Bridge Construction Inspection Training Resources and Practices (2025)

Chapter: 4 Case Examples

CHAPTER 4

Case Examples

Introduction

This chapter documents the key findings related to bridge construction inspection training resources and practices reported from case examples of six state DOTs that have considerable experience with bridge construction inspection. After explaining the selection of agencies for the case examples, this chapter provides readers with details on how selected state DOTs train and set qualifications for the bridge construction inspector workforce. Each case example contains the following sections: organization structure of bridge construction inspection, bridge construction inspection training, training effectiveness and resources, benefits and challenges of bridge construction inspection training, and experience and findings.

Selection of Case Examples

Using the following criteria, data collected from the literature review and the survey questionnaire were used to identify state DOTs for further study:

- Years of experience/number of bridges under construction

- Comprehensiveness and availability of inspection guidance for bridge construction inspection

- Types of resources and tools for training bridge construction inspectors

- Whether the DOT differentiates between bridge construction inspectors and general construction inspectors

- What AASHTO region the DOT is located in

- The willingness of agency personnel to participate in the study, as determined by the survey responses.

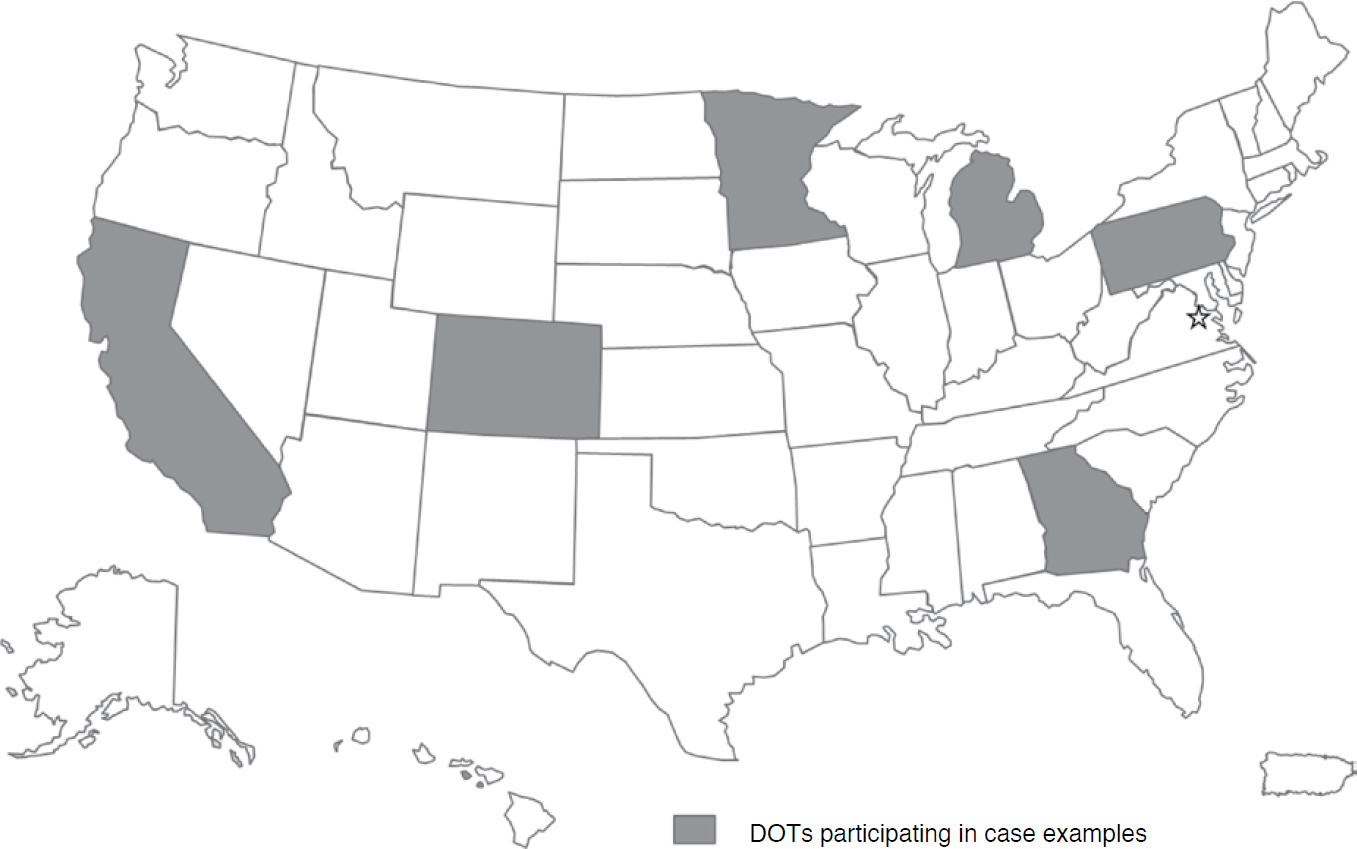

After applying the specified criteria, the synthesis team initially identified 12 state DOTs to potentially serve as case examples. The team reached out to these DOTs through a combination of phone calls and emails. Following the outreach efforts and considering the availability of DOT staff, six DOTs ultimately took part in the study: those of California, Colorado, Georgia, Michigan, Minnesota, and Pennsylvania (see Figure 39). The participation of these DOTs entailed conducting structured interviews with knowledgeable staff regarding bridge construction inspection training. The synthesis team further refined the case examples by gathering relevant documents and reports and then cross-referencing the findings with state staff to ensure accuracy.

Each DOT was interviewed using the same list of questions. The questions were structured around the six sections of the questionnaire: (1) overview of bridge construction inspection, (2) organization structure and responsibilities for bridge construction inspection, (3) training for bridge construction inspection, (4) training effectiveness and qualification/certification for bridge construction inspection, (5) training opportunities, benefits, and challenges of bridge construction inspection, and (6) final thoughts. The questionnaire for the case examples is available in

Appendix C. This chapter presents the case example findings aligned with the order of the interview questions.

California Department of Transportation

The California DOT (Caltrans) averages between 100 and 200 bridges being under construction in any given year, with another 100 to 200 bridges having maintenance performed. With the number of bridges to construct and maintain annually, Caltrans requires personnel to inspect bridges properly and efficiently. In-house DOT and consultant construction bridge inspectors are used, with about 10% to 15% of inspections performed by consultants across the state. The Structure Construction subdivision within the Division of Engineering Services handles the inspections of bridges during construction. The entire Structure Construction subdivision has about 500 individuals, and a resource exercise is conducted annually to determine the workforce needs for the upcoming year. The Structure Construction subdivision supports all districts statewide for any structural construction work.

The 12 districts within Caltrans manage the construction of projects. Resident engineers in each district look through the bid items for a project to split the work up into district roadway work and central office structure construction work. Inspections of the work are also separate, in that district roadway inspectors inspect the roadway work while structure construction inspectors inspect all structure work, including bridges.

Organization Structure of Bridge Construction Inspection

The Structure Construction subdivision has area managers overseeing the state’s geographical regions, including the districts within those regions. Each area manager has senior

bridge engineers who assist them with managing specific areas of the region. Maps are provided to each district so they know who the area manager and bridge engineers are for the district, thereby offering complete transparency between the central office and the districts. Then, structural representatives and bridge inspectors in each geographical area are assigned to projects based on availability. When internal personnel are not available, this is offset by consultant inspectors. The structural representatives are licensed engineers; all who are below them are assistant structural representatives or inspectors. The resident engineer leads the project, but the structural representative assists the resident engineer with the structural portions of the project, including inspections.

All bridge construction inspectors at Caltrans are in transportation engineer positions. There are three levels of minimum qualifications for transportation engineers at Caltrans. Level 1 qualification requires a 4-year civil engineering degree from a program accredited by the Accreditation Board for Engineering Technology (ABET). Level 2 qualification requires a degree in an engineering discipline covering basic engineering courses as well as the passing of a written examination to prove the individual’s understanding of engineering fundamentals. Level 3 qualification requires a master’s or doctorate degree in civil engineering from a program that is ABET accredited.

In discussions with Caltrans Structure Construction personnel, the primary daily responsibilities of construction bridge inspectors are observing and documenting structural work, ensuring that the work is in accordance with the contract documents, attending weekly meetings, reviewing schedules and work plans, and providing plan reviews for the structural portions of the project. For any aspect of a project that includes structures, the construction bridge inspectors are on site to observe and inspect the work. To assist with daily responsibilities, Caltrans has its Bridge Construction Records and Procedures Manual, which provides Structure Construction staff with specific policies, processes, procedures, expectations, technical guidance, and specification interpretation to properly perform project administration and bridge inspections. The manual includes a series of bridge construction memos (BCMs) that detail the specific steps and processes to follow in all aspects of bridge construction, including proper ways to conduct inspections of structures during construction.

Bridge Construction Inspection Training

Annual training is conducted for construction bridge inspectors at Caltrans. The winter training offered rotates through seven core topics, with one topic covered in detail each year. The topics are falsework, trenching and shoring, foundations, concrete, prestress, rehabilitation, and building construction. Caltrans also has a manual for each topic that is used for training and in the field. The Structure Construction subdivision facilitates winter training with its SMEs and updates and maintains the materials for each topic. Additionally, part of the winter training is for inspectors to learn about Caltrans’ quality management system, which is based on ISO 9001 and was implemented about 5 years prior to this writing. Inspectors are a big part of ensuring a constructed facility’s quality, and understanding the quality management system is essential to performing the responsibilities of a construction bridge inspector.

The winter training includes all Structure Construction staff plus consultants and is conducted in person over 14 to 15 different classes using PowerPoint slides and the associated manual for the topic. The slides are provided to the trainees as PDF files. A pre-test and a post-test are used to evaluate the inspector trainees on what they have learned. Structure Construction also asks for feedback at the end of each winter training course to determine what worked and what can be improved for future training. Structure Construction also inquires about specific areas that should be taught in the rotating seven topics. The feedback is helpful for updating the training and the associated manuals.

Caltrans has recorded the winter training sessions. The recorded sessions are then available to Caltrans staff to view on demand. CT Learns is an internal website that houses all the recorded

winter training sessions, and Structure Construction can track who is taking the training through CT Learns. Structure Construction is in the process of getting more training online but is still using the same process of a pre-test and post-test given to trainees before and after they view the online training.

Other training is offered to inspectors through the Division of Construction, which provides training for project administration, such as for change orders and risk management. Caltrans personnel mentioned that they train inspectors in technical and soft skills, such as communication and conflict resolution. In addition, Structure Construction staff are trained to be resident engineers for projects with high numbers of structures and bridges in the scope of work. Therefore, inspectors in Structure Construction can work to be resident engineers through Caltrans’ resident engineer certificate program.

Caltrans has no in-house certification program for construction bridge inspectors but uses ACI certification for all concrete work. Therefore, construction bridge inspectors are required to be certified by ACI to perform inspections. All other areas of structures are covered in the winter training topics, but completing the training does not result in a formal certification.

Training Effectiveness and Resources

Caltrans personnel mentioned that they have a key performance indicator that tracks their Structure Construction inspection staff to ensure that they are trained in areas essential to current and upcoming work. By this means, Structure Construction can ensure that if inspectors have not been taught certain core areas, they can provide that training. Furthermore, training for bridge inspectors in the fundamentals of structural construction work is important, but inspectors also need to learn how to use new technologies for conducting inspections. Therefore, updates have been made by Structure Construction staff to include technologies in the winter training.

The Structure Construction subdivision has a variety of manuals to assist with all aspects of structures and bridges for a construction project, which include the following:

- Bridge Construction Records and Procedures Manual

- Bridge Deck Construction Manual

- Bridge Removal Manual

- Building Construction Manual

- Concrete Technology Manual

- Controlling Shrinkage Cracking

- Falsework Manual

- Foundation Manual

- Glossary of SC Quality Management Terms

- Outline of Field Construction Practices

- Prestress Manual

- Reinforced Concrete Construction Manual

- Trenching and Shoring Manual

- Structure Construction Bridge Construction Survey Manual

- Structure Construction Quality Manual.

Benefits and Challenges of Bridge Construction Inspection Training

One of Caltrans’ primary challenges for construction bridge inspectors is the level of experience and turnover. Structure Construction personnel mentioned that about 60% of the subdivision staff has less than 4 years of experience. Additionally, Caltrans noted that they are hiring inspectors. However, it seems that as they hire inspectors, others leave after a few years due

to other opportunities in the construction industry. Once Caltrans invests a few years in an inspector and they leave, Caltrans starts over with new employees. However, the Caltrans quality management system captures and manages knowledge so that an experienced inspector’s knowledge does not leave the department once that person leaves or retires; the knowledge can be transferred to new inspector employees.

While Caltrans faces retention and turnover issues, it has successfully attracted new talent by advertising that the work is outdoors and that individuals get to work on exciting projects that improve communities. Additionally, Structure Construction personnel mentioned that they have an open and transparent culture and a positive work environment that supports employees, which helps to keep employees long term. New Structure Construction hires at Caltrans undergo a mandatory rotation program over the first 2 years of employment to be exposed to different parts of project delivery and operations. This rotation program covers different areas of design and construction, such as bridge design, materials, project management, and hydraulics. In addition, bridge construction inspectors have the ability to move into a resident engineer role or become an SME for the winter training program, which has helped with retaining experienced employees.

Experience and Findings

From the experiences of Caltrans staff involved with bridge construction inspection training, there are findings to share to help others with their training program and associated processes, procedures, and resources. The findings from Caltrans include the following:

- Update training regularly: Caltrans mentioned that for training to be effective, training materials need to be current and relevant. The training approach and materials need to be something that helps bridge inspectors do their job better. Structure Construction uses its subject-matter experts to help update the training and the associated manuals.

- Use manuals and other documents as resources: Caltrans has produced many documents related to structural construction components used for training and in the field. The manuals provide specific processes and approaches for all project administration and inspection areas. The BCMs outline the steps to follow to conduct responsibilities properly.

Colorado Department of Transportation

In 2023, Colorado DOT (CDOT) identified 252 bridges for replacement/new construction and 634 bridges for widening and rehabilitation (The American Road & Transportation Builders Association 2023). The Construction Support and Fabrication Inspection Unit is a resource for CDOT structure construction projects statewide and is responsible for:

- Providing support during structure construction;

- Quality assurance inspection during fabrication of structural components;

- Identifying and proposing mitigation strategies to structure construction claims, failures, errors, and deficiencies;

- Increasing bridge and structure construction safety;

- Enhancing design and details to improve constructability and field clarity;

- Inspecting, reporting, and providing assistance during major bridge construction events (e.g. girder erection and bridge deck concrete pours);

- Maintaining the fabrication inspection manuals and the quality assurance procedures referenced by the manuals;

- Inspecting Colorado-based fabrication plants prior to any fabrication for acceptability of fabrication processes, material handling processes, and the quality control plan; and

- Inspecting out-of-state fabrication plants prior to any fabrication if budget and qualified personnel are available (CDOT 2024).

Organization Structure of Bridge Construction Inspection

CDOT has a 50/50 mix of in-house and consultant construction management teams. Project teams are assembled based on availability and project location. A construction management team can sometimes be all consultants if no in-house personnel are available. The resident engineer leads the construction management team and is assisted by project engineers. In terms of inspectors, CDOT does not differentiate between bridge inspectors and general inspectors. Inspectors are a part of the construction management team, and they are assigned full-time to a project to observe and inspect all work, including the structural bridge work. However, more experienced inspectors or those with expertise in bridge inspection are typically assigned to the bridge and structure inspection responsibilities of a project. The size of the inspection team depends on the size and scope of the project. A bridge replacement project would have fewer inspection staff than a major interchange project. Some projects may have full-time materials testing personnel as a part of the inspection team.

The common responsibilities of a bridge inspector at CDOT are observing, inspecting, and testing the work; documenting inspections and filling out daily logs; compiling quantities for payment; taking photos and videos; reviewing submittals; comparing the work to the contract documents; and checking dimensions. Project engineers typically also help perform the field documentation. CDOT has slowly introduced tablets in the field for inspectors to use in performing tasks. Daily logs are completed using a fillable PDF form.

While CDOT does not have different levels of inspectors, it does have different pay grades for inspectors once an inspector works for CDOT for a certain amount of time. The more time spent as a CDOT inspector, the more pay and responsibilities one receives. Pay raises are not tied to knowledge or certifications. Furthermore, the educational background of bridge inspectors varies, from a high school diploma to a 4-year degree in civil engineering. Those inspectors without a civil engineering degree are required to pass a series of exams related to math, plan reading, and other areas critical to bridge inspections.

Bridge Construction Inspection Training

Bridge inspector training includes OJT and formal classroom training. OJT is conducted informally and pairs more experienced bridge inspection personnel with new hires to teach field responsibilities. The formal classroom training is CDOT’s bridge inspection training program, facilitated by the Bridge and Structures Inspection Unit staff. The inspection training program was developed to teach bridge and consultant inspectors to increase their knowledge and understanding of structural and bridge construction projects. The training includes discussions of commonly identified quality assurance and quality control challenges, including high-risk structural construction elements, critical points requiring additional documentation and inspection, and how to anticipate, mitigate, and manage the structural construction elements of a project. The topics covered in the bridge inspection training are listed in Table 11. While structural engineering is important to bridge inspections, the materials focus on the practical applications of how structures are built and where things can go wrong when inspecting the constructed structures.

Third-party consultants helped CDOT develop the materials for the bridge inspection training, while licensed professional engineers, who are subject-matter experts from the Bridge and Structure Inspection Unit, teach the topics to inspection employees. CDOT conducts the training in person and tries to work its way around to each of the five regions to perform the training across the state. Typically, CDOT runs the training program four times a year, twice at the CDOT headquarters and twice scattered around the regions of the state. After the 2-day training program, attendees are given a survey to provide feedback on what worked and what can be improved.

Table 11. CDOT bridge inspection training agenda.

| Day 1 | Topic |

|---|---|

| 8:00 a.m. | Check-in/Introduction |

| 8:30 a.m. | Deep Foundations—Driven Piles |

| 9:30 a.m. | Break |

| 9:45 a.m. | Deck Rehab |

| 10:30 a.m. | Break |

| 10:45 a.m. | Deck Construction |

| 11:30 a.m. | Lunch Break |

| 12:30 p.m. | Deep Foundations—Caissons |

| 1:45 p.m. | Break |

| 2:00 p.m. | Overhead Sign Structures |

| 3:00 p.m. | Conclusion |

| Day 2 | Topic |

| 8:00 a.m. | Check-in/Introduction |

| 8:15 a.m. | Expansion Devices |

| 9:15 a.m. | Break |

| 9:30 a.m. | Girder Erection |

| 10:15 a.m. | Break |

| 10:30 a.m. | MSE Walls |

| 12:00 p.m. | Lunch Break |

| 1:00 p.m. | Bridge Demolition |

| 1:45 p.m. | Break |

| 2:00 p.m. | Temporary Shoring |

| 3:00 p.m. | Conclusion |

CDOT leadership initiated the training program with support from the five CDOT regions to educate bridge inspectors on the core elements of structure construction and how to inspect these elements properly and effectively without any problems occurring. The program aims to improve the quality of in-house and consultant inspection staff. The program has no testing components, and passing the course is based on attendance.

CDOT staff and consultants have collected data on bridge and structure inspections for the past 2 years. The data help Bridge and Structure Inspection Unit staff look for patterns of issues or problems in bridge inspections so that these issues can be addressed in the bridge training program. The training program is dynamic in that materials are updated regularly to address inspection changes, and new materials are added.

Other training outside of bridge inspection is available to bridge inspectors at CDOT. These training options are geared more toward project administration and construction operations such as scheduling. This training is led by construction personnel.

Training Effectiveness and Resources

CDOT uses a performance measure to track the number of people taking the bridge inspection training. However, the program is only 2 years old, and CDOT staff have not used the data yet. CDOT personnel mentioned that once there are enough data, they would like to compare the number of inspectors taking the course to the number of problems occurring in inspections in each region to see if having more inspectors trained results in fewer issues arising in bridge inspections.

CDOT has a variety of bridge and inspection manuals and guides to assist with performing structure and bridge inspections properly and effectively. For example, the Colorado Bridge Inspection Manual provides the specific CDOT policies and procedures used to inspect bridges (called major structures), minor structures, and miscellaneous structures on CDOT roadways.

Benefits and Challenges of Bridge Construction Inspection Training

One of the challenges CDOT is facing with its bridge inspection training program is converting it into a certification program. Additionally, CDOT mentioned that recruiting and hiring bridge inspectors and professional engineers is a challenge. There are many opportunities for technicians and engineers in the construction industry that offer higher salaries. However, CDOT noted that many of the bridge inspectors took the job at CDOT due to a good work–life balance. Further, CDOT has successfully hired interns who convert to full-time employees once they graduate.

The benefits mentioned by CDOT personnel are that the regions and inspectors like the course based on the feedback received from the end-of-course survey, and they like that staff come to them in the regions to conduct the training rather than having to drive to headquarters in Denver. Attendance is higher for the regional training classes as it is easier for inspection personnel to attend when a class is close by. Additionally, the survey feedback has led to providing new topics to the training program as inspection staff are asking for training in areas such as caissons and pile driving.

Experience and Findings

From the experiences of CDOT staff involved with construction bridge inspector training, there are findings to share to help others with their training program and associated processes, procedures, and resources. The findings from CDOT include the following:

- Creating a bridge inspection training program is worthwhile: CDOT staff mentioned that the training program, while still in its infancy, has been a success. Inspectors like the training, and it has been helpful to make bridge inspections more consistent and effective. While it takes resources and time, CDOT realizes that this is a crucial program to the success of projects that have structural elements.

- Providing resources: The Bridge and Structure Inspection Unit has staff available to help inspectors, and the various manuals and guides provide inspectors with direction in the field to accomplish bridge inspection tasks. The resources are updated based on current conditions and are crucial to effectively performing bridge inspections.

Georgia Department of Transportation

GDOT has seen an increase in bridge replacement projects over the last several years, with 35 bridge replacement projects in 2020 increasing to 154 in 2022. With the uptick in bridge replacement projects, GDOT requires a bridge inspection workforce to ensure that the work is completed per the plans and specifications. The Office of Bridge Design and Maintenance is in charge of bridge inspections, and the office develops the plans for bridge improvement projects, conducts emergency repairs and replacements of bridges, performs permit reviews, evaluates damage to bridges, and conducts various bridge inspections to ensure that all bridge structures meet the highest standards of safety.

Organization Structure of Bridge Construction Inspection

Depending on availability, GDOT uses a mix of in-house and consultant bridge inspectors. Consultant inspectors represent about 65% of the inspection workforce, with the other 35% being in-house inspectors. All bridge inspectors, in-house and consultants, perform the same duties for a project. Typically, the project manager for a project is a GDOT employee who oversees the inspection workforce. More experienced bridge inspectors, whether in-house or consultants, are

typically used for larger projects with lots of structures. The size of the inspection team depends on the size and scope of a project, as larger and more complex projects, such as interchange projects that involve numerous structures, require more experienced inspection personnel than small bridge replacement projects.

GDOT has different inspection positions, ranging from entry-level (e.g., Inspector 1, Inspector 2) to intermediate (e.g., Inspector 3, Inspector 4), up to senior or advanced level (e.g., area manager). Each team for a project may include the project manager, area managers, assistant area managers, and a variety of inspectors, from senior level, who lead the inspection processes, to entry-level, who assist the more experienced inspectors. Advancing in inspection positions is based on the amount and type of experience. For example, an entry-level inspector who has worked on several bridge projects may be able to move into an intermediate bridge inspector role. Moving into an advanced bridge inspector role takes even more experience on numerous bridge projects before one is considered for position advancement.

In-house inspectors are trained to inspect both the general components of a project (e.g., pavements) and the structural components of a project. GDOT has specialty bridge inspectors, but they are also expected to be able to inspect all components of a project, not just bridges, due to the limited pool of inspectors GDOT has at its disposal. Consultants are assigned to four different bridge inspector positions, each based on specific requirements, so that GDOT knows it has the right consultant inspectors on a project. Consultant inspectors are expected to be able to inspect all components of a project, including bridges and other structures.

The common responsibilities of an entry-level inspector at GDOT, whether in-house or consultants, include testing materials such as concrete in the field, understanding plans and how to scale/measure, and verifying the installation of structural components such as rebar. The intermediate inspectors have a more involved role and are expected to have a quality understanding of the bridge plans and specifications so that they can perform thorough and detailed inspections of structural components. Advanced senior inspectors are in supervisory roles, managing the intermediate and entry-level inspectors and overseeing the complex structural aspects of a project, such as pile driving. Some project types that involve complex foundations or structural components are not assigned entry-level inspectors as these types of components need to be observed, documented, and inspected by more experienced inspectors.

Bridge Construction Inspection Training

GDOT uses a combination of on-the-job and classroom-based training along with mentoring of entry-level inspectors. OJT is the most common type of training, where GDOT pairs experienced inspectors with entry-level inspectors to impart bridge inspection knowledge to the newer employees. The self-paced training, called Construction Engineering Inspection Training, includes three different groups of courses, as shown in Table 12. Each of the topics in each group has a guidance manual to support the training in these areas, which can be found here: https://www.dot.ga.gov/GDOT/Pages/certificationtraining.aspx#tab-2.

Group 3 includes the bridge inspection training. This training includes the Construction Engineering Inspection Training—Bridges Inspection Manual. The manual provides the training

Table 12. GDOT construction engineering inspection training groups.

| Group 1 | Group 2 | Group 3 |

|---|---|---|

| General Provisions | Pavements | Earthwork |

| Auxiliary Items | Bases and Subbases | Incidental Items |

| Basic Highway Plan Reading | Minor Drainage Structures | Bridges |

| Basic Highway Math | Construction Erosion Control |

contents, which are listed in Table 13. For each topic listed, the manual includes information on how to test and inspect the structural components of a bridge project. For example, Section 501 is for inspecting steel structures. This section outlines the steps to prepare for the inspection and the components for inspection, which include bolts, welds, and straightening material, along with information for payment of work after inspection.

GDOT holds annual bridge inspection training in each of the seven districts across the state, which is done in person. In-house construction personnel in each district are required to attend, and consultants are also required to attend. The district inspection training covers the basics of inspecting bridges and structures. The annual training program focuses on the inspection side of bridge projects, including how to observe, inspect, and test the work, but also includes basic construction operations such as proper sequencing.

In addition, GDOT has recently implemented an advanced bridge training program focusing on the finer details of bridge construction and inspection. GDOT identifies three to four individuals from across the districts who have shown potential for career advancement in bridge inspection. At the time of this writing, GDOT is conducting the second round of the advanced inspection training, which takes about 6 months to complete through various bridge inspection–related sessions. The advanced bridge training program was created based on feedback from GDOT employees wanting more training. At this time, the advanced inspection training is for in-house personnel only.

GDOT also has web-based training available to all GDOT and associated consultant inspectors through the internal Training Office. GDOT sometimes hosts a web-based NHI course. GDOT would like to do more with web-based training and other national training programs if budgets allow.

GDOT mentioned that it has identified additional areas for training based on employee feedback. For example, personnel identified issues with welding and welding inspections. Therefore, a separate training course was developed to address these issues and provide construction and inspection staff with more welding knowledge.

GDOT inspectors must meet certain qualifications, regardless of whether the inspector holds a civil engineering degree. There are a series of classes to take that include an exam that must be passed to become qualified. Most of these classes and exams are self-study, and inspectors complete them independently. Inspectors with a civil engineering degree are only required to pass the

Table 13. Contents of GDOT Construction Engineering Inspection Training—Bridges Inspection Manual.

| 500 Concrete Structures | 516 Aluminum Handrail |

| 501 Steel Structures | 520 Piling |

| 502 Timber Structures | 522 Shoring |

| 504 24-Hour Accelerated Strength Concrete | 525 Cofferdams |

| 505 Corrugated Steel Bridge Plank | 528 Epoxy Pressure Injection of Concrete Cracks |

| 506 Expanded Mortar | 529 Navigation Lighting |

| 507 Prestressed Concrete Bridge Members | 530 Waterproofing Fabrics |

| 508 Asphalt Plank Bridge Floor | 531 Damp Proofing |

| 509 Prestressing Concrete by Post-Tensioning | 533 Bridge Deck Waterproofing Membrane |

| 510 Protective Platforms | 535 Painting Structures |

| 511 Reinforcement Steel | 540 Removal of Existing Bridge |

| 512 Shear Connections | 541 Detour Bridges |

| 513 Precast Reinforced Concrete Box Culverts Barrel Sections and End Sections | 542 Contractor Proposed Alternative to Reinforced Concrete Deck Girder |

| 514 Epoxy-Coated Steel Reinforcement | 543 Bridge Complete |

| 515 Handrail-Ferrous Metal and Pipe |

erosion control and concrete training. However, inspectors without a civil engineering degree are required to pass exams in more areas, such as those listed in Table 13.

GDOT personnel mentioned that they have started to use specific YouTube videos from other transportation departments for various components of bridge inspection. The YouTube videos are helpful because inspectors can watch them at their convenience and then ask questions about them afterward. The videos are short, so they are easily digestible. Furthermore, GDOT uses Bluebeam construction software in its training so that inspectors can learn the basics of scaling and measuring within Bluebeam.

GDOT has three in-house trainers who handle inspection training across the state. These instructors are qualified to train inspectors based on their extensive experience in bridge construction. One of the GDOT trainers has worked in bridge construction for over 30 years. These trainers have experience in OJT and classroom training. With their knowledge and years of experience, the trainers are the subject-matter experts for GDOT regarding bridge inspections.

Training Effectiveness and Resources

At the completion of the district training and the advanced training class, GDOT performs an evaluation to determine if the training has produced improvements in the field. The GDOT representative noted that certain inspectors have demonstrated progress and have effectively retained the knowledge gained during training. According to GDOT personnel, untrained inspectors frequently seek guidance when they encounter unfamiliar situations. Once trained, inspectors are able to confidently assess and address such scenarios. Trained inspectors are adept at providing solutions, whereas untrained inspectors may struggle to determine the appropriate course of action.

GDOT tracks the attendance of its training programs. The performance metric is to have 75% of all construction staff attend the training annually. Typically, GDOT reaches around 90% of construction staff being trained.

GDOT has a variety of manuals and guidance documents to assist inspectors in inspecting and testing structures and bridges for highway construction. The following lists the manuals and guides that include information for assisting with bridge inspections:

- Construction Manual: Includes sections of information for construction inspections and final inspections.

- Bridge, Culvert, and Retaining Wall Construction Manual: This manual intends to aid project engineers and inspectors in inspecting bridges, culverts, and retaining wall construction. The bridge section of the manual includes information for foundations, substructures, and superstructures.

- Construction Engineering Inspection Training—Bridges Inspection Manual: Includes inspection information and processes for various structural bridge components of a project. In addition, GDOT has a Sampling, Testing, and Inspection (STI) section (https://www.dot.ga.gov/GDOT/pages/TheSourceSamplingTestingInspection.aspx) that provides information on the correct sampling and testing procedures and standard operating procedures to follow for a variety of construction components, including bridge and structure elements. The STI also has a set of quick guides that outline different inspection approaches to use depending on the construction type.

Benefits and Challenges of Bridge Construction Inspection Training

GDOT has recently been using Microsoft Teams to share information virtually, which has been beneficial in sharing critical inspection information in real-time, whether it be documents,

photos, plan sheets, or other information for a specific bridge inspection situation. Microsoft Teams has helped GDOT address issues more quickly than in the past. In addition, GDOT has a lessons-learned platform where any employee can record specific scenarios and situations, such as what happened, how it happened, and how it was resolved. The lessons-learned platform is for all aspects of GDOT operations and includes some information related to bridge inspection situations that have occurred.

One challenge highlighted by GDOT personnel is the turnover of bridge inspectors. Senior inspectors retire and are succeeded by less experienced individuals who require training. However, after being trained and gaining a few years of experience, inspectors sometimes pursue other opportunities, such as with consulting firms. GDOT mentioned that it is hard to keep qualified staff as there are many opportunities in the construction industry today. To help offset the turnover issue, GDOT often sees that consultants hire DOT retirees who perform the same work on bridge projects but as consultants rather than GDOT employees.

One aspect of recruiting that has helped GDOT with turnover is its internship program. The program is statewide and not specific to bridge inspection. The internship program follows a rotation across different offices within GDOT so that interns get a taste of how things work. Interns in the Office of Bridge Design and Maintenance are placed in the field at some point to observe and shadow personnel conducting bridge construction and inspection activities. One advantage is that interns have the opportunity to assess their compatibility with the job responsibilities, work environment, and overall experience. The ones who like the work may be hired for full-time positions once they graduate.

Experience and Findings

The findings from GDOT include the following:

- Annual training is key: GDOT personnel highlighted the importance of GDOT’s yearly inspection training program. Because of the training, inspectors are more knowledgeable, and having the training each year keeps them updated on current inspection processes and approaches.

- Training subject-matter experts: GDOT employs three inspection trainers who travel across the state to visit projects and aid inspectors with their duties. These trainers play a vital role in helping inspectors retain and apply the knowledge gained from training. Inspectors who receive training from these subject-matter experts also serve as mentors and are available to offer assistance whenever needed.

Michigan Department of Transportation

The Michigan Department of Transportation (MDOT) oversees an extensive and multifaceted bridge construction program that includes preservation, rehabilitation, and new build projects. MDOT manages these projects through a decentralized system of 22 Transportation Service Centers (TSCs), each responsible for the construction activities within their designated areas. TSCs in more urbanized areas may only include one county, whereas more rural centers could manage five or more counties.

MDOT would typically have 80 to 100 open bridge-related contracts within a normal year. These would be construction contracts for work, including rehabilitation, repairs, replacements, or new construction, and could range in project stage from recent award to project closeout. However, due to recent bonding executed by MDOT, it currently has over 350 active and open bridge contracts.

Organization Structure of Bridge Construction Inspection

Bridge construction inspection within MDOT involves a hierarchy of technical staff and engineers. For MDOT in-house staff at the TSCs, the core construction technical staff range from entry-level (Tech 8) to senior-level (Tech 12) inspectors. In each TSC, there is typically one senior-level (Tech 12) inspector, a couple of additional lead-level (Tech 11) inspectors, and a balance of entry- to mid-level (Tech 8–10) inspectors. The mid- to senior-level (Tech 10–12) inspectors often have the necessary expertise and experience related to structural construction and oversee projects to ensure adherence to standards. For these projects, it is recommended that the in-house inspectors have the Bridge Construction/Rehabilitation Inspection and Bridge Paint training course, but it is not required. The TSCs also have engineering staff with a lead engineer and an assistant to support the management of these projects with technician inspectors.

Additionally, MDOT will use consultant construction inspectors and engineers. For consultant inspectors who will be on bridge construction projects, there are training and experience requirements as part of the consultant selection and prequalification process. Consultants are required to take the MDOT Bridge Construction/Rehabilitation Inspection and Bridge Paint course.

Whether the bridge project entails in-house or consultant inspection, this inspection is supported by the central office Bureau of Bridges and Structures Bridge Construction section (BoBS Construction). The BoBS Construction team consists of the chief bridge construction engineer, the statewide bridge construction engineer, the bridge rehabilitation engineer, and three senior technicians. The BoBS Construction team assists in providing technical support across all bridge construction operations. Each of the three senior technicians has a specialization stemming from their expertise and experience, including in steel, concrete, and paint or coatings. While specialized, these technicians have the expertise necessary to support bridge inspection across all topics. These technicians generally handle specific TSC areas and can support one another when their detailed expertise is needed. Based on the level of support needed or available by TSC or consultant experience, the central office support role can vary from project to project and can include requests by project inspection staff. If significant problems arise, the BoBS Construction section engineers are involved in the issue.

Bridge projects vary significantly in complexity, from simple overlays to intricate multi-span bridges. Central office engagement and inspection frequency and intensity are adjusted according to project demands, ensuring that all projects receive adequate support. The BoBS Construction team’s support includes providing OJT to the project inspection staff, mentoring, and calling attention to supporting resources and training as needed.

Bridge Construction Inspection Training

The MDOT Bridge Construction/Rehabilitation Inspection and Bridge Paint training and associated certification is a 3-day course; one day is dedicated to the inspection of new structure construction, one day is dedicated to the inspection of structure rehabilitation, and one day is dedicated to the inspection of painting and coatings. This training is taught by the engineers and technicians from the BoBS Construction team, matching the delivery of training content with the expertise of the engineer or technician. This training is offered two to three times annually to 150 to 200 inspectors. The training is classroom based and provides the basic understanding and knowledge of resources to support bridge inspection, although experience is needed to reach proficiency in bridge construction inspection. This training is supported by OJT and mentoring from the central office. The training involves a competency exam that participants must pass for certification. The certification is active for 5 years, and recertification requires repeated completion of the 3-day training.

A description of the training as provided by MDOT is as follows:

The Bridge Deck Construction Inspection portion of this course is intended to educate field staff on the proper inspection techniques and best practices associated with bridge construction. Topics include:

- Overview of Structures and Terminology

- Inspection Forms

- Construction Manual

- Standard Specifications

- Pour Sequencing

- Haunch Grades

- Beam Erection and Reinforcing Steel

- Concrete Pours and Cure Requirements

- Common Mistakes and Troubleshooting.

The Bridge Construction/Rehabilitation Construction portion of this course educates field staff on major aspects of bridge construction and rehabilitation. It is intended to improve comprehension of basic terminology, best practices, and interpretation of MDOT’s Standard Specifications related to bridge rehabilitation. Topics include:

- Bridge Scoping

- Standard Specifications

- Foundation and Substructure best practices

- Substructure Patching

- Beam Repair (Concrete, Steel, Pin and Hanger)

- Deck Patching

- Deep and Shallow Overlays

- Epoxy Overlays

- Expansion Joints

- Deck Removal

- Pressure Relief Joints

- Pour Sequences and Setting Haunch Grades.

The Bridge Paint portion of the course is designed to prepare attendees for the inspection of bridge painting projects. It covers corrosion, paint systems, paint equipment, surface preparation, field cleaning and coating, inspection procedures and equipment, documentation and reports, environmental regulations concerning removal of lead paint, and specifications for bridge cleaning and coating.

In addition to the 3-day training course, MDOT offers 30-minute to hour-long online training sessions on specialized topics, including fabrication, bolting, geotechnical inspection, and more-detailed training for coatings. MDOT has found in-person training to be more effective unless the topics are specialized and focused for online sessions. Specialized training continues to be developed as new topics are found to be needed.

Training Effectiveness and Resources

MDOT prioritizes continuous training and professional development for its bridge construction inspectors. The agency uses a three-step teaching process: understanding the specification, comprehending the rationale behind the specification, and applying the rule to real-world conditions. MDOT has observed the effectiveness of its training approach through noticeable differences in conducting inspections between those who are trained and those who are not trained. One example of the noted effectiveness of the training is a case where an inspector identified a problem after receiving the training. As a result, the issue was corrected before it could affect the long-term integrity of the structure.

The 3-day training entails presentations and discussions using many visuals. A large component of the training involves hands-on learning using samples and the actual use of inspection tools and testing mechanisms.

Benefits and Challenges of Bridge Construction Inspection Training

The decentralized structure of MDOT’s inspection program offers several benefits, including localized expertise and rapid response to emerging issues. Inspectors and engineers are well-integrated into their communities, fostering a sense of ownership and responsibility. However, this structure also presents challenges, such as ensuring consistent training and maintaining high standards across diverse geographic regions. Potential for turnover and varying project availability add to the complexity, requiring adaptable and continuous training approaches.

Providing training, OJT, mentoring, and field support requires a substantial amount of work and time from the central office bridge construction group. As the MDOT program grows, it is a challenge to have enough qualified and experienced people to provide inspections, and resources become stretched. This places even more emphasis on having a quality training program to build consistency and alignment across the state.

Experience and Findings

The bridge construction inspection program at MDOT is distinguished by its strong structural framework, extensive training program, and a focus on mentorship and real-time problem solving. MDOT’s training program continues to improve and expand. This was noted as being fundamental to a quality training program by MDOT; training needs to evolve, as does technology, so a training program must not be stagnant. MDOT suggests that a DOT’s greatest assets are its people and their experience, and training is an investment in them. MDOT believes that a training program can begin by first identifying problem areas and developing training to solve the major problems first.

Minnesota Department of Transportation

MnDOT is responsible for managing a complex network of transportation infrastructure. MnDOT’s responsibilities include the maintenance, construction, and inspection of numerous bridges across the state. This responsibility is managed through seven districts and one metro area distributed throughout Minnesota, each acting somewhat independently to cover its designated area. Additionally, Central Bridge Engineering within the Central Bridge Office is ultimately responsible for all bridges and structures in the state. The Central Bridge Engineering office assists the state construction staff in these responsibilities.

MnDOT is responsible for the Interstate and trunk highway portion of the system, which amounts to about 15 to 20 new bridges and rehabilitation projects per year. Depending on local office workloads, the inspection of these structures may be handled using in-house staff or through hiring consultant inspectors. MnDOT’s major projects or more complex projects typically use consultant inspection with MnDOT oversight.

Organization Structure of Bridge Construction Inspection

As has been noted, MnDOT’s bridge construction inspection workforce is composed of both in-house staff and consultants. MnDOT in-house construction inspectors, while not exclusively dedicated to bridges, often specialize based on experience and seniority. The levels of inspection these staff may provide are as a material tester or as an inspector, depending on their certifications and experience. The senior technicians tend to provide the bridge inspection, leveraging their extensive experience to oversee and ensure the quality of bridge construction projects. The inspectors are tasked with handling various aspects of bridge construction, from initial project

oversight to resolving on-site issues. All (in-house and consultant) bridge construction inspectors are required to have Bridge Construction Inspector Certification (BCIC), which requires attending a course and passing exams.

Bridge Construction Inspection Training

MnDOT’s BCIC training course is located on a website dedicated to the program (https://www.dot.state.mn.us/technical-certification/courses/bcic.html). MnDOT’s BCIC training course is a 2-week, in-person course that requires passing two exams, one at the end of each week. The BCIC also has extensive prerequisite requirements, with the e-learning components noted to take up to 30 hours to complete. To stay current through periodic training, inspectors need to complete a 1-day refresher course known as the Bridge Construction Recertification Course (BCRC) every 5 years. This ensures that inspectors are up-to-date with the latest practices, regulations, and technology related to bridge construction. This kind of requirement maintains high standards of safety and quality in bridge construction projects.

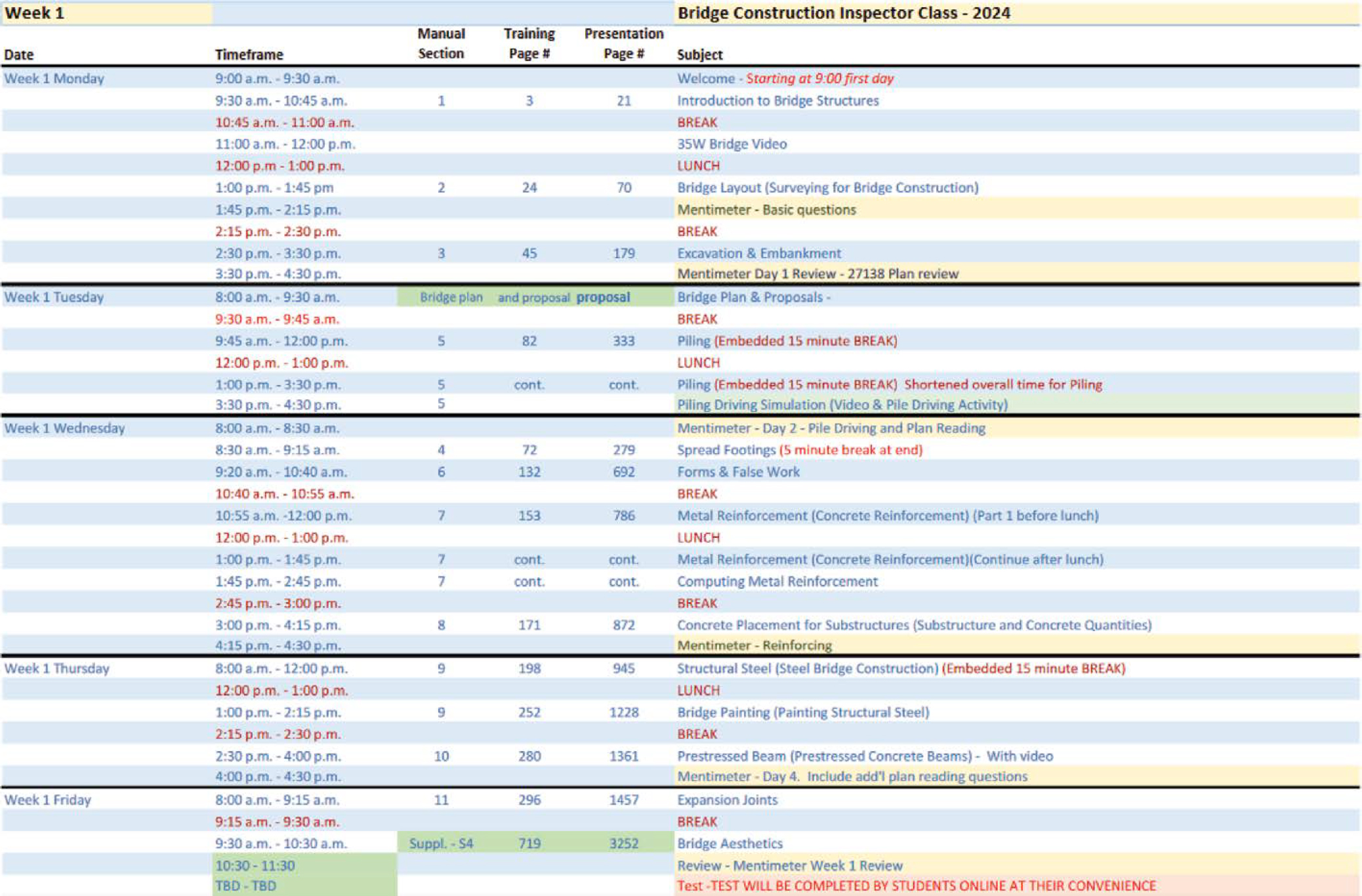

The prerequisites for the BCIC training program, detailed on the MnDOT website, include completion of programs required to be an aggregate production tester, concrete field tester, concrete field inspector, and grading and base tester, as well as completion of MnDOT e-learning components and AASHTO/TC3 (also sometimes referred to as TTS courses) Construction Inspection of Structures Series E-Learning courses on subsurface, substructure, superstructure, rehabilitation and maintenance, and reinforcement of structures. The agenda for the MnDOT BCIC training program is presented in Figures 40 and 41.

In summary, the BCIC training includes a mock project with a proposal, plans, and other contract documents. During the course, trainers guide the students through the project with the necessary knowledge and documentation, inspection requirements, and project management. Specific BCIC modules include grading and excavations, pile driving, erosion control and environmental concerns, concrete inspection, rebar placement, plan reading, and even basic sessions on bolting and structural steel bridges. These can be supplemented with additional specialized training if needed, although the inspection of more complex structures tends to be done with consultant inspectors.

The trainers of the BCIC program are mostly MnDOT employees, although there are a few consultants. They are considered SMEs within the topics they cover. They are responsible for developing the content delivered as part of the mock project, but otherwise, there are no formal requirements of the trainers. Having experienced trainers who are specifically selected to teach the content of the BCIC is crucial for maintaining the quality and relevance of the training. Their experience includes extensive knowledge and hands-on expertise in bridge construction, which they can impart to the inspectors attending the course. These trainers are chosen based on their deep understanding of the subject matter, their ability to effectively communicate complex concepts, and their familiarity with the latest developments and best practices in bridge construction. Their role is not only to teach theoretical knowledge but also to share practical insights and real-world examples that can benefit inspectors in their work.

The MnDOT BCIC program was developed from an initial effort started through a federal requirement to have a training program for inspection of bituminous pavements. In addition to pavement inspection training, MnDOT believed structural inspection warranted a training and certification program as well. Initially, the BCIC program was a 3-week program, but that was determined to be too time-intensive, so the program was restructured for 2 weeks. MnDOT is investigating more changes that could reduce the training to 1 week or potentially divide the course into two levels, where both levels of certification would be necessary for the overall management of a structural project.

The BCIC program costs $1,500 and is a large time commitment, but MnDOT finds the program necessary to ensure that structural construction inspection is properly performed. The program aims to build consistency and proficiency across the state, addressing the challenges posed by the decentralized structure of MnDOT’s operations. Additionally, senior inspectors and engineers often mentor less-experienced staff, sharing knowledge and expertise gained from years of working on various bridge projects.

Training Effectiveness and Resources

The BCIC program is delivered by trainers using an instructional manual developed by the Central Bridge Office. This manual is accompanied by a PowerPoint presentation that trainers update to fit with the current training project. At the time of this writing, the training manual is being revised; MnDOT is adding details so that it will serve as an inspector resource and further support the training. These changes coincide with the consideration of reducing the course to 1 week.

Along with PowerPoint delivery, the BCIC program enriches the training content through engagement by using Mentimeter software and various forms of questions and discussion. As time allows, the Central Bridge Office develops new training, new tools, new videos, and additional resources. These are on the MnDOT Bridge Construction website (https://www.dot.state.mn.us/bridge/construction.html), which is also a resource for inspectors. This website has checklists and videos on topics such as bridge deck panel placement, low-slump concrete work, and prestressed structural members. A newer segment is called “Do It Right,” which shows pictures and videos from sites to illustrate how certain procedures should be followed and, in some cases, what happens when things go wrong. Resources such as detailed documentation, bridge committee minutes, and a searchable database of past projects and problems are invaluable tools for inspectors. These resources enable inspectors to draw on historical data and experiences to address current challenges, thus enhancing the overall quality and consistency of bridge construction inspections.

The effectiveness of MnDOT’s training programs is reflected in the ability of inspectors to manage complex bridge projects and resolve issues efficiently. The Central Bridge Office also solicits and receives feedback regarding the training; although the feedback has mainly been qualitative in nature, it has demonstrated the effectiveness of the training.

Benefits and Challenges of Bridge Construction Inspection Training

The benefits of MnDOT’s approach to bridge construction inspection include the development of a highly knowledgeable and experienced workforce capable of managing a wide range of projects. The use of both in-house staff and consultants allows MnDOT to scale its operations according to project demands, ensuring oversight of all bridge construction projects.

One of the primary challenges is maintaining consistency across the various MnDOT districts. Additionally, the decentralized nature of MnDOT’s operations can lead to communication and coordination issues, further complicating efforts to standardize procedures. This challenge presents the fundamental need for programs like the BCIC, as well as the need to be flexible. With retirements and retention being a concern, MnDOT also has provisional certifications for employees needed as testers to provide quicker credentials to help support inspection responsibilities. In all, MnDOT has resources and options to build consistency in the bridge construction inspection program. However, the effectiveness of these resources is sometimes hindered by the time constraints of construction projects. In Minnesota, where the construction season is limited by weather conditions, inspectors often do not have the luxury of spending extended periods searching for

information. This reality underscores the importance of effective training and readily accessible resources. Encouraging inspectors to reach out to the Central Bridge Office for support indicates a commitment to providing ongoing assistance and guidance. This support network likely serves as a resource for inspectors facing challenges or needing clarification on specific issues related to bridge construction and inspection. It ensures that inspectors have access to expertise beyond what is covered in the initial training courses, thereby enhancing their effectiveness in the field.

Moreover, emphasizing that the knowledge gained in the initial 2-week course is just a foundation underscores the importance of practical experience in developing expertise. Bridge construction and inspection involve nuanced complexities that often require hands-on learning and continuous adaptation to new situations. The training program acknowledges this by preparing inspectors with fundamental knowledge while recognizing that true mastery comes through applying that knowledge in real-world scenarios over time.

Experience and Findings

MnDOT has been using and improving its BCIC training program since 1987 and has served as a model for several other states in the development of similar programs. MnDOT highly recommends having a bridge construction inspection training program for the positive impact it will have on the overall quality and consistency of inspection. MnDOT resources are available for other state DOTs’ training, and MnDOT suggests that states beginning a training program review what is already developed and revise it for their needs. MnDOT also notes the importance of continuously improving the program with evaluation measures and having trainers with education experience involved.

MnDOT’s approach to bridge construction inspection is characterized by a blend of formal training that ensures inspectors receive foundational knowledge and stay updated in industry standards and practices, practical experience applying their knowledge in real-world situations, and the strategic use of resources such as support networks and the Central Bridge Office website and staff. While challenges remain, particularly in achieving consistency across a decentralized organization, the department’s commitment to training and knowledge sharing has enabled it to effectively manage a large and diverse portfolio of bridge construction projects.

Pennsylvania Department of Transportation

The Pennsylvania Department of Transportation (PennDOT) oversees an extensive network of bridges, ensuring they are safe and well-maintained. Its network includes 25,400 bridges with structures spanning longer than 8 feet. As part of its responsibilities, PennDOT manages and inspects numerous bridge construction and rehabilitation projects annually, relying on a structured team of inspectors to uphold quality and safety standards. In 2023, PennDOT reported 684 bridge projects, inclusive of repairs, rehabilitations, and replacements. This involved 243 federally funded projects, including culverts and bridges, with 72 of those being full replacements. State-funded projects make up the balance of the bridge projects.

Organization Structure of Bridge Construction Inspection

At PennDOT, there is no distinct designation for bridge construction inspectors. Instead, all inspectors are classified as either transportation construction inspectors or transportation construction inspector supervisors. These professionals are versatile and capable of being assigned to various projects, including those for roadways and bridges, depending on the needs of the department. While these inspectors receive various types of training, there is not a specific structural training program required.

To support quality control inspection of bridge construction projects, PennDOT has structural-specific construction positions. These employees are called structural control engineers, and they must have a structural-related background, have knowledge of basic structural construction and design practices, and be PEs. This position acts as a liaison between bridge design and construction. There is one structural control engineer in each PennDOT district, and based on the workload of the district, this position may have an assistant or two assistants. As the districts maintain a certain level of autonomy, structural control engineers may fall under the direction of the district bridge engineer within design or the assistant district executive for construction. In the districts, the structural control engineer visits projects and supports inspection for specific construction-related tasks such as pile driving, beam setting, reviewing erection plans, and deck placement plans.

Bridge Construction Inspection Training

Training for PennDOT inspectors is multifaceted, involving both OJT and continuing education. Although there is no specific training solely dedicated to bridge construction inspection, inspectors benefit from a combination of practical experience and professional development opportunities that enhance their capabilities. PennDOT does not currently mandate National Institute for Certification in Engineering Technologies (NICET) certification for its in-house inspectors. However, consultant inspectors who are hired to supplement PennDOT’s inspection efforts are required to have NICET certifications. This requirement ensures that consultant inspectors meet a recognized standard of competency and expertise. Additionally, a significant number of veteran PennDOT in-house inspectors do have NICET certifications or expired NICET certifications. This is largely due to a past program where PennDOT sponsored NICET training, certification, and recertifications for inspectors.

In addition to internal resources, PennDOT inspectors can obtain field certifications through programs administered by the Northeast Center for Excellence in Pavement Technologies (NECEPT). For example, to become a NECEPT-certified concrete field technician, inspectors must first hold a valid ACI certification for concrete field testing. PennDOT previously required this ACI certification for in-house inspectors, but now it is only required as a prerequisite to obtain their initial NECEPT certification. Therefore, PennDOT inspectors only need to maintain the NECEPT recertification (every 5 years) to witness and perform testing for concrete materials.

PennDOT does offer training on special topics such as drilled shafts. This training is optional and project-specific, and frequency and topics can range broadly. Training is also offered as needed by the PennDOT materials division, which inspects and oversees fabrication facilities. This group provides training on welding inspection, rotational capacity of bolting, nondestructive evaluation (NDE) inspection, and other topics, as needed by projects. It also offers field support for these specialized inspections.

For the structural control engineers, there is no defined training program. As PEs, these employees are expected to maintain the required continuing education to fulfill their licensure requirements. Additionally, their license requires the training and development necessary to complete inspection and engineering functions.

Training Effectiveness and Resources

PennDOT leverages various resources to support training and development of its inspectors. The primary sources of guidance for inspectors are the Project Office Manual (PUB 2, https://www.dot.state.pa.us/public/PubsForms/Publications/PUB%202/PUB%202.pdf ) and the Construction Manual (PUB 8), which provide comprehensive instructions and standards for

construction inspection. These manuals serve as crucial reference points for inspectors, ensuring consistent and high-quality inspection practices across the state. PennDOT inspectors may be assigned projects based on their experience and expertise, but this is not a formalized process, so OJT or project-specific training may be necessary.

PennDOT makes available a range of training opportunities to its inspectors and employees through NHI, other third-party training providers, and some internally developed training. To make them accessible to a wide audience, these programs are offered at various times throughout the year and across all areas of the state.

In addition to training, informal mentoring supports PennDOT bridge construction and general inspection staff. For example, the district bridge engineers hold a statewide meeting twice a year that allows for best practice exchange, discussion, and training, if necessary. As part of this meeting, the structural control engineers have their own sessions to support their development.

Benefits and Challenges of Bridge Construction Inspection Training

The integrated approach to inspector training at PennDOT offers several benefits, including flexibility in inspector assignments and a broad skill set among the inspectors. This versatility is crucial for managing the diverse range of construction projects undertaken by the department. Additionally, the combination of OJT and formal certifications ensures that inspectors are well-prepared to handle bridge construction and maintenance complexities.

However, this approach also presents challenges. The lack of a specific bridge construction inspector training program means that inspectors must rely heavily on their general construction knowledge and experience and that structural control engineers may have slightly varied expertise. While this approach has been effective, it may lead to differences in inspection and practices across different projects and districts. There is also a challenge in staffing availability to maintain training and continuing education with the construction work schedule. When construction schedules permit, structural control engineers often take on additional design responsibilities.

Experience and Findings

Over the years, PennDOT has refined its approach to bridge construction inspection through practical experience and continuous improvement. The department’s decentralized structure, with 11 districts operating semi-autonomously, allows for tailored management of projects but can also result in varying practices and standards. To mitigate this issue, PennDOT’s central office provides policy guidance and handles or closely supports the inspection of complex or unusual structures, ensuring a degree of uniformity across the state.

PennDOT’s inspectors are integral to the department’s mission of maintaining safe and reliable infrastructure. While not specialized exclusively in bridge construction, their training equips them with the necessary skills to oversee a wide range of projects effectively. The combination of formal guidance, practical experience, and ongoing professional development fosters a competent and adaptable inspection workforce capable of meeting the challenges of modern infrastructure management. The position of the structural control engineer has traditionally been a well-regarded one with a high retention rate. This position aids in bringing professional engineering–based capabilities and consistency to bridge construction inspections while also allowing general inspectors to learn from these engineers through project experience.

In conclusion, while PennDOT’s approach to bridge construction inspection training presents certain challenges, it also offers flexibility and comprehensive skill development benefits. The department’s ongoing efforts to enhance training resources and maintain high standards of inspection will continue to play a critical role in the upkeep and safety of Pennsylvania’s bridges.

Summary

This chapter has presented key findings on bridge construction inspection training practices and resources from the case examples of six state DOTs. The DOTs included in this chapter have a wide variety of experience in bridge construction inspection training and represent all four AASHTO regions. Each of the case examples was discussed in detail in terms of general findings on bridge construction inspection, organization structure of bridge construction inspection, bridge construction inspection training, training effectiveness and resources, benefits and challenges in bridge construction inspection training, and experience and key lessons learned related to bridge construction inspection training. The findings presented in this chapter provide current effective practices on bridge construction inspection training from experienced state DOTs across the nation.