Use of Supplementary Cementitious Materials for Concrete (2025)

Chapter: 3 State DOT Practices

CHAPTER 3

State DOT Practices

Introduction

A survey questionnaire was prepared and sent to members of AASHTO Committee on Materials and Pavements (COMP) of all 50 state DOTs and those of the District of Columbia and Puerto Rico. The survey included 25 questions about DOT practices related to uses and applications of SCMs, shortages of fly ash and DOT actions in response, and the use of ASCMs in DOT concrete projects. The final question in the survey was used to determine the willingness of the respondent or another designated DOT staff member to be interviewed by the authors with for the purpose of preparing case examples for this report. Responses were received from 42 state DOTs and the Puerto Rico DOT.

Responses to Survey Questionnaire

While 42 state DOTs and the Puerto Rico DOT responded to the questionnaire, not all respondents provided a response to each question. The majority of the responses were to the questions related to conventional SCMs, followed by questions related to the availability of fly ash. Fewer responses were received on questions related to ASCMs. Also, in response to some of the questions, state DOT respondents offered comments, exceptions, or other alternatives to the options listed. The survey questionnaire is presented in Appendix A. Individual responses to each question and specific comments or exceptions to some of the questions are presented in Appendix B.

Responses to the results of survey questions are shown under the general topics shown here:

- Contact information

- State DOTs’ use of SCMs in concrete

- Applications in which state DOT specification allows the use of SCMs

- Conditions that require the use of SCMs in concrete

- Types of SCMs in concrete

- Percentage of SCMs used in concrete mixtures

- NPs used in concrete mixtures

- Ternary and quaternary SCM mixtures

- Acceptance strength and other test requirements for concrete with ASCMs

- SCMs in concrete with Type IL cement

- Availability of fly ash

- Alternative SCMs

- Case example interviews

Contact Information

The question asked for the contact information of the respondent. However, the report will only show the list of state DOTs that responded to the survey. Most responses were returned

Figure 17. States allowing the use of SCMs in concrete.

from the state DOT COMP members, but it is assumed that other DOT staff may have offered input as well.

State DOTs’ Use of SCMs in Concrete

All 43 responding DOTs allow the use of SCMs in concrete mixtures. Thirty-five allow SCMs as additives to the concrete mixture or as blends in cements. Six states allow their use only as additives, and two states allow their use only as ingredients in blended cement, as shown in Figure 17.

State DOTs’ Specifications Allowing the Use of SCMs in Pavements or for Bridges

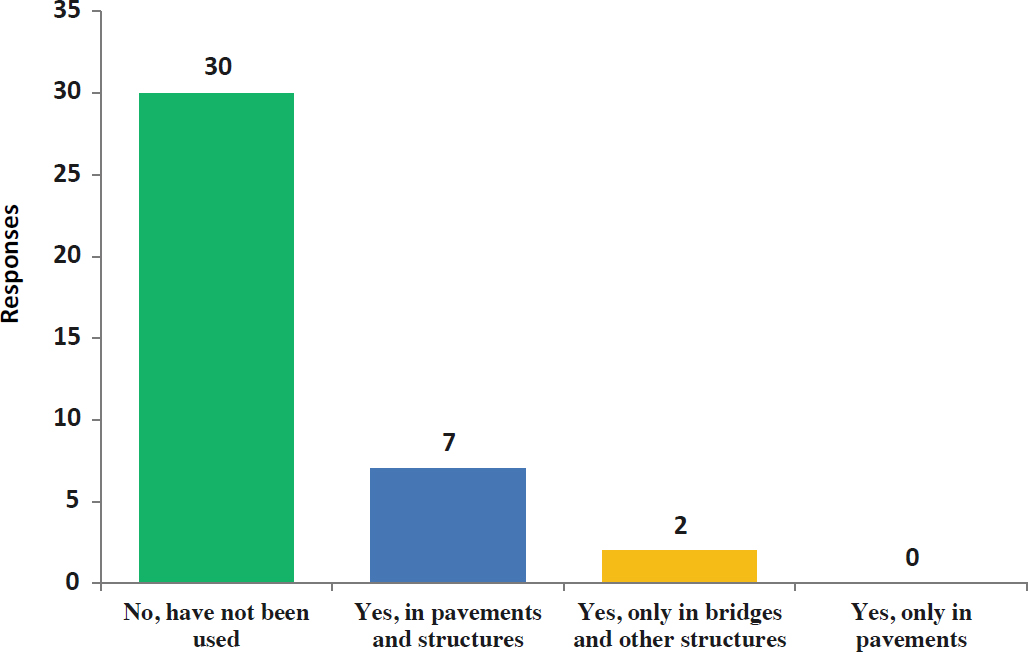

Of the 39 responses to this question, 38 state DOTs specify the use of SCMs in both concrete structures and pavements (Figure 18). The Vermont DOT was the exception. It specifies SCMs only in bridges and other structures, since no concrete pavements are currently present in its state highway system.

Figure 18. SCM applications for pavements and structures.

Conditions That Require the Use of SCMs in Concrete

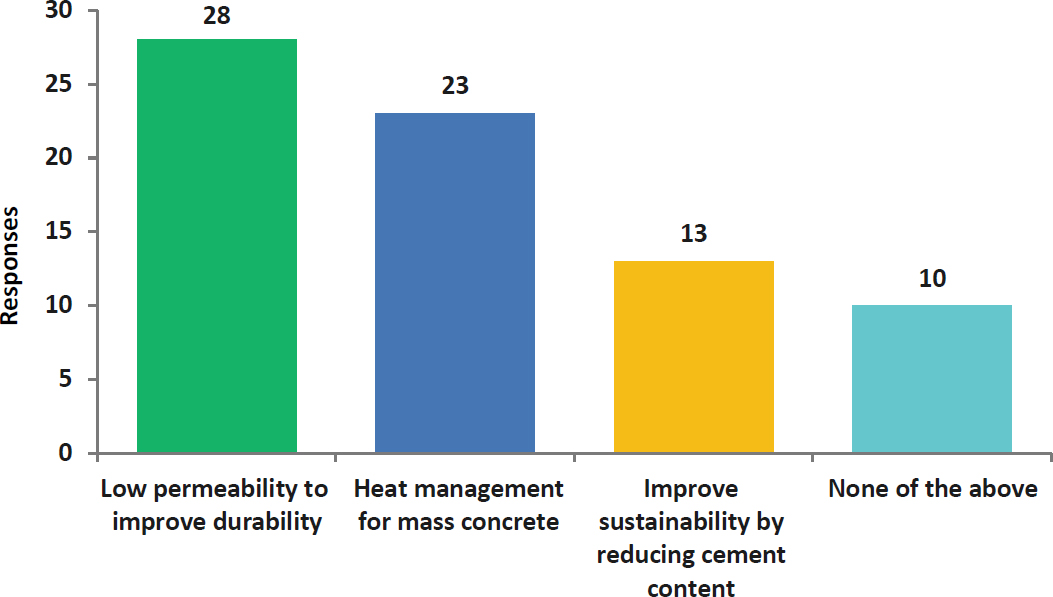

The majority of state DOT respondents use SCMs for durability of concrete, for heat management in mass structures and, to a lesser extent, to improve sustainability, although substituting Portland cement in the mixture will also contribute to improved sustainability (Figure 19). Twelve DOTs (AZ, CO, DE, ME, MI, MN, NE, PA, RI, SD, TX, and VT) commented that the use of SCMs specifically helps mitigate ASR (Appendix B). North Carolina uses SCMs with high alkali cement (≥0.6%), while Colorado uses SCMs in concrete to resist sulfate attack. Tennessee specification allows, but does not require, the use of SCMs in various applications.

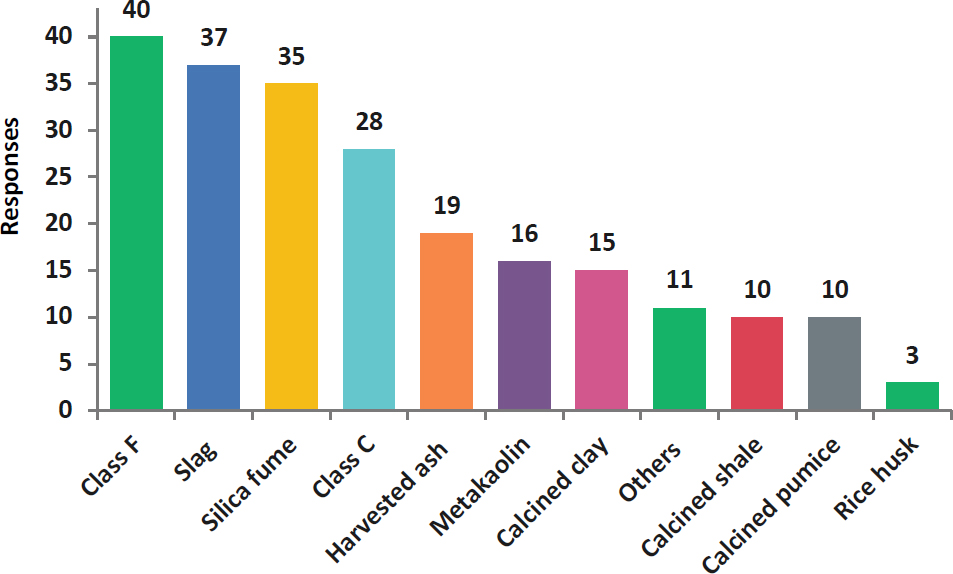

Types of SCMs in Concrete

Among the 41 responses to this question, the majority of DOTs allow the use of the conventional SCMs (fly ash Classes F and C, slag, and silica fume) (Figure 20). Based on their availability in the state, other SCMs were also being used. Nineteen states allow the use of harvested or beneficiated fly ash. Ten to 16 states allow the use of natural pozzolans such as metakaolin and calcined clay, shale, and pumice, and three states allow the use of rice husk. Washington State allows the use of harvested ash provided that it satisfies AASHTO M 29 (ASTM C618-23) requirements for Class F or Class C ash and the DOT’s specific chemical requirements. Illinois allows high-reactivity metakaolin and blended SCMs per ASTM C1697. North Carolina allows Class N pozzolans, and California uses ultrafine fly ash. Massachusetts has experimented with nanosilica, SCMs, and recycled ground glass. Vermont uses GGPs.

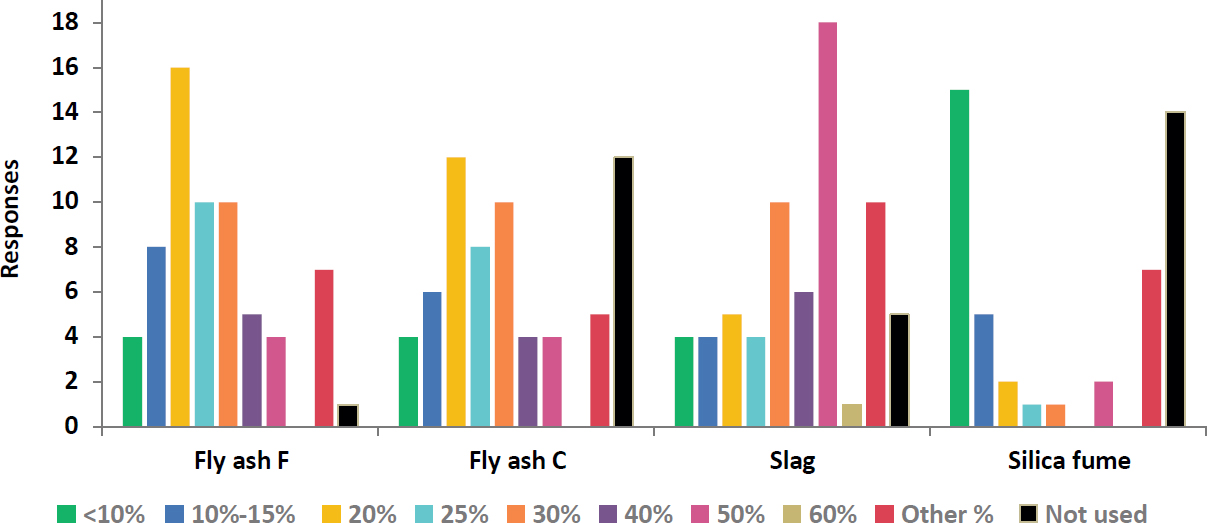

Percentage of SCMs Used in Concrete Mixtures

Percentage of SCMs Used in Concrete for Pavement Applications

Table 7 and Figure 21 show replacement rates of SCMs for Portland cement in concrete for pavements. Most responding DOTs use 20% fly ash Class F, 50% slag cement, and less than 10% silica fume. Other replacement rates are also being used. Fifteen states do not allow use of silica fume in pavements, and 11 states do not allow the use fly ash Class C in pavements. Comments were received from a number of respondents providing additional details regarding allowable

Figure 19. Specific applications of SCMs.

Figure 20. Use of conventional SCMs, harvested coal ash, NPs, and other pozzolans in concrete.

Table 7. Percentage of conventional SCMs permitted in pavement concrete.

| State DOT | <10% | 10%–15% | 20% | 25% | 30% | 40% | 50% | 60% | Other % | Not Used |

|---|---|---|---|---|---|---|---|---|---|---|

| Fly ash F | ND, WI, IL, MS | ND, WI, GA, MO, IL, FL, DE, MS, HI | SD, ND, IA, SC, AZ, KY, CT, WV, NV, IL, TX, FL, OK, MS, VA | TN, SD, NE, MO, OH, IL, TX, FL, MS, VA | MT, ME, OR, RI, NC, AL, TX, FL, MA, UT | MI, PR, PA, TX, FL | CO, TX, FL | WI, WA, MN, CA, NY, MS, LA | VT | |

| Fly ash C | ND, WI, IL, MS | ND, WI, GA, MO, IL, FL, MS | ND, WI, IA, SC, AZ, CT, WV, IL, TX, FL, OK, MS | TN, WI, MO, OH, IL, TX, FL, MS | MT, WI, OR, KY, RI, AL, IL, TX, FL | MI, PA, TX, FL | CO, TX, FL | MN, WA, NC, NY, LA | SD, NE, NV, CA, PR, VT, DE, VA, MA, UT, HI | |

| Slag | ND, WI, IL, MS | ND, WI, IL, MS | ND, WI, NV, IL, MS | ND, WI, PR, IL, MS | MT, MO, WA, WI, MO, KY, CT, IL, TX, MS, OH | MI, PA, TX, DE, MS, VA | CO, SC, OR, GA, WV, RI, NC, AL, TX, FL, OK, DE, MS, VA, MA | FL | TN, NE, IA, MN, CA, NY, PR, IL, FL, LA | SD, AZ, VT, UT, HI |

| Silica fume | MT, WI, OR, MO, WV, RI, NC, KY, OH, PR, IL, PA, TX, FL, UT | WI, GA, KY, AL, OK | WI, NV | WI | WI | CO | TN, SC, CT, CA, LA, MA | SD, ME, WA, MI, ND, IA, NE, MN, AZ, NY, VT, DE, MS, VA, HI |

Total Responses: 41

replacements. These details are shown in Appendix B. For example, Louisiana allows 50% replacement of cement with a combination of slag cement and fly ash, and the use of 70% slag replacement of Portland cement in mass structures. Connecticut and Maine waive the maximum allowed silica fume to achieve reduced concrete permeability, while Tennessee allows 10% to 20% silica fume. North Carolina sets no limit on the maximum fly ash Class F or Class C replacement used in concrete for both pavements and bridges. Minnesota allows 33% fly ash, while Illinois, Mississippi, Tennessee, and Washington State allow 35%. Nebraska limits the use of slag cement in concrete mixtures at 38%, Iowa at 50%, Puerto Rico at 65%, and Florida at 70%.

Percentage of SCMs Permitted in Concrete for Bridges and Other Structures

Table 8 and Figure 22 show the allowable percentage of SCM replacement rate of cement for concrete used in bridges and other structures by the 41 responding DOTs. Most states use 20% to 25% fly ash Class F, 50% slag cement, and less than 10% silica fume. Other slightly different rates are also being used by the same states or other states. Comments and exceptions to the replacement options in the question were received from a number of respondents and are presented in Appendix B. Texas determines the percentage of fly ash Class C based on testing according to ASTM C1576 using the project aggregates. Vermont determines slag and silica fume based on performance. Minnesota uses 35% slag cement and 5% silica fume for bridge deck mixtures, and 4% to 6% silica fume for bridge deck overlays. Tennessee uses up to 35% slag and 10% to 20% silica fume. Ohio uses a 60% blend of fly ash and slag. Massachusetts uses 15% silica fume.

Natural Pozzolans Used in Concrete Mixtures

Twenty-three of the 41 responding DOTs indicated that NPs are either not permitted or not included in their specifications. However, 18 other states allow the use of one or more NPs and included specific percentage replacement rates for concrete mixtures (Table 9). However, not all the states using NPs have specifications prepared specifically for NP materials and instead rely on the requirements of AASHTO M 295 for fly ash Classes F and C (see results in Appendix B). Illinois has not included NPs in its specifications, but these materials are being considered for use. Minnesota has recently allowed the use of NPs and is determining the application rate based on the type of NP. Ohio has included NPs in its specifications but has not used any yet. Florida is using NPs, but these materials have not yet been included in its specifications.

Table 8. Percentage of conventional SCMs permitted in structures.

| State DOT | <10% | 10%–15% | 20% | 25% | 30% | 40% | 50% | 60% | Other % | Not Used |

|---|---|---|---|---|---|---|---|---|---|---|

| Fly ash F | ND, WI, IL, MS | SD, ND, WI, GA, MO, IL, FL, DE, MS, HI | SD, ND, IA, SC, NE, MO, AZ, KY, CT, WV, NV, OH, IL, TX, FL, OK, MS, VA | TN, SD, ND, IA, NE, MO, AZ, KY, CT, NV, OH, IL, TX, FL, MS, VA, WV, OK | MT, ME, MN, OR, RI, NC, AL, TX, FL, MA, UT | MI, PR, PA, TX, FL | CO, TX, FL | WA, WI, MN, CA, NY, VT, IL, MS, LA | ||

| Fly ash C | WI, IL, MS | WI, GA, MO, IL, FL, MS | WI, IA, SC, AZ, CT, WV, OH, IL, FL, OK, MS | TN, WI, IA, AZ, CT, WV, OH, IL, FL, OK, MS | MT, WI, MN, OR, KY, RI, AL, IL, FL | MI, PA, FL | CO, FL | WA, MN, NC, NY, TX, LA | SD, ND, ME, NE, NV, CA, PR, VT, DE, VA, MA, UT, HI | |

| Slag | WI, IL, MS | WI, IL, MS | WI, NV, PR, IL, MS | WI, NV, PR, IL, MS | MT, MO, WI, KY, CT, OH, IL, TX, MS | MI, PA, TX, DE, MS, VA | CO, ME, WA, SC, OR, GA, WV, RI, NC, AL, TX, FL, OK, DE, MS, VA, MA | FL | TN, NE, MN, CA, NY, VT, IL, FL, LA | SD, ND, AZ, UT, HI |

| Silica fume | MT, WA, MI, WI, OR, MO, MN, AZ, KY, WV, RI, NC, OH, PR, IL, PA, TX, FL, VA, UT | WI, GA, AZ, KY, AL, OK | WI, NV | WI, NV, PR, IL, MS | WI | CO | TN, ME CT, CA, NY, VT, LA, MA | SD, ND, IA, SC, NE, DE, MI, HI |

Total Responses: 41

Table 9. State DOTs that reported a percentage of natural pozzolans permitted in their specifications.

| State DOT | % Calcined Clay | % Calcined Shale | % Calcined Pumice | % Metakaolin | % Rice Husk | % Natural Pozzolans Not in Specification |

|---|---|---|---|---|---|---|

| California | Note Below | |||||

| Colorado | 50 | 50 | 50 | 50 | 50 | |

| Florida | 15–50 | 15–50 | 15–50 | 8–12 | ||

| Georgia | ≤15 | |||||

| Iowa | 20 | 20 | 20 | 20 | ||

| Louisiana | 50 | |||||

| Massachusetts | 30 | |||||

| Missouri | 15 | |||||

| Nebraska | 25 | 25 | 25 | |||

| Nevada | 20 | 20 | 20 | 20 | 20 | |

| New York | Note Below | |||||

| North Carolina | 30 | 30 | 30 | 30 | 30 | |

| Oregon | 30 | 30 | 30 | 30 | ||

| Puerto Rico | 40 | |||||

| Texas | 20 | 20 | 20 | 20 | ||

| Utah | 30 | 30 | 30 | |||

| Virginia | 7–10 | |||||

| Washington | 35 | |||||

Total Responses: 41

Notes: Blank cells are not applicable.

California: For concrete structures, NPs must be proportioned in accordance with the requirements of Sec.90-1.02B (3) [of the California DOT (Caltrans) Construction Manual (specifications)], which allows for the use of multiple SCMs in amounts related to the total specified cementitious material quantity. SCMs must be proportioned in accordance with Sec.49-3.01B(2) for mass-concrete piles, 90-1.02I(2)a) for structures in freeze–thaw zones, 90-1.02I(2)(b) for concrete exposed to deicing chemicals, and 90-4.02 for precast concrete elements. The use of rice husk is only allowed in minor concrete, per the requirements of Sec.90-2.02B. This information is detailed in the Caltrans case example in Chapter 4.

New York: No limits are specified. However, SCMs are allowed in performance-engineered mix (PEM) concrete to achieve desired performance characteristics. Also, natural pozzolans are not commonly used but are allowed.

Ternary and Quaternary SCM Mixtures

Ternary Mixtures in State DOT Specifications

Twenty-six of the 33 responding DOTs allow the use ternary concrete mixtures in pavements and structures, as shown in Figure 23. Four states do not allow their use. Three states use them exclusively in bridges and other structures. No state indicated the use of ternary mixes only in pavements. Appendix B provides the responses of the 33 responding state DOTs.

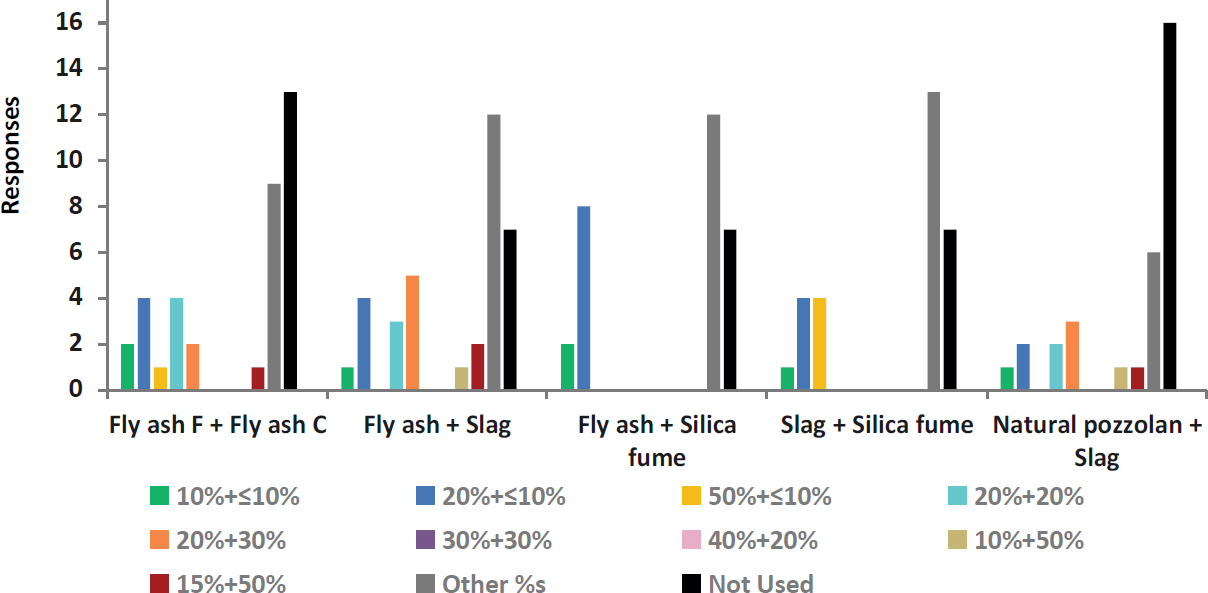

Percentage of SCM Ternary Concrete Mixtures

A few states checked more than one combination of the two SCMs, as shown in Table 10 and Figure 24. Also, nineteen states use percentage combinations that are different than or in addition to the percentages provided in the questionnaire. (Details are provided in Appendix B.) Texas uses 35% slag and less than 10% silica fume, Vermont uses 25% and 5%, Michigan uses 25% and 4%, Pennsylvania uses 25% and 5% to 10%, Florida uses 40% and 10%, and Washington State uses 50% and 10%. New York uses a blend of 20% fly ash or 20% slag combined with 6% silica fume. Illinois allows 65% SCMs with limits of 40% fly ash, 65% slag, and 5% silica fume for mass concrete mixtures, while Colorado, Tennessee, and Ohio allow a blend of SCMs not

Figure 23. Use of ternary concrete mixtures.

Table 10. Percent SCMs in ternary mixtures.

| State DOT | 10% + ≤ 10% | 20% + ≤ 10% | 50% + ≤ 10% | 20% + 20% | 20% + 30% | 30% + 30% | 40% + 20% | 10% + 50% | 15% + 50% | Other % | Not Used |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fly ash F + Fly ash C | OR, FL | MI, OR, TX, FL | FL | RI, TX, FL | TX, FL | WA | CO, MI, WI, NY, OH, IL, PA, OK, LA | TN, SD, ME, IA, AZ, WV, NC, CA, PR, VT, MS, VA, UT | |||

| Fly ash + slag | OR, FL | OR, PR, TX | MI, OR, TX | IA, OR, RI, TX, VA | WA, FL | TN, MT, MI, WI, MN, NC, CA, NY, OH, VT, IL, PA, LA | SD, ME, AZ, WV, OK, MS, UT | ||||

| Fly ash + silica fume | OR | OR, WV, RI, TX, FL, VA, UT | WA, WI, NC, CA, NY, OH, IL, PA, FL, OK, LA | ME, MI, IA, AZ, PR, MS | |||||||

| Slag + silica fume | OR, AZ | OR, WV, VT, VA | ME, OR, RI, FL | WA, MI, WI, NC, CA, NY, OH, VT, IL, PA, TX, OK, LA | TN, SD, IA, PR, MS, UT | ||||||

| Natural pozzolan + slag | OR | OR, TX | OR, TX | IA, OR, TX | FL | FL | WI, MN, NC, CA, NY, OH | TN, SD, ME, MI, AZ, RI, PR, VT, IL, PA, OK, MS, LA, VA, UT |

Total Responses: 29

exceeding 50% by mass of total cementitious material. Louisiana allows combinations of SCMs not exceeding 50% for pavement and bridges and 70% for mass concrete mixtures, but limits silica fume to 10% in any SCM blend. Utah allows a blend of 25% a natural pozzolan and 5% fly ash. Michigan allows a 40% blend of SCMs. Mississippi only allows ternary mixtures when blended cement is used in combination with an SCM.

Use of Quaternary SCM Mixtures

The use of quaternary mixtures (three SCMs) is not as common as the use of ternary mixtures. Only nine of the responding 39 DOTs allow the use quaternary mixtures. Seven DOTs use the mixtures in pavements and structures, and the remaining two limit their use to only bridges and other structures. No state indicated their use in pavements only (Figure 25).

Acceptance Strength and Other Test Requirements for Concrete with ASCM

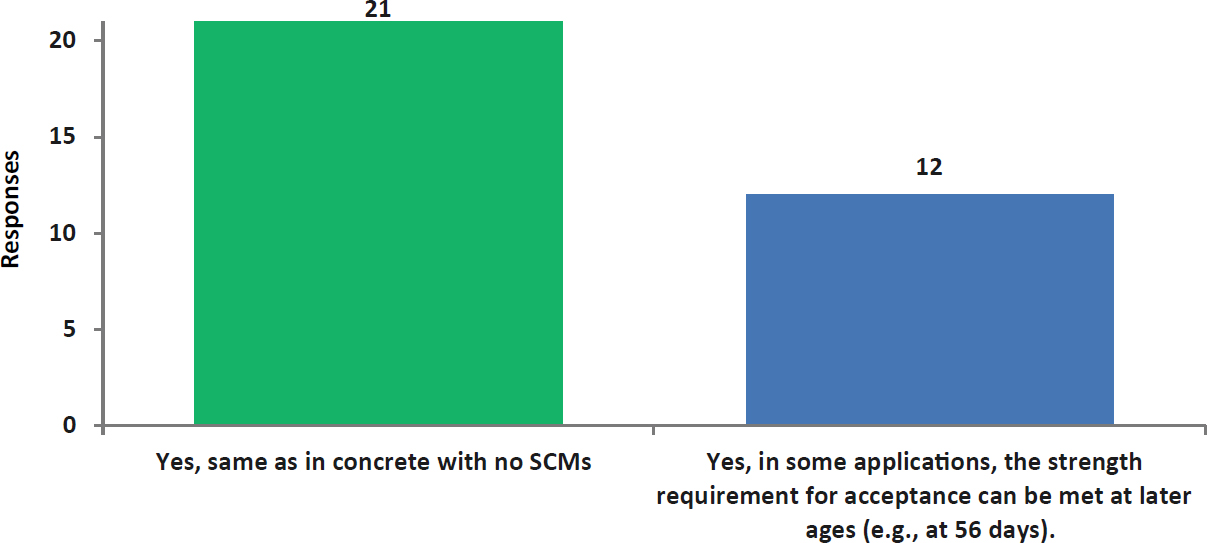

Acceptance Strength Requirement at 28 Days and Later Ages

Twenty-one out of 33 responding DOTs indicated acceptance strength at 28 days for concrete mixtures with or without SCMs, while 12 other DOTs accept strength at later ages, such as 56 days (Figure 26). Louisiana only accepts 56-day strength in the case of mass concrete, while Pennsylvania allows its district materials engineers to make the decision to accept the 56-day strength based on test results. The Illinois DOT’s acceptance requirement is 14 days, but this can be extended to 56 days. Minnesota allows 56-day test results to be used for high-performance concrete mixtures used in bridge decks. California allows for 42 days to attain the required strength for mixtures with strength greater than 3,600 psi, and in specific mixture designs strength acceptance may be extended to 56 days. Comments related to the acceptance of 56-day strength, and URLs for specifications from Florida, Montana, Texas, Rhode Island, and Vermont, are provided in Appendix B.

Tests Required by State DOT Specifications

Many DOTs do not require special tests for concrete mixtures with SCMs. Sixteen state DOT specifications require surface resistivity tests, and 12 require direct chloride permeability tests. Thirteen DOTs perform shrinkage tests, and 10 perform air-void tests. Minnesota uses performance-based specifications, which require some of the tests noted in Figure 27. New York uses the Super Air Meter during performance-engineered mix (PEM) design for all concrete mixtures with or without SCMs. The California DOT (Caltrans) requires all SCMs to be on its authorized list of those having passed the specified ASTM tests (see case example in Chapter 4 for more details). Also, Caltrans performs shrinkage and freeze–thaw tests (where needed) on concrete mixtures with or without SCMs. Specific responses by some states and URLs to their specifications are provided in Appendix B.

SCMs in Concrete with Type IL Cement

Use of SCMs in Concrete with Type IL Cement

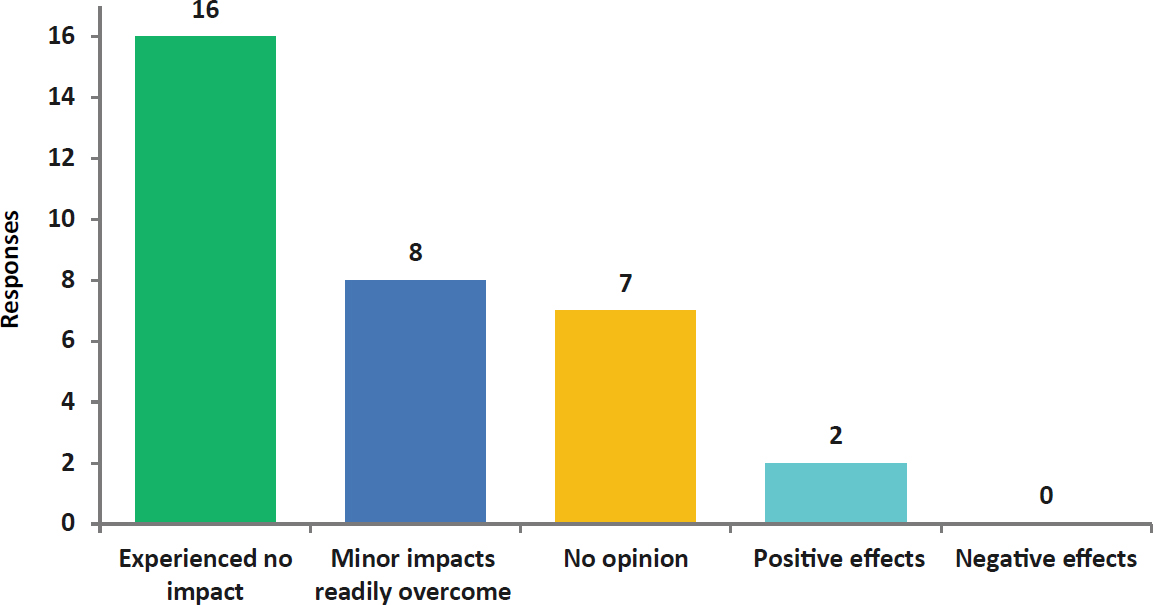

Sixteen DOTs experienced no impact on the performance of concrete when using SCMs with Type IL cement. Eight respondents indicated a minor impact, which was overcome by the

Figure 26. Acceptance strength requirement at 28 days and later.

Figure 27. Specification-required tests for concrete with SCMs.

contractor or concrete producer, two respondents reported positive effect, and seven respondents had no opinion on the issue (Figure 28). Responses from specific states with additional comments are provided in Appendix B.

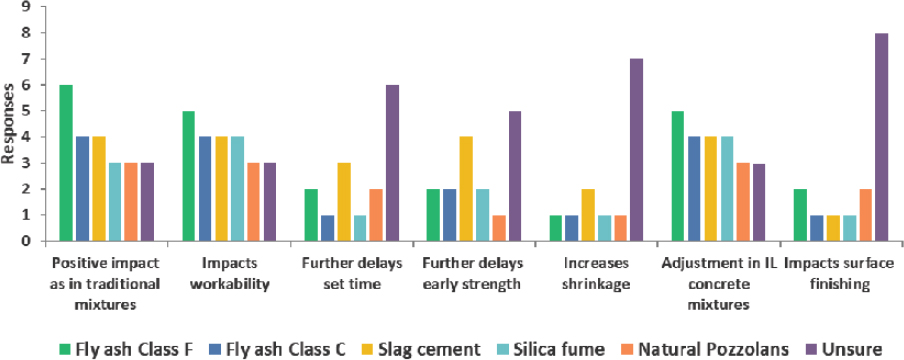

Type of Impact on Performance of Concrete with Type IL Cement

Table 11 and Figure 29 present results from the 15 state DOT responses on the impact of SCMs on performance of Type IL concrete mixtures. The Illinois DOT’s experience with using SCMs in concrete mixtures has been positive despite some incidents of delay in early strength development. Ohio reported some contractor complaints about delay in early strength development. These cases were resolved by adjusting admixtures and other ingredients. Maine commented that, in its experience, the issue is not how SCMs affect Type IL but rather how Type IL cement is different from Type II cement. The experience of the Louisiana Department of Transportation

Figure 28. Effect of SCMs on performance of concrete with Type IL cement.

Table 11. Impact of SCMs on performance of concrete with Type IL cement.

| Impact/SCM | Fly Ash F | Fly Ash C | Slag Cement | Silica Fume | Natural Pozzolans | Unsure |

|---|---|---|---|---|---|---|

| Has same positive impact on IL concrete as on concrete with other traditional cements | MT, IA, FL, MS, LA, UT | IA, FL, MS, LA | MT, IA, FL, LA | MT, FL, LA | IA, FL, UT | OH, VT, PA |

| Impacts on workability | IA, FL, MS, LA, UT | IA, FL, MS, LA | MT, IA, FL, LA | IA, VT, FL, LA | IA, FL, UT | WA, OH, PA |

| Further delays concrete set time | IA, UT | IA | MT, IA, FL | IA | IA, UT | WA, OH, VT, PA, MS, LA |

| Further delays early strength development | IA, VT | IA, VT | MT, IA, VT, FL | IA, VT | IA | WA, OH, PA, MS, LA |

| Increases shrinkage | FL | FL | MT, FL | FL | FL | WA, IA, OH, VT, PA, MS, LA |

| Requires further adjustments in IL concrete mixture designs | IA, VT, FL, MS, UT | IA, VT, FL, MS | MT, IA, VT, FL | MT, IA, VT, FL | IA, FL, UT | WA, OH, LA |

| Impacts on surface finishing quality | LA, UT | LA | LA | LA | LA, UT | MT, WA, IA, OH, VT, PA, FL, MS |

Total Responses: 15

and Development (LaDOTD) has been that, compared to regular Type I/II mixtures containing SCMs, SCMs in Type IL mixtures increase long-term concrete strength after minor adjustments.

Availability of Fly Ash

Fly Ash Shortage Experienced by State DOTs

The majority of the responding DOTs, 25 out of 33, indicated that they had experienced shortages in the availability of fly ash during the previous 5 years or more, were experiencing shortages at the time of the survey, or anticipated shortages in the near future (Figure 30). Eight states had no shortage of fly ash nor anticipated any shortage in the future. Appendix B includes the list of specific states responding to this question.

Figure 30. State DOT experience with shortage of fly ash.

State DOTs’ Actions to Address the Challenge of Fly Ash Shortages

As shown in Figure 31, 13 DOTs rely on industry-based solutions to fly ash shortages; 11 modify specifications to allow other SCMs, such as slag, silica fume and NPs, and ASCMs; seven purchase imported fly ash; three modify specifications to limit the use of fly ash for durable concrete; and four modify mixture design to improve durability without using fly ash. One DOT allows off-spec SCMs that do not meet AASHTO M 295/ASTM C618-23, and nine use other actions to substitute for the use of fly ash. Among the respondents’ comments, Arizona uses 100% cement, Delaware uses slag, and Washington State is working with the industry to update specifications on alternative SCMs. Appendix B provides a list of actions by specific states to address shortages of fly ash.

Alternative SCMs

Use of ASCMs in Concrete

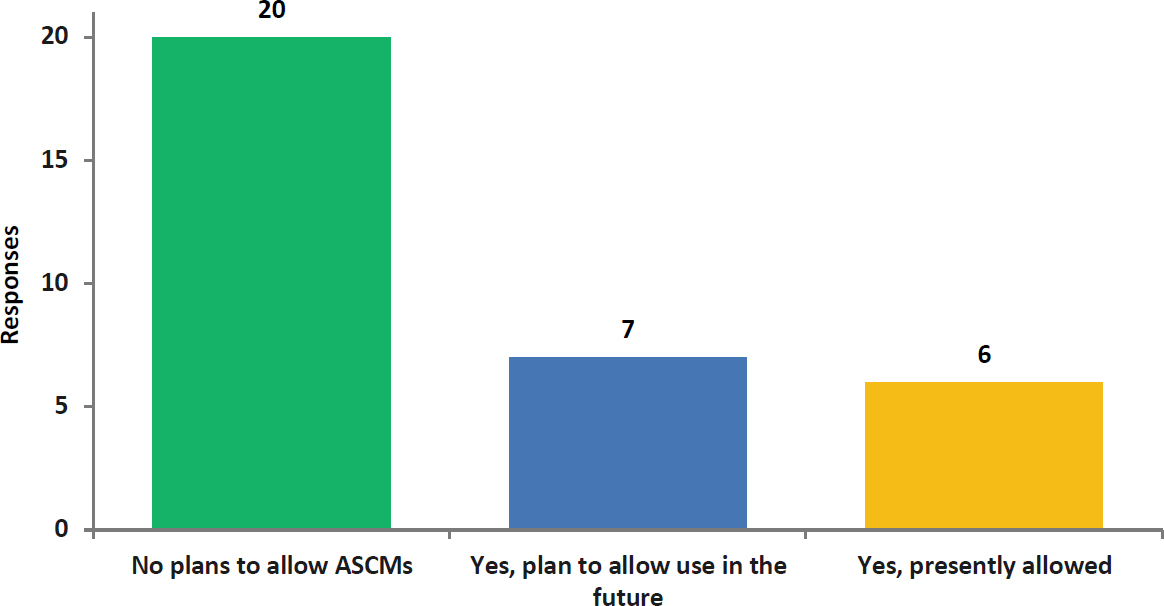

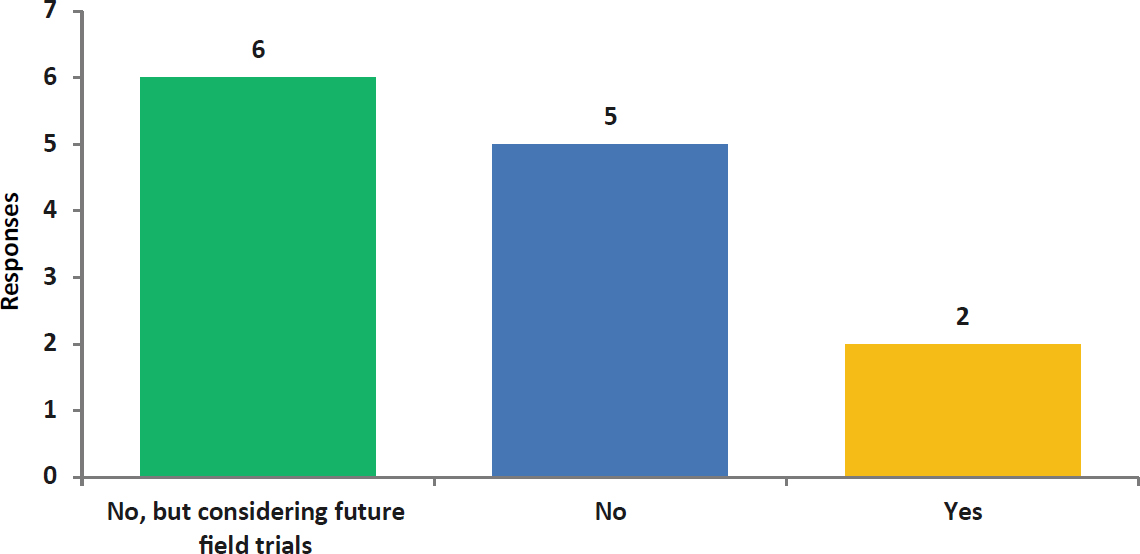

Twenty of 33 DOTs indicated that they had no plans to use ASCMs, while six allow their use, and seven will consider using them in the future (Figure 32). Vermont shared the URL for its

Figure 31. Actions taken by DOTs in response to shortages of fly ash.

Figure 32. Use of ASCMs by state DOTs.

specifications on ASCMs (see Appendix B), and Washington State is working with industry to update its specifications.

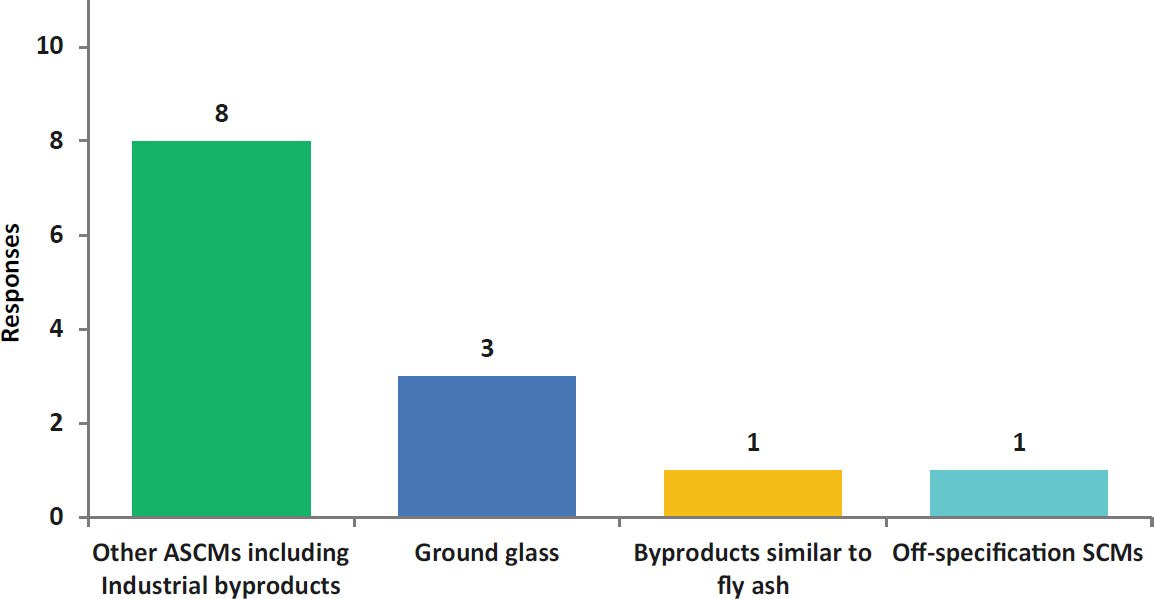

ASCMs Permitted for Use in Concrete Mixtures

Thirteen states responded to the question about permitted ASCM use in concrete, as shown in Table 12 and Figure 33. Three states permit the use of ground glass as an ASCM, one state allows industrial by-products with characteristics similar to fly ash, and one state allows use of a material not meeting AASHTO M 295 and ASTM C618-23 for fly ash in concrete (Table 12). Ten respondents indicated that their DOTs do not use ASCMs, are exploring the use of some materials, or would approve an ASCM that meets ASTM and AASHTO standards. For example, Minnesota is exploring ASCMs at the Minnesota Test Road (MnROAD) research facility through National Road Research Alliance (NRRA) pooled funds [see Minnesota DOT (MnDOT) case example in Chapter 4]. Colorado and Vermont would permit any ASCM that meets AASHTO specifications. More information on Colorado’s allowed use of ASCMs is also included in the case examples.

Table 12. Types of ASCMs permitted by some state DOTs.

| Ground Glass | Industrial Secondary or ByProducts Similar to Fly Ash or Other ASCMs | Off-Specification (Not Meeting AASHTO M 295/ASTM C618-23) Fly Ash |

|---|---|---|

| NY, VT, FL | CO, WA, MI, WI, SC, AZ, CA, OH, UT | MN |

| 3 | 9 | 1 |

Total Responses: 13

Dosage Rate of ASCM Permitted in Concrete

Only nine states responded that they specify a percentage rate of specific ASCMs in concrete mixtures or have specifications for ASCMs (Table 13). With respect to ground glass, Florida allows 18% to 50% replacement of cement, and New York allows 20% replacement of cement. Some DOTs, including those of California, Colorado, and Minnesota, indicated that they are exploring the use of some ASCMs. Wisconsin and Utah allow the use of ASCMs at 30% cement replacement, and Washington State permits the use of ground pumice to replace cement. Appendix B provides URLs for state DOT specifications related to ASCMs.

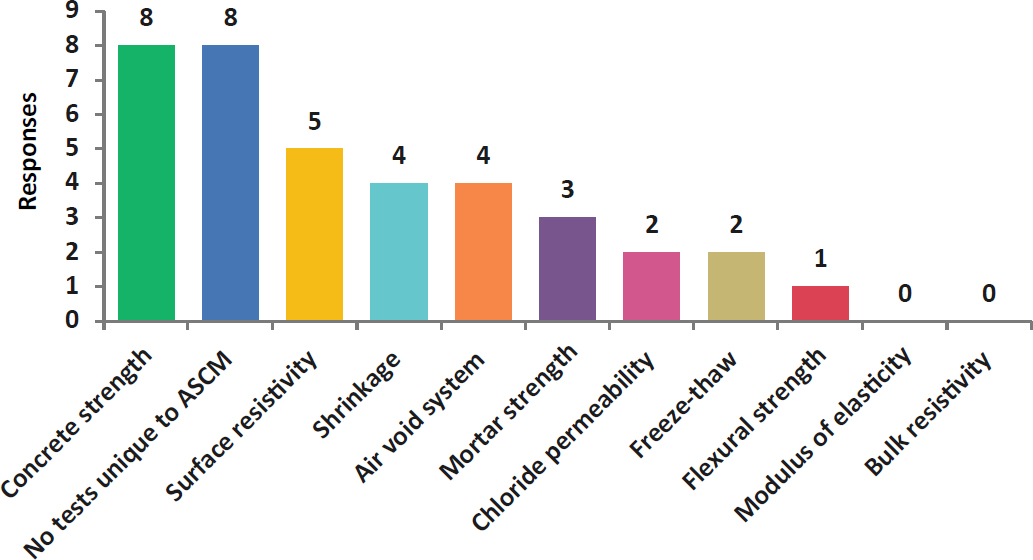

Test Results Typically Required for ASCM Approval

Figure 34 shows the number of DOTs that perform the listed tests on ASCMs. Appendix B provides information from specific states that perform the tests. Eight respondents indicated that concrete strength is a requirement for approval of an ASCM. Also, eight respondents indicated that tests unique for ASCM concrete are not yet specified, and that tests required for conventional

Table 13. Percentage of ASCMs used by state DOTs.

| State DOT | Percent Ground Glass in Concrete | Industrial or ByProducts Similar to Fly Ash | Percent Off-Specification (Not Meeting AASHTO M 295/ASTM C618-23) Fly Ash | Other ASCMs | Not Sure at Present Time Pending Further Evaluations |

|---|---|---|---|---|---|

| California | x | ||||

| Colorado | x | ||||

| Florida | 18%–50% | ||||

| Minnesota | x | ||||

| New York | 20% | ||||

| Utah | 30% | ||||

| Vermont | Performance based | ||||

| Washington | Ground pumice | ||||

| Wisconsin | 30% |

Total Responses: 9. Note: Blank cells are not applicable.

Figure 34. Tests required to approve ASCMs.

concrete mixtures may be required to approve mixtures with ASCMs. The Utah DOT (UDOT) and Colorado DOT (CDOT) perform three of the listed tests; they have provided URLs for their ASCM specifications that can be found in Appendix B.

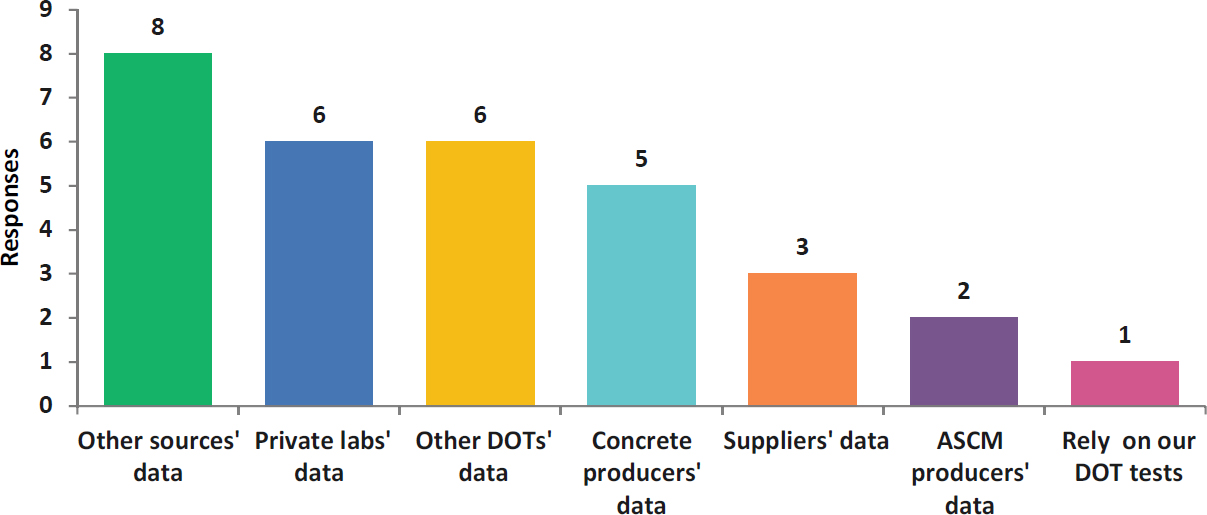

Other Sources of Acceptable ASCM Test Results

Eight states accept ASCM test result data from other (not specified) sources, six accept results from private laboratories and other DOTs, and five accept results from concrete producers (Figure 35). Appendix B provides information on responses of specific states that accept data from other sources to approve the use of ASCMs.

Field Trials of ASCMs

Two state DOTs, those of Minnesota and Utah, indicated that they currently support field trials of ASCMs. (More details are provided in the MnDOT and UDOT case examples in Chapter 4.) Another six states indicated that they will consider one or more field trials in the future, and the

Figure 35. Sources of accepted test result data.

Figure 36. Field trials for ASCMs.

remaining five states have not performed any field trials (Figure 36). Appendix B provides information on the responses of state DOTs and includes a URL for New York DOT’s specification on ground glass.

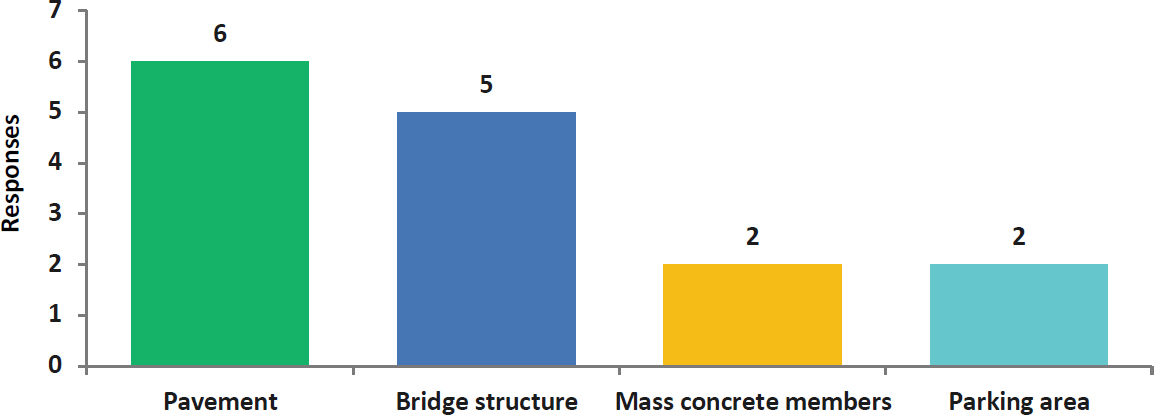

Field Trials Planned by State DOTs to Evaluate ASCMs

Figure 37 and Table 14 show responses from seven DOTs regarding planned field trials. The respondents plan to do field trials for pavements and bridges as well as mass concrete and parking areas. MnDOT shared the final report of its completed field trials and indicated that three more trials are underway (see MnDOT case example in Chapter 4).

Case Example Interviews

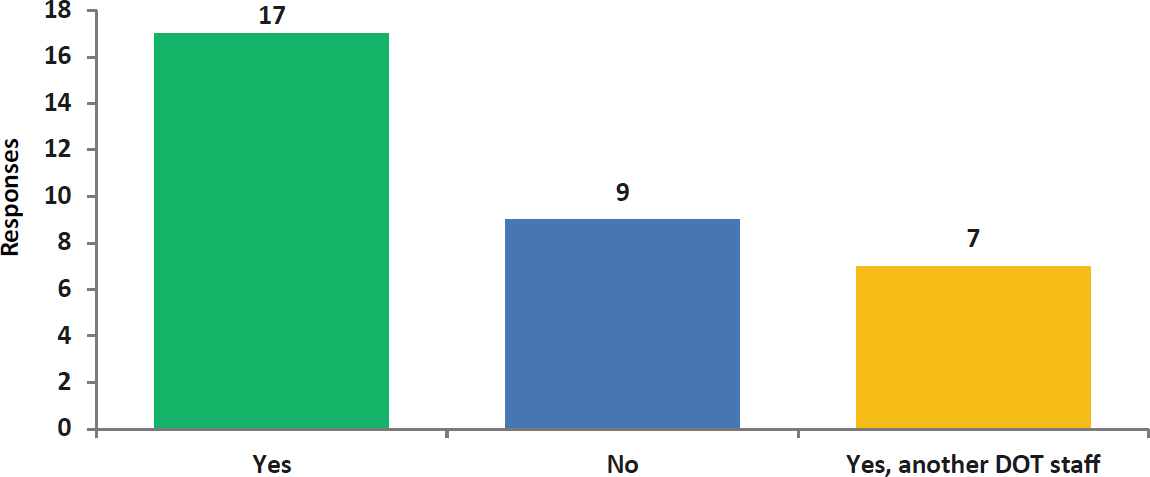

Participation in Case Example Interviews

Twenty-four DOTs agreed to be interviewed for the case examples (Figure 38); five were selected. Individual DOT responses are shown in Appendix B.

Figure 37. Planned field trials of ASCMs.

Table 14. Field trials by seven states.

| State DOT | Type of Field Trial |

|---|---|

| Minnesota | Pavement: https://www.dot.state.mn.us/mnroad/nrra/structureteams/rigid/sustainable-concrete-mix-selection.html |

| Arizona | Pavement and bridge structure |

| California | Pavement, bridge structure, mass concrete, and parking area. Location to be determined. |

| New York | Ground glass is planned to be used in a project with sidewalks in the 2024 construction season. |

| Ohio | Pavement bridge structure, mass concrete, and parking area. No trials yet. |

| Vermont | Bridge structure |

| Utah | Bridge structure |

Figure 38. Responses for follow-up interviews to prepare case examples.