Options for a National Plan for Smart Manufacturing (2024)

Chapter: 5 Challenges and Opportunities in Realizing Broader Impacts of a Smart Manufacturing Sector in the United States

5

Challenges and Opportunities in Realizing Broader Impacts of a Smart Manufacturing Sector in the United States

THE ECONOMIC VALUE OF A SMART MANUFACTURING SECTOR IN THE UNITED STATES

Smart manufacturing is built on the business case that digital integration within factories can directly lead to increases in productivity (use less, waste less), precision (drive specification, greater accuracy, and quality), and performance (manage resources for better, faster, cheaper, and more flexible operations), which in turn lead to benefits in multiple dimensions—economic (reduced resources, market share, product velocity, product delivery, higher quality, new markets), sustainability, safety, track and traceability, and national security. Smart manufacturing uses advanced sensing, controls, platforms, and modeling to drive operational data, information, and insights into proactive management and automation for greater productivity, precision, and performance at all levels of manufacturing operations.

To put this in quantitative perspective, several studies have examined the potential return on investment (ROI) of implementing smart manufacturing processes. One study conducted by the National Institute of Standards and Technology (NIST)1 focuses on cost and cost-effectiveness of additive manufacturing, which may reduce inventory (in 2011 the equivalent of 14 percent of the annual revenue was held in inventory). Based on Deloitte consulting projects, implementing secure smart manufacturing processes could lead to a 20 percent increase in overall

___________________

1 D.S. Thomas and S.W. Gilbert, 2014, “Costs and Cost Effectiveness of Additive Manufacturing,” NIST Special Publication 1176(2014):12.

equipment effectiveness and a 30 percent reduction in maintenance costs.2 The studies estimated that smart manufacturing processes could lead to a 30 percent reduction in product defects and a 10 percent increment in improved safety and sustainability. However, NIST also reports that 61 percent of small businesses have experienced a cyberattack.3 The NIST studies highlight the importance of implementing secure smart manufacturing processes to mitigate the economic impact of cyberattacks and truly harvest the economic benefits of smart manufacturing.

Both the Clean Energy Smart Manufacturing Innovation Institute (CESMII) and the Cybersecurity Manufacturing Innovation Institute (CyManII) have analyzed industry impact projections for smart manufacturing. CESMII has analyzed economic value, energy reduction, and corresponding greenhouse gas (GHG) emission reductions based on a first smart manufacturing application and its economic and energy impacts relative to a current as-is operation. Projections are industry-validated as initial improvement reachability estimates for multiple industry sectors. CyManII has analyzed energy efficiency improvement for multiple industry sectors, assuming needed data can be securely used for key applications for eight industry sectors. The energy efficiency impacts were developed with industry input applied to an American Council for an Energy-Efficient Economy report, which included contributed information by CESMII. These analyses were independently conducted with the crossover results for energy reduction effectively the same.

Across all industries, the in-factory economic value ranged from 5 to 30 percent improvement relative to current base operations.4 The average minimum economic benefit as an average across all industries is 15 percent. Monetization is the result of increased productivity, high-precision products, and overall performance. The average energy reduction impact ranged from 10 to 25 percent. For supply chains, industry projections of 12–15 percent in economic benefits from supply chain effects were the result of increased productivity, better demand-dynamic management, better consumer product delivery, and greater visibility. Sustainability impacts are projected in terms of energy use reduction and reduced GHG emissions when all manufacturers for an industry sector adopt similar solutions for similar operations (i.e., the materials and product are held constant). Energy reductions are a direct result of higher energy productivity. Reduced GHG emissions are a direct result of using less fuel or electric energy.

___________________

2 Deloitte US, n.d., “Smart Factory for Smart Manufacturing,” https://www2.deloitte.com/us/en/pages/consulting/solutions/the-smart-factory.html, accessed September 14, 2023.

3 MEP National Network, 2019, Manufacturers Guide to Cybersecurity, for Small and Medium-Sized Manufacturers, https://www.nist.gov/system/files/documents/2019/11/14/mepnn_cybersecurity_guide_10919-508.pdf.

4 Manufacturing USA, 2021, “Ensuring Industry 4.0 Is Accessible to All Manufacturers,” https://www.manufacturingusa.com/studies/ensuring-industry40-accessible-manufacturers.

If smart manufacturing is widely adopted, CESMII projected the full potential of these first solutions at 5 percent (1,000 TBTU) per year reduction in total manufacturing energy consumption and a 7 percent (84 MMT) per year reduction in CO2 emissions. CyManII analyzed potential more broadly than just the first application and projected a full adoption reduction potential to be as high as 2,600 TBTU per year. CESMII and CyManII have independently estimated the market penetration of smart manufacturing to average around 9–10 percent over the next 10 years. While the potential for economic benefit is significant for individual manufacturers and supply chains, accelerated adoption of smart manufacturing industry-wide is key to significant environmental impacts.

Finding: Monetization of smart manufacturing involves quantifying the ROI of incorporating novel technologies throughout the supply chain networks while minimizing the cyber vulnerabilities associated with digitalization. It also involves transitioning to a new data-savvy workforce and a workforce that can not only sustain and expand the value of smart manufacturing but also secure, interface and interact with, oversee, and develop new system capabilities and innovations.

THE VALUE OF A SMART MANUFACTURING INDUSTRY FOR ENVIRONMENTAL SUSTAINABILITY

Smart manufacturing is a key enabler of environmental sustainability and is among the basic strategies that include (1) using less harmful materials and making products that have less impact; (2) using new physical technologies such as electrification and process intensification; (3) removing and repurposing harmful emissions (i.e., decarbonization); and (4) applying smart manufacturing for measuring, controlling, managing, and optimizing industry operations to maximize the use of resources, recycle, and manage a circular economy as well as enable industry-wide strategies. A recent report from Arthur D. Little and CEFIC, the European Chemical Industry Council, highlighted the necessity of digital technologies to advance industry sustainability objectives throughout the value chain.5

Manufacturing actions that improve environmental sustainability are motivated best when they are aligned with economic benefits or required by regulation. There is increasing government and public pressure for environmental sustainability along with increasing regulation, as illustrated by the recent Securities and

___________________

5 CEFIC and A.D. Little, 2023, Digital Technologies for Sustainability in the European Chemical Industry, https://cefic.org/app/uploads/2023/04/ADL_CEFIC_Digital_technologies_for_sustainability_2023.pdf.

Exchange Commission–proposed rule for climate disclosures.6 Smart manufacturing stands out because environmental sustainability is a potentially economically beneficial outcome that results from significantly improving end-to-end management and optimization of resources, creating less waste, and making products right the first time. Elimination of rework, reduced production time, and factory stability all have the broader impact of reducing energy, water, and material consumption, leading, in turn, to the reduction of GHG emissions and reduced embodied energy.

For manufacturing industries that are large energy users—for example, nonmetallics (cement), iron and steel, food and beverage, and chemical and oil and gas industries—there are substantial environmental sustainability impacts with improved productivity, precision, and performance and the more effective use of resources. There is great opportunity in focusing attention on these industries at the factory level because they account for greater than 80 percent of the energy usage and the GHG emissions, and they tend to be concentrated at large manufacturing facilities.7 However, the greatest economic benefit and the greatest long-term sustainability impacts occur when smart manufacturing solutions are scaled industry-wide and environmental sustainability is quantitively measured, monitored, and driven in individual factories and across supply chains and ecosystems. This entails marrying the direct impacts within the four walls of the manufacturing plants with supply chain impacts and with sector-wide impacts. End-to-end life-cycle management and optimization focuses on reducing end-to-end raw material and material intermediate consumption by driving industry integration strategies—that is, measure embodied energy, material consumption, and end-to-end carbon footprints (regulated or market encouraged—for example, carbon credits management). These industry-wide strategies can be extended with smart manufacturing for measuring, controlling, managing, and optimizing recycling and circular economic approaches and for wide-area scale resource management. Generating consistent, interoperable data ecosystems throughout the value chains allows for understanding the complete environmental footprint of manufactured products.

Unintended consequences still would have to be monitored. As industry begins to adopt smart manufacturing, energy consumption and GHG emission management activities will also increase in the following areas: sensors and electronics manufacturability; the components of electrification; and the impacts of computation, data transmission, and storage. Currently, data centers consume 1–1.5 percent

___________________

6 Proposed Rule: The Enhancement and Standardization of Climate-Related Disclosures for Investors (sec.gov) as well as the reporting recommendations from the Task Force on Climate-Related Financial Disclosures (TCFD) to which many corporations have committed to adhere (https://www.sec.gov/news/press-release/2022-46, accessed November 2, 2023).

7 Department of Energy, 2021, “Manufacturing Energy and Carbon Footprints (2018 MECS),” https://www.energy.gov/eere/iedo/manufacturing-energy-and-carbon-footprints-2018-mecs.

of U.S. electricity,8 and data centers account for around 2 percent of global GHG emissions.9 Additionally, sensors, batteries, and electronic components contain minerals that require energy and material resources to be extracted from the earth, and to be processed and delivered to their respective manufacturing or research center for implementation. Hence, the tools that are used to drive and optimize smart factories and smart manufacturing to gain efficiency and national competitiveness can have opposing environmental impacts without life-cycle considerations. With this in mind, electrical power and CO2 emissions resulting from smart manufacturing activities (e.g., artificial intelligence [AI]/machine learning [ML], digital integration, data flows) would need to be included in life-cycle assessments of the participating smart manufacturing industries.

Finding: The economic benefits and sustainability impacts occur when smart manufacturing solutions are scaled industry-wide and environmental sustainability is quantitively measured, monitored, and driven in individual factories and across associated supply chains networks. A systematic scheme to track energy, emissions, and materials across the supply chain and throughout the life cycle will allow for an accurate quantification of the gains (usually measured as energy productivity, as energy needed to manufacture a part, as product carbon footprint, or via product life-cycle assessment). This quantification must include an energy, emissions, and materials baselining analysis that includes the potential opposing environmental and social effects of digitization technologies, making sure that solutions benefit society at large and are equitable.

OPTIONS TO LEVERAGE SMART MANUFACTURING TO REALIZE SUSTAINABILITY BENEFITS

The challenges in smart manufacturing to realize its broader sustainability benefits fall into three categories: operational strategies, required tools, and implementation of tools:

- Smart manufacturing is among the key operational strategies and enablers for environmental sustainability:

- Change the materials—design and manufacture more sustainable, safer materials and products that require less energy for manufacture and are easily recycled, without environmental persistence.

___________________

8 J. Dunn, presentation to the committee at the March 7, 2023, workshop, https://www.nationalacademies.org/event/03-07-2023/workshop-on-the-broader-impacts-of-smart-manufacturing.

9 NoVertical Group, n.d., “The Impact of Data Centers on Global Carbon Emissions and How Removing ROT Data Can Help Reduce It,” https://nowvertical.com/the-impact-of-data-centers-on-global-carbon-emissions-how-removing-rot-data-can-help-reduce-it, accessed June 24, 2023.

-

- Change the energy footprint—move to alternative renewable, lower-carbon, or zero-carbon energy sources and process electrification, while being mindful of not impacting the global food supply.

- Capture the carbon—establish carbon capture or carbon conversion operations.

- Move to a circular economy—move to a zero waste economy.

- Manufacture with increased productivity, precision, and performance—implement secure smart manufacturing.

- Smart manufacturing defines the advanced sensor, controls, platform, and modeling technologies needed to control and manage manufacturing operations involved in the strategies above within factories and across end-to-end enterprises, supply chains, and ecosystems (raw and recycled material to consumed product).

- Smart manufacturing provides the advanced sensors, measurements, and harmonized data for measuring and monitoring environmental impacts and carbon and water footprints that are needed to implement industry-wide strategies and policies.

Implementing an energy management system (EMS) or factory energy management systems can help manufacturers monitor and manage energy use in real time. EMS can track energy consumption by collecting data, identify areas of high energy use, analyze past data to predict energy consumption, run digital simulations to see the potential impact or energy consumption change at the machine and product levels, and achieve optimization of energy consumption on a continuous cycle without compromising product quality.10 To enable secure utilization of EMS, cybersecurity considerations should be in place. Data provenance and accuracy must be in place to truly harvest the benefit of smart sensors coupled with EMS embedded with AI/ML. An advanced ledger approach to store, transform, secure, and analyze these data streams is needed to harvest the benefit of smart manufacturing in terms of energy efficiency.

Another possible strategy is to use renewable, lower-, or zero-carbon energy sources, such as wind and solar, nuclear, or hydrogen with carbon capture, to power manufacturing processes. Manufacturers can install solar panels or wind turbines on their facilities, purchase renewable energy credits, or enter into power purchase agreements with renewable energy providers. Using smart manufacturing to optimize the use of renewable energy resources will improve energy efficiency. Modeling and optimization are required to integrate new advanced small modular nuclear reactors optimized for manufacturing operations. Smart sensor–driven

___________________

10 D. Lee and C.-C. Cheng, 2016, “Energy Savings by Energy Management Systems: A Review,” Renewable and Sustainable Energy Reviews 56(C):760–777.

modeling, real-time measurement, and EMS have shown improvement in energy productivity.11

Using sustainable materials is another effective strategy for reducing carbon footprint. Manufacturers can use bio-based materials, recycled materials, and other sustainable materials that have a lower carbon footprint than traditional materials made from fossil fuels. These materials can be used in product design, packaging, and transportation, among other areas. Additionally, AI is beginning to be used to assist product life-cycle management to help with decision-making.12

Monitoring and measuring carbon emissions throughout the product life cycle can help manufacturers identify areas of inefficiency and implement measures to reduce GHG emissions. This can be achieved by using carbon accounting software and tools that track carbon emissions from raw material extraction to product disposal. Energy, transportation, distribution, raw material, and process data can build the carbon footprint.13 By monitoring and measuring carbon emissions, manufacturers can set targets for reducing their carbon footprint and track their progress in achieving these targets. Cyber-physical ledgers that support decarbonization help to achieve decarbonization goals. CESMII has used its platform technology in a global collaboration on a carbon reporting demonstration.14

Optimization of production processes not only has an impact on energy efficiency but also can aid in waste reduction. By identifying and eliminating waste in the production process, such as overproduction, defects, and excess inventory, manufacturers can significantly reduce waste generation and enhance sustainability. Additionally, if during the design process disassembly is included, at the end of its life cycle the product may be recycled or reused, which leads to reduced waste generation and enhances the recovery of valuable materials.

Closed-loop production systems are also recommended as they involve the reuse of materials at different stages of the production process, thereby reducing waste generation and minimizing the demand for new raw materials. The use of three-dimensional printing technologies is another recommended strategy for mass customization and similar applications. It enables the production of products with

___________________

11 T. Edgar and E. Pistikopoulos, 2017, “Smart Manufacturing and Energy Systems,” Computers & Chemical Engineering 114:130–144, https://doi.org/10.1016/j.compchemeng.2017.10.027.

12 L. Wang, Z. Liu, A. Liu, and F. Tao, 2021, “Artificial Intelligence in Product Lifecycle Management,” The International Journal of Advanced Manufacturing Technology 114:771–796, https://doi.org/10.1007/s00170-021-06882-1.

13 J. Davis, T.F. Edgar, J.T. Porter, J.A. Bernaden, and M. Sarli, 2012, “Smart Manufacturing, Manufacturing Intelligence and Demand-Dynamic Performance,” Computers and Chemical Engineering 47:145–156, https://doi.org/10.1016/j.compchemeng.2012.06.037.

14 CESMII, 2021, “Global Collaboration to Develop a Carbon Reporting Demonstrator,” https://www.cesmii.org/factsheet-joint-demonstrator-on-interoperability.

minimal waste by utilizing only the necessary materials required for the product’s design, thus reducing material consumption and waste generation.15

Manufacturers can also use sustainable materials with lower environmental impact, such as bio-based materials, and recycled materials. By monitoring and measuring waste generation throughout the entire life cycle of the product, manufacturers can identify areas of inefficiency and implement measures to reduce waste generation. Waste monitoring–based analytics can be used to uncover hidden patterns, correlations, and other insights.16

Finding: Relative to most other countries, energy is still cheap in the United States, which influences manufacturers’ decisions to improve energy efficiencies. While cheap energy is a competitive advantage for the United States, companies are less incentivized to implement smart manufacturing as a route to reducing energy costs because of the investments required. This is primarily due to a lack of granularity of the energy consumption. Most of the energy efficiency efforts are at the building level, but the visibility and capability to capture the embodied energy at the part level needs to be advanced. A cultural change is needed to start incentivizing the computation of energy productivity (i.e., energy consumed per item) and link energy productivity with profitability.

Finding: Smart manufacturing requires a framework that allows for the quantification of the broader environmental and social sustainability benefits of implementing secure smart manufacturing. This framework must define the advanced sensors, controls, platforms for data harmonization, and modeling needed to control and manage the energy and emissions created by manufacturing operations within factories and across end-to-end enterprises, supply chains, and ecosystems.

Conclusion: The development of a modular and extensible framework that can be applied to existing or new manufacturing facilities and their associated supply chains to estimate embodied energy and emissions while maintaining a desirable level of cyber resiliency is needed. Advanced Internet of Things–enabled ledgers that allow for the quantification of embodied energy, emissions, and waste must be pursued for computing the ROI of implementing smart manufacturing and realizing a secure and sustainable future of smart manufacturing in the United States.

___________________

15 A. Thomas and U. Mishra, 2022, “A Sustainable Circular Economic Supply Chain System with Waste Minimization Using 3D Printing and Emissions Reduction in Plastic Reforming Industry,” Journal of Cleaner Production 345:131128, https://doi.org/10.1016/j.jclepro.2022.131128.

16 H. Niska and A. Serkkola, 2018, “Data Analytics Approach to Create Waste Generation Profiles for Waste Management and Collection,” Waste Management 77:477–485, https://doi.org/10.1016/j.wasman.2018.04.033.

Conclusion: The sustainability framework may leverage the proposed Cyber Interstate and platform technologies to define the advanced cyber-physical ledger for improved quantification, control, and management of the energy and emissions created by manufacturing operations within factories and across supply chain networks.

Conclusion: The intersection of sustainability and smart manufacturing technologies will inevitably be a core curricular component for all national smart manufacturing training programs, thus training workers that can simultaneously advance U.S. manufacturing competitiveness and U.S. climate change objectives.

Key Recommendation: Funded by the Department of Energy, in consultation with other relevant federal departments and agencies, a framework should be developed to quantify the broader sustainability benefits of implementing secure smart manufacturing (considering three pillars: environment, economy, and society) as well as industry-wide sustainability metrics.

Sustainability may be thought of as encompassing three pillars: environment, economy, and society. Much has been said above about the economic and environmental impacts of smart manufacturing. As the United States moves forward, responds to recommendations, and implements new policies, programs, and systems, attention must also be given to social consequences. In particular, any changes would need to use due diligence to ensure that specific groups are not disadvantaged, advantaged, or penalized. For example, the creation of the Cyber Interstate should ensure that small-to-medium manufacturers (SMMs), especially in rural areas, are not “left out.” The creation of the railroad system in the United States in the 19th century and the Interstate Highway System in the 20th century both avoided certain towns and regions, negatively impacting these towns and regions. Appropriate lessons should be learned from past infrastructure projects and applied to the creation of infrastructure for realizing smart manufacturing and smart manufacturing education, including educational methodologies and metrics.

CHALLENGES FACED BY U.S. INDUSTRIES IN INTEGRATING SMART MANUFACTURING

There is sometimes a lack of understanding by executives in manufacturing companies as to the value of smart manufacturing. Because of the drive to manufacture products rapidly, decisions are often made in short time spans that are only focused on near-term ROIs and not on long-term competitive advantage. Business decisions about smart manufacturing, however, dive more deeply into long-held approaches to how ROIs are calculated because smart manufacturing

is not a one-time project. Rather it is a journey that begins with a single use case and associated data set but with a vision about how to grow value by expanding the span of data to extend the scope of applications horizontally across operations, factories, and supply chains. This journey involves the upfront investment and coordination on infrastructure, tools, and practices. Finally, there is also a change in business culture from one of protecting all data and expertise to one of being willing to work in various kinds of partnership with data, expertise, and applications with trust. With a lack of standardized and accepted metrics and standardization of tools and platforms, companies face obstacles in determining the contributions smart manufacturing directly makes to the ROI. These obstacles include knowing where to start, having the trained workforce, and overcoming the inertia required for adoption.

Large companies typically realize the importance of effective human interaction with technology to dramatically increase their productivity by closing the loop, analyzing data, and autonomously making changes to the control system for better process control and fault tolerance—but if not done right, all of this can come at a cost in productivity. Many large manufacturers are multinational organizations, making it challenging to bring all of their data together in a usable form. Many expressed the need for a standardization of the tools with open platforms for development that can be used across industries to avoid duplication of efforts and allow for more rapid interactions with suppliers.

Transitioning to new systems from current legacy approaches needs to involve not only manufacturing but also business operations, supply chain, data analytics, and information technology (IT). Ownership of smart manufacturing needs to be embraced beyond manufacturing to allow the business case to be made and the IT and data science expertise to contribute to a productive smart manufacturing methodology. The challenge presented is to standardize metrics that quantify the benefits of smart manufacturing in the form of an ROI and to encourage tighter collaboration and information sharing among the IT, data science, and manufacturing functions. Other roadblocks for large manufacturers in adopting smart manufacturing include cybersecurity and tracking of data through the entire process. Smart manufacturing requires the protection of precious proprietary data when transferred intra- and interorganizationally to include the suppliers of the large manufacturer. Some large manufacturers have the resources and wherewithal to use encryption tools for sensitive data transfer; however, this places a significant burden on their smaller sub-tier suppliers to invest in the same encryption tools in order to receive and return information.

It is understood that original equipment manufacturers (OEMs) with legacy equipment serving long-standing, active production lines have little incentive to stop active production to retrofit and add sensors or automation to enable smart manufacturing. Stopping an active production line causes the company to

incur financial losses; furthermore, changes to the production system often create unexpected issues that take time to resolve, leading to loss of schedule, which can have serious consequences. Alternatively, legacy equipment repurposed for new production lines established for new products or for production lines moved from one location to another are good retrofit candidates for smart manufacturing. Hence, OEM investment in upgrading legacy equipment will be limited and selective.

“Competitiveness” is an important but not sufficiently defined concept to specify recommendations because it is a moving set of targets that vary widely by industry segment. The U.S. government, however, has taken policy positions in the form of recent bills about particular industries (e.g., semiconductors, batteries, and electric automobiles, among others), environmental sustainability (e.g., electrification, alternative energy sources), and U.S.-based manufacturing and jobs. The situation is such that these government decisions and a national plan defining some elements of competitiveness exist, while industry is largely defining competitiveness based on business interests. The discrepancy is such that there are neither policy positions nor clear market drivers to support smart manufacturing technologies or to disrupt the growing complexity of integrating data systems based on legacy compartmentalized data and software approaches.

Finding: Deploying smart manufacturing is a journey consisting of multiple steps, with benefits often realized at the end of the journey. The initial steps often add cost and complexity with no clear benefit in the short term. There is a lack of success stories (i.e., case studies) to persuade company leadership to deploy smart manufacturing.

Conclusion: Smart manufacturing requires merging of boundaries between IT and operational technology (OT), which are different units in most companies. Neither IT nor OT experts want to take the lead in being champions for smart manufacturing.

Conclusion: Most individual companies do not have large enough data sets to benefit from the latest ML technologies. Data sharing across multiple organizations is a potential solution. However, there is reluctance to share data due to intellectual property and cybersecurity concerns.

CHALLENGES FACED BY SMALL AND MEDIUM-SIZED MANUFACTURERS

For the manufacturing sector in the United States, 98.4 percent of U.S. manufacturers are employed by SMMs, and 85 percent of SMMs have less than

20 employees.17 An ability to be agile and quickly respond to the needs of the military for legacy replacement parts is an advantage that SMMs can deliver. The age of military assets drives the need for replacements or repairs. Often, the OEM is unable to meet these needs because of disassembled manufacturing lines, lost knowledge with no digital prints of the legacy parts, and costs. Many SMMs have demonstrated their eagerness and ability to meet these needs by applying new manufacturing methods while having an agile culture of adapting, testing, and re-designing components to meet the replacement needs. Oftentimes the SMM will require partnership with a larger OEM or government entity to ensure that the pre-manufacturing workstream consisting of advanced engineering design and analysis required to meet the government’s technical requirements for certified military flight hardware is satisfied.18

In addition to needing a skilled workforce, as discussed in Chapter 2, other roadblocks identified by SMMs in adopting smart manufacturing include costs, access to data and common platforms for sharing data, and, in some cases, lengthy and costly certifications. When integrating sensors, for example, spending even as little as $50 can be a costly decision for SMMs. As another example, qualification and certification for manufacturing aerospace components requires many months and can cost more than $1 million if there are manufacturing process, material, or design changes required.

SMMs face challenges because many do not even know what is possible with smart manufacturing, as they do not have the required bandwidth to discover and implement factory improvements. Many SMMs have concerns about implementing smart manufacturing because they are not aware of training resources and best practices; however, they are keenly aware of the dearth of available resources for capital improvements and are already facing lost capabilities resulting from the offshoring of manufacturing by the United States over the past decade. Continuous investment by SMMs to keep up with the multitude of IT and data analytics improvements and different platforms that are continuously becoming available requires significant financial resources.19

Case studies have shown that when large companies assist with costs and processes in developing their suppliers, success can be achieved. Hence, the best-case scenario is for the OEM and supplier relationship to be a partnership in which they jointly develop their workforce, skills, tools, and digital integration roadmap, as opposed to the standard transactional OEM and supplier relationship.

___________________

17 International Trade Commission, 2010, Small and Medium-Sized Enterprises: Overview of Participation in U.S. Exports, Washington, DC, https://www.usitc.gov/publications/332/pub4125.pdf.

18 Department of Defense, 2023, “DoD Releases Small Business Strategy,” Press Release, January 26, https://www.defense.gov/News/Releases/Release/Article/3279279/dod-releases-small-business-strategy.

19 C. Schroder, 2016, The Challenges of Industry 4.0 for Small and Medium Sized Enterprises, Bonn, Germany: Friedrich-Ebert-Stiftung, Division for Economic and Social Policy.

Finding: Deploying smart manufacturing technologies requires significant investments. Many SMMs cannot envision the ROI to justify these investments, and most small manufacturers do not have access to the capital to deploy new technologies.

Finding: Deploying new smart manufacturing technologies causes disruption to production. Many manufacturers cannot afford disruption because of tight deadlines.

Conclusion: Typical legacy equipment does not have the right sensors and controllers to implement smart manufacturing concepts. Upgrading legacy equipment is challenging due to capital requirements. The lack of standards and interoperability in component technologies makes it very difficult to integrate component technologies to realize deployable systems.

CHALLENGES OF MANUFACTURING AT ECOSYSTEM LEVEL

Distributed manufacturing is a paradigm enabled by smart manufacturing. It enables manufacturing to be performed efficiently and cost-effectively at small scales across manufacturing sites that are geographically dispersed. A distributed manufacturing capability finds promise in industries such as consumer products, oil and gas, heavy industry, automotive, and other sectors, as permitted by their regulation and manufacturing tolerance requirements.

New technologies such as additive manufacturing enable a “print-at-point-of-use” model, or “data-as-a-service” model, in which a technical data package complete with a digital build file of the components to be printed (manufactured) and machine instructions (and intellectual property) for printing can be sent electronically to a supplier.20 Companies that specialize in encryption and intellectual property protection of said data files are beginning to dot the high-tech startup landscape. In the case of the aerospace and defense industry, the suppliers and printers (down to the level of print machine serial number) must be pre-qualified according to industry best practices and regulation if the hardware to be printed is flight worthy.21 Similar pre-qualification is expected for any highly regulated industry (e.g., health care).

___________________

20 W. Heising, T. Kruger, D. Kupper, et al., 2022, “3D Printing Helps Realize the Promise of Distributed Manufacturing,” https://www.bcg.com/publications/2022/3d-printing-can-help-achievedistributed-manufacturing.

21 AIA Additive Manufacturing Working Group, 2020, Recommended Guidance for Certification of AM Component, https://www.aia-aerospace.org/wp-content/uploads/AIA-Additive-Manufacturing-Best-Practices-Report-Final-Feb2020.pdf.

Distributed manufacturing enables supply chain scale at speed and provides an opportunity to a host of SMMs across the country. Distributed manufacturing also has key sustainability benefits, as the CO2 footprint associated with transportation and other logistics is greatly reduced. Finally, distributed manufacturing can enable greater resilience in the face of natural disasters and supply chain disruptions. However, currently several challenges exist in the manufacturing ecosystem to fully realize the benefits of distributed manufacturing.

In general, there is a need to deconflict some market, government, and industry drivers and disrupt others without more broadly disrupting primary U.S. market-driven factory interests and innovation. There are four interrelated pieces missing to promote smart manufacturing.

First, the data needed for powerful smart manufacturing and AI applications throughout the industry reside in distributed and compartmentalized functional, operational, and IT infrastructure within factories. The current business culture of all-or-nothing trade secret protection, intercompany transactions not operations, the aversion to contributing data and having them sold back, and infrastructure compartmentalization all contribute to compartmentalizing data in business and market structures and keeping them from being developed and used. Moreover, the data are not categorized, discoverable, or accessible for aggregation and application building, and there are limited cross-manufacturer or cross-provider incentives to free up data. There is a strong need for a testbed to perform life-cycle analyses via national laboratories, universities, standards organizations, and industry to evaluate smart manufacturing strategies that include the effects of data handling (i.e., analysis, transmission, storage) in the end-to-end value stream.

Second, the tools, skills, expertise, and business wherewithal for building, implementing, and sustaining data-centered applications within and across factories and supply chains go beyond any one company—even large companies. Most small manufacturers have few to none of these capabilities to proceed. The experts who can build the applications and tune the models often do not have access to the data needed. Industry demonstrations need to go well beyond factory-only Lighthouse projects that demonstrate factory value. Industry demonstrations are also executed at higher technology readiness levels (TRLs) to work within current market drivers but are still organized to drive change and show and measure value stemming from access to contextualized data and models. Participating consortia and supply chains would need to implement collaborative solutions in multiple sites, and return contextualized data and proven ways to orchestrate and use data and models into wider industry use. In doing so, industry business models about intellectual property, trade secrets, data, and know-how that are preventing the industry from taking advantage of data sharing can be addressed.

Third, a long-term approach is needed to simultaneously address how manufacturing can draw on the full power of the network for scaling access to data and

solutions fully categorized with respect to equipment, processes, and to application objective. Standard metrics are needed to establish the benefits of smart manufacturing, which are for the most part nonexistent. While existing technology, practices, and capability can produce benefits, there is also the need to start now on the development of more powerful AI solutions and improved AI methods and architectures that can be produced by broader communities with access to categorized, cross-company data that are discoverable and contextualized at scale. Scaling is achieved with open access to categorized data and application models together with aligned business value propositions to simulate bottom-up development of solutions. This changes how systems are engineered and broadens how innovation occurs. It stimulates training, skills, and professional interest based on value that can be achieved with the wide availability of aligned network tools.

Fourth, educational programs at all levels are lacking. Training is sparse for the current workforce as are curricula for technical trade schools, colleges, and universities. For those either in the workforce or already in higher educational programs, there are no identifiable scholarships, fellowships, or other support available to those seeking opportunities to contribute to the implementation and operations of smart manufacturing. Integrated into these educational and training programs should be principles of sustainability: environmental, business, and societal.

Conclusion: Deploying smart manufacturing practices in a scalable manner would require solutions at multiple levels across multiple organizations. Representative focus areas could include the following:

- Plantwide optimization as well as agile, demand-driven supply chains and sustainable production to form smart factories, smart supply chains, and smart ecosystems.

- End-to-end manufacturing digital integration and optimization, at all levels of manufacturing.

- Function block and programmable logic controller ladder logic control such that continuous and batch processes leverage workflow, and machine and discrete parts processes leverage function block control.

- Automation, autonomy, and robotics to address minimal set up to changes and responsive, autonomous responses to changing conditions.

- Cybersecure shared data, models, and tools curated and developed for shared application needs within industry segments while using industry-wide infrastructure, tools, and practices within a U.S. Cyber Interstate system.

- Distributed front-facing simplification with complexity managed within cyber modeling and workflow.

- Security, zero trust, and opportunity as different sides of the same coin to be addressed together.

- Integration of control and information management systems that utilize computing power in the cloud, edge, and device. Cloud-based information management systems can democratize advanced technology for small and medium-sized companies that would otherwise struggle with the cost and support requirements for large on-premises systems.

It is particularly important to enable how supply chains will or should form in the future by being market-driven for global market share with better end-to-end productivity, precision, and performance; onshoring; intersecting supply chains; new technologies; and new kinds of supply chains. Also, combining factory market drivers with those that are industry-wide is important and requires avoiding recommendations that select “how” or “what” but still encourage old supply chains to change and new supply chains to form.

Conclusion: Taking full advantage of smart manufacturing requires effective collaboration across multiple organizations (due to the need for visibility into the supply chains). This is difficult to accomplish due to the lack of incentives for sharing information and problems associated with information sharing in heterogeneous systems spread across multiple organizations.

ROLE OF ACADEMIA, INDUSTRY, AND GOVERNMENT

As stated in Chapter 1, smart manufacturing is the scaled integration of plantwide agility and optimization; resilient, demand-driven supply chains; and sustainable production in the networked factories, supply chains, and ecosystems of manufacturers industry-wide. Government funding becomes useful in accelerating, aligning, and integrating technical, training, business, and market requirements to stimulate scaled adoption of smart manufacturing and its dependence on scaled sharing of data. Success with integrating smart manufacturing can be enhanced with public–private partnerships that can execute industry-wide strategies with trust, neutrality, and objectivity.

All options for smart manufacturing strategies depend on industry-wide strategies that consider the integration and scaling of all three primary dimensions together. Both plantwide agility and optimization and resilient supply chains are heavily driven by economics, market share, and consumer demand. Resilient supply chains have additional considerations with respect to national security and inter-dependencies on other countries for critical materials and products. Sustainable production is driven by environmental regulation; public demand; social risk; and national strategies for addressing climate change, including decarbonization, electrification, and alternative energy sources. As such, sustainable production is best when considered hand-in-hand with economic benefit and not just added cost or

response to regulation. In general, there is increasing government and public pressure with greater regulation and tighter requirements in planning and discussion. A key advantage of smart manufacturing is that it links environmental sustainability and financial sustainability so that environmental sustainability can remain more of a business decision and less of a policy requirement (i.e., when productivity and performance are improved, big energy users use less fuel and electricity and manufacturers waste less energy, materials, and water while improving economics).

From a strictly environmental sustainability standpoint, paper, nonmetallics (cement), metals and fabrication, food and beverage, and chemical and oil and gas account for much of the U.S. energy usage and GHG emissions. These are also largely concentrated with the larger manufacturers in these industries. However, given the broader smart manufacturing objective for scaling sustainable production, greater economic benefits and sustainability impacts occur together when smart manufacturing is adopted industry-wide, by all small, medium-sized, and large companies. Scaled effects occur when measuring, monitoring, and driving sustainability not only in individual factories but also across supply chains and ecosystems.

Smart manufacturing is extensively horizontal, cross-industry, crosscutting, and disruptive in business, workforce, and technical changes that involve factory, industry, and government strategies. It is at the same time vertical with specifics for monetization by industry segment and kinds of operation. There is significant opportunity to empower the Manufacturing USA institutes to much more strongly develop industry business and technology integration and implementation projects and industry-wide tools, training, and technology going well beyond in-factory technology projects. This would require mechanisms; interagency agreement; aligned agendas; aligned funding mechanisms; and common, more simplified operating terms and conditions for the 17 current institutes. The objective would be to orchestrate joint projects more easily; work more easily with manufacturers with integrated interests in multiple institutes; combine efforts and resources for industry-wide strategies; work with industry at higher TRLs; and work better and be jointly involved with far less effort throughout a fragmented fabric of related federal programs, initiatives, and offices (e.g., the Manufacturing Extension Partnership program; the national laboratories; Small Business Innovation Research and Small Business Technology Transfer programs; and a myriad of tech hubs, Regional Innovation Engine sites, research centers, and demonstration programs). The sheer advantage of more easily mounting joint projects especially at higher TRLs would leverage a massive investment in relationship and trust building that is in place. New institutes to take on new initiatives need to be similarly empowered. This public–private partnership institute structure is equipped to bring industry, academia, and government together in tackling how to align sustainability, global competitiveness, national security, and business economic goals—reinventing next-generation manufacturing, not just further optimizing a legacy structure.

Conclusion: The role of the federal government in enabling the adoption of smart manufacturing can be brought about by enabling the following:

- New data and algorithm suppliers and the associated cyber supply chains, which require bringing domain, data science, and modeling expertise together to build application algorithms and models for industry segments.

- Industry segment coalitions to invest jointly in digital twin development for common high-value assets.

- Open data industry and academic coalitions to build application algorithms as an SMM industry strategy.

- Factory and industry incentives for resilience, national security, and global sustainability.

- Development of the tools required to accurately capture the metrics needed for small, medium-sized, and large manufacturers to assess how smart manufacturing can help meet their sustainability goals.

- Academia and industry to develop educational programs together for the needed skills and educational programs to meet industry’s needs.

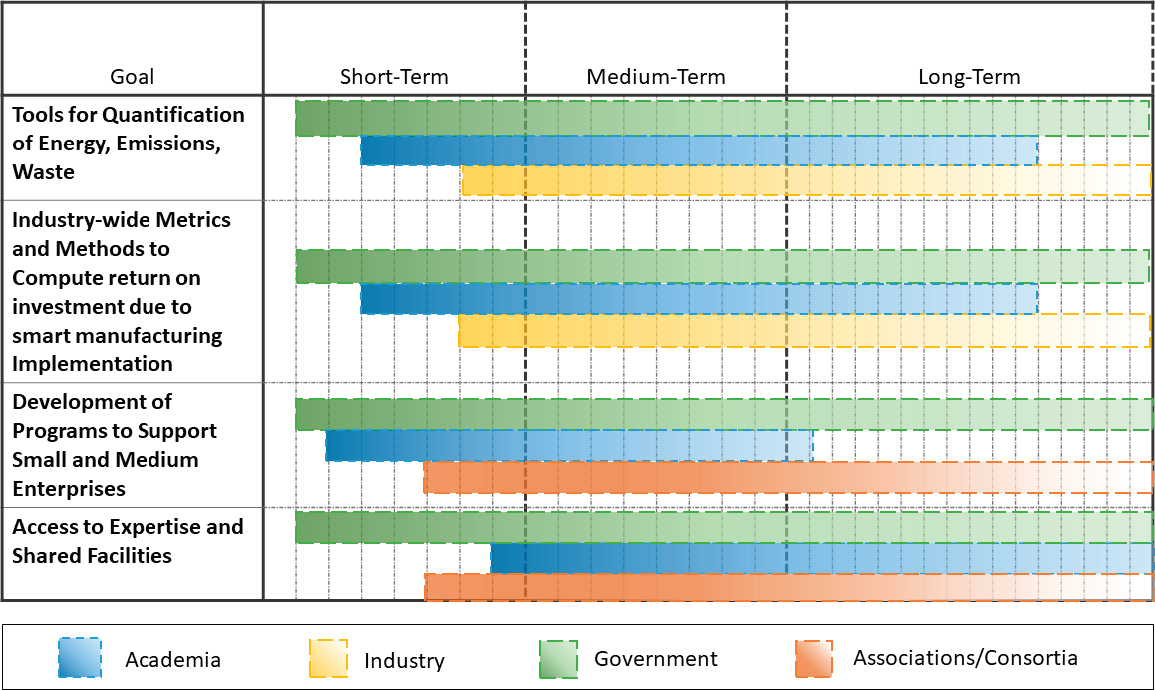

See Figure 5-1 for a timeline on how to realize broader impacts of smart manufacturing. The committee considers the short-, medium-, and longer-term timeframes to be in the ballpark of 2, 4, and 6 years, respectively.

Conclusion: To accelerate industry adoption of smart manufacturing, several resources would be needed to overcome existing barriers. These resources could include the following:

- Incubating algorithm builders as cyber equivalents of equipment builders.

- Developing and testing methods and models for the industry to leverage the network for search and bottom-up development of aligned tools and business models.

- Compiling case studies to address industry concerns about intellectual property, trade secrets, data, and know-how that are preventing the industry from taking advantage of the full capability of smart manufacturing technologies.

- Developing programs for scaling workforce development and labor needs with smart manufacturing concepts, use case experiences, available tools, and the flexibility for emerging or changing business and technology experiences.

- Getting resources to the SMMs for implementing smart manufacturing because the market does not accomplish this. Financial intervention is needed, with tax credits or other mechanisms viewed as priorities. However, financial intervention alone is not sufficient. Most SMMs are not equipped to overcome resource fragmentation. There needs to be support to access and use available resources to move into smart manufacturing.

- Empowering the Manufacturing USA institutes, as described above, to position themselves for a stronger role in disrupting and reinventing industry business and technology for the broader future of smart manufacturing—for example, by addressing industry integration demonstrations, addressing higher TRL projects, resourcing institute collaborations, working more seamlessly across memberships, and taking on greater scaling and scoping challenges.

Recommendation: Industry associations and consortia should fund pilot programs that create case studies for data sharing and intellectual property retention and protection to be used by small and medium-sized enterprises with nascent efforts in smart manufacturing.

Recommendation: Agencies, such as the Department of Energy, with interests in smart manufacturing should support new programs to provide funding and resources for small-to-medium manufacturers to update and secure their current operations and equipment by deploying smart manufacturing technologies. Potential options include, but are not limited to, tax credits and loan guarantees.

Recommendation: Agencies, such as the Department of Energy, in collaboration with universities and consortia with interests in smart manufacturing should support the development of new programs to provide easy access to expertise and facilities and to aid in the design and development of prototype systems and processes design and development. Potential options include (1) developing shared smart manufacturing facilities at universities, national laboratories, and manufacturing institutes; and (2) creating new outreach programs at the Manufacturing Extension Partnership to provide access to smart manufacturing expertise.

Recommendation: The Manufacturing Extension Partnership program, the Industrial Assessment Centers, and the Manufacturing USA institutes should be empowered and funded by government agencies, such as the Department of Energy, to work together on smart manufacturing capabilities for small-to-medium manufacturers (SMMs). These same partnerships need to be empowered to work with the SMMs in sharing data and offering expertise.

Recommendation: Threaded through all of these conclusions and recommendations is the need for federal agencies to better coordinate resources, agendas, and operating expectations. Greater financial, administrative, and priority coordination among the agencies to take advantage of existing investments will go a long way. But there is a need to now consider strategic national alignment across agencies. Several of the recommendations in this report are national in scale and are simply not possible without strategic coordination among the federal agencies together with joint agreements on implementation. This leads to the important recommendation of forming a subcommittee of the federal agencies—for example, through the National Science and Technology Council—with the charge and support to address and implement cross-agency strategic, financial, and administrative coordination in a timely manner. This should be supported by appropriate budget and resource allocations.