Practices to Enhance Resiliency of Existing Roadway and Embankment Culverts (2025)

Chapter: 4 Case Examples

CHAPTER 4

Case Examples

The case example DOTs were selected for their geographic diversity, representing different climates and all four AASHTO regions, as well as for the variety of culvert materials and shapes in use, the number of culverts under the jurisdiction of the DOT, and the DOTs’ resilience efforts, as documented in the project survey. For each case example, the DOT representative that submitted the survey was contacted to schedule an hour-long interview with the representative and any additional DOT members who would be able to provide additional information on the case example questions.

Although the final scope of this synthesis includes seismic susceptibility, slope and embankment stability, watershed characteristics, and urban development and land uses as potential challenges of culvert resiliency, the interviewed case example state DOTs prioritize variability in extreme weather events as the focus of their resiliency efforts. It is worth noting that DOTs have guidance documents available for these additional challenges, but this section of the report documents DOT practices to enhance culvert resilience that align with state DOT prioritization of extreme weather events.

4.1 Caltrans

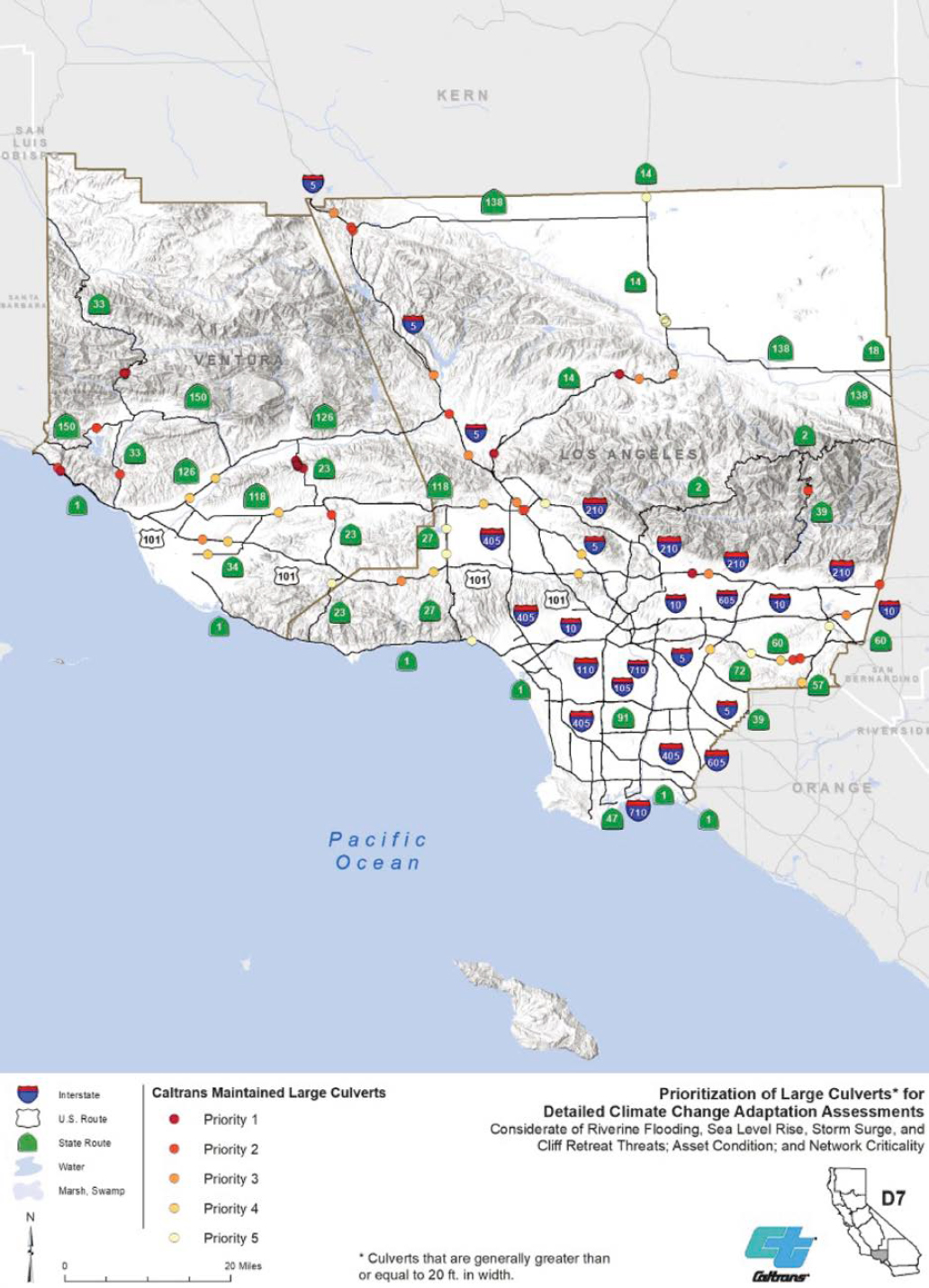

Caltrans has developed numerous guidance documents on resilience planning, climate risk assessment, decision-making, and monitoring progress. The primary climate-related threats to California are temperature change, changes in precipitation, wildfires, and sea-level rise. Caltrans offers specific guidance on sea-level rise, which includes projected sea-level rise rates and coastal adaptation strategies. The Caltrans Division of Maintenance works with local fire officials to incorporate wildfire reduction techniques, such as fuel or vegetation reduction, into project plans. The DOT’s robust asset management system generates prioritization scores and ranks at-risk assets within the system based the severity and duration of climate impacts, the asset condition, and affected users. Figure 32 shows an example screenshot of culvert maintenance and assessment based on the Caltrans prioritization scores.

4.1.1 Resilience of Various Culvert Shapes and Materials

The Caltrans representatives noted that any asset serving as a drainage facility that does not meet the definition of a bridge as defined by the National Bridge Inspection Standard (NBIS) is considered a culvert. The following description of a culvert is included in the Caltrans Culvert Inspection Manual (not publicly available): “. . . structures less than 20 feet in span are called culverts. This includes extreme ends of openings for multiple boxes; it may also include multiple pipes, where the distance between openings is less than one half of the smaller contiguous opening.” The structure must serve as a drainage facility; equestrian crossings, pedestrian crossings, and tunnels are not considered culverts even if the opening is less than 20 ft.

4.1.2 Maintenance Practices to Enhance Culvert Resilience

Common maintenance practices employed to enhance culvert resilience are cleaning of the culverts and clearing debris to allow for water flow. A proactive resilience effort employed by Caltrans is thorough culvert inspections. There are five categories on which the culvert condition rating system is based: waterway adequacy, alignment, structural integrity of the shape, condition of the joint, and condition of the material. Culvert inspectors rate these five attributes on a 0 to 4 scale. The five attribute scores are then combined in a weighted scoring matrix to produce a health score of 0 to 100. The health score produces the overall condition rating of poor (0–49), fair (50–79), or good (80–100). When a culvert receives a condition rating of poor, the DOT carries out a site assessment and makes recommendations for appropriate repair and rehabilitation practices such as applying culvert liners or CIPP to restore the service life of the culvert; Caltrans considers this rehabilitation of the culverts as opposed to maintenance. Caltrans provides supplemental design guides and design bulletins that detail frequently implemented rehabilitation methods such as use of culvert liners, invert repairs, and joint repairs. Qualifying materials and repair strategies are approached on a case-by-case basis and often vary between districts. While there are not established service life extensions associated with individual repair and rehabilitation practices, the DOT does attempt to regain a 50-year service life from any work performed. Examples of practices to prolong service life and therefore enhance culvert resilience are the use of CIPP liners to provide an enhanced wear layer where abrasion is a problem and using different concrete mixes for invert paving to boost abrasion and corrosion resistance.

4.1.3 Resilience Assessments – Identification and Prioritization

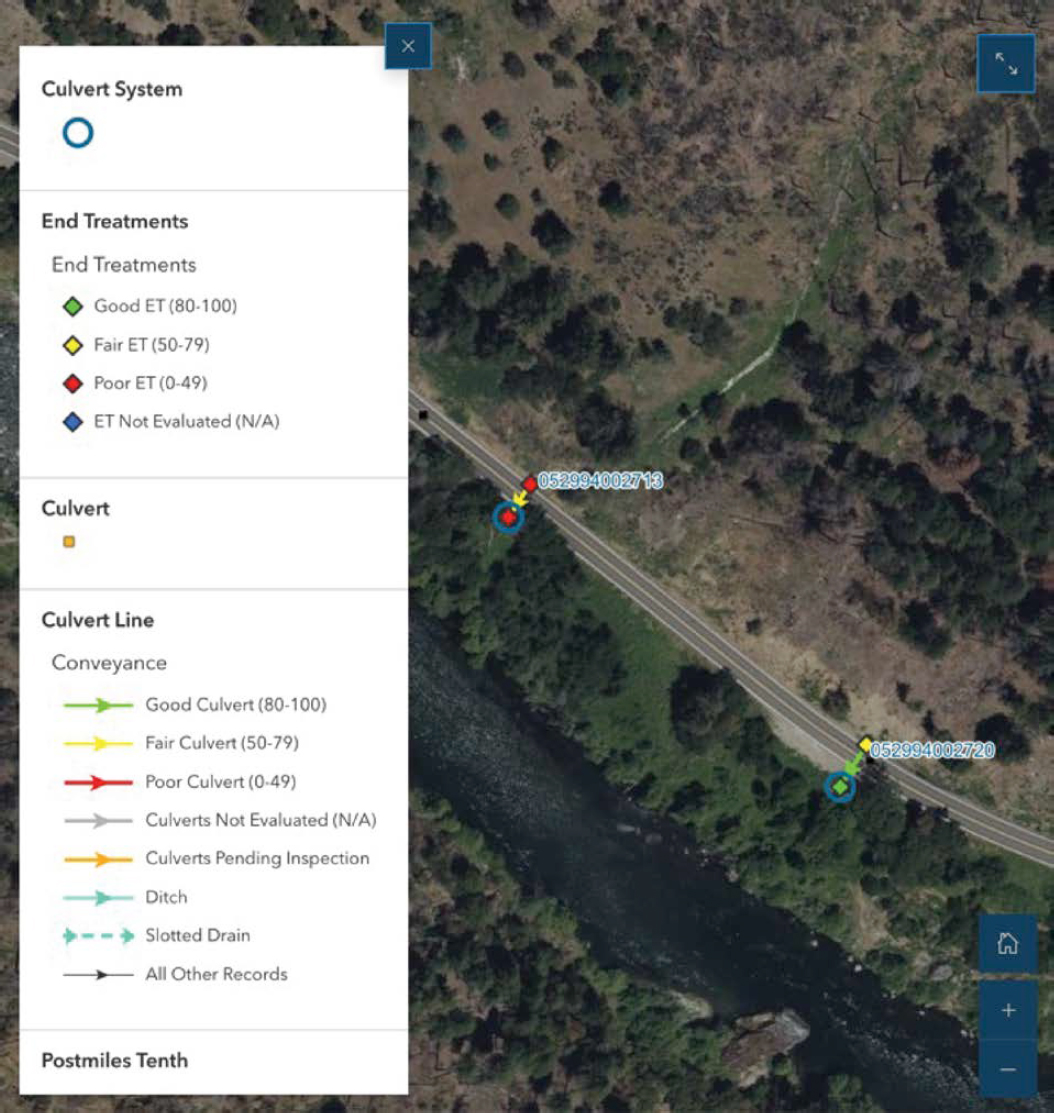

The Caltrans Culvert Inspection Program inspects all culverts on a 5-to-7-year cycle. The DOT requires this schedule to avoid deterioration-related condition changes. During inspections, the culvert is identified using field maps with GIS to map the precise culvert location on the Statewide Culvert Webviewer (https://svctenvims.dot.ca.gov/env_viewer/). While inspections do not directly improve the resiliency of the culverts, awareness of culvert condition and location allow for proactive maintenance and repair before rehabilitation or replacement is required. Before implementing this culvert inspection cycle, Caltrans struggled to prevent failures. This system improves culvert resiliency by easily locating and tracking culverts in need of repair, rehabilitation, or replacement.

During inspections, a crawler is sent through the culverts, and video and photos are taken of the inlets and outlets. Through an online survey software tool, culverts are rated and assigned a culvert health score and overall condition rating. Based on the culvert’s properties and individual attribute scores, a decision tree will recommend an appropriate treatment, which is then reviewed by designers before implementation. Recommendations can range from repair strategies such as using a CIPP liner or changing the inlet to full replacement of the culvert. Caltrans monitors 256,000 culverts in its asset management system, and it estimates its total inventory to be over 300,000. An example of the Caltrans scoring assessment is shown in Figure 33.

The Road Repair and Accountability Act of 2017 (Senate Bill 1) created performance targets that Caltrans must meet for asset tracking. Caltrans created its Transportation Asset Management Plan (TAMP) as a guide to achieve these performance targets for its transportation investments. The State Highway System Management Plan, created from TAMP, defines asset classes and performance measures for the established targets. All districts have implemented a 10-year plan for achieving a 90% good or fair rating for all Caltrans culverts by 2027. Every June, the California Transportation Commission requires a benchmark progress report with plans for achieving these performance measures. The highway drainage advisory team reviews culvert health conditions in submitted projects for all 12 districts to ensure adherence to the required performance targets.

The 5- to 7-year inspection cycle is challenging in bigger districts because of the number of culverts requiring inspection. Culvert inspections are uploaded into the Caltrans asset management system, and districts are notified when a reinspection is due. It is important for the DOT to know the actual condition of culverts relative to the timeframe to avoid potential for culverts to slip from a fair rating into a poor rating.

4.1.4 Cost Assessment Methodologies for Culvert Resilience Improvements

Caltrans has created an in-house computer software program called “AltPipe” that is used for selecting new culverts. The program analyzes characteristics unique to a location, such as soil PH

and resistivity, estimated abrasion loads, and geotechnical loads, and provides options that will fulfill a minimum estimated service life of 50 years. The software is applicable to all culvert types. For existing culverts, Caltrans has many rehabilitation techniques to extend service life that can be adapted to address issues such as invert deterioration and corrosive environments.

4.1.5 Risk Management Strategies

Caltrans does not have a formal risk assessment framework in place but is focusing on assessing and prioritizing the condition of culverts as a risk mitigation strategy. The DOT is considering a risk assessment framework for the future using its GIS system because of its ability to layer different maps; the GIS system could overlay its poor-condition-rated culverts with documented storm surges in the area so culverts in areas of risk could be identified and prioritized. So far, 10 of the 12 districts have documented all culverts in their area, with the remaining two most populated districts not far behind. A screenshot from the Caltrans Culvert Inspection Program map is shown in Figure 34.

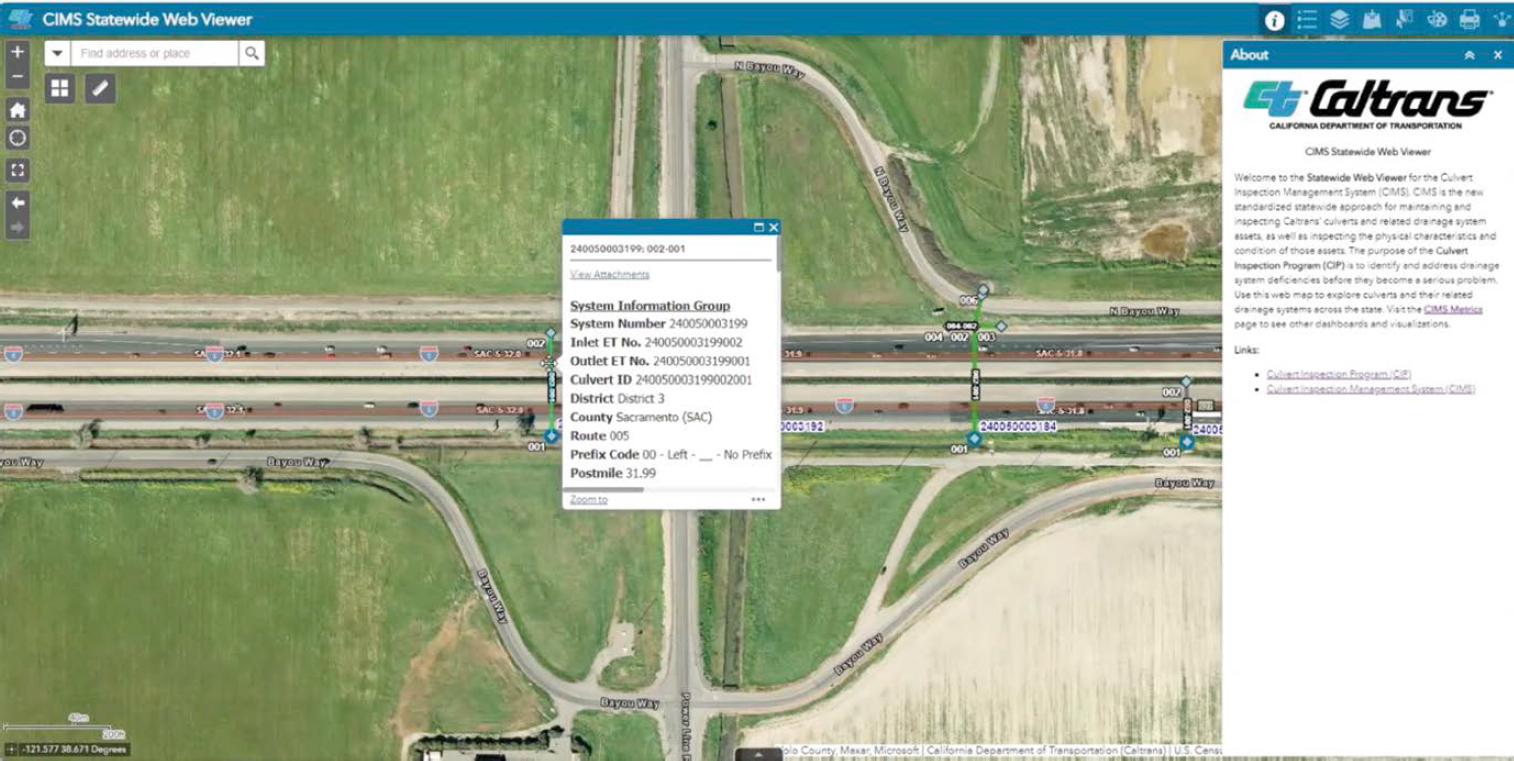

Caltrans uses geo-mapping software called the Culvert Inspection Management System (CIMS). The CIMS user interface is not available to the public, but anyone in the Caltrans system can use the software. CIMS allows Caltrans to see geospatial data and specific asset information, such as the current health condition of a culvert, as well as activity information that details the culvert’s latest inspection date or additional comments, as shown in Figure 35.

Previously, each of the 12 districts maintained its own asset database, which would then be compiled into one centralized database at headquarters. The separate systems resulted in inconsistencies between the districts and headquarters. Since 2023, all districts share one single database and work together on one platform, allowing for easy collaboration and efficient communication between districts and headquarters. All new inspections recorded in the system have photo attachments from all dates of inspections. Because Caltrans had legacy data from the previous databases, not all historical records have been entered into the new system, but the DOT still maintains all records of older inspections. CIMS only includes culverts and end treatments but has the potential to layer different maps to identify critical areas for risk management strategies; one such layer could include areas affected by climate change and extreme weather events. CIMS also includes information for users such as how to conduct a culvert inspection, how to map culvert locations, and how to use the software to review the collected data. Figure 36 shows the CIMS homepage as available to Caltrans employees.

4.1.6 Practices to Mitigate Piping

Caltrans provides a maintenance bulletin to help inspectors identify where piping occurs and how to identify signs of it. Additionally, inspectors can make comments on inspection records so that when a culvert is involved in a new project, designers and engineers will know if piping is an issue. The Caltrans representatives emphasized the importance of diligent inspections and adhering to specifications during initial installation so the joints of the culvert systems are tight and prevent piping. If signs of infiltration, exfiltration, or material loss are identified, the DOT employs different techniques to mitigate this. Pressure grouting is used to stop piping and stabilize the surrounding embankment material by injecting pressurized chemical grout through the affected joint. Another practice to mitigate piping is the use of rubber seals installed with expanding metal rings to span the pipe joints. Piping has been a problem for Caltrans since sinkholes can develop, leading to catastrophic pavement failure, emergency repair, and potential harm to the traveling public. Caltrans does not specify certain types of backfill to prevent piping but does allow contractors to provide controlled low-strength material or a concrete slurry backfill on pipes because of the cost-effectiveness and ease of these methods.

Most instances of infiltration or exfiltration are seen in older pipes, where inspection reports from installation are not accessible.

4.1.7 Practices to Address Embankment Overtopping

All culverts are designed to handle a Q100 design storm (where Q is the quantity of the runoff; Caltrans 2020b) without causing objectionable backwater depths or outlet velocities. In areas with potential for debris or sediment to plug a culvert, debris racks or culvert risers are installed as fail-safe options. Armoring the embankment with rock slope protection or down drains are frequently

implemented practices in areas where a fail-safe cannot be provided. Isolated overtopping events have been recorded, most notably in District 8 on the eastern side of California; unusual flooding in the desert has overwhelmed numerous culverts and bridges. Assets affected by the flood events have been overtopped and had their embankments eroded, which closed portions of Interstate 15 and Interstate 40 while the repairs were carried out. The DOT representatives suspect the non-cohesive soils characteristic of desert locations are the reason behind the washouts. Regardless of the soil type, the flows during these flooding events are exceeding the design flows from the bridges’ initial construction. Caltrans is conducting research in partnership with University of California, Berkeley to update the bulking factors used for flows located in desert settings. This research is also updating the bulking factors used in the Sierra Nevada mountain range, which has been having more frequent forest fires. The post-fire, burn-scarred areas are producing large sediment loads and woody debris, causing obstruction of culverts. These updated bulking factors will apply to other fire events where systems have been completely inundated by sediment and woody debris, and the goal is to accommodate these potential impacts through the initial design of culverts. Caltrans is focusing its work on the replacement and installation of new culverts; many culverts in the Caltrans inventory were designed 30 to 40 years ago, when the hydraulic design criteria were different. Legacy culverts do not always meet current design criteria and may become a safety issue. Caltrans is developing hydraulic design recommendations for upsizing culverts to meet current standards and updated climate change rainfall data. More recently, to avoid disrupting roadways, Caltrans has begun employing trenchless technologies such as boring and jacking larger-diameter culverts through large embankments where upsizing is the best option.

4.1.8 Practices to Address Coastal and River Impacts

Coastal impacts and storm surge are a major concern for Caltrans. The 7th Edition of the Highway Design Manual (Caltrans 2020a) contains a chapter on shoreline protection (Chapter 880) along coastal areas and lakes that provides design guidance for hydraulic engineers. This, in collaboration with environmental, landscape, construction, and maintenance teams, allows for the selection of appropriate storm scenarios, consideration of wave heights and high water levels, the use of different wave models, flood analysis, and consideration of scour in design solutions. The process of choosing predicted sea-level rise and potential coastal impact factors has been a lively topic of discussion for Caltrans. The DOT prioritizes the latest and best available science when making decisions and references FHWA Hydraulic Engineering Circular 25 Highways in the Coastal Environment (FHWA 2020) for its approaches to solve coastal issues. Armoring is a commonly implemented practice for mitigating coastal impacts. Caltrans is prioritizing research on the approach and treatment of this ever-evolving issue.

4.1.9 Post-Event Response Practices

Districts will create an emergency project using what is called a Director Order (DO), which falls under the Major Damage Restoration program, which is a program in the State Highway Operation and Protection Program for the reopening and restoration of a highway after a catastrophic event. The Emergency Work Guidance Manual was developed under the California Public Contract Code Section 1102. DOs are formal documents signed by the district director that allocate funding and grant authority to accelerate a project. DOs help Caltrans respond quickly and effectively to emergencies on the state highway system. The Major Damage Restoration program covers all types of catastrophic events, including wildfires, sinkholes, and seismic activity.

4.1.10 Future Potential Research

Caltrans is conducting research on cementitious liners, specifically liners for culverts sized 36 in. and greater. Caltrans currently limits cementitious liners to 36-in. culverts and below with

a 1-in. minimum specified thickness for the liner. The DOT is researching recommended liner thickness calculations based on loading, host pipe condition, and abrasion level. Caltrans is also exploring geopolymer cement mortar used in the spray-applied liner process. The representatives are interested in a large-scale research project on investigating new cementitious material application methodologies for all culvert diameters. Their goal is to standardize rehabilitation practices so all district engineers can have these techniques readily available in their toolbox.

The Caltrans representatives emphasized the benefit of GIS and the ability to monitor systems and assets in real time to increase culvert resilience overall. Caltrans is looking forward to advancements in layering of the GIS data for resilience improvements and expects the software to play a major role in programming transportation projects in the future.

4.2 FDOT

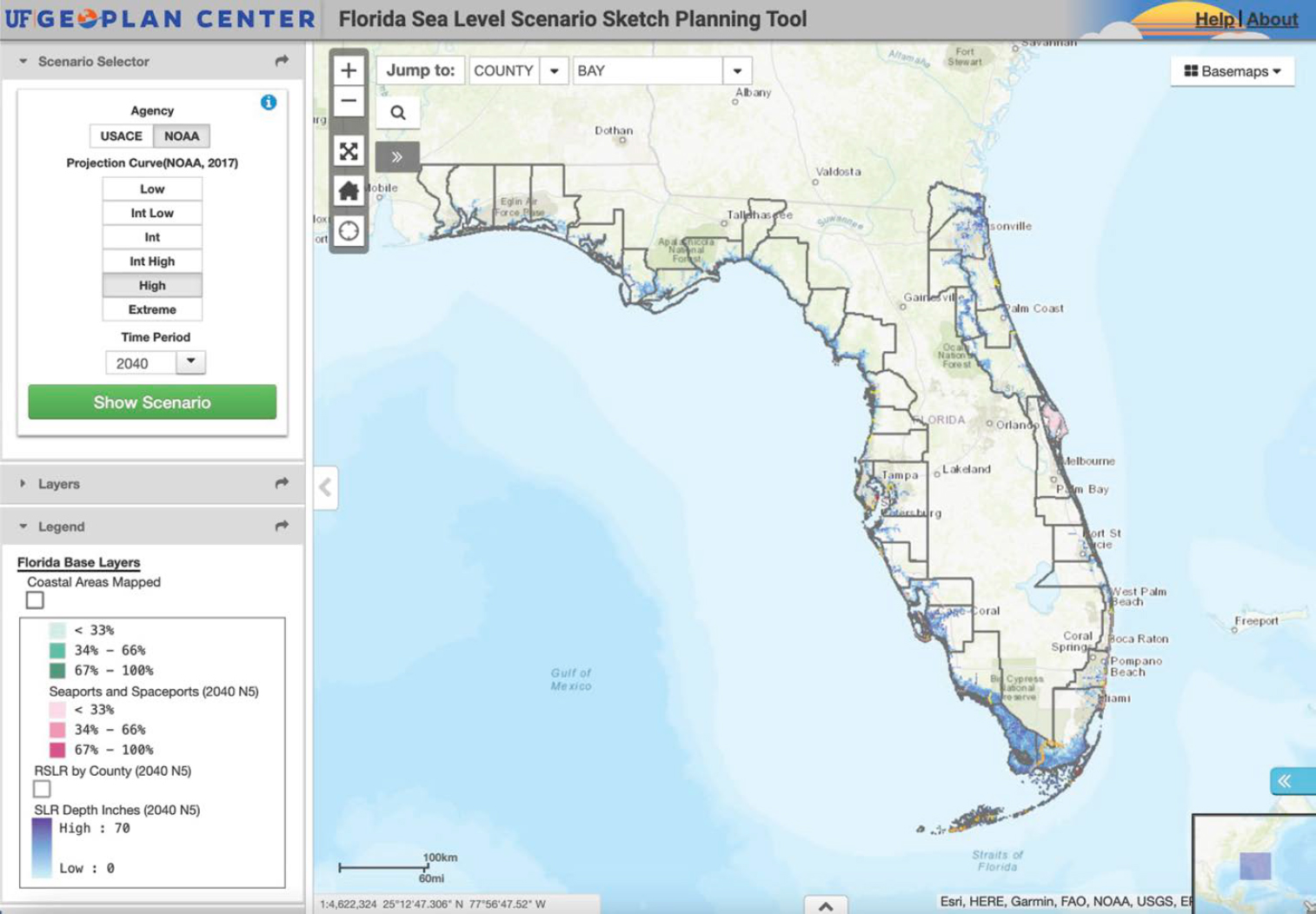

FDOT has prepared a Resilience Improvement Plan to comply with the requirements of the PROTECT act and to receive funding for short- and long-term resilience improvement projects. Resilience improvement strategies at FDOT include addressing hazards facing drainage and stormwater system design by including climate change uncertainty into design criteria, developing a risk management and decision-making framework to incorporate climate risks into all project phases, and adjusting project designs to consider cost of maintenance over the life cycle of assets. FDOT also focuses on preparation for and response to extreme events as a key focus of its resilience strategy. Research conducted by FDOT in 2023 focused on updating manuals of practice for transportation project design and emphasized extreme rainfall and sea-level change as two major implications of climate change. One tool FDOT uses in infrastructure planning is the Sea Level Scenario Sketch Planning Tool, which allows for long-term assessment of sea-level rise (see Figure 37). FDOT uses projected sea level and tides to aid in making decisions regarding maintenance, repair, and replacement projects.

The FDOT representative commented on the concept of culvert resilience, mentioning that FDOT has always implemented high standards in planning, design, construction, and maintenance of its transportation network. A definitive element of the DOT is its commitment to quality, and resilience has always been factored into FDOT’s engineering practices.

4.2.1 Resilience of Various Culvert Shapes and Materials

FDOT identifies most resilience issues through routine maintenance. The DOT has mitigated potential materials-related issues through the use of its Culvert Service Life Estimator, shown in Figure 38. This computer program was developed by the State Materials Office and uses environmental characteristics such as surrounding soil properties and structural requirements, including culvert pipe cover height, to determine which culvert material types can be used in construction projects.

FDOT does not frequently experience material-related culvert failures because it has addressed material-specific failure modes within its allowable culvert material specifications. Long-standing requirements of the DOT are the specification of watertight joints and the requirement of higher joint performance for culverts in critical locations.

4.2.2 Maintenance Practices to Enhance Culvert Resilience

FDOT uses liners and joint repair methods for remedial maintenance. Because the DOT has stringent requirements for where specific culvert materials can be used, maintenance practices to enhance resilience have not been needed. Culvert maintenance is incorporated into design

projects or completed through maintenance contracts. Because protective repairs often do not significantly extend the service life of culverts and have similar costs as culvert replacements, FDOT prefers to replace culvert pipes if there is an opportunity to include the replacement in an upcoming construction project. This saves on maintenance of traffic while fully re-establishing the entire service life of the culvert.

4.2.3 Resilience Assessments—Identification and Prioritization

FDOT does not have a formal asset assessment program specifically for resilience. Some district offices are developing a GIS-based program to track past maintenance activities, and the central office is working on a framework for a statewide GIS program for culverts. The DOT is focused on first locating and identifying assets, and then implementing an inspection program. Because FDOT emphasizes routine maintenance and has not encountered many resilience-related issues, frequent inspections of culverts will likely not be implemented. Culverts are currently tracked in FDOT’s Roadway Characteristics Inventory, which broadly details linear feet of pipe per mile of roadway.

4.2.4 Cost Assessment Methodologies for Culvert Resilience Improvements

Resiliency improvements are decided upon by districts based on previous experience with lining technologies. District maintenance offices typically select and specify products known to be successful for the type of damage experienced and previous repair successes. The central office is beginning to standardize the various methods for which is has specifications. The DOT has developed a Pipe Repair Matrix (FDOT 2022a) for post-installation culvert video inspections, which details requirements of repair or replacement from damage. The Pipe Repair Matrix provides various repair options for metal, HDPE and polypropylene, PVC, and concrete culvert pipe materials. An example of the repair options for steel-reinforced concrete pipe is shown in Figure 39. Repairs are required to reinstate the service life of the culvert to full design service life.

Additional criteria for the post-installation inspection of rigid culverts are the measurement of cracks and the measurement of joint gaps via video micrometers; flexible culvert pipe criteria include laser profile measurements to identify whether the shape of the culvert is maintained within the specified limits of deflection.

4.2.5 Risk Management Strategies

FDOT conducts post-event damage surveys to evaluate system resilience. FDOT emphasizes the need to consider the additional risks that can be posed in response to improvement strategies. Florida experiences frequent extreme weather such as heavy rainfall and hurricanes, which affect the state’s numerous floodplains and its high groundwater table. FDOT’s standards have improved its resilience to these frequent events, and the DOT frequently revises and updates specifications and standards based on lessons learned to ensure that similar issues do not occur in the future. FDOT also participates in post-event field reviews with the state’s Chief Resilience Officer, providing resources to help improve the resilience of local systems.

4.2.6 Practices to Mitigate Piping

Because of the long-established specifications for culvert joints, which include wrapping of the joints, FDOT does not commonly experience piping, although coastal roads in the Florida panhandle region have been affected by the change in pressure from storm surge during coastal storms. The culverts that were affected were older culverts that may not have been installed with the current

standards. Although there is no active research in this area, FDOT emphasizes the need for understanding criteria that were in effect when systems were built.

4.2.7 Practices to Address Embankment Overtopping

While overtopping is not a significant issue for FDOT, it has experienced overtopping related to excess water during a hurricane storm surge. FDOT approaches transportation projects by designing the entire system for resilience through consideration of all elements and assets of the project for various design events. In 2007, the DOT installed a vertical, polyvinyl sheet pile wall reinforced by buried gabion baskets along US 98, a critical coastal roadway located in Okaloosa where overtopping was frequently occurring, as shown in Figure 40. The purpose of the project was to investigate methodologies for assessing vulnerability and adaptation alternatives to roads affected by coastal storm washout (FHWA 2017b). The wall was successful in preventing further roadway erosion from overtopping and is still in use, as seen in the figure.

4.2.8 Practices to Address Coastal and River Impacts

FDOT conducts studies on practices to mitigate the over-washing of roadways from coastal storms. Experience from Hurricane Ian on Sanibel Island showed that the presence of shoreline vegetation led to preservation of the roadway. Additional projects include a secant wall design along the

eastern side of Florida to protect roadways from Atlantic storm events. While this practice does not prevent the sand dune system from overtopping, it does protect the road, which can be cleared after the storm event. FDOT maintains that the removal of debris after storm events will always be necessary, but protection of the roadway is the hallmark of a resilient design. FDOT is compiling a list of specifications for various installations and case examples of their performance after severe weather events, with the goal of providing state engineers with a toolbox to aid in resilient design.

4.2.9 Post-Event Response Practices

The two main post-event response practices employed by FDOT are the inspection and desilting of culverts after every storm event. FDOT is currently investigating tools to evaluate roadway embankments to inspect for soil loss post-event. During Hurricane Ian, the DOT did experience embankment washouts adjacent to bridge structures, but none related to culvert resilience failures. The FDOT representative detailed a local roadway where a multi-barrel culvert section and concrete end-wall were replaced after Hurricane Irma, but during Hurricane Ian, the culvert pipes were blocked with debris and the adjacent roadway embankment washed away. It was suspected that soil loss through the embankment during hurricane Irma was not caught during inspection, and the weakened soil system caused the washout during the following storm.

4.2.10 Future Potential Research

FDOT is interested in the development of a guidebook for post-inspection practices to assess damage and provide repair solutions or guidance on whether replacement is more appropriate. Documentation of repair strategies specific to observed damage would help maintenance and design offices in making decisions regarding culvert repair and replacement projects. The FDOT representative stressed the importance of continual communication and collaboration across maintenance, materials, and design offices in successful resilience strategies.

4.3 MDOT

MDOT has developed a strategic plan called the Transportation Resilience Improvement Plan (TRIP) to guide the funding received through the PROTECT program toward infrastructure resilience improvements such as planning activities to assess vulnerabilities, strengthening

evacuation routes to protect communities, and stabilizing at-risk coastal assets. Coastal impacts are of extreme concern for MDOT. Because of its considerable shoreline, coastal flooding, storm surge, and inundation magnified by sea-level rise present challenges to the DOT and have resulted in soil erosion, accelerated deterioration of roads and bridges, and subsequent safety hazards.

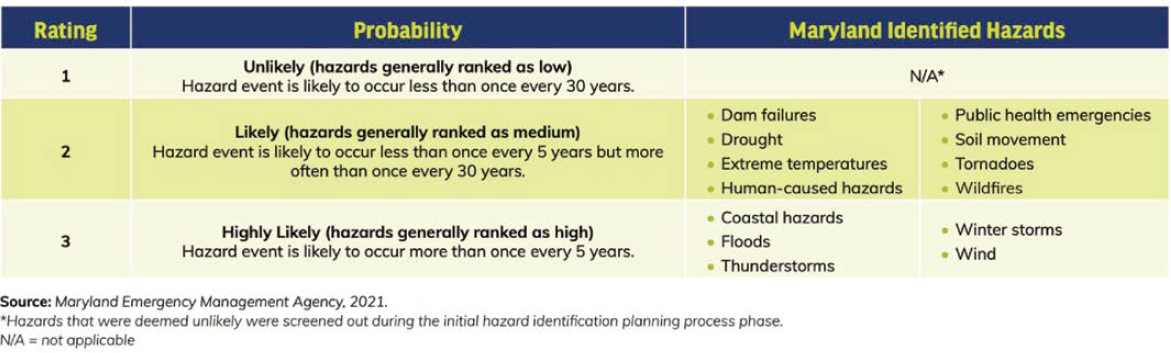

MDOT uses its TRIP as a framework for “project planning and design, investment, prioritization, and life-cycle planning . . .” (MDOT 2024b) as well as incorporating extreme weather event risk assessment into decision-making to accommodate and mitigate potential challenges due to climate change. Multiple transportation sectors within MDOT are conducting vulnerability and risk assessments to analyze the impacts of climate change on the state’s assets. An example of MDOT’s Hazards Probability Rating is shown in Figure 41.

4.3.1 Resilience of Various Culvert Shapes and Materials

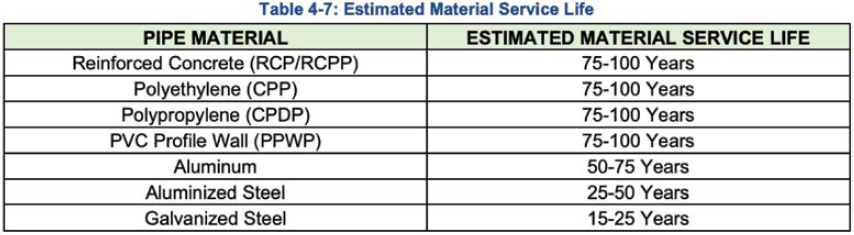

One of the biggest resilience issues Maryland faces is the acidity of the groundwater. MDOT has identified locations where it cannot use metal culverts or must specify only aluminum, aluminized steel, or stainless (galvanized) steel to avoid corrosion. Many of MDOT’s culverts were installed in the 1950s and 1960s, and frequent failures due to corrosion are requiring the DOT to proactively assess the condition of its culverts before failure. Figure 42 shows the estimated service life of various pipe materials given the acidic installation conditions.

A challenge facing MDOT is the presence of acidic soils all over the state, but particularly on the western side of Maryland; former mining activity in this region has resulted in acidic watersheds. The groundwater is receiving treatment for its acidity, but culvert failures are still resulting from past corrosion damage. Although corrosion is a less frequently experienced issue for reinforced concrete

culverts, the DOT frequently employs asphalt linings or epoxy coatings on the invert to protect culverts from groundwater conditions and to prevent corrosion of the reinforcing steel.

4.3.2 Maintenance Practices to Enhance Culvert Resilience

MDOT uses a combination of efforts to enhance culvert resilience. It has a team working specifically on culvert lining, focusing their efforts in the western part of the state where culverts are often installed under hundreds of feet of fill and replacement is an extreme challenge. Currently, the DOT is investigating sinkholes on Interstate 70. Inspection of the culverts showed that the pipes themselves were in good condition, but voids in the surrounding soil are causing piping issues. A frequently employed practice to mitigate this is polymer injections to fill the voids and keep the culverts supported. The material technology team at MDOT uses ground-penetrating radar to identify voids in the soil around culverts and uses these locations to inject the polymer through the walls and into the voids. The MDOT representatives suspect the voids were created by a combination of poorly compacted soil at installation, leaking joints, and increased frequency of flood events. Piping is a resilience concern for MDOT because the peak storms experienced by the state have been increasing in intensity, leading to ponding upstream and subsequent piping along the sides of culverts because of increased capacity demand. Additional remedial maintenance includes CIPP using a recently developed specification that is in accordance with MDOT’s advanced sediment control Stormwater Pollution Prevention Plan (SWPPP) for all construction projects. The SWPPP dictates frequent testing of waterways for all chemicals used in the construction process to mitigate harmful chemical runoff.

4.3.3 Resilience Assessments – Identification and Prioritization

MDOT is developing an asset management program for drainage assets and is modeling its design after its fully developed stormwater management program. The documentation process consists of screening culverts via field inspection and assigning a rating to them based on different factors such as criticality to the roadway, ADT, and overall condition. Maintenance issues may get prioritized differently amongst districts. Recently approved federal funding for the culvert asset management and inspection programs will improve the robustness of MDOT’s highway hydraulics team’s efforts; the DOT estimates up to 20 years to complete full identification and documentation of the 100,000 culverts within the state’s jurisdiction.

4.3.4 Cost Assessment Methodologies for Culvert Resilience Improvements

MDOT has step-by-step guidance for culvert condition rating detailed in the Highway Drainage Manual to identify and compare appropriate and cost-effective improvement strategies (MDOT 2023a). Resilience-enhancing practices have different service life extensions and cost impacts, but the availability of workers to perform the service and an understanding of the contracting process are important factors. Additionally, whatever strategy is chosen must be maintained by the district maintenance teams, which handle all culvert maintenance. While there are no standardized cost–benefit assessment methodologies at the DOT, a requirement of every project is to “consider the total life-cycle cost of a culvert, including maintenance, rehabilitation, and replacement costs . . .” (MDOT 2023a) and suggest the most life-cycle cost-effective option, although cuts in funding can result in choosing the cheapest option. In the latest version of MDOT’s drainage manual, larger-sized culverts are specified to provide scoping for potential upsizing. MDOT currently designs for a 50-year service life of culverts, but this design does not consider more frequent flooding, which has become a major issue for the DOT. New designs account for future upsizing of culverts and use ditch irrigation as an auxiliary catch-basin overflow for these extreme weather events while mitigating future replacement issues.

4.3.5 Risk Management Strategies

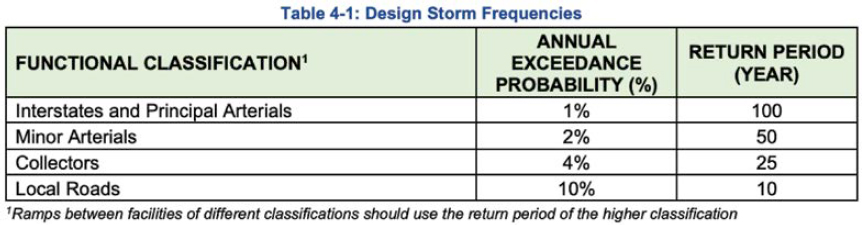

The Highway Drainage Manual (MDOT 2023a) dictates the use of NOAA Atlas 14 precipitation frequency estimates and other rainfall curves in new and replacement culvert installations. The Highway Drainage Manual specifies flood-level allowance for different roadway classifications; additional considerations include FEMA-mapped floodplains and the Maryland Department of the Environment dam safety guidelines for roadway embankments. For designs that do not meet the required metrics, to allow justification, a design exemption must be obtained that evaluates the risk. Figure 43 shows the design storm frequencies used in the design of various roadway classifications.

4.3.6 Practices to Mitigate Piping

MDOT employs end treatments to alleviate the effects of highly erodible soil. The representatives stated that most culverts are installed with end treatments, which consist of end walls, end sections, riprap, and inlet and outlet protection. Additional use of wing walls lessens the risk of piping from ponding. A focus of the DOT is to prevent erosion and reduce scour potential around culvert inlets and outlets. The representatives did state that maintaining hydraulic capacity of culverts after relining is an issue due to undersizing. Inland culverts experience a riverine flow with distinct differences between the upstream and downstream flow, subsequently affecting the performance of the culvert and the surrounding soils.

4.3.7 Practices to Address Embankment Overtopping

Reducing overtopping is a major focus of MDOT. Coastal culverts experience roadway overtopping more frequently because of inundation on both sides, and extreme events that lead to overtopping result in excessive loose soil downstream. Erosion control is a frequently implemented strategy to reduce the risk of overtopping. MDOT’s responses to slope failures include the flattening of slopes in initial design and providing a denser vegetation cover. Stabilization standards and soil requirements have evolved, but local fills and materials are frequently used to avoid long-distance hauling.

4.3.8 Practices to Address Coastal and River Impacts

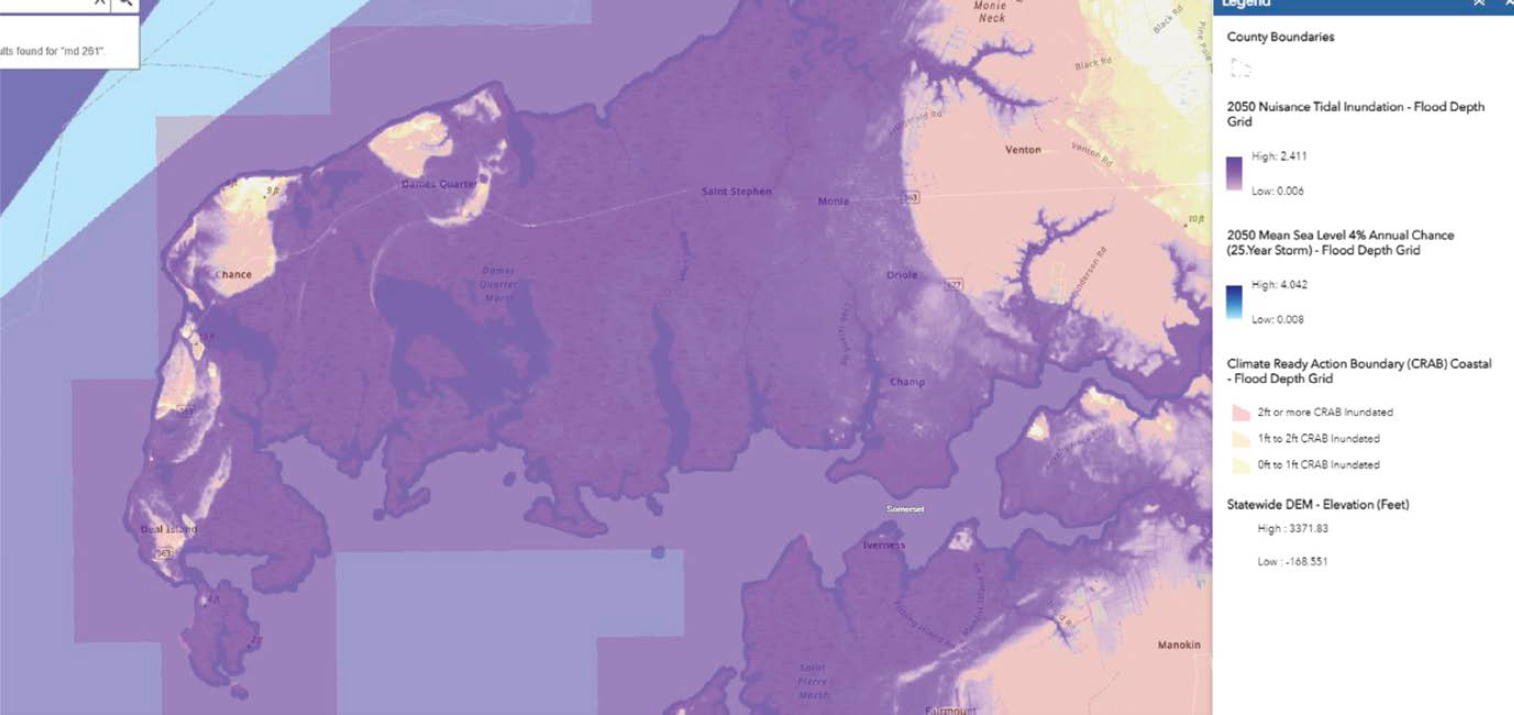

Sea-level rise and coastline progression inland are significant issues for MDOT, and it is taking steps to address them. Camera inspections of inundated culverts are only performed on request, but MDOT currently has projects investigating shoreline erosion from wave impacts that include inspection of affected culverts. The Highway Drainage Manual (MDOT 2023a) provides guidance on the structural design of culverts in coastal regions. Coastal inundation results in drainage investigation requests. Drainage investigations consist of an initial evaluation of the culvert and provide a quick recommendation in a timeframe of 4 to 6 weeks. When larger investigations are needed, the Highway Hydraulics division will take action. MDOT has multiple studies proposed to investigate the effects of sea-level rise and consequent inundation in coastal areas. Figure 44 shows the projected sea-level rise of Maryland’s coastal region.

The goal of the research is to develop permanent guidelines and solutions for coastal areas specific to enhancing resiliency. Initial solutions include raising the roadway above the affected culvert, providing alternative evacuation routes, and maintaining the existing structures.

4.3.9 Post-Event Response Practices

When extreme events result in serious impairments to roadways, districts submit emergency declarations (EDs) to headquarters to approve funding and expedite permitting for construction. Recently, Interstate 68 in Maryland experienced a sinkhole from the failure of a 38-in. metal culvert. The ED resulted in emergency procurement and repair approval the same day, and after replacing the system with a concrete pipe, the roadway was reopened to traffic the following morning. Concrete culverts are favored for the Interstate system for emergency replacement because structural backfill is not necessary. Occasionally, resilience upgrades will be considered in emergency repairs. Severe emergencies usually involve identical-material substitutions; the quick turnaround time required for these projects does not allow for full analysis of alternatives. The Maryland Emergency Management Committee has teams consisting of state DOT and district representatives to respond to events quickly and efficiently.

4.3.10 Future Potential Research

MDOT does not allow plastic pipes in Interstate or major arterial projects and is interested in long-term structural and resilience data on the product. It is also interested in the salinity durability of various pipe materials. The state already experiences brackish water due to its coastal location, but the rising sea level is resulting in increased inland waterway salinity. Concrete is currently the standard material choice under Interstates. MDOT is concerned about failures from saltwater corrosion. It expressed additional interest in research on a multi-objective resilience optimization approach investigating materials, cost, decision methodologies, initial design, and emergency response.

The biggest challenge facing MDOT when implementing resilient infrastructure is the impact on large, long-established multi-generational communities. It is expected the effect of climate change on sea level will result in major loss of habitable land within the next 25 years.

4.4 MnDOT

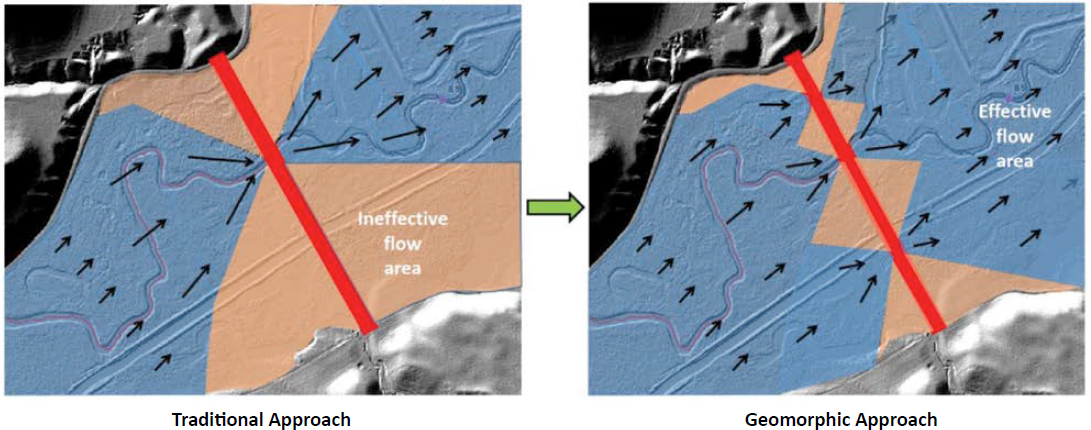

MnDOT is focusing on planning, design, construction, operation, and maintenance of its transportation system to enhance resiliency, with an emphasis on preparing assets for projected precipitation increases and larger, more frequent storms. MnDOT stresses the need for infrastructure risk reduction through assessments, check storms (checking against design storms), and extreme weather event projections to prioritize assets for resilience. MnDOT has been involved in pilot projects involving cost–benefit analyses of different culvert design options under increased flooding and has created the Extreme Flood Vulnerability Analysis PowerPoint presentation (MnDOT 2022) to characterize vulnerability of assets to flood events. One practice employed by MnDOT in conjunction with the Minnesota Department of Natural Resources is the use geomorphic design to reduce infrastructure failure due to flooding. This ongoing research involves adding floodplain culverts instead of upsizing to increase waterway connectivity and reduce the risk of overtopping. Figure 45 shows a comparison of the traditional and geomorphic design approaches. The red line in the figure indicates a roadway, the black arrows indicate flow direction, and the two depictions demonstrate the difference between the use of one culvert (traditional approach) and multiple floodplain culverts (geomorphic approach) in waterway flow.

4.4.1 Resilience of Various Culvert Shapes and Materials

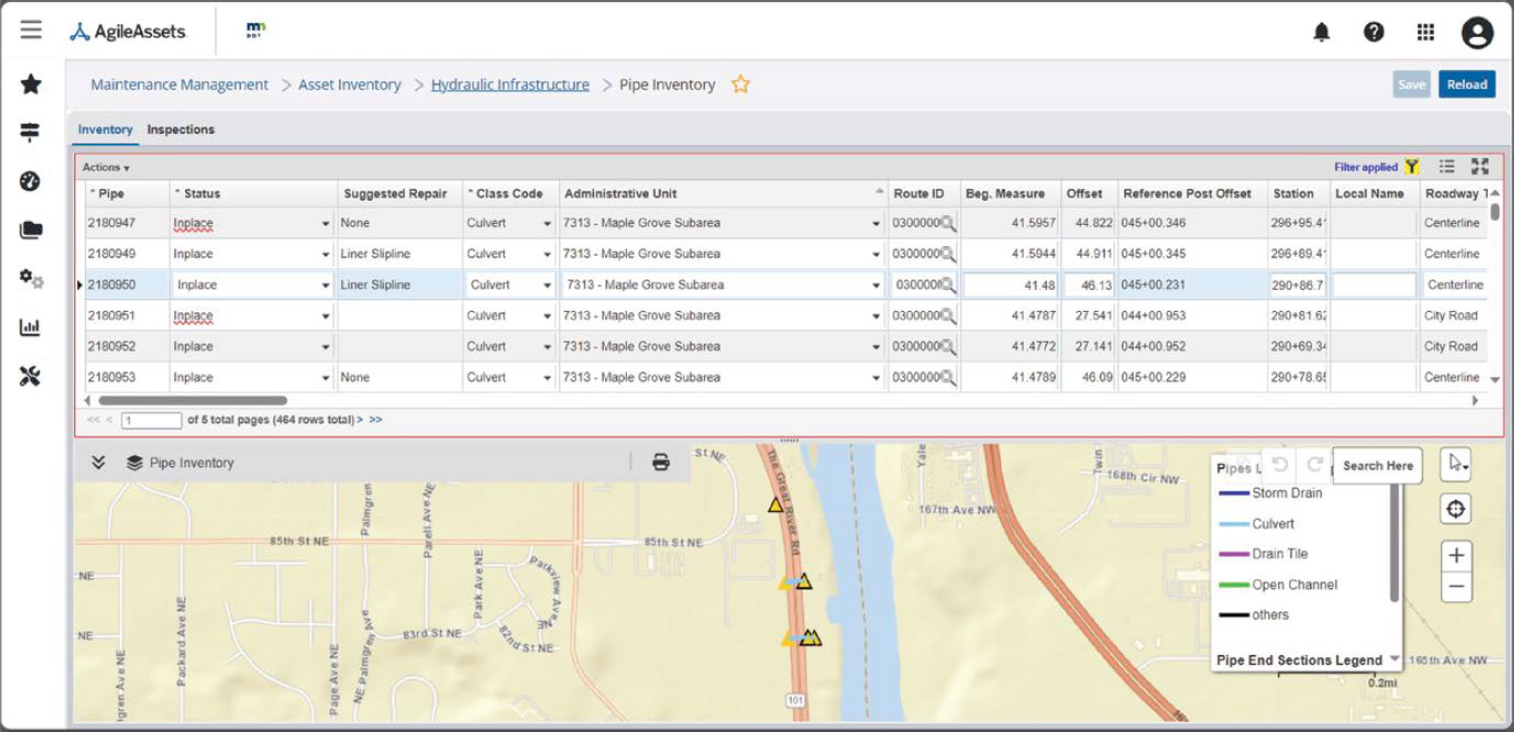

MnDOT classifies non-bridge culverts as structures under 10 ft in diameter. Inspection criteria are specific to culvert material, but culvert shape does not affect these criteria. The DOT strongly emphasizes the importance of culvert condition on culvert resilience, and inspectors consider flooding history and joint separation issues during inspections to identify and mitigate any potential resilience-related failures. The inspection frequency of culverts is based on their condition. Typically, highway culverts are inspected every 6 years if in good condition, but inspection can be as frequent as every 1 to 2 years if the culvert is experiencing severe issues. The DOT monitors inspections through its TAMS, which tracks all MnDOT assets, and contains a special section for hydraulic infrastructure called HydInfra. The TAMS HydInfra database includes all culverts and their historical inspection data, and also projects inspection schedules for assets based on their condition rating. Figure 46 shows an example of a TAMS HydInfra culvert inventory window.

The TAMS HydInfra database includes policies and manuals for inspection training for identifying common failure mechanisms for the different culvert materials; it has been successfully producing consistent culvert condition ratings statewide. Some districts will include an additional separate paper inspection sheet for each asset so inspectors can add sketches and any additional notes. The DOT representatives added that the culverts in the worst condition are often the culverts that fail in extreme events. Additional metrics the DOT is monitoring for resilience are areas of recent exposure to flood events, sag locations on roadways, culverts with undersized hydraulic capacity, culverts with continuous flow (i.e., from drain tile), and criticality of traffic detour length.

4.4.2 Maintenance Practices to Enhance Culvert Resilience

MnDOT focuses on extending culvert service life through proactive resilience. Liners are a common remedial maintenance measure to extend the service life of culverts. Invert repairs are less common, but the DOT has used concrete cloth or concrete canvas as a quick and cost-effective invert maintenance practice to enhance durability when full invert paving is not feasible. Concrete cloth is a dry concrete-filled flexible geotextile mat that cures when it is sprayed with or submerged is in water. Concrete cloth is thought to extend the service life of culverts by 25 years; although there is no formal documentation of this extension, the practice is helpful as a short-term durability solution. CIPP liners are used during construction to prolong the life of culverts, whereas during

routine maintenance, slipliners are more commonly used. During the lining process, MnDOT is careful to maintain current design standards for culvert pipe capacity. Centrifugally cast concrete pipe liners, which are spin cast with geopolymer or cementitious material, can save money on larger-diameter culvert repairs. The representatives commented on the high frequency of joint separations experienced by the DOT in unlined reinforced concrete pipe (RCP). Common joint repair methods to extend the service life of culverts include metal gasket gusset bands across the joints and using polyurethane resin–soaked rope and epoxy as a seal over any joint gaps. Districts are open to innovation and have experimented with proprietary chemical grout to fill voids in the backfill material. The DOT reports great success in using epoxy instead of cementitious material as a seal for joint separations, and it is actively researching the causes of joint separation as well as different mitigation strategies. In culverts with major defects prior to repair, there is greater risk of hidden/bridged voids and resulting catastrophic failure for concrete pavement compared to bituminous pavement; therefore, more consideration is given to using a repair method that addresses any voids in the road core.

4.4.3 Resilience Assessments – Identification and Prioritization

When prioritizing decisions for improving culvert resilience, MnDOT focuses on proactive asset management. In TAMS HydInfra, maintenance supervisors create dashboards of proactive repairs for specific culvert performance measures; for high-traffic areas, these maintenance practices can include resetting aprons, repairing joints, and paving inverts. MnDOT has implemented maintenance dashboards to proactively schedule culvert repairs, and it maintains a statewide goal of completing 20% of these repairs each year. MnDOT representatives commented that culvert condition should be prioritized when evaluating culvert vulnerability and risk of overtopping; they also emphasized the importance of considering culvert condition when determining funding.

4.4.4 Cost Assessment Methodologies for Culvert Resilience Improvements

When scoping projects, MnDOT compares various resilience improvement methods. The representatives emphasized that maintaining the capacity of the culvert is the most important factor when considering feasible resilience improvements; cost is considered secondary to capacity preservation. Decisions are typically made by rule of thumb based on previous experience in repair cost versus service life extension, but additional considerations include potential vehicle detours and project crossovers. The MnDOT Extreme Flood Vulnerability Assessment (EFVA) tool, a screenshot from which is shown in Figure 47, investigates cost and benefits of different maintenance and repair practices to enhance culvert resilience.

Updating projects for improved resilience has proven to be a challenge for the DOT, with the representatives recognizing the need to incorporate culvert condition assessments into original project scoping so that there are appropriate funding and scheduling available in the future. Additionally, TAMS is collecting data on the costs of culvert installation and maintenance over the entire life cycle of assets. In July of 2019, MnDOT launched the maintenance management module for hydraulics, which houses the asset cost dataset for culvert materials and projects. The representatives noted the need for further refinement of the data but are optimistic for life-cycle planning for all culvert materials and exposure situations.

To enhance culvert resilience, MnDOT also focuses on service life extension. Based on internal knowledge and experience, the DOT specifies a 50-year service life for CIPP liners. The service life for different culvert materials varies significantly based on how the culverts were installed. Factors contributing to the variability in service life include joint separation during initial installation, installation procedures, compaction of surrounding soil, and the structural

integrity of the culvert during and after the installation of the liner. This unpredictability highlights the need to improve TAMS and establish clear data on expected service life, life-cycle timelines, and extended service life associated with various maintenance practices.

The DOT acknowledges that the effects of climate change and changing precipitation patterns add complexity to asset management, and it has begun to implement its Resiliency Improvement Plan to start to address this. Severe storms have increased in frequency and severity and have led to unprecedented damage to roadways in Minnesota. MnDOT is working on compiling culvert life-cycle costs with the culverts’ associated risk exposure to create a portfolio of life-cycle analyses; this will be a tool for designers to optimize their culvert designs for improved resilience. The increase in severe storm frequency and severity may shorten culvert service life due to capacity inadequacy. Typically, service life is dictated by repair or replacement needs based on culvert condition.

4.4.5 Risk Management Strategies

MnDOT is continuously developing its EFVA tool to examine future expected damage costs and socio-economic risks to the public associated with flood events, and it expects to further expand and scale up its framework. Additionally, the DOT is developing a Risk Corridor tool to evaluate risks in specific locations. This software uses GIS layers to map all assets within a user-specified project boundary and entails four levels of data maturity: asset inventory, condition information, risk score for the specific asset, and a cost–benefit analysis. Figure 48 shows an example of a Risk Corridor tool window. This tool will identify culverts at risk to extreme weather events and prioritize maintenance of these assets. The DOT is working to establish strong datasets for each of the information avenues, but the current prototype shows strong potential to reach full maturity within a few years.

4.4.6 Practices to Mitigate Piping

MnDOT emphasizes the importance of thorough inspections for mitigating piping. Inspections include examination of the roadway surface to look for evidence of patching or cracking above the culvert, examination of the embankment and culvert end for soil loss or in-slope

cavities, checking under the apron for indication of piping, and investigation within the culvert to check for infiltration of soil into the water. Traditionally, MnDOT used a concrete culvert design with a gasket-less, tongue-in-groove joint and a geotextile wrap. This type of pipe is still installed, but the DOT is encouraging new installations to use gasketed joints with a soil-tight connection to retain bedding despite joint movement. Districts have investigated using a clay cap on the inlet to prevent piping altogether, and they frequently specify use of joint ties or flat-bar ties for installation of concrete culverts to ensure that culvert pipes are fully connected. The representatives commented on internal debates about watertight versus soil-tight joints; the DOT is encouraging use of gasketed culvert pipes but is not yet specifying watertight joints.

4.4.7 Practices to Address Embankment Overtopping

MnDOT is collecting information on overtopping locations and has found the results to be dependent on district topography. Overtopping is a frequent issue within the state, and as storms become more frequent and intense, design storms will likely increase, which may lead to replacement of a culvert due to overburdened hydraulic capacity regardless of the culvert’s condition. The DOT is developing a robust tracking system to determine overtopping locations and is adding in-slope armoring to known overtopping locations in the form of root-rap (buried riprap with vegetation planted on top for added protection), as well as articulated blocks and fleximats. Figure 49 shows examples of the in-slope armoring efforts.

The representatives noted that these protection measures provide improved resilience for undersized culverts without having to upsize, which can be costly and cause road delays. Some districts identified frequent overtopping locations and have implemented practices to mitigate overtopping; paving of the in-slope has proven effective for high tailwater and low-head differential across the road. MnDOT provides guidance on overtopping in Chapter 6 of its Drainage Manual (MnDOT 2024), but the representatives noted the need for a more detailed document to help designers choose an appropriate material to armor embankments.

4.4.8 Practices to Address Coastal and River Impacts

Some districts in southern Minnesota that experience frequent flooding and inundation of their culverts specify a flood compaction detail for new installation of culverts. The method consists of flooding the trench while installing the culvert to preemptively promote compaction that would usually happen after a flood event. The flood compaction method is a unique installation practice, and the DOT has been cautious implementing it statewide with contractors due to the precision required to avoid backfill washout or infiltration of the surrounding soil.

4.4.9 Post-Event Response Practices

In Minnesota, some districts have well-prepared extreme weather event response plans because they have predictable flood patterns. Other districts find extreme weather event response harder to plan for because they lack large watersheds with well-gauged streams, and forecasts from national weather services are variable. MnDOT is exploring options to improve overall state preparedness for flooding events by monitoring weather forecasts for significant rainfall and recording significant flooding events. To identify the assets most at risk in certain parts of the state, the DOT has overlaid the location of these weather events with culverts identified as being in “very poor condition.” This has been useful in alerting maintenance crews about specific locations in need of monitoring, and the response has been positive. Figure 50 shows the projected flood exposure risk in Dodge County, a district located in southeastern Minnesota. From this flood data collection, MnDOT is creating consistent maintenance records within TAMS to document all maintenance activities for flood response; this also contributes meaningful data to its life-cycle costing efforts.

4.4.10 Future Potential Research

MnDOT is working with NOAA to research recent extreme weather event exposure to bridges, culverts, and storm-sewer systems to record their flood history. This research will document where existing hydraulic assets were recently (in the past 25 years) exposed to extreme storms with precipitation intensities greater than their design storm. This data layer is combined with observations from the most intense event recently experienced, such as if the asset was flooded, and information on any damage that was incurred to the culvert or roadway. The goal of the research is to identify culverts that withstood the extreme weather event, which likely suggests that they are not vulnerable. Virtual vulnerability assessments can then be applied to other locations that have not experienced extreme events. Combining the real-world and virtual vulnerability assessments creates a prioritization plan of the less resilient assets and those damaged during extreme weather events. The DOT is hoping to develop software that allows historical flood data to be overlaid with geographical regions of Minnesota to identify and target areas that do not have a history of recent exposure to extreme weather; often, areas that have not experienced extreme floods are underprepared in terms of culvert hydraulic capacity and vulnerability assessments. MnDOT is optimistic that the prototype for this software will be completed and implemented soon.

Additional research about flood damage and mitigation effectiveness is also of interest to MnDOT. Information regarding the cost of damage for a range of flood-prone locations could be used in a BCA and in the EFVA tool. From this information, BCAs could be conducted on mitigation alternatives for cost-effective and resilient strategies.

MnDOT also has an interest in using lidar to identify sag locations in roadways. Sag locations are vulnerable to extreme weather events, and identifying these locations on a map could provide guidance on where to focus resilience efforts.

4.5 ODOT

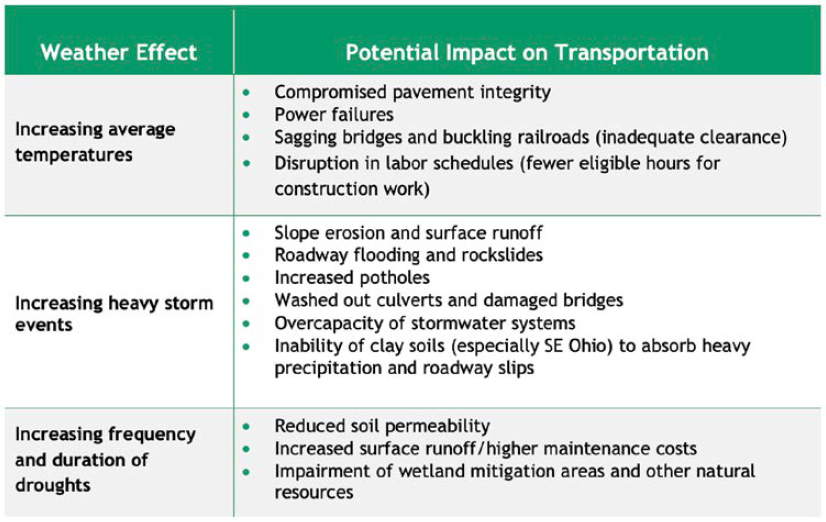

ODOT is embracing long-term planning practices and adaptive approaches as a part of its resilience efforts. It is looking to improve data collection and asset management practices to identify vulnerabilities in its system. This will allow for new design standards to protect assets at risk to the effects of climate change and inform economic decisions. Figure 51 details the potential impact of extreme weather events on Ohio’s transportation network. ODOT’s 2016 Infrastructure Resiliency Plan assessed and ranked assets by their vulnerability to extreme weather events and presented adaptation options for high-risk assets to mitigate vulnerabilities (RSG and McVoy Associates LLC 2016). Using this information, ODOT could begin to prioritize transportation projects based on asset vulnerability. Additionally, the DOT is focused on advancing weather analysis and modeling tools and improving internal coordination regarding resilience efforts.

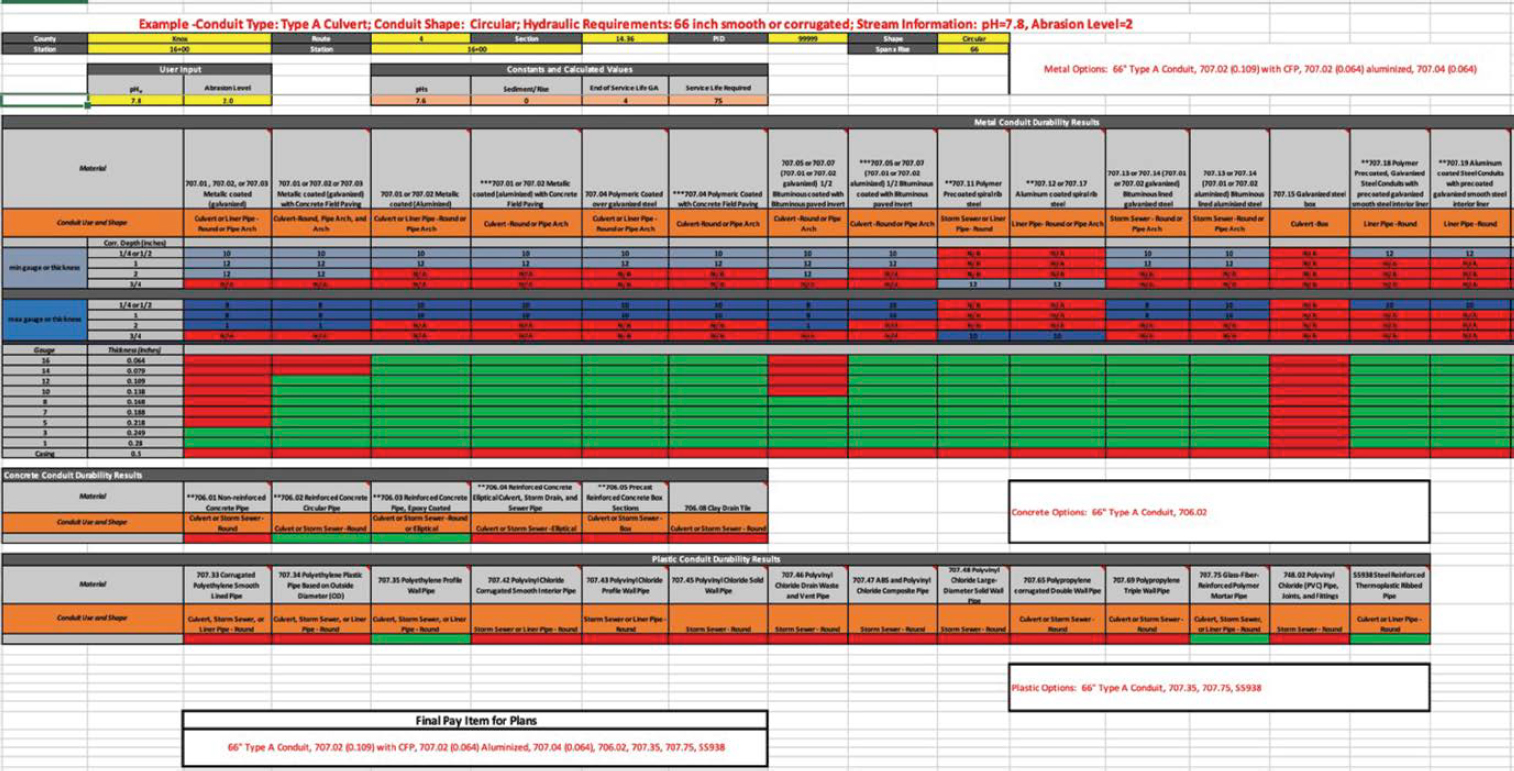

4.5.1 Resilience of Various Culvert Shapes and Materials

ODOT defines a culvert as being 12 to 120 in. in diameter, with anything above 10 ft. considered a buried bridge and therefore within the bridge division’s inventory. Larger-diameter culverts are managed by the bridge team and utilize a different asset inventory system. Additionally, ODOT does not consider its practices as enhancing resiliency as classically defined by the FHWA, and the DOT representatives emphasized the grey area between typical culvert wear and durability issues versus categorically resilient issues. While additional resiliency measures are actively discussed within ODOT, enhancing resilience is considered inherent to all ODOT efforts, and this priority is demonstrated through its exemplary culvert asset management system.

Issues related to culvert condition are picked up through routine inspections. ODOT has a robust asset management program specifically for culverts and uses different inspection frequencies for different sized culvert pipes; culverts over 48 in. in diameter are inspected more frequently than culverts under 48 in. in diameter. Culverts within the bridge inventory (10-ft. span and larger) are inspected every 2 years. Culverts that are inundated by water, where a full inspection is not possible, are given partial end-inspections every year. Culverts in worsening condition, or those given a general appraisal (GA) value of 4 or less, are inspected every year. The GA scale, detailed in ODOT’s Conduit Management Manual (ODOT 2024a) and shown in Figure 52, runs from 0 to 9,

with 0 defined as a complete failure and 9 defined as brand new. The manual explains the inventory and inspection process and GA rating and scoring of culverts in service. Certain characteristics, such as material condition, have significant influence on the overall GA score.

Also detailed in the manual are the inspection and inventory of culverts, including specific ratings and criteria based on the culvert pipe material and shape or type. For example, flexible culvert pipes have a shape criterion, whereas rigid culvert pipes do not since they are not intended to experience deflection. Resiliency-focused inspections include inspection of the embankment and headwalls, stream alignment, and potential scour at the culvert outlet. Additionally, inspections for signs of piping include surveil of the embankment, headwalls, joints, and the pipe material itself for perforations potentially allowing infiltration of backfill and exfiltration of water. Any issues identified during inspections are used to inform future decisions around asset management, whether these decisions are related to service life or durability design for materials, rehabilitation or replacement, or culvert linings. The findings during inspections and the consequent decisions made for ODOT’s asset management program affect the specifications, installation practices, and backfill requirements the DOT adheres to, and this information guides ODOT’s research. The interview participants stressed the importance of data collection on culvert condition and its impact on policy changes for future generations. A focus of research for ODOT is material durability and exploring specific coatings to enhance the protection and service life of culvert pipes. Research topics in the past have included investigating invert paving and polymeric coatings, rock-channel protection for outlet velocity, and spray-applied linings. Most research is state funded, and it varies from large projects to smaller, research-on-call partnerships with local universities to complete projects on a quicker timeline (6 months or less) and a smaller budget.

4.5.2 Maintenance Practices to Enhance Culvert Resilience

ODOT uses different techniques for culvert rehabilitation to extend service life without full replacement. A cost-effective and frequently used practice for extending service life of specifically corrugated metal culverts is concrete invert paving. This practice is limited to culverts sized 60-in. and above, but ODOT has assigned this practice a 20-year extension of the service life of culverts based on internal knowledge and experience.

Other practices employed by ODOT for improving culvert resilience include sliplining of the culvert, spray-applied liners, and internal bands. Use of CIPP is a frequent practice to improve resilience for storm sewers. ODOT has explored the use of fiberglass expand-in-place integration, where fiberglass is glued to the host pipe for added durability, although the cost–benefit analysis of this technique is still underway. Less frequent practices include tunnel lining, grouting voids, and spot repair techniques such as using epoxy or zinc-rich paint.

For joints that are leaking or separated, internal expanding seals have sometimes been used on concrete culvert pipes where the overall structure is in satisfactory condition but the pipe is experiencing a joint gap with minor infiltration. For joints with more significant leaking, chemical grouting is an option for mitigation. The representatives concluded that, overall, joint leaking was not a frequent issue.

ODOT does not have a specific guide for culvert rehabilitation practices, but the ODOT Location and Design Manual (ODOT 2024b) briefly discusses rehabilitation methods. ODOT uses supplemental specifications for sliplining and CIPP, also detailed in the Location and Design Manual. Mainly, the DOT uses internal knowledge and rules of thumb to assess best practices for enhancing culvert resiliency. Specific remedial maintenance practices are assessed on a case-by-case basis by the districts in which the culverts are installed, and appropriate rehabilitation methods are subsequently determined. Typically, contractors will perform culvert rehabilitation, but internal maintenance crews are responsible for routine maintenance and repairs such as

embankment and headwall repair, culvert cleanout, removal of debris at the inlet and outlet ends, and replacement of rock-channel outlet protection.

4.5.3 Resilience Assessments – Identification and Prioritization

The assets recorded in the asset management system inventory are culverts and storm sewers located under pavement. Every asset in inventory has a calculated replacement cost based on its size and length, with additional cost multipliers for fill height and the facility under which the asset was installed. ODOT has an estimate of the replacement cost of its poorer-condition assets, but the cost is significant even before labor costs. The strategy to address these declining assets is to portion out an annual budget of $22 million to the districts and tackle the worst-rated assets first. Assets with a low GA rating are funded on capital or operations projects as incentive to districts for improvement. This worst-case-first basis is determined strictly by the condition and severity of the culvert, not by its location, although to decide on funding, districts may prioritize assets based on surrounding projects, ADT, or facility type. District maintenance crews will often perform smaller-scale rehabilitation or replacement; this approach has been successful. One area for improvement is in the prediction of degrading structures. Since the system inventory only deals with assets’ conditions at the most recent date of inspection, ODOT is limited in its ability to predict when an asset will need funding for repair, rehabilitation, or replacement. Failures of culverts lead to user-cost delays and redirect funding away from other projects. ODOT’s goal is to be able to predict funding needs and to move away from the worst-first scenario to allow for the planning of funding.

4.5.4 Cost Assessment Methodologies for Culvert Resilience Improvements

ODOT does not follow a life-cycle cost or cost–benefit analysis framework but does factor an expected design service life of 75 years into cost decisions. The DOT uses a durability design methodology when installing new culverts; in a recent durability study conducted in partnership with Ohio University, researchers reviewed in-service culverts, evaluating the material condition and service life to create a prediction methodology using regression equations. When designing new culverts, ODOT inputs environmental conditions and allowable material types into the regression equations in its durability design spreadsheet to estimate expected service life based on condition (see Figure 53). Wall thickness is considered in this equation but is primarily related to metal culverts more than the other culvert material types.

ODOT defines asset end-of-service life as a GA value of 4 or below. The GA scale, detailed in ODOT’s Culvert Management Manual (ODOT 2003), runs from 0 to 9, with 0 defined as a complete failure and 9 defined as brand new. Once the asset has reached a GA value of 4, the manual instructs users to begin planning for rehabilitation.

Rehabilitation versus replacement decisions are typically based on internal knowledge regarding suitability and cost-effectiveness for the situation. Rules of thumb regarding contributing factors such as roadway ADT and fill height in excess of 5 to 8 ft are used in these decisions. Districts use a roadway user cost spreadsheet to determine when a detour versus a road closure is a more economical choice, taking into consideration factors such as detour length, ADT, and height of cover to determine the cost to the public.

4.5.5 Risk Management Strategies

ODOT tries to address risk up front by implementing frequent inspections that look specifically for signs of piping, especially during flood events where this risk is elevated. Culvert inspection

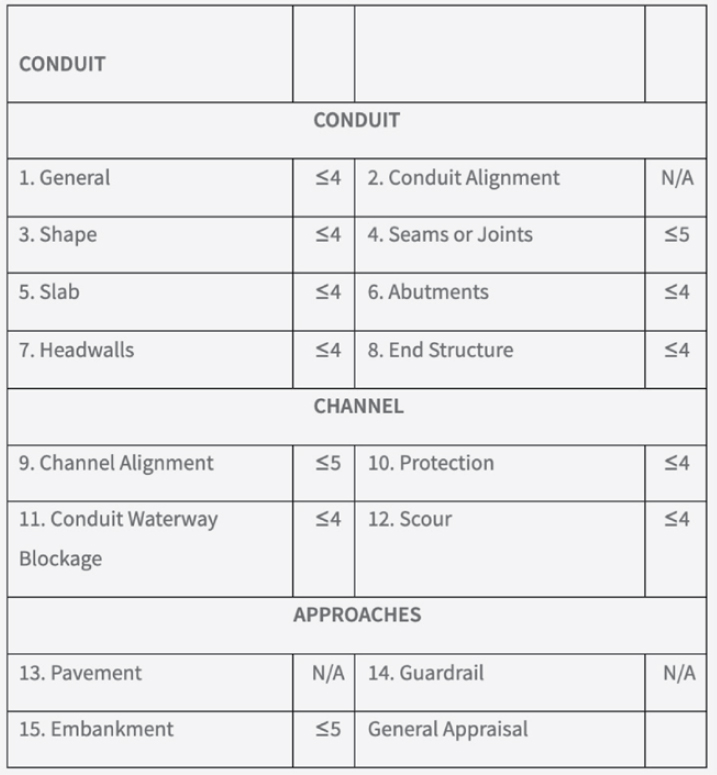

frequency is decided based on culvert size, condition, and level of inspection (for example, fully inundated culverts receive more frequent inspections). Other resilience-based risk management strategies include more stringent allowable headwater criteria for larger drainage areas, larger minimum pipe sizes and upsizing to allow sliplining based on facility type and height of cover, and ongoing material durability assessment to avoid the risk of piping. Culvert maintenance activities are recommended once segments receive a rating of less than or equal to the values shown in the conduit management recommendations table of the Conduit Management Manual (ODOT 2024a), which is reproduced in Figure 54. ODOT uses the word “conduit” as a term for culvert pipe.

More restrictive construction installation and post-installation inspection requirements are under development; these are based on culvert location and other risk factors such as facility type, fill height restricting the ability to perform open-cut replacement of culvert pipe sections, locations with existing flooding or inundation problems, and risk due to culvert size, condition, and ability to be thoroughly inspected.

ODOT’s Conduit Management Manual details risk management strategies employed by the DOT, including annual inspections of poorly rated culverts; additional inspection by and guidance from the district bridge engineer is required for culverts with a GA score of 2 or less. ODOT’s bridge group has identified locations deemed “risk-critical” to its assets, but this has not yet been implemented by the culvert group, although the representatives see this as a useful tool.

4.5.6 Practices to Mitigate Piping

Practices employed by ODOT to mitigate piping and soil loss through joints include the use of headwalls and cutoff walls, regulating installation procedures for the placement and compaction of backfill and joint gaps, and routine inspections to check the joints for potential perforations to avoid infiltration and exfiltration. Piping is a major concern for the DOT, and the representatives stressed the importance of backfill as structural support for their culvert systems. Their main strategy for mitigating piping is the prevention of backfill loss. ODOT requires soil-tight joints in its culvert systems. It has begun specifying premium joints in areas with tufa contamination. Tufa is a byproduct of the use of slag from steel mills as fill in Interstate projects in the Cleveland, Ohio, area. If the tufa infiltrates into the culvert, the minerals harden over time and restrict flow in the pipe. The Cleveland district has dealt with numerous replacements of affected culverts because cleaning and removal of tufa are extremely difficult. Fortunately, this issue is regional and not widespread.

Additional discussion has taken place regarding the restriction of certain backfill types or use with certain culvert materials or in certain conditions due to associated risk factors. ODOT’s backfill material specifications allow sand or #57 or 304 Ohio pavement base; #57 and 304 pavement bases are graded aggregate backfill materials. Low-strength mortar can also be used but is a less common choice. The representatives noted that industry has pivoted toward the use of aggregate as the preferred backfill material, although the increasing use of #57 during installation, regardless of culvert material, has led to complications that will be addressed in future projects. Sand has been an acceptable choice for backfill material because of its compaction potential, especially when compared to #57 and its lack of gradation, but the use of sand with metal culvert pipes is a primary concern because of the risk of infiltration from perforation and invert abrasion. Sand backfill has created emergency projects for ODOT, and while no accidents or fatalities have been reported, multiple culvert pipe failures have given reason for concern about using sand as a backfill material.

4.5.7 Practices to Address Embankment Overtopping

Embankment overtopping has not led to any ODOT culvert failures and is not considered an issue for the DOT. Overtopping is addressed in the Drainage Design Manual through the design and check-storm requirements for allowable headwater. Culverts are sized for an allowable headwater below the edge of the occupied roadway for the design storm, with criteria based on roadway type, ADT, and drainage area. ODOT performs a check storm on all culverts to ensure proper sizing of culverts. Goals for the DOT include locating frequent flooding and overtopping locations, and headquarters is considering a centralized database to access these data and more effectively prevent and respond to these issues.

4.5.8 Practices to Address Coastal and River Impacts

Although coastal and river impacts are not considered major issues in Ohio, one issue ODOT experiences is complete culvert inundation near the Ohio River and Lake Erie, making inspection of these assets difficult. These culverts receive partial inspections of the inlets and outlets every year. Dive inspections or underwater camera inspections for inundated culverts are not always a viable option due to water opacity issues and the narrow pipe diameter of smaller culverts. ODOT is looking into dewatering methodologies because partially inspected culverts do not receive a GA value, which can negatively affect districts looking for funding. The DOT has been able to use funds distributed in 2021 through the PROTECT program as a part of the Infrastructure Investment and Jobs Act, Pub. L. 117-58 (Nov. 15, 2021), to pay for dewatering to fully inspect inundated culverts. ODOT also requires field paving upon installation of all new corrugated metal culvert pipes 60-in. in diameter and above in inundated locations to proactively prolong material service life.

4.5.9 Post-Event Response Practices

ODOT does not have a centralized, formal post-event response strategy. For ODOT’s asset inventory, there is an option to perform a post-event damage inspection from which any information gathered is recorded in the inspection database, but post-event inspection is considered optional. The DOT is considering identification of frequently affected locations in its inspection program to mitigate roadway shutdowns and damage to assets from extreme events.

4.5.10 Future Potential Research

ODOT representatives noted that ODOT’s biggest challenge is the lack of formalized rehabilitation practices, specifically when it comes to spray-applied liners. Spray-applied liners are a major concern for the DOT because, while it is a frequently used practice, design methodologies backed by supporting research are lacking. The lack of a standardized approach or guide to rehabilitation methods and rehabilitation structural design is a challenge for the DOT. Additional research on material durability, backfill material, and installation practices would be useful in developing more resilient strategies for the future.

ODOT plans include improving installation practices, including more restrictive backfill requirements in certain situations; improving the post-construction installation inspection process to ensure that a better product is accepted; updating hydrology methods on a routine cycle and considering climate change impacts using StreamStats, a U.S. Geological Survey web-based GIS tool to map drainage areas and flow statistics, and intensity–duration–frequency curves, which are probability curves that estimate the severity of and time between rainfall events; tracking and addressing culverts prone to flooding or inundation using PROTECT funds for cleanout and the tracking of flooding locations; and continuously researching culvert material durability and durability design methodologies.