State DOT Certification Programs for Materials Sampling and Testing Personnel (2025)

Chapter: 6 Standards and Certifications

CHAPTER 6

Standards and Certifications

This chapter addresses the common practices and test methods (standards) that are used for certification programs for the basic material categories of soils and aggregate, asphalt mixture, and concrete, and other less common certifications in use by DOTs. The first section covers the practices and test methods by material. By presenting information in relation to the material types, readers may quickly access a specific materials area of interest. DOTs may choose to focus on just one materials aspect of their program at a time. The second section covers other certifications found in the DOT websites and documentation. By presenting information on other specific certifications (such as mix designer), a DOT that is interested in creating a new certification is provided with some potential options for adopting an existing certification or with considerations for follow-up to assist in developing their own certification.

Standards by Material Type

Practices and test methods will be discussed primarily in terms of AASHTO methods, although some DOTs may use their own methods, ASTM methods, or may modify the AASHTO or ASTM methods.

As part of this section, the list of practices and test methods compiled from DOTs and included in Appendix F was mined to identify the most common standards that are used by the DOTs. The listed information was found on the DOT’s website or from a document or documents on the website. Note: these certifications and test methods have not been verified by the DOTs, and changes may have occurred since the information was gathered.

The certifications were first categorized as either (1) soil and aggregate, (2) asphalt mixture, (3) concrete, or (4) other. The AASHTO standards that were identified in more than five certifications were included in a table in each section. The states that are in NETTCP or WAQTC were listed as such in Appendix F; the individual tests were not repeated under their certifications unless they were different in some way. This was done on purpose to see the different test methods in use more clearly, otherwise the tests NETTCP and WAQTC used would always be identified as being used by five or more DOTs since each has more than five DOT members. For this reason, each table includes the test methods of NETTCP and WAQTC for comparison. The data were analyzed using a statistical program with text mining capabilities. Note that in the tables, AASHTO standards with an “R” are practices and those with a “T” are test methods.

Soils and Aggregate

Although structures are typically built of wood or concrete, roadways are built of engineered soil, also known as embankments. Aggregates are used in many different areas of road and bridge

construction. Aggregates can be used as a layer in a pavement structure, typically as a base material. Aggregates can be stabilized and combined with asphalt binder or Portland cement to build asphalt mixtures or concrete pavements and structures. Overall, aggregates can comprise 100 percent of a pavements base layer, typically compose 95 percent of all asphalt mixtures by volume, and typically compose 60 to 80 percent of all concrete mixtures by weight.

Different characteristics of the aggregate can be important for different uses. Some aggregates react with Portland cement in an undesirable manner (e.g., alkali-silica reaction); in concrete, some aggregates are affected by moisture more than others when mixed with asphalt binder (e.g., stripping). The type of aggregates available for use by the DOT plays a role in the type of testing that is performed on the aggregate; the type of aggregate that is most economical is local aggregate, therefore geology is a consideration. Soils and aggregates are geologic material that vary based on the underlying geology of the location, as shown in the United States Geological Survey (USGS) map in Figure 30.

Important soil properties related to embankments include density, soil characteristics, and volume change. Aggregate properties are related to the parent rock or geological formation and include hardness, angularity, and deleterious materials. The gradation, or size, of the soil or rock particles is also an important property. Adequate compaction, or density, in an embankment or base is needed to support the pavement and affects the longevity of the roadway. Density can be tested using different methods, including nuclear density gauge, sand cone, and (more recently) intelligent compaction.

The list compiled from DOTs and presented in Appendix F was mined to identify the AASHTO tests related to soils and aggregate that were potentially most used by the DOTs. Over 40 different soils and aggregate AASHTO standards were identified as being used by at least one DOT. The soils and aggregate standards that were identified in more than five individual certifications are included in Table 26. The table also shows the standards that are included in AASHTO TTS training, the standards included in the current AASHTO R 25-22, and the

Source: USGS, Geologic Map of the US, https://www.usgs.gov/media/images/geologic-map-us.

Table 26. Soils and aggregate–related AASHTO standards identified that are included in more than five different certifications.

| Soils and Aggregate AASHTO Standards | TTS | R 25 | NETTCP | WAQTC |

|---|---|---|---|---|

| R 58, Dry Preparation of Disturbed Soil and Soil–Aggregate Samples for Test | X | |||

| R 76, Reducing Samples of Aggregate to Testing Size | * | X | X | X |

| R 90, Sampling of Aggregates | * | X | X | X |

|

T 11, Materials Finer Than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing |

** | X | X | |

|

T 19, Bulk Density (“Unit Weight”) and Voids in Aggregate |

X | |||

|

T 27, Sieve Analysis of Fine and Coarse Aggregates |

X | X | X | X |

|

T 84, Specific Gravity and Absorption of Fine Aggregate |

X | X | ||

|

T 85, Specific Gravity and Absorption of Coarse Aggregate |

X | X | X | X |

|

T 89, Determining the Liquid Limit of Soils |

X | X | ||

|

T 90, Determining the Plastic Limit and Plasticity Index of Soils |

X | X | ||

|

T 96, LA Abrasion Test for Aggregates |

X | |||

|

T 99/T 180, Moisture–Density Relations of Soils (using a drop hammer) |

X | X | X | |

|

T 104, Aggregate Soundness (sodium sulfate or magnesium sulfate) |

X | |||

|

T 176, Plastic Fines in Graded Aggregates and Soils by the Use of the Sand Equivalent Test |

X | ** | X | |

|

T 255, Total Moisture Content of Aggregate by Drying |

X | X | X | |

|

T 265, Laboratory Determination of Moisture Content of Soils |

X | X | ||

|

T 272, One Point Method for Determining Maximum Dry Density |

X | X | X | |

|

T 310, In-Place Density and Moisture Content of Soil and Soil–Aggregate by Nuclear Methods |

X | X | X | X |

* AASHTO Technical Training Solutions does have Aggregate Sampling and Reduction training videos, but they are not identified as AASHTO R 76 or R 90.

** These test methods are included in the standard but are found under asphalt mixtures, not soils or aggregate

standards identified in the two major cooperative efforts (NETTCP and WAQTC). Note that NETTCP and WAQTC each have more than one soils and aggregate certification and that the standards noted under NETTCP and WAQTC include all of the practices and test methods under all of the certifications. It should also be recognized that AASHTO R 25 was originally written based on the NETTCP model, therefore overlap with AASHTO R 25 is expected.

Eighteen practices and test methods are included in Table 26. The standards are listed in alphanumeric order by their designation. AASHTO R 76 and R 90 were the most often referenced (each was included in at least 25 of the 114 certifications); both are related to obtaining samples for testing. Test methods AASHTO T 11, T 27, and T 255 were identified in more than 20 certifications. These methods are related to gradation and moisture content.

ASTM D4791, Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate was also found in more than five certifications, but because it is an ASTM method, for clarity it was not included in the table.

Following are the practices and tests by AASHTO number included in NETTCP and WAQTC soils or aggregate certifications that are specific to soils and aggregate and not identified in Table 26:

- NETTCP: T 21, T 30, T 88, T 191, T 224, T 304, T 311

- WAQTC: R 75, T 335

These nine practices and test methods are used by more than five DOTs (the members of the cooperative efforts). Therefore, there are 28 different practices and methods used in at least five of the certifications. AASHTO R 25 lists 18 practices and test methods, but not all of the methods are listed in Table 26. Some of the differences in the practices and test methods are related to different types of materials. Although soils and aggregates may seem basic, they can be very

complex. The Texas DOT has five different soils and base technician certifications: SB 101, SB 102, SB 103, SB 201, and SB 202. The different certifications cover both laboratory and field testing and address specific areas of in-place density, moisture–density relations, and specialized testing of stabilized bases (Epps et al. 2014).

Asphalt Mixtures

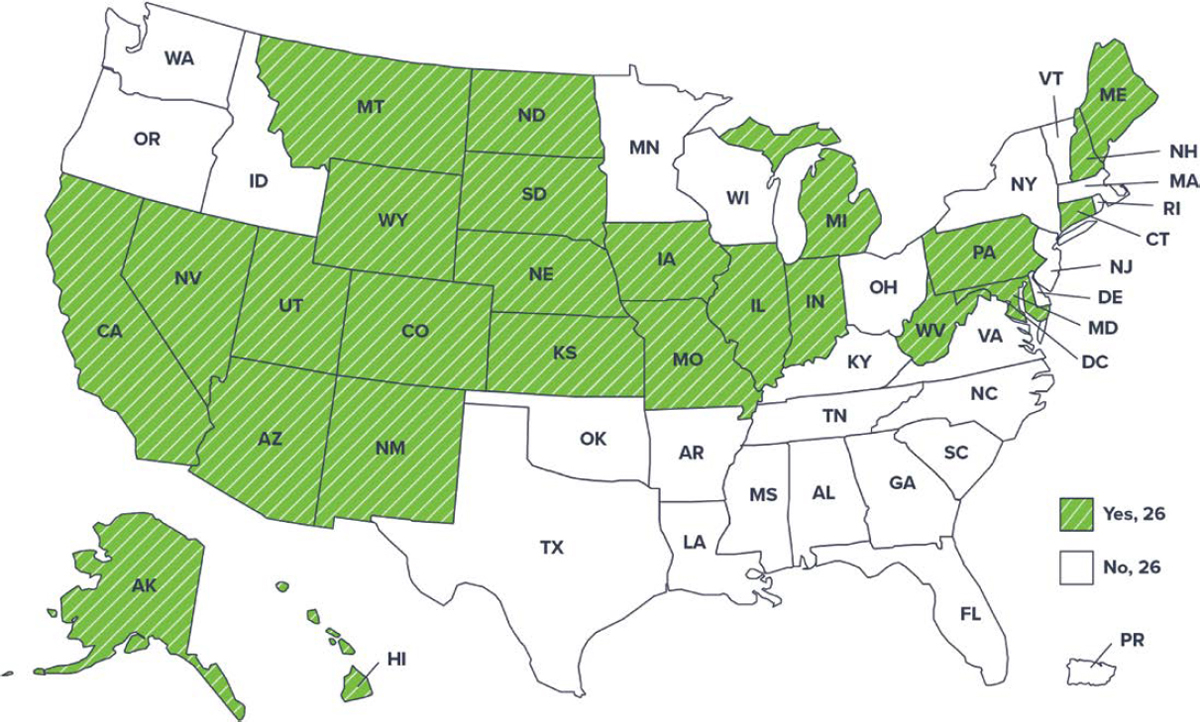

Over 95 percent of pavement surfaces in the United States are composed of asphalt mixtures. About 95 percent of asphalt is made up of aggregates; the remainder is asphalt binder. The variability of aggregates related to geology was discussed previously. The asphalt binder material used varies based on the anticipated pavement temperature and anticipated loading, therefore different asphalt binders are used in the northern and southern states and even within states. Asphalt mixtures can contain different aggregates and different asphalt binders, which may then require different practices and test methods in order to assure quality. Asphalt mixtures can be sampled for testing before being placed on the roadway, or after being placed; this varies based on the state, as shown in Figure 31.

Placement techniques for asphalt mixtures can be different. States in the East predominately use dump trucks; states in the West and Northwest may use belly dumps and pickup machines (Figure 32).

One reason for this is the haul distance required; as an example, Georgia is about 1.4 times smaller than Utah. But the Georgia DOT has 119 asphalt plants on their Qualified Producers

Source: Grogg and Espinoza-Lugue 2023

List; Utah has half as many certified asphalt mix producers (48). Therefore, asphalt mixture typically travels farther from the plant to the roadway in Utah than it does in Georgia. The belly dumps haul larger loads and keep the asphalt mixture hotter for longer than end dump trucks. Some of these differences can lead to the use of different practices and test methods.

To look at the different standards in use, the list compiled from DOTs and presented in Appendix F was mined to identify the AASHTO practices and methods related to asphalt mixtures that were potentially most used by the DOTs. The asphalt mixture test methods that were identified in more than five individual certifications are included in Table 27. AASHTO T 166 was the most often referenced (included in 21 of the 148 certifications). The table also shows the practices and test methods that are included in AASHTO TTS training, the practices and methods included in AASHTO R 25, and the practices and test methods identified in the two major cooperative efforts (NETTCP and WAQTC). Nineteen AASHTO asphalt practices and test methods are included in the table.

ASTM D4791, Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate was also found in more than five certifications and is included in AASHTO R 25 and the NETTCP certification, but because it is an ASTM method, it was not included in the table for clarity.

The full listing of different individual methods includes 36 additional AASHTO standards and 10 additional ASTM standards for a total of 64 different practices and test methods used in the United States for asphalt certification. That number does not include state methods or modifications of AASHTO methods. That number of standards would be daunting for a national certification program.

A recent survey conducted by Caltrans identified DOTs using four different methods to measure asphalt pavement density (Edmiston et al. 2023). The survey also noted different methods that are in use to determine the asphalt content of an asphalt mixture. Of the 24 DOTs surveyed, 23 (96 percent) used the ignition oven method and one (4 percent) used a solvent method, but seven (30 percent) of the 23 used the solvent method as well as the ignition oven method. Even when most DOTs use one test method, they may also allow several test methods. AASHTO T 308 is the AASHTO version of the ignition method; it was found in 20 certifications. AASHTO T 164, Quantitative Extraction of Asphalt Binder from Hot Mix Asphalt (HMA), is a solvent method that is not listed in the table; it was found five times in the certifications, but in four of the five times, the certification included AASHTO T 308, somewhat simulating what Caltrans had found.

Table 27. Asphalt mixture-related AASHTO standards that are identified in more than five different certifications.

| Asphalt Mixture AASHTO Standards | TTS | R25 | NETTCP | WAQTC |

|---|---|---|---|---|

| R 47, Reducing Samples of Asphalt Mixtures to Testing Size | X | X | X | |

| R 66, Sampling of Asphalt Materials (liquid asphalt) | X | X | X | X |

| R 76, Reducing Samples of Aggregate to Testing Size | * | ** | ** | ** |

| R 90, Sampling Aggregate Products | * | X | X | ** |

| R 97, Sampling Asphalt Mixtures | X | X | X | |

|

T 11, Material Finer than 0.075-mm (No. 200) Sieve in Mineral Aggregates by Washing |

X | X | ** | |

|

T 27, Sieve Analysis for Fine and Coarse Aggregate |

X | X | X | ** |

|

T 30, Mechanical Analysis of Extracted Aggregate |

X | X | X | X |

|

T 84, Specific Gravity and Absorption of Fine Aggregate |

X | X | ||

|

T 85, Specific Gravity and Absorption of Coarse Aggregate |

X | X | ** | ** |

|

T 166, Bulk Specific Gravity (Gmb) of Compacted Asphalt Mixtures Using Saturated Surface-Dry Specimens |

X | X | X | X |

|

T 176, Plastic Fines in Graded Aggregates and Soils by the Use of the Sand Equivalent Test |

X | X | X | ** |

|

T 209, Theoretical Maximum Specific Gravity (Gmm) and Density of Asphalt Mixtures |

X | X | X | X |

|

T 269, Percent Air Voids in Compacted Dense and Open Asphalt mixtures |

X | |||

|

T 275, Bulk Specific Gravity (Gmb) of Asphalt Mixtures Using Paraffin-Coated Specimens |

||||

|

T 283, Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage |

X | X | ||

|

T 304, Uncompacted Void Content of Fine Aggregate |

X | X | X | |

|

T308, Determining the Asphalt Binder Content of Asphalt Mixtures by the Ignition Method |

X | X | X | X |

|

T 312, Determining the Density of Asphalt Mixture Specimens by Means of the Superpave Gyratory Compactor |

X | X |

* AASHTO Technical Training Solutions does have Aggregate Sampling and Reduction videos, but they are not identified as AASHTO R 76 or R 90.

** These test methods are included in the program, but are found under soils or aggregate, not asphalt mixtures.

Balanced Mix Design (BMD) is the new Superpave in the asphalt industry. BMD is an approach in which selected performance tests are used to balance rutting and cracking in asphalt mixtures. West and Lynn forewarned in 1999 that Superpave created an opening to coordinate training and certification efforts on asphalt materials but that with the “proliferation of programs nationwide” it was looking like a missed opportunity (West and Lynn 1999).

Concrete

Concrete is the most frequently used engineered material in the world. Historically, the quantity of concrete used in the building industry is more than that used for DOT construction. The building industry uses ASTM standards; DOTs primarily use AASHTO standards. This led to an AASHTO and ASTM harmonization effort to keep the separate standards aligned so that suppliers would not have to follow different methods for DOT and industry. Therefore, AASHTO and ASTM are used somewhat interchangeably by DOTs as related to concrete practices and methods. ACI recognizes and uses ASTM standards in its certification programs, although it does identify the equivalent AASHTO standards for its aggregate and base certifications.

As with the other materials, the list compiled from DOTs and presented in Appendix F was mined to identify the AASHTO practices and methods related to concrete that DOTs used most often. Due to the prevalence of ASTM standards, AASHTO and ASTM standards were considered equivalent and were combined in the analysis. The concrete practices and test methods that were

Table 28. Concrete-related AASHTO/ASTM standards that are identified in more than five different certifications.

| Concrete AASHTO Standards | ACI-CFT Grade 1 | ACI-CST Grade 1 | TTS | R 25 | NETTCP | WAQTC |

|---|---|---|---|---|---|---|

| ASTM Standards | ||||||

| R 60, Sampling Fresh Concrete | C172 | X | X | * | ** | |

| R 100, Making and Curing Cylinders | C31 | X | X | * | X | |

| T 22, Compressive Strength of Cylindrical Concrete Specimens | C39 | X | ||||

| T 97, Flexural Strength | C78 | |||||

| T 119, Slump | C143 | X | X | * | X | |

| T 121, Density (Unit Weight), Yield | C138 | X | X | * | X | |

| T 152, Air Content (Pressure method) | C231 | X | X | * | X | |

| T 196, Air Content (Volumetric method) | C173 | X | * | |||

| T 231, Capping Cylindrical Concrete Specimens | C617 | |||||

| T 309, Temperature of Freshly Mixed PCC | C1064 | X | X | * | X | |

* NETTCP requires ACI-CFT Grade 1 as a prerequisite for taking the NETTCP concrete certification class.

** WAQTC has its own sampling method for concrete.

identified in more than five individual certifications are included in Table 28. The most referenced standard (20 references) was AASHTO R 100/ASTM C31, and the most referenced test method (18 references) was AASHTO T 152/ASTM C231.

The table also shows the test methods that are part of the ACI-CFT Grade 1 and ACI-CST (concrete strength) Grade 1 certifications. It includes practices and test methods that are included in AASHTO TTS training, the practices and methods included in AASHTO R 25, and the practices and test methods identified in the two major cooperative efforts (NETTCP and WAQTC). Note that ACI only references ASTM methods for concrete, so the ASTM number for the associated AASHTO method is included in the table. Ten concrete practices and methods are listed in the table. If the certification recognized ACI-CFT Grade 1, it was noted for the certification. Fifty-nine of the 130 identified certifications noted ACI-CFT Grade 1 in some way. This aligns with the survey that found ACI to be the most accepted external certification.

Overview of Standards by Material Type

Soils, aggregates, and asphalt mixtures clearly do not show the consensus of standard practices and methods as concrete materials do in the DOTs. It does appear that AASHTO TTS is recognizing the asphalt mixture tests that are performed by many DOTs and is providing training for those practices and test methods along with the more standard concrete test methods. The practices and methods that are not included in AASHTO R 25 appear to be tests that are traditionally performed in a laboratory setting, which would fall under AASHTO R 18.

Other Certifications

This section describes different types of certifications that may or may not be part of an acceptance program. Survey Question 23 asked about certifications other than those related to soils, aggregate, asphalt mixtures, and concrete. This section describes some of these certifications and others found during the review of DOT websites. The following section is based on documents found on the DOT websites or in the technician certification policy documents. This section is broken into five different headings: Certifications from Survey Question 23, Generic Quality Assurance Certifications, Supervisor/Manager Certifications, Inspector Certifications, and Additional Certifications.

Certifications from Survey Question 23

Survey Question 23 asked: What other types of qualifications/certifications (beyond the standard Soils, Aggregate, Asphalt Mixtures, and Concrete) are included in the DOT’s program? (select all that apply). The 12 potential selections and the DOTs that selected them are shown in Table 29. Most (47) of the DOTs identified using at least one of the 12 certifications provided. About a quarter (16) also identified others; details on those are shown in Appendix B. Each certification area noted in Table 29 is briefly described using examples from the DOTs. If any similar external, national, or regional certifications were also found (entities identified in Chapter 2 and Appendix E) they will be noted first.

Because most of the DOTs that identified prestressed concrete plant also identified precast concrete plant, these are discussed together. Similarly, bridge foundation and bridge construction are combined.

Asphalt Binder and Emulsion

The AI, NETTCP, and NCAT all have asphalt technician certification programs. AI has a National Emulsion Technician Certification. The AI website noted that the NETTCP binder certification is fully reciprocal to the AI National Binder Technician Certification (AI 2024).

- The Connecticut, Maine, Massachusetts, New Hampshire, and Rhode Island DOTs noted asphalt binder certification, and they are part of NETTCP.

- The Alabama DOT ALDOT-463 program describes the requirements for four different types of asphalt materials technician certifications: Cutback, Emulsion, Performance Graded

Table 29. States identifying other certifications in response to Question 23.

| Certification | # | DOTs |

|---|---|---|

| Asphalt binder and emulsion | 18 | Alabama, California, Connecticut, Delaware, Louisiana, Maine, Massachusetts, Michigan, Mississippi, New Hampshire, New Jersey, New York, North Carolina, Puerto Rico, Rhode Island, Texas, Utah, DC |

| Asphalt mix designer | 23 | Alabama, Arizona, California, Florida, Idaho, Illinois, Iowa, Kentucky, Massachusetts, Michigan, Mississippi, New Jersey, North Carolina, North Dakota, Oklahoma, Oregon, Puerto Rico, Rhode Island, South Carolina, South Dakota, Tennessee, Texas, Utah |

| Ready mix concrete plant | 12 | Alabama, Arizona, California, Maine, Maryland, Nebraska, North Carolina, Puerto Rico, Rhode Island, Tennessee, Texas, West Virginia |

| Prestressed concrete plant | 15 | Alabama, Arizona, California, Colorado, Florida, Iowa, Louisiana, Maine, Mississippi, New Hampshire, New Jersey, North Carolina, Rhode Island, Utah, Wisconsin |

| Precast concrete plant | 16 | Alabama, Alaska, Arizona, California, Colorado, Connecticut, Florida, Louisiana, Maine, New Hampshire, New Jersey, North Carolina, Rhode Island, Utah, West Virginia, Wisconsin |

| Concrete mix designer | 14 | Alabama, Arizona, California, Illinois, Iowa, Kentucky, Mississippi, North Carolina, Oregon, Puerto Rico, Rhode Island, Tennessee, Texas, West Virginia |

| Paint or pavement marking | 8 | Alabama, Georgia, Indiana, Kansas, Kentucky, Maryland, Texas, Virginia |

| Bridge foundations inspection | 9 | California, Colorado, Georgia, Kansas, Louisiana, New Jersey, Rhode Island, South Carolina, Virginia |

| Bridge construction inspection | 12 | Colorado, Florida, Georgia, Kansas, Louisiana, Maine, Minnesota, New Jersey, Oregon, South Carolina, South Dakota, Virginia |

| Ride quality/smoothness | 16 | Alabama, California, Colorado, Indiana, Iowa, Kansas, Louisiana, Maryland, Michigan, Nebraska, New York, Oregon, Rhode Island, Vermont, West Virginia, Wyoming |

| Erosion control | 7 | Arkansas, Iowa, Kansas, Kentucky, Nebraska, South Dakota, Virginia |

| Steel welding | 10 | Alabama, California, Colorado, Connecticut, New Jersey, New York, North Carolina, Rhode Island, Utah, Virginia |

| Other | 16 | List shown in Appendix B |

- Binder, and Terminal Performance Graded Binder. The Alabama DOT requires Superpave Binder Technician certification through a training course from the AI, NCAT, or other institutions every 3 years as well as documentation that the technician has performed specified test methods.

Asphalt Mix Designer

The AI, NCAT, and individual DOTs have Asphalt Mix Design certifications (NETTCP and WAQTC do not).

- The Alabama DOT’s mix design certification is noted as an Asphalt Level III Mix Design Technician and indicates that the certification requires an approved 5-day classroom and laboratory training course (ALDOT 2024).

- The Illinois DOT has a Hot Mix Asphalt Level III certification that is a 5-day class held at Chicago Testing Laboratory. The class has aggregate and asphalt testing certification as prerequisites and a 4-hour written exam (open-book) with a minimum passing score of 70 percent. The Asphalt Level II Manual (and others) are available online (Lake Land College 2023).

- The Texas DOT’s Mix Design Specialist certification is identified as Level 2 and is a 3-day class that focuses on Texas test methods (HMAC, n.d.).

- The Utah DOT has a 3-day class for Superpave Mix Design that includes performance exams related to AASHTO specifications and practices for Superpave (AASHTO M 323 and R 35) and Stone Matrix Asphalt (AASHTO M 325 and R 46) and covers UDOT specifications.

- The Mississippi DOT has two mix design certification levels: Certified Mixture Design Technician is a 4-day course and Master Mixture Design certification requires 5 years as a Certified Mixture Design Technician as well as ongoing continuing education, with recertification required after 5 years.

- The Oklahoma DOT’s Asphalt Mix Design certification has two levels. Level 1 is focused on the AASHTO standards, and Level 2 is focused on Oklahoma DOT procedures.

- The Oregon DOT’s Certified Mixture Design Technician certification is managed by the Asphalt Pavement Association of Oregon.

- The South Carolina DOT requires certified Asphalt Level 2 technicians who submit job mix formulas to participate in the AASHTO re:source Gyratory Proficiency Sample Program and maintain a rating of three or higher.

- At least two DOTs—Arizona and Colorado—require asphalt mix designs to be sealed by a Professional Engineer.

Ready Mix Concrete Plant

The NRMCA has three levels of technician certification for plant personnel, as indicated in Appendix E. NRMCA Quality Managers are expected to hold the NRMCA Concrete Technologist Level 3 certification.

- The California DOT’s ready mix certification program oversees the concrete plants and certifies the plants but does not have certification requirements for the individual technicians.

- The Maine DOT specifications state that plants will be inspected annually by the DOT or the NRMCA.

- The Tennessee DOT (TnDOT) has a Concrete Plant Quality Control Technician Certification Program that includes test methods from ACI-CFT Grade 1 as well as TnDOT specifications and procedures.

Prestressed and Precast Plants

The PCI and the NPCA both have certification programs for plant technicians, as indicated in Appendix E. NETTCP recently developed a Precast Concrete Inspector certification, which is equivalent to the PCI Level II.

- The Maine, Massachusetts, New Hampshire, and Rhode Island DOTs noted prestressed and precast plant certification, and they are part of NETTCP. Recent research performed for the New England Transportation Consortium by the University of New Hampshire developed guidelines on a QA plan and technician qualification requirements for precast and prestressed elements (Dave et al. 2018).

- ALDOT requires the PCI Level I/II 3-day certification and recommends the NPCA Production and Quality School (NPCA PQS Level 2) for prestressed and precast plant technicians, respectively. ALDOT also has a Precast Products Technician requirement for pipe and nonstructural precast concrete products (ALDOT 364).

- UDOT has a Quality Management Plan that is used to certify precast/prestressed plants, which includes requirements that the plant have a Quality Manager and Quality Inspector. Depending upon the product, the UDOT Quality Manager and Quality Inspector are required to have different types of certifications, including ACI Self-Consolidating Concrete Testing Technician and PCI Level I/II/III.

Concrete Mix Designer

A national or regional certification primarily for concrete mix design was not found. ACI has an online course (Concrete Mix Design: Basics) that includes a 10-question quiz and provides a certificate. Both the ACI Concrete Quality Technical Manager and PCI Level III certification requirements include some aspects of concrete mix design in the training.

At least three DOTs have certification-type requirements for submitting mix designs in their specifications:

- AzDOT requires a Professional Engineer, a NICET Level III Technician or higher, an NRMCA Level 3 Concrete Technologist, or an ACI Concrete Laboratory Testing Technician – Grade II (AzDOT Section 1006-3.02) for most concrete mixes. For precast/prestressed mixes, the requirement is a Professional Engineer or a PCI Quality Control Technician/Inspector Level II.

- The Illinois DOT has a PCC Level III certification that is required for concrete mix designs. The course manual includes a description of the Tarantula Curve method.

- TxDOT specifications require that a concrete mix design be sealed by a Professional Engineer (TxDOT specifications Item 421).

Paint or Pavement Marking

The American Traffic Safety Services Association (ATSSA) is an organization related to roadway safety infrastructure. ATSSA has a Pavement Marking Technician training and certification program along with others (i.e., traffic control, traffic signs, and flagger certificate programs). None of the DOTs were found to reference the ATSSA certification.

- The Alabama DOT has a Traffic Marking Materials Technician certification that includes training by industry with the DOT observing tests performed by the technician (laboratory testing of the materials). The certification is valid for 3 years.

- The Indiana DOT (InDOT) requires technicians performing testing on retroreflective pavement marking materials (ITM 931) to be certified by the manufacturer of the retroreflectometer and pass both a written exam and an observation (InDOT Directive 107).

- Maryland DOT has a 2-hour online MARTCP course (Maryland DOT 2021) and a Pavement Marking Student Manual that covers materials and installation of pavement marking. The class is noted as having both a written and a performance exam.

- The Virginia DOT has a self-study course on pavement marking through the Community College Workforce Alliance that includes a Virginia test method covering installation, QC testing, and visual inspection of markings (VDOT 2021).

Bridge Foundation and Construction Inspection

AASHTO TTS has bridge inspection training that has been used by DOTs, but AASHTO TTS does not provide certifications. Some DOTs do have inspection certifications in this area.

- CDOT has Construction Inspector Qualifications for Major Structures (Bridges and Concrete Box Culverts), Minor Structures (pipes), and a general Concrete Transportation Construction Inspector qualification.

- The Indiana DOT has a Bridge Construction and Deck Repair certification.

- The Virginia DOT has certification classes that are offered both in person or virtually for inspections related to VDOT specifications and standards for construction of both new and widened bridges. The New Structures and Bridges for Inspectors class and the Bridge Preservation for Inspectors class are offered through the Community College Workforce Alliance.

Ride Quality/Smoothness

AASHTO R 56, Certification of Inertial Profiling Systems, describes a certification procedure for equipment and operators. The standard recommends an NHI course (131100) and a proficiency test for certification. Technicians and equipment are both certified.

- The Indiana DOT requires inertial profiler operators to attend an operator course and pass an exam every 3 years using the DOT’s test track.

- The Louisiana Department of Transportation and Development’s Authorized Profiler Operator exam tests the operator on potential measurement errors, data requirements, and DOTD specifications.

- The Arkansas DOT recently added a 3-year certification in Inertial Profiling. The course is a review of profiling concepts, and the operator and equipment are certified together. The University of Arkansas Center for Training and Transportation Professionals hosts the course (University of Arkansas, n.d.-b).

Erosion Control

Since erosion control is an inspection function, no certification programs were identified as part of the literature review in Chapter 2. The EPA has its own online Construction Inspection Training Course (USEPA 2024) and may also recognize the International Erosion Control Association Certified Professional in Erosion and Sediment Control.

- The Georgia DOT specifications require construction personnel to have Worksite Erosion Control certification.

- The Kentucky Transportation Cabinet has a 1-day Kentucky Erosion Prevention & Sediment Control for Roadway Inspectors course that includes a 1-hour exam. The class is offered by the University of Kentucky, either in person or over Zoom (the Zoom class has an online exam) (University of Kentucky, n.d.).

- The South Dakota DOT has a certification for Erosion and Sediment Control and Stormwater Inspection.

Steel Welding

The American Society for Nondestructive Testing has nondestructive testing (NDT) training and certification courses that cover inspecting steel welding (ultrasonic testing). ANSI/ASNT CP-189: ASNT Standard for Qualification and Certification of Nondestructive Testing Personnel describes the qualifications. The American Welding Society (AWS) also has a Certified Welding Inspector certification that covers NDT methods. AWS also has a Certified Welder program, which consists of performance testing of actual welded material in accordance with AWS D1.1. DOTs that indicated they have certifications for steel welding, such as the Connecticut DOT, perform in-house certification of the welders; their standard specifications require this welder

certification. Other DOT specifications, such as those of the Utah DOT, require their welders to have the AWS D1.1 certification.

Generic Quality Assurance Certifications

The ASQ has a generic Certified Quality Technician (CQT) certification that covers areas like statistical sampling and analysis and use of control charts; this certification is described more in Appendix E. NHI has a 2½-day Quality Assurance for Highway Construction Projects training class (NHI 131141) that includes QA concepts like those for the ASQ CQT certification. It also has an end-of-course exam, but it is not a certification class.

- NETTCP offers a generic QA certification: Quality Assurance Technologist (QAT). The NETTCP QAT course is a 3-day class covering quality assurance concepts and statistical tools such as random sampling and percent within limits (PWL). Although it is like the other NETTCP certifications in that it has a 2-hour open-book exam with a minimum 80 percent overall required for passing, it is considered one of the most difficult NETTCP certifications.

- The Florida DOT’s QC Manager course provides training on basic quality concepts (e.g., PWL) and is focused on contractor personnel that are filling the role of QC Manager on FDOT’s projects; this is described further in the section on Supervisor/Manager Certification.

No other generic QA or QC technician certifications were found.

Supervisor/Manager Certifications

ACI has a Concrete Quality Technical Manager designation that requires three different ACI Field certifications as well as experience in concrete QA/QC plans. NRMCA also has a type of quality manager certification.

- The Florida DOT has a Quality Control Manager Qualification and exam. Applicants must possess a Level 2 Qualification in a materials area to be eligible for the Manager Qualification. The Quality Manager program is a 2-day class and includes a written exam (closed book, 50 questions; a 70 percent minimum score is required to pass). The class covers quality control, DOT verification, IA, statistical concepts (such as random sampling and PWL), and specific FDOT QC and QC plan requirements from the specifications.

- The Ohio DOT has an Asphalt Field Quality Control Supervisor (FQSC) certification that requires a 1-day seminar on Ohio DOT polices and specifications; the FQSC is required by the DOT specifications to “routinely and usually” be at the paving site during placement (Ohio DOT Specification Item 403.03.A.). The specifications also require the contractor to name a person holding an Asphalt Level 3 certification as the Quality Control Manager for the asphalt plant.

- The South Carolina DOT and the Georgia DOT similarly have Asphalt Quality Control Managers. South Carolina DOT’s Asphalt Quality Control Manager is a Level 3 qualification that requires completion of both Level 1 and 2 and recommends 2 years of experience at a managerial level. The Georgia DOT’s Asphalt Quality Control Manager must be a Level 2 technician, and the requirement that every asphalt plant must employ a Level 2 is found in GDOT’s specifications (Section 400.3.06.A.3.b.).

Inspector Certifications

The need for inspection certification based on 23 CFR 637B has been debated. It should be noted that the regulatory text for qualified personnel in 23 CFR 637.209 specifically references “sampling and testing personnel.” Many inspector certifications were found in the review of DOT websites, but not all DOTs were found to have inspector certifications. Some DOTs

specifically identified their certification classes as Inspector or Tester (e.g., Oregon DOT), and some were found to have inspector courses but did not consider them to be certification courses (e.g., Iowa DOT).

The Oregon DOT’s Inspection Certification Program describes seven inspector certifications: (1) Certified General Construction Inspector, (2) Certified ADA Ramp Inspector and Contractor, (3) Certified Asphalt Concrete Pavement Inspector, (4) Certified Bridge Construction Inspector, (5) Certified Drilled Shaft Inspector, (6) Certified Environmental Construction Inspector, and (7) Certified Traffic Control Technician/Supervisor. The program document specifies activities that may be performed by noncertified personnel (e.g., collect weigh memos, monitor certain aspects of paving) (Oregon DOT 2024).

Other survey respondents also noted having inspector certifications in the areas of Traffic Control Inspection, Utilities and Asphalt Paving Inspector (Kansas DOT), Drilled Shaft Foundation Inspector, Driven Pile Foundation Inspector, and Subsurface Inspector (Maine/NETTCP).

Recent NCHRP research related to inspector certifications culminated in NCHRP Report 1027: Guide to Recruiting, Developing, and Retaining Transportation Infrastructure Construction Inspectors (Harper et al. 2023). The guide includes recommendations on certification programs for inspectors, along with training strategies. Both NHI and AASHTO TTS are noted in the guide.

Additional Certifications

Some unique certifications were identified in the survey, and some were identified in the review of individual DOT websites. The following are brief descriptions of some of these certifications.

- Basic math. Several certification programs require basic math prerequisites and provide tools or links to online training. The Minnesota DOT’s link is to the AASHTO TTS Math Basics: Introductory Math Concepts online class. It is a 3½-hour online course consisting of 11 modules. The Kansas DOT’s math exam is required unless the applicant has previously passed the Fundamentals of Engineering exam or equivalent.

- Bulk specific gravity (Gmb) of asphalt mixtures. The Idaho Transportation Department (ITD) noted that it had just started issuing separate internal (central and district labs) qualifications for determining Gmb according to AASHTO T 166 Bulk Specific Gravity (Gmb) of Compacted Asphalt Mixtures Using Saturated Surface-Dry Specimens. Gmb is an important volumetric property for verifying asphalt mix designs with reclaimed asphalt pavement. AASHTO T 166 is also included in ITD’s Asphalt II Qualification (WAQTC AsTTII).

- Maturity Curve. The Nebraska DOT has two certifications related to the concrete Maturity Method (a way to estimate the strength of concrete for opening pavement to traffic or stripping formwork early). The Maturity Curve Method of Development and the Maturity Method Field Monitoring certifications both rely on the Nebraska DOT’s version of ASTM C1074, Estimating Concrete Strength by the Maturity Method. These certifications are valid for 5 years.

- Pavement Preservation. The South Carolina DOT developed three Level 1 certifications for pavement preservation: Asphalt Seal Coats, Micro/Slurry Seals, and Concrete Pavements. The certifications require 6 months of related experience as with other SCDOT certifications, but some options are provided as substitutions for the Asphalt Seal Coat and Concrete Pavements experience requirements. The Asphalt Seal Coat and Concrete Pavements class also encourages technicians to complete related web-based NHI classes (NHI-131132 and NHI-131126, respectively) before taking the certification class. The certification classes were driven by the maintenance office. Contractors are required to have a certified person on site for these types of preservation projects. SCDOT personnel also can (and have) taken the classes.

- Partnering. UDOT has a Partnering Certification that is required for UDOT, consultant, and contractor project personnel. The training consists of a 1-hour online Partnering 101 class

- and a 1-day in-person class (UDOT, n.d.-b). The DOT maintains a list of certified partnering personnel in their online certifications database.

- Self-consolidating concrete. WAQTC, the Michigan DOT, and the Tennessee DOT all have specific self-consolidating concrete certifications.

- Super Air Meter (SAM). The SAM is a new AASHTO test procedure (AASHTO T 395, Characterization of the Air-Void System of Freshly Mixed Concrete by the Sequential Pressure Method). AASHTO T 395 measures air voids and characterizes the distribution of the pores in fresh concrete. The Michigan Concrete Association website has a specific certification for the SAM that is noted as being offered in conjunction with the Michigan DOT. The Wisconsin DOT includes the SAM in their Portland Cement Concrete Technician I certification.

Standards and Certifications Summary

The number of different types of DOT certification programs that exist is extensive. As shown in Appendix F, over 500 individual DOT certifications were found. Along with the certifications, the standard practices and test methods involved in the certification programs are extensive. The standards related to the individual certifications are also included in Appendix F.

The DOT certifications were classified as to material, and the standards associated with the different certifications were evaluated using a text mining program to identify standards that were used in more than five of the certifications identified.

The number of different standards used in more than five certifications for soil and aggregate was 28, and over 40 standards were identified in at least one certification. A total of 64 different standards were identified in at least one certification for asphalt mixtures; 18 of these were identified in more than five certifications. Some of the standards are requirements in both the aggregate and the asphalt certifications (e.g., AASHTO T 84 and T 85, Specific Gravity for Fine and Coarse Aggregates, are each included in both aggregate and asphalt certifications). Accounting for the seven test methods that were duplicated in both materials areas, there is a total of 39 standards that are in use in more than five certifications for soils, aggregate, and asphalt. The text mining for concrete found 10 standards used in more than five certifications; none of them duplicated the standards for the other materials. Combining all materials, a total of 49 different standards—39 for soils, aggregate, and asphalt and 10 for concrete—were identified in at least five different certifications as part of this text mining effort.

For comparison, AASHTO R 25 recommends that 18 soils and aggregate, 22 asphalt mixture, and 12 concrete sampling or testing standards be used in certification programs. Some of these methods (e.g., AASHTO T 84 and T 85) are repeated in each material section. When accounting for these duplicates in AASHTO R 25, a total of 42 separate standards (41 AASHTO and 1 ASTM) are included in AASHTO R 25 for soils, aggregate, asphalt mixtures, and concrete. For comparison, 49 separate standards were identified in at least five different certifications.

Based on this analysis, AASHTO R 25 appears to contain a relatively complete listing of the most frequently used standards for certification programs. AASHTO TTS has identified and created training for almost half (20 out of 49, or 41 percent) of the most frequently used standards identified in this analysis. In addition, the 10 concrete test methods that were found in more than five certifications are covered in the two basic ACI certifications (ACI-CFT Grade 1 and ACI-CST Grade 1).

Beyond the common soils, aggregate, asphalt mixture, and concrete certifications, over 20 other certifications were found. Asphalt mix designer and asphalt binder technician were noted the most, by almost half the DOTs (23 and 18 out of 52, or 44 and 35 percent, respectively). Some of the certifications found were found in just one or two DOTs. The information provided here could be beneficial to a DOT with a need to develop a new certification in one of these other areas.