing should continue working toward realizing cyber-informed digital threads by solving the fundamental challenges that prevent a truly secure IT/OT integration and data utilization. With CESMII focused on infrastructure for standards-based scaling of repeatable use information models, CyManII, MxD, and CESMII need to work toward the secure scaling of methods for data collection, ingestion, and contextualization.

The global race for manufacturing competitiveness centers on harnessing and applying data at scale and increasing the pace of industry adoption, upskilling the workforce, and greatly expanding the pipeline for the future data-savvy workforce. To scale smart manufacturing adoption throughout the industry, there is a need to scale the ability for manufacturers to access and use data. Digital integration across value streams, including data flows to and from suppliers, drives end-to-end efficiency, productivity, resilience, precision, and stability within end-product production. End-to-end management increases competitiveness.

There is also broad agreement globally that data are needed—for smart manufacturing in the United States, “Industrie 4.0” in Germany, and all other efforts in other countries. All data-centered forms of modeling and how they are orchestrated together to apply data—AI, ML, digital twin, etc.—are important, but AI/ML, particularly when scaled, promises to be a powerful tool for expanding knowledge, increasing prosperity, and enriching the human experience. The nature of manufacturing requires orchestrated industry-wide actions that encourage data sharing and industry adoption to derive the full potential of AI. From a government perspective, investment focuses on industry-wide strategies and infrastructure that encourage and speed up adoption. Also emerging are intercountry coalitions on infrastructure to address environmental sustainability in partnership and to focus market share on product value instead of the infrastructure. Major differences in countries’ approaches and their respective evolutions arise with different balances

___________________

21 Manufacturing x Digital (MxD), 2022, Playbook for CMMC 2.0 Level 1, June, https://www.mxdusa.org/cmmcplaybook.

in government investment versus market-driven expectations, differences in how governments invest, different approaches to learning and training, differences in how labor is approached, and cultural differences in how R&D and implementation are planned and incentivized. In taking a global view, one can identify differences in approach and areas of emphasis not just in Germany and the United States but also in China (critical advanced technology for manufacturing and military use), Japan (robotics), India (Make in India focuses on ease of doing business), the United Kingdom, South Korea, Australia (energy), and others.

Finding: To scale smart manufacturing adoption throughout the industry, there is a need to scale the ability for manufacturers to access and use secure data. Securing legacy systems, overcoming legal and intellectual property challenges, and mitigating cybersecurity risks in a dynamic environment present many hurdles to the adoption of Industry 4.0 technology and the convergence of IT and OT systems.

Industry Data- and Expertise-Sharing Strategies

The potential for smart manufacturing and AI to increase U.S. manufacturing productivity, precision, and performance accrues from actions that create a market-driven, networked industry willing to share and aggregate data; generate AI development with a broader base of data science and data engineering expertise; and collaborate on applications, all at an industry scale.22 There is a rich base of contextualized data for many kinds of operations across the collective base of small, medium, and large manufacturers in the United States, but currently the data reside in distributed and compartmentalized operational and business structures. Data are not categorized, discoverable, or accessible for aggregation and for building far more powerful AI applications.

A key understanding is that most factories, especially small and medium manufacturers (SMMs), do not have enough of the right data harmonized to build and sustain an adequate algorithm or model for a particular application, but every company produces valuable operational data that are embedded with its expertise. Many U.S. companies have legacy technology. SMMs collectively have a significant amount of expertise and data on a full range of useful operations, materials, parts, quality, etc. In general, much time is wasted by reformatting technical data between vendors (~80 percent time spent) so that the data can be analyzed (~20 percent time spent).23 It is essential to smart manufacturing to have data--

___________________

22 NIST, 2022, Towards Resilient Manufacturing Ecosystems Through Artificial Intelligence—Symposium Report, https://nvlpubs.nist.gov/nistpubs/ams/NIST.AMS.100-47.pdf.

23 C3.ai, 2023, “Data Format,” https://c3.ai/glossary/features/data-format.

streaming techniques that preserve semantics. Rather than use data streams from IoT devices that are basic arrays of numbers, the representation should accompany the data (i.e., categorize and conglomerate data on a per-time-sample basis). Innovative technologies, services, infrastructure, and software tools are needed to provide manufacturers assurance that their valued data will be protected when they are aggregated industry-wide to provide the scaled, enhanced benefits of AI methods. Those benefits include new network-based business models that provide faster process development and increased productivity, quality, and environmental sustainability.24

Realizing this potential requires the adoption of new business structures and practices that enable the industry to become truly networked and interconnected. Even though the real-time collection and analysis of streaming data from the shop floors are key enablers for improving automated processes and monitoring the state of cyber-physical manufacturing plants, streaming data are characterized by high-volume, diverse, heterogeneous formats and protocols, and variable spatial-temporal resolution, which imposes multiple challenges when it comes to transforming data into actionable knowledge. In the absence of advanced secure data infrastructure, manufacturers resort to the save and download practice for infield data acquisition, which is labor-intensive, error-prone, and inefficient for real-time data analytics. There is a need to create extensible and open-access data infrastructure for the development and deployment of sector-specific data-driven analytics, as well as reliable hosting of applications with seamless access to in-field IIoT devices. Data provenance is critical to ensure that the data analytics are meaningful and reliable. Similarly, the protection of data streams is crucial to ensure that readings are accurate and sensors are tamper-proof.

Finding: In the absence of real-time secure data infrastructure, manufacturers resort to the traditional save and download practice for shop floor data acquisition, which is labor-intensive, error-prone, and inefficient for real-time data analytics.

___________________

24 NIST, 2022, Towards Resilient Manufacturing Ecosystems Through Artificial Intelligence—Symposium Report, https://nvlpubs.nist.gov/nistpubs/ams/NIST.AMS.100-47.pdf.