Capturing the Durability of High Recycled Binder Ratio Asphalt Mixtures (2024)

Chapter: 1 Introduction

CHAPTER 1

Introduction

Significant economic and environmental benefits provide motivation to use more recycled asphalt materials (RAM) in asphalt mixtures. The National Asphalt Pavement Association (NAPA) estimates that 98.1 million tons of reclaimed asphalt pavement (RAP) and 0.7 million tons of recycled asphalt shingles (RAS) were reused in approximately 442 million tons of asphalt mixtures produced in 2022 (Williams, Willis, and Shacat 2024). Use of these RAM preserved virgin asphalt binder and aggregates and saved approximately $4.7 billion in material costs and 68 million cubic yards of landfill space. However, these sustainability benefits can be fully realized only if durability can be maintained by engineering each unique combination of virgin materials, RAM, and any additives. To control durability, state highway agencies (SHAs) currently limit RAP and RAS contents, their associated binder ratios (RAPBR and RASBR), and the overall recycled binder ratio (RBR) as defined in Equation 1 (assuming 100% RAM binder availability).

| (1) |

where Pbi = binder content of RAM component i or total, and Pi = RAM content by weight of mixture.

Currently, AASHTO has no uniform standard practice for assessing the component materials, their proportions, or their combination in binder blends or mixtures with high 0.3–0.5 RBRs. The current mix design specifications focus on the quantity of binder in the mixture primarily through volumetric requirements. However, as RAM content or RBR (and the need for additives) increases, the quality of the effective blended binder and its interaction with any additives must be considered. Balanced mix design (BMD) approaches address this issue by requiring practical tests on mixtures to assess their resistance to the most prevalent distresses. Characterizing mixtures can account for the effects of partial RAM binder availability (RBA) and incomplete blending of virgin and recycled binders and additives, with mixture performance governed by the contributions of its component materials at selected proportions. Moreover, mixture characterization can capture various mitigation strategies that help offset the effects of stiff, brittle, aged RAM. These high RAM strategies include the following:

- Using a softer virgin binder, a binder with an increased capacity for use with RAM, or a polymer-modified asphalt (PMA)

- Incorporating a recycling agent (RA) or warm-mix asphalt (WMA) additive

- Reducing the RBR or RAM content

- Increasing effective binder content (Pbe) by gradation adjustment or alternate mix design requirements (regressed air voids [AVs], increased voids in the mineral aggregate [VMA], reduced number of gyrations, or consideration of decreased RBA). The decreased RBA strategy specifies that a reduced percentage of the asphalt binder in the RAM be credited to the total

- asphalt binder in the mixture. For example, in a mixture with 30% RAP (by weight of mixture) with a 4.5% RAP binder content, a 75% RBA limits the share of RAP binder contributing to the total binder content to 1.0% (0.30 × 4.5% × 0.75). The remaining 35% (0.30 × 4.5% × 0.25) is black rock.

BMD approaches are gaining significant interest, and their development and implementation are progressing rapidly. As of 2024, the National Center for Asphalt Technology (NCAT) showed that 35 SHAs have a draft, provisional, or standard BMD specification. Per AASHTO PP 105, there are four BMD approaches, with varying levels of volumetric requirements adopted from existing specifications (West et al. 2018). Although the majority of the implemented BMD specifications still require satisfactory volumetrics before mixture performance verification, some allow for a true performance mix design that provides greater innovation potential (Powell and Yin 2020).

When using RAM in a BMD approach, additional characterization of the RAM binder, virgin binder, and blends may be warranted depending on the available resources and risk tolerance. Figure 1 shows a three-tiered system from a recent NAPA guide (Hand and Epps Martin 2020). All approaches include mixture evaluation, and the process requires either a control mixture with a record of satisfactory field performance or thresholds or criteria for binder and mixture evaluation tools tied to adequate field performance. The intermediate and comprehensive approaches require additional evaluation of virgin and RAM binders to reduce field performance risk and mix design iterations, with the comprehensive approach also requiring evaluation of the binder blend. It follows that the intermediate and comprehensive approaches require more resources (time, equipment, and cost).

These three approaches stem from a Standard Practice draft for high 0.3–0.5 RBR mixtures, developed through NCHRP Project 09-58 (Epps Martin et al. 2019), that balances rutting and cracking resistance. The draft Standard Practice for AASHTO consideration includes the following:

- Component material selection guidelines for virgin and RAM binders and their proportions, including an RA dose selection method

- Binder and blend rheological evaluation tools, including blend preparation procedures, aging protocols, and thresholds or criteria

- Mixture evaluation tools, including specimen fabrication procedures, aging protocols, and thresholds or criteria

These guidelines and tools provided a framework this project revised, expanded, and updated to facilitate the design of durable asphalt mixtures within the context of BMD. For example,

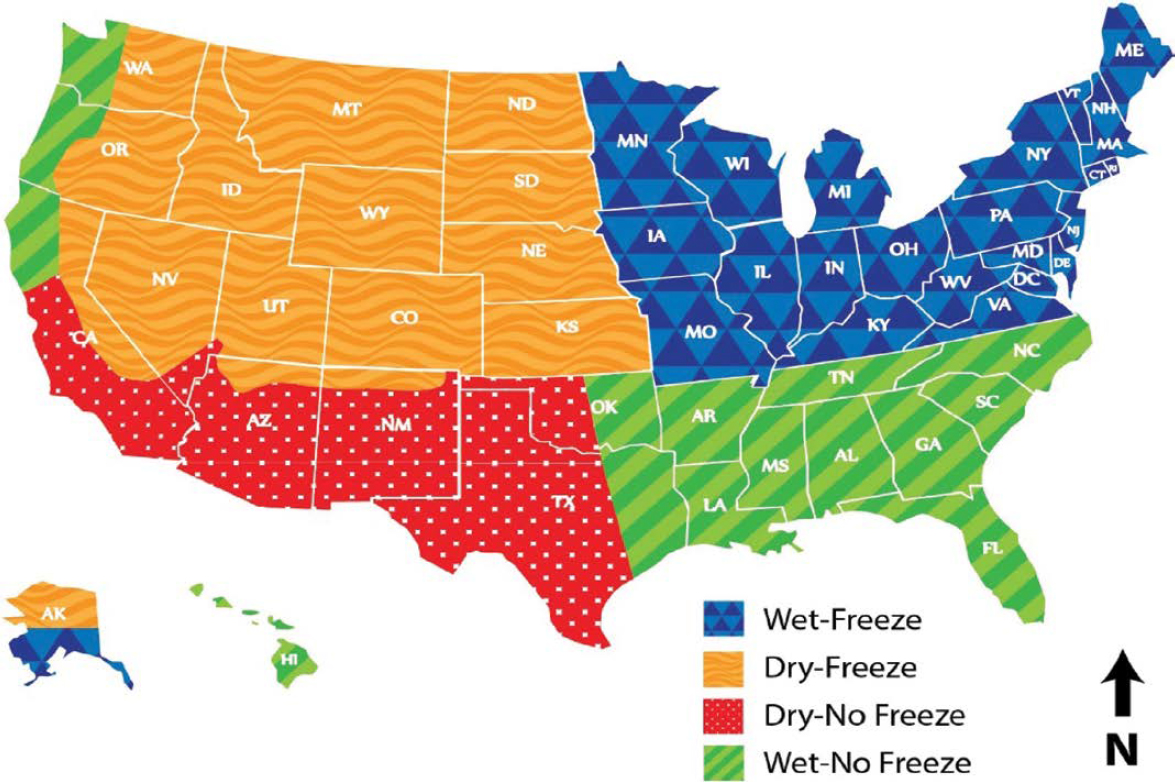

characterization of RAP without extraction and recovery of the RAP binder can be added, and specific mixture aging and moisture conditioning protocols can be tied to the four long-term pavement performance (LTPP) climatic zones shown in Figure 2.

1.1 Objective

The objective of this project is to produce a comprehensive draft Standard Practice for AASHTO consideration and associated test methods for the design and evaluation of durable asphalt mixtures, regardless of RAM content or the presence of additives. In this research, a durable mixture refers to one that can withstand traffic and environmental conditions without showing signs of deterioration, such as raveling, surface cracking, pop-outs, and moisture damage.

Raveling is defined as the dislodgement of aggregate particles at the surface caused by traffic. This distress may be related to mix design and materials, such as binder aging and loss of bond between the component materials (Pavement Interactive 2020). Surface cracking may arise from a combination of traffic, low temperature, and binder aging that can manifest in various forms, including block cracking, top-down cracking, low-temperature cracking, and reflection cracking. Pop-outs refers to the occurrence of deleterious aggregate particles or significant cracking that creates small pieces of pavement that are then dislodged by traffic.

All of these durability issues can be exacerbated by the effects of moisture, which can weaken or disrupt the bond between incompatible component materials, causing reduced stiffness and, in extreme cases, stripping. Thus, the distresses identified are a cumulative result of the combined effects of traffic and various environmental conditions (i.e., temperature and moisture levels).

1.2 Approach and Scope

This project was conducted in two phases. Phase I included a critical review of the literature, development of the work plan, and documentation of these efforts in an interim report. Online questionnaires were used to obtain input during the development of the work plan. Input from eight panel members was used to define relative weights of seven attributes for evaluating laboratory performance test methods and aging and moisture conditioning protocols. The seven attributes included availability, practicality, variability, sensitivity, simplicity, cost, and relevance. Input from up to seven members of the research team was used to rate each test method and conditioning protocol with respect to the seven attributes. Phase II included conducting laboratory experiments and evaluating available information to address each primary durability issue (raveling, surface cracking, and moisture susceptibility), producing a technical report, proposing a comprehensive draft Standard Practice for AASHTO consideration, documenting the project in this final report, and presenting a virtual workshop to the AASHTO Committee on Materials and Pavements. The Phase I interim report can be found in the online appendices to this report, including a review of relevant literature and results obtained from the questionnaires.

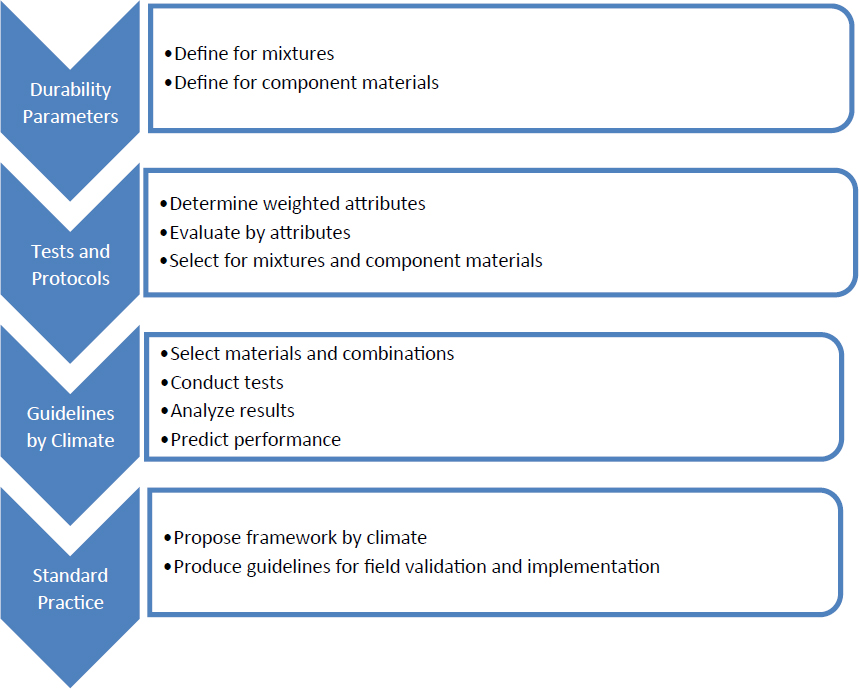

A staged approach, as shown in Figure 3, was used to gather information and design the laboratory experiments necessary to complete the work plan to produce a draft Standard Practice for the

design and evaluation of durable asphalt mixtures. The interim report described the information collected and reviewed in designing laboratory experiments to evaluate the effects of component materials and proportions (material combinations) on mixture durability. Additionally, a preliminary durability assessment framework by climatic zone was proposed, supported by evaluation methods that included pavement performance modeling. The technical report documented the extensive laboratory experiments and their results, and this final report builds on the technical report with analyses used to develop the project deliverables, including the draft Standard Practice for AASHTO consideration and its associated implementation guide (the latter of which was sent to the AASHTO Committee on Materials and Pavements for evaluation) and a virtual workshop and materials.