Practices to Enhance Resiliency of Existing Roadway and Embankment Culverts (2025)

Chapter: 2 Literature Review

CHAPTER 2

Literature Review

This chapter summarizes a review of federal legislation and regulations, existing literature, and other sources of DOT practices for enhancing resiliency of roadway and embankment culverts. The purpose of this review is to identify existing documentation of practices related to the resiliency and durability of roadway and embankment culverts. Relevant documents were identified through the TRID database and supplemented through Internet searches. This review describes the current state of the practice of state DOT strategies to enhance culvert resilience; the reference section of this report contains the full list of sources.

2.1 Federal Legislation and Regulation

Federal legislation and regulation are crucial to developing, implementing, and maintaining resilience efforts. Some resilience challenges experienced by state DOTs are region-specific, suggesting that resilience improvement efforts vary across the United States. This variation in approach is inherent given the inhabitance and climatological diversity of the United States.

The Moving Ahead for Progress in the 21st Century Act (MAP-21) was signed into law in July of 2012 and provided over $105 billion to surface transportation programs over fiscal years 2013 and 2014. MAP-21 instituted performance goals and measures into federal-aid highway improvement projects. One of the national performance goals set for federal highway programs relevant to the topic of resilience is the maintenance of infrastructure assets in a state of good condition [(§1203; 23 U.S.C. 150(b)]. Additional performance measures were developed by individual state DOTs, and performance targets to achieve these measures were detailed in state long-range planning documents. Alongside these performance goals, MAP-21 required state DOTs to develop and implement a risk- and performance-based asset management plan (MAP-21 §1106; 23 U.S.C. §119). As detailed in the FHWA Public Roads magazine (2013), these asset management plans must include “. . . objectives and measures, identification of performance gaps, life-cycle cost and risk management analyses, a financial plan, and investment strategies.” The FHWA does not have authority to determine which culvert material types are to be specified on federal-aid highway projects pursuant to Section 1525 of MAP-21. In January of 2013, FHWA issued a final rule to implement full state DOT autonomy in culvert and storm-sewer material selection in federal-aid highway construction.

In December 2015, the Fixing America’s Surface Transportation Act (or “FAST Act”) was signed into law. The FAST Act furthers the changes implemented by MAP-21 and requires consideration of resilience and reliability improvements and stormwater mitigation during transportation project planning and continues to support inclusion of performance measures in statewide long-range planning to achieve the MAP-21 performance targets. The FAST Act expedited funding distribution for the purpose of accelerated project delivery, allowing for quicker implementation of state DOT resilience improvement projects.

In November of 2021, the Infrastructure Investment and Jobs Act (2021), also known as the Bipartisan Infrastructure Law (BIL), was signed into law. This law provides $550 billion for infrastructure projects from the years 2022 to 2026. Part of this legislation is the Promoting Resilient Operations for Transformative, Efficient, and Cost-Saving Transportation (PROTECT) formula program, which directs funds to state DOTs and provides discretionary grants to improve infrastructure asset resilience to extreme weather events due to climate change. The PROTECT program is administered by the FHWA and offers $7.3 billion in funding from the years 2022 to 2026. Funding is apportioned by the FHWA to each state and then subsequently apportioned within eligible state programs. Eligible state DOT projects include resilience planning activities, improvement projects such as those for culvert upsizing and rehabilitation, community resilience and evacuation routes, and at-risk coastal infrastructure including culverts susceptible to coastal erosion and sea-level rise. At least 2% of a state’s PROTECT funding must be allocated to resilience planning activities such as developing a resilience improvement plan or resilience design work. Qualifying state DOTs can use PROTECT funds to install, upsize, replace, or rehabilitate culverts affected by extreme weather events. Additional amendments to the BIL included consideration of extreme weather and resilience in life-cycle cost and risk management analyses within state DOT transportation asset management plans [23 U.S.C. §119(e)(4)(D)]. Guidance for applicants on discretionary grant programs, such as the PROTECT program, is offered in the U.S. DOT’s Benefit–Cost Analysis Guidance for Discretionary Grant Programs (U.S. DOT 2023). This document provides a framework methodology for completing a benefit–cost analysis (BCA) as a part of a grant application requirement. Benefits of the infrastructure project are weighed against the anticipated costs of the project and are used by the U.S. DOT to evaluate applications based on investment outcome.

2.1.1 Asset Management

Asset management can optimize the performance of culverts by prioritizing maintenance based on costs and benefits (Beaver 2018). Culvert inspections, maintenance, and repairs can be scheduled appropriately to mitigate costly rehabilitation and replacement projects. An asset management guidance framework is available from AASHTO. The AASHTO Transportation Asset Management (TAM) Guide (FTA and AASHTO 2020) cites its main benefit to users as maintaining assets to extend their service life and therefore improve asset resilience. The TAM guide thoroughly explains goal setting, life-cycle planning, maintenance and capital investment processes, asset tracking strategies, data collection and importance, and management practice implementation. The TAM guide specifies that its target audience is state DOTs, but its use can be extended to local departments of transportation as well.

Culverts under state DOT jurisdiction are sometimes managed by different departments based on size thresholds; larger-diameter culverts are typically handled by the state bridge team, although this size threshold is not universally defined. Additionally, different teams within the same DOT may use different methods for culvert documentation, tracking, and scheduling of inspection, maintenance, and repair (FHWA 2007). Asset management practices detailing culvert data collection and its use in decision-making and fund allocation differ among state DOTs (FHWA 2007).

2.1.2 Repair and Rehabilitation Practices

The FHWA provides guidance on decisions related to culvert repair and rehabilitation. The Culvert and Storm Drain Inspection Manual (Beaver and Richie 2016) is an updated version of a 1986 FHWA manual. It provides condition assessment tables for culverts of various material types, details common field indicators that can lead to performance problems of varying severity, and offers a flowchart decision-making tool to assist users in making post-assessment recommendations of action. The manual also includes a photo library as a guide for culvert assessment. The FHWA’s Hydraulic Design of Highway Culverts (FHWA 2012a) provides in-depth

discussions of various culvert repair and rehabilitation techniques for all culvert materials. The FHWA’s Culvert Pipe Liner Guide and Specifications (FHWA 2005a) details various state-of-the-practice lining techniques for rehabilitation or replacement of deteriorated culverts and explores various materials, advantages and limitations, costs, and general installation guidelines.

2.1.3 Risk Assessment for Extreme Weather Vulnerability

The FHWA’s Hydraulic Engineering Circular (HEC) No. 17 (FHWA 2016c) contains floodplain policies and guidance on hydrologic modeling using historical data to project future flooding risk. HEC-17 presents strategies to reduce vulnerability to flooding and extreme weather events and provides a framework for performing risk and vulnerability assessments of riverine culverts. State DOTs concerned with flooding and severe storms can use this framework to estimate the impact of extreme events on their culverts and incorporate weather uncertainty into the design of their drainage assets accordingly.

The FHWA’s Vulnerability Assessment and Adaptation Framework, 3rd Edition (FHWA 2017a) presents a detailed process for conducting a vulnerability assessment of infrastructure subject to extreme weather events and the effects of climate change. The manual also presents examples incorporating results of a vulnerability assessment in decision-making around planning, design, asset management, and maintenance of assets. State DOTs can use this framework to prioritize projects based on how climate change affects a specific geographic location and how a project could potentially contribute to system vulnerability.

The FHWA’s Climate Change Adaptation Guide for Transportation Systems Management, Operations, and Maintenance (FHWA 2015) targets management, operations, and maintenance to help incorporate climate change adaptation into planning activities and programs by providing information and resources on understanding risks posed by climate change and actionable steps to mitigate these risks. This report is complementary to the Vulnerability Assessment and Adaptation Framework (FHWA 2017a), and the use of both is encouraged in developing and implementing resilience strategies. The 2017 report details a vulnerability and risk assessment matrix, a checklist for performing a vulnerability or risk assessment, operations objectives, and performance measures to improve response to extreme weather events. These documents provide actionable steps for state DOTs to use in their resilience improvement plans.

A methodology to assess the risks that extreme weather events pose on culverts and buried drainage structures was proposed and presented at the Transportation Research Board Annual Meeting in 2020 and published in the Transportation Research Record (Pluimer 2023). The methodology is currently being balloted as an ASTM Standard Practice in ASTM Committee E60 (Sustainability) and allows users to calculate the risk that various extreme events (e.g., floods, severe storms, wildfires, and hurricanes) pose to their buried drainage structures based on the likelihood of their occurrence within the specific region of interest. The proposed standard practice also provides a method for calculating a vulnerability rating of buried drainage structures and outlines mitigation strategies to help improve the rating.

2.2 Trade Association Information on Resilience

Trade associations representing the various culvert industries publish a significant amount of information related to culvert resilience of their respective products and materials. Though not discussed at length in this synthesis, readers are directed to these trade associations if further information is desired. Some trade associations that may be of interest are the American Concrete Pipe Association (ACPA), the National Corrugated Steel Pipe Association (NCSPA), and the Plastics Pipe Institute (PPI).

2.3 Relevant NCHRP Reports

NCHRP Research Report 938: Incorporating the Costs and Benefits of Adaptation Measures in Preparation for Extreme Weather Events and Climate Change: Guidebook (Dewberry Engineers, Inc., et al. 2020) provides a framework for state DOTs on whether, when, and to what extent to implement resilience measures into current or future infrastructure projects specifically for adapting to extreme weather events due to climate change. The report offers varying levels of cost–benefit analyses (CBAs) for users and explains the data needed to conduct a CBA as well as potential sources for such data. It also provides a general educational background on CBAs, climate change, and typical cost evaluations. The report cites stationarity of climate-based modeling and design of infrastructure as a contributing factor in failing assets. Culvert-specific sensitivities to climate stressors are detailed in the FHWA Transportation Climate Change Sensitivity Matrix (FHWA 2013a).

The final report from NCHRP Project 14-19, “Culvert Rehabilitation to Maximize Service Life While Minimizing Direct Costs and Traffic Disruption” (Allouche 2017), details interactive charts for users to identify cost-effective rehabilitation techniques for culverts of concrete, metal, and thermoplastic materials exhibiting defective structural stability, bedding deficiencies, and reduced hydraulic capacity.

Additionally, NCHRP Project 18-20, “AASHTO LRFD Design, Installation, and Standard Practice of Testing for Cured In-Place Pipe Liners” (Hebeler 2024), is at the time of this writing developing an AASHTO guide for the design and installation of cured in-place liners, a trenchless repair method to structurally rehabilitate existing culvert pipes by inserting a resin-material liner into the host pipe. This project will also include design examples illustrating the various applications of the guide.

These resources provide detailed guidance strategies state DOTs can implement to improve culvert resiliency.

2.4 Select State DOT Approaches to Resilience

Although the final scope of this synthesis includes seismic susceptibility, slope and embankment stability, watershed characteristics, and urban development and land uses as potential challenges of culvert resiliency, the interviewed case example state DOTs prioritize variability in climate and extreme weather events as the focus of their resiliency efforts. It is worth noting that DOTs have guidance documents available for these additional challenges, but this section of the report documents DOT practices to enhance culvert resilience that align with state DOT prioritization of climate and weather events.

2.4.1 California

The California Department of Transportation (Caltrans) has a Highway Design Manual, with Chapter 820: Cross Drainage (Caltrans 2020a) detailing culvert shape selection criteria, explaining that shape and cross-section depend on cost of construction, upstream elevation, embankment height, and hydraulic performance demand. The design manual also details debris control methods to prevent clogging and guidance on joint specification and structural additions to reduce piping, as well as design strategies for tide and storm flooding. In the Highway Design Manual, Chapter 850: Physical Standards (Caltrans 2020a) discusses culvert material selection criteria and thoroughly explains design considerations for all culvert material types, including durability and durability issues, shapes and hydraulic performance, and specific repair techniques. Culvert lining options for rehabilitation projects specifically focused on mitigation

corrosion and abrasion damage are discussed in detail; examples of lining options include plastic pipe, cured-in-place pipe (CIPP), spiral wound polyvinyl chloride (PVC) pipe liner, cementitious pipe lining, invert paving, and steel tunnel lining plates.

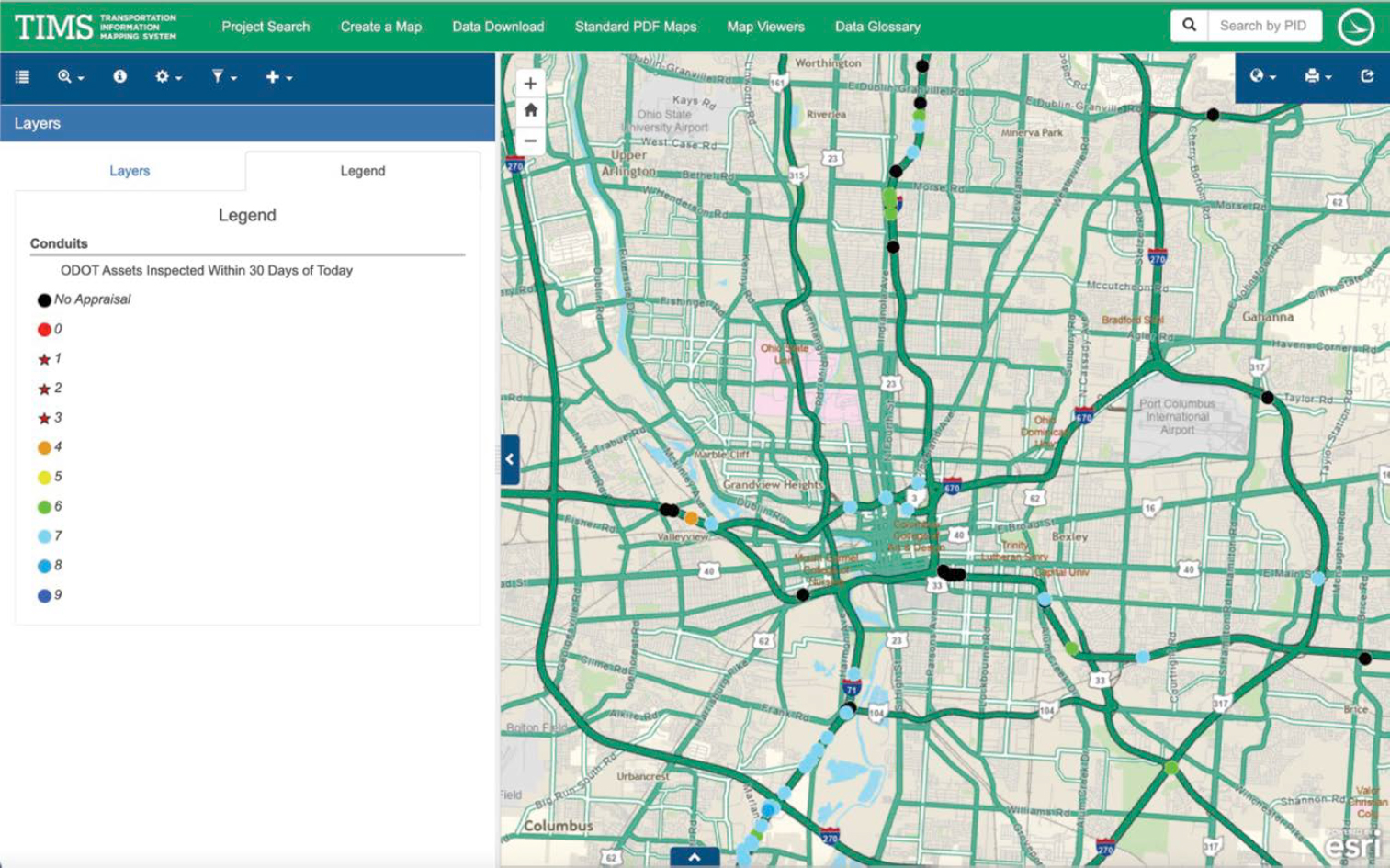

The Caltrans Design Information Bulletin No. 83-04 (Caltrans 2014) details culvert assessment and inspection procedures and includes photo examples of commonly found problems such as overtopping, scour, debris clogging, joint separation, and channel erosion. The Design Information Bulletin also provides material-specific repair techniques, explains the construction process of the repair, and includes reference documents elaborating on each technique. The bulletin explains that there is no specific methodology for determination of the most appropriate repair or rehabilitation technique, and instead engineers must understand the conditions that caused the culvert failure or deterioration to select an appropriate repair strategy. Tables with benefits and limitations of repair techniques specific to culvert diameters and materials are included in the document. The Design Information Bulletin references multiple case examples that detail initial observed problems and explain the selected design solution and reasoning behind the choice, construction process, total cost, and lessons learned. This resource provides thorough background explanation of various repair and rehabilitation techniques for all culvert materials. The table of alternative repair techniques compares rehabilitation techniques based on cost, applicable culvert materials and size range, and advantages and limitations of each problem resolution. A section of the table is shown in Figure 3.

The Caltrans Transportation Asset Management Plan (https://dot.ca.gov/-/media/dot-media/programs/asset-management/documents/2022-tamp-a11y.pdf), completed in 2022, focuses on life-cycle planning to optimize culvert service life and maximize investment in culvert maintenance and management. Caltrans uses a physical asset model in its life-cycle planning to predict asset deterioration. Factors affecting deterioration of culverts include material durability,

hydraulic demand, and surrounding environment, and rates of deterioration can be used to predict culvert maintenance and rehabilitation/replacement timelines. The Transportation Asset Management Plan identifies culverts in need of restoration and an appropriate plan to reinstate expected service life. Also detailed in the plan are expected costs per culvert of regular maintenance, repair, and replacement practices, as well as expected cost comparisons with full failure of a culvert. The plan discusses consideration of risk and its importance in asset management to prevent unplanned repair, rehabilitation, or replacement of culverts. Caltrans’ strategies to prioritize and mitigate risk include identification of additional resources (funding, expertise, and training) to alleviate potential consequences, and continual monitoring of identified issues to prevent acceleration of problems.

2.4.2 Florida

The Florida Department of Transportation (FDOT) has a Drainage Design Guide (FDOT 2024) in which Chapter 4: Culverts details culvert material, shape, and cost considerations to assist in maximizing culvert service life. This chapter also provides detailed walk-through examples of culvert design procedures for multiple scenarios with exact steps to mitigate potential issues. Chapter 8: Optional Pipe Material discusses culvert service life, which is specified as 100 years in most applications. The chapter presents information on expected service life for all culvert materials. For concrete and metal culverts, expected service life is determined based on environmental corrosivity of the water and surrounding soil, and for plastic culverts, expected service life is determined by the State Drainage Office rather than by corrosion analysis. Corrosion tables for estimated service life of concrete and metal pipes are provided in Appendix M of the Drainage Design Guide.

Additional drainage design guidance documents (https://www.fdot.gov/roadway/drainage/drainage-design-aids2) are provided on the FDOT website, including the Culvert Service Life Estimator (CSLE; https://csle.fdot.gov/#/estimator), which allows users to input desired culvert service life, environmental factors (pH, chlorides, and sulfates), and structural requirements. The web application then outputs possible culvert materials and types to fulfill the design requirements. Detailed examples of how to use the CSLE tool are included in Chapter 8 of FDOT’s Drainage Design Guide, as are additional examples of the selection process for an appropriate culvert material.

FDOT has collaborated with the GeoPlan Center to develop a resilience report (Goodison, Pierre-Jean, and McCain 2023) to assess flood vulnerability of transportation assets. The resilience report displays current and future flood exposure over the state of Florida and allows users to specify particular areas of interest. While the current resilience report focuses on coastal flooding, the tool will help FDOT as it prepares for all types of flooding related to climate change. The resilience report is a further development of two ongoing projects between FDOT and the GeoPlan Center: the Environmental Screening Tool (EST; https://etdmpub.fla-etat.org/est/) and the Sea Level Scenario Sketch Planning Tool (Florida Department of Transportation Office of Research, Development, and Technology 2012). The EST is a web application that evaluates the impact of transportation projects on the surrounding community. Figure 4 shows a screenshot from the EST detailing transportation projects overlapped with areas at risk due to sea-level rise. The Sea Level Scenario Sketch Planning Tool is a Geographic Information System (GIS) tool to map current and future flood exposure and sea-level rise. Both of these projects provide access to flood data to help inform resilience-based decisions and identify areas in need of attention.

2.4.3 Maryland

The Maryland Department of Transportation (MDOT) uses the Highway Drainage Manual Design Guidelines (MDOT 2009), which details the selection criteria for culvert materials, diameters, bedding materials and fill heights, and types of joints. Soil chemistry and saturation

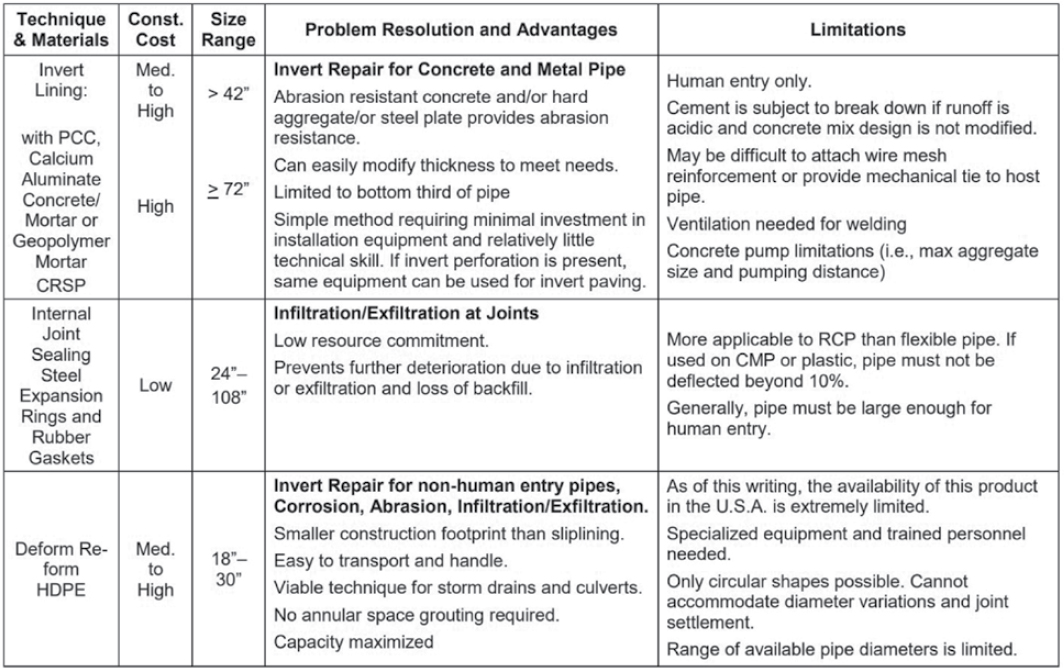

levels, abrasion, fill height, and outlet velocity are factors that affect culvert material selection. MDOT defines culvert service life as “. . . the expected maintenance free service life of each installation” (MDOT 2009) and recommends designers include protective measures to ensure all specified culvert materials can withstand environmental factors to uphold their expected service life of 50 years. Chapter 4 of MDOT’s Highway Drainage Manual (MDOT 2023a) discusses design considerations such as culvert size, shape, and material, and emphasizes the importance of replacement cost, difficulty of construction, and traffic delay when designing a culvert. Additionally, the drainage manual explains that environmental factors such as soil and water pH and resistivity, abrasion levels, and UV exposure are important considerations that affect culvert service life. The Highway Drainage Manual includes inspection criteria and explains culvert condition rating based on expected remaining service life. An example of culvert condition rating is shown in Figure 5. The manual also provides rehabilitation practices in response to commonly experienced issues for all culvert materials.

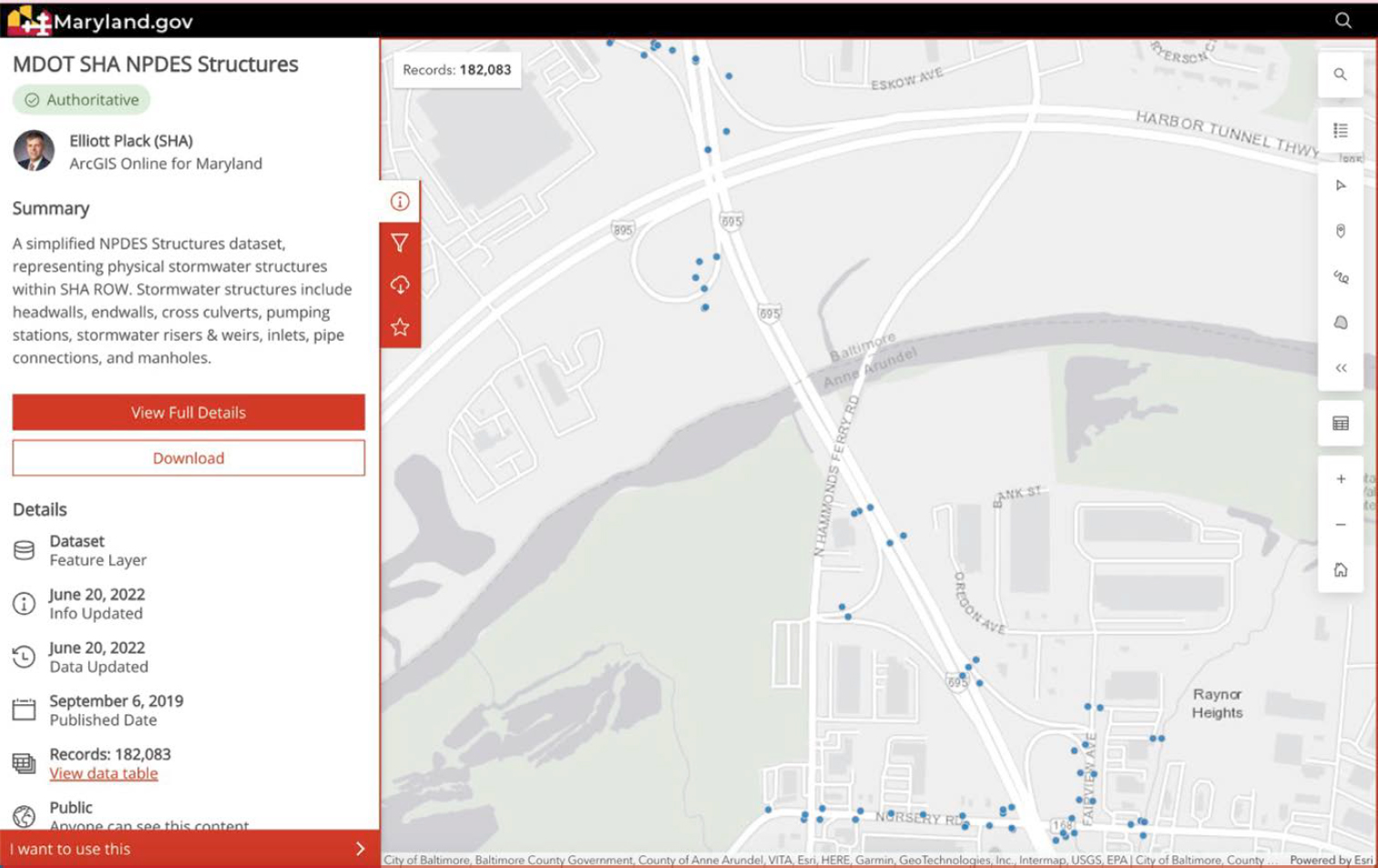

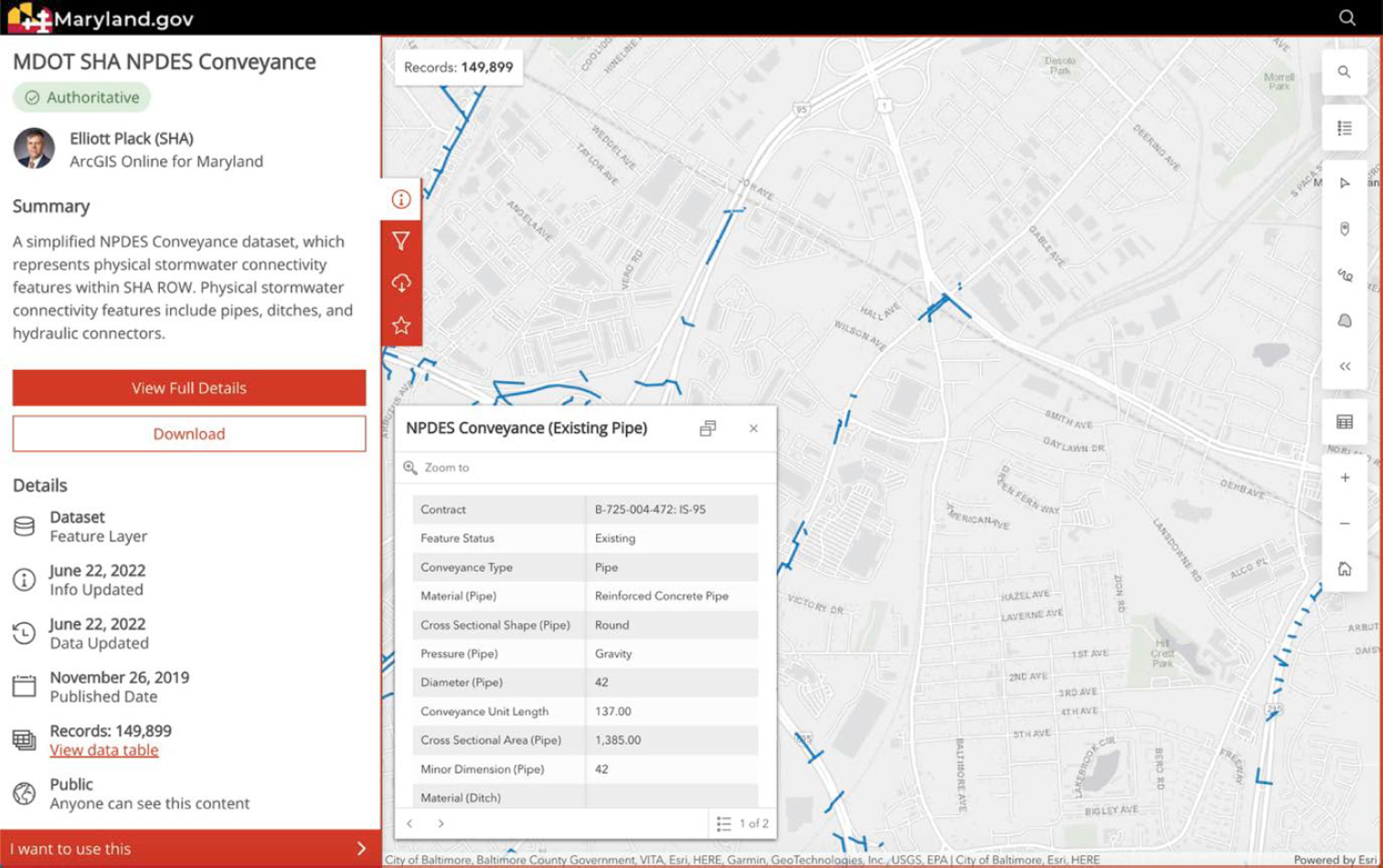

MDOT uses an asset management data portal to document, track, and manage culverts within the DOT system. MDOT uses multiple applications for asset management. The MDOT Asset Condition Viewer (https://mdot-sha-amo-maryland.hub.arcgis.com/) is a GIS-based web application that allows for MDOT personnel to view information related to critical transportation assets and their current condition. The MDOT Project Research Tool (https://data-maryland.opendata.arcgis.com/pages/mdot-apps-internal) details the location of culverts, the current status of projects, the expected completion date of projects, links to Google Street Views of the locations, and expected disruption to the traveling public (if a lane is closed). The GIS web application allows for layering of different assets, project years, and regions within Maryland. Examples of the different layering capabilities of the Project Research Tool are shown in Figures 6 and 7.

2.4.4 Minnesota

The Minnesota Department of Transportation (MnDOT) uses Chapter 2: Pipe Materials of its Drainage Manual (MnDOT 2024), which provides guidance on culvert material selection based on hydraulic demand and structural requirements of the installation as well as environmental factors affecting service life. The Drainage Manual states that the end of service life is indicated when the culvert requires major rehabilitative maintenance or replacement. The manual details design criteria and appropriate site conditions for all culvert materials and provides guidance on additional measures to mitigate common material-related issues. Installation requirements for all culvert materials, pipe diameters, and roadway classifications are also provided.

MnDOT uses a Transportation Asset Management System (TAMS) called TAMS HydInfra (hydraulic infrastructure) for inventory and inspection of culverts. HydInfra is coupled with a GIS information collection app for field inventory and inspection of culverts. Also contained in this system are culvert repair records and work orders for future repairs. MnDOT’s TAMS

HydInfra Culvert and Storm Drain Inspection Manual (MnDOT 2021) provides thorough explanations of the various culvert materials, shapes, and liners for inspection assessment. Culvert condition rating criteria and performance measures are discussed for identifying when a culvert needs repair, and examples of condition ratings for each culvert material are presented in tables.

MnDOT’s Culvert Repair Best Practices, Specifications, and Special Provisions: Best Practices Guidelines (Wagener 2014) details repair and rehabilitation practices. The document emphasizes the importance of identifying the cause of a culvert’s condition in order to implement an effective repair or rehabilitation technique and provides information on the likely causes of identified deterioration. The guidelines thoroughly explain the rehabilitation process, starting from preparation of the culvert, continuing to installation and construction expectations, and going through future maintenance. Additionally, open-cut and trenchless culvert replacement options are presented in detail.

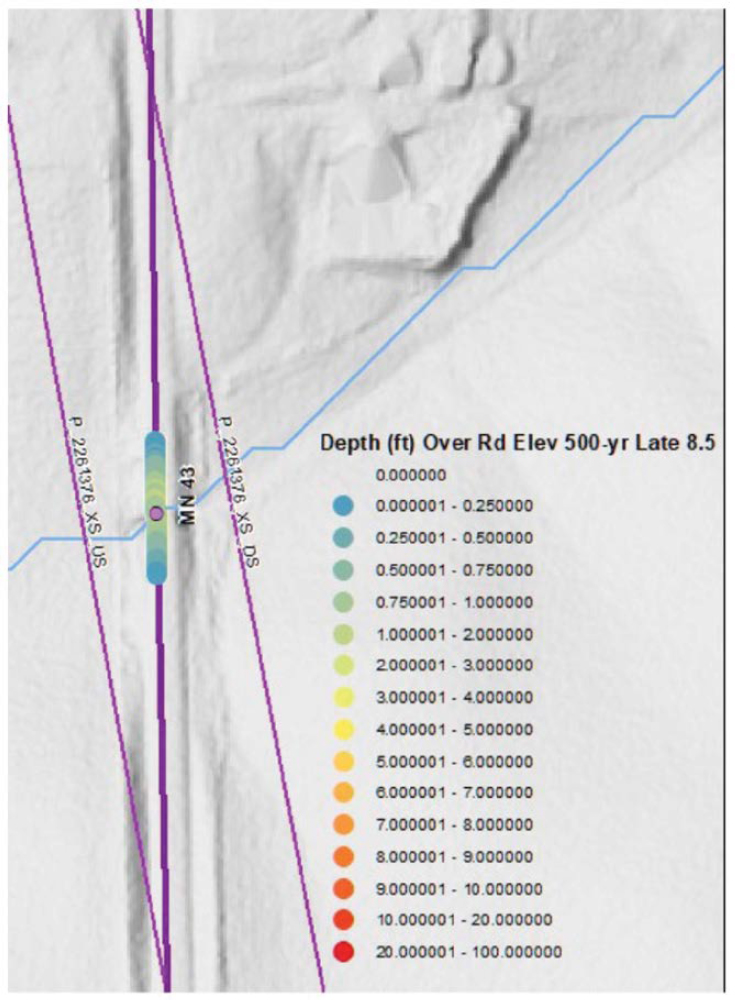

MnDOT’s Extreme Flood Vulnerability Analysis PowerPoint presentation (MnDOT 2022) includes a model to assess the expected risks associated with climate stressors and compare damage and repair costs to the associated impact on the traveling public. The analysis includes hydraulic modeling of future flow statistics and watershed storage capabilities. This hydraulic modeling was combined with predicted cost estimates for repair and replacement of culvert physical characteristics. The result is a cost–benefit analysis tool that considers cost implications over the service life of the culvert. MnDOT is still developing and improving this tool and has plans to implement it statewide and enhance its accuracy with more data. Figure 8 shows an example from the presentation of flooding across a roadway featuring a reinforced concrete pipe during a 50-year flood event.

2.4.5 Ohio

The Ohio Department of Transportation (ODOT) specifies that at least one alternate from each of its culvert material categories be considered during the design process; the material categories are concrete, metal, and thermoplastic (ODOT 2024a). Specially shaped culverts are “. . . generally limited for use under shallow cover installations or extremely low or restrictive headwater control . . .” (ODOT 2024a) and include culverts such as concrete elliptical, three-sided and box culverts, and corrugated metal arch culverts. ODOT’s Location and Design Manual, Volume 2, Drainage Design, specifies a culvert pipe material lifetime of at least 75 years (ODOT 2024b). ODOT requires field testing of the water’s pH and determination of abrasion level when considering service life of the culvert. ODOT uses its Office of Hydraulic Engineering’s Durability Design spreadsheet (https://www.dot.state.oh.us/hydraulic/Additional%20Design%20Resources%20%20Publications/Forms/AllItems.aspx), which allows for users to input certain design factors such as shape and span of the culvert and pH and abrasion level of the water. The spreadsheet then provides various culvert materials and shapes that will meet the specified 75-year service life of the culvert based on the information input. Reasoning is provided for options that do not meet the criteria, along with tables detailing appropriate applications for various culvert materials, shapes, and sizes. Additional resources on culvert design to maximize service life are included on the Ohio DOT website, including guidance on structural analysis of deteriorated culverts to determine the level of invert paving required to reinstate service life, and design guidelines outlining common problems with culvert materials and their associated remediation techniques. The Location and Design Manual also provides supplemental specifications on culvert rehabilitation regarding spray-applied liners to add structural support (ODOT 2015) and guidance on liner pipes (ODOT 2007). The manual emphasizes that the first step in

choosing a rehabilitation technique is evaluation of the problem to determine which solution will mitigate the issue and prevent its recurrence.

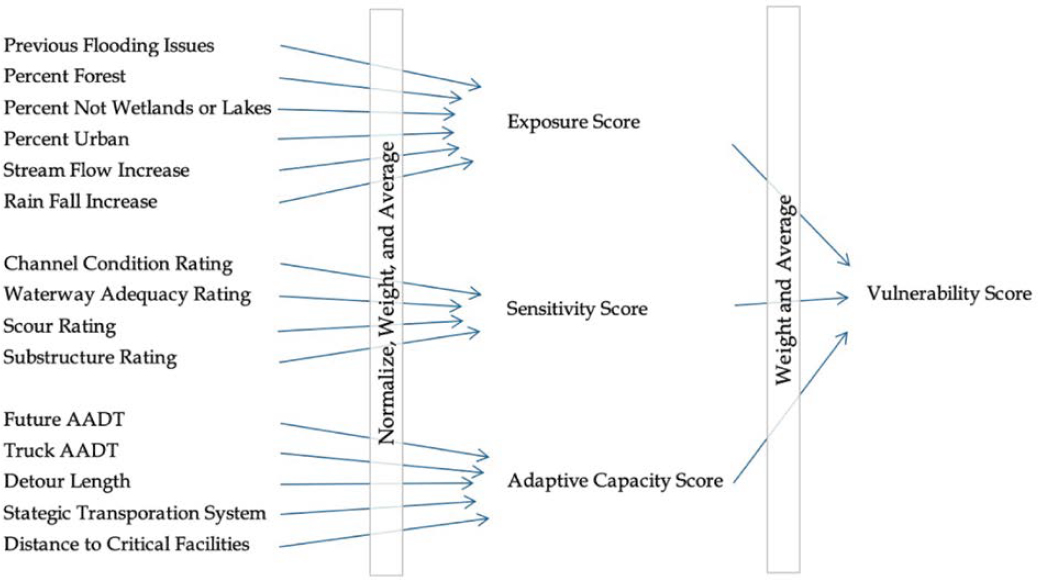

Additional work by ODOT includes the Infrastructure Resiliency Plan (RSG and McVoy Associates LLC 2016), which evaluated ODOT culverts on their vulnerability to extreme weather events. Culverts within the National Bridge Inventory (NBI) and the 2014 Ohio Bridge Inventory were evaluated and given waterway adequacy ratings, scour critical ratings, and average daily traffic scores to determine the culverts’ vulnerability ratings. This project resulted in identification of vulnerable culverts within ODOT’s system based on exposure level, sensitivity to the event, and adaptability after the event. The development of the Vulnerability Assessment Screening Tool (VAST) identification system allows for ODOT to prioritize culvert maintenance, repair, and rehabilitation to extend the service life of its culverts. The VAST vulnerability scoring approach is shown in Figure 9.

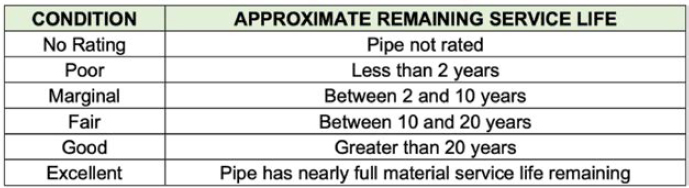

ODOT uses a Transportation Information Mapping System (TIMS) (ODOT 2020) to collect information on its culverts. TIMS is a GIS that allows users to create, map, and manage culverts within the DOT inventory and filter results into layers based on relevant criteria. This application is available to the public to view culvert locations and conditions and is used internally during inspections to log and update culvert information. This tool is useful for tracking culvert condition and maintenance history. TIMS is designed to be used in conjunction with ODOT’s Conduit Management Manual (ODOT 2024a), which details culvert inspection practices, frequency of inspection, and maintenance recommendations based on inspection results. Examples of the TIMS layer options are shown in Figures 10 and 11.