Pile Design for Downdrag: Examples and Supporting Materials (2024)

Chapter: Appendix E: Design Example 3 - Embankment Fill Over Clay (SHANSEP) Using Hand Calculations

APPENDIX E

Design Example 3 — Embankment Fill Over Clay (SHANSEP) Using Hand Calculations

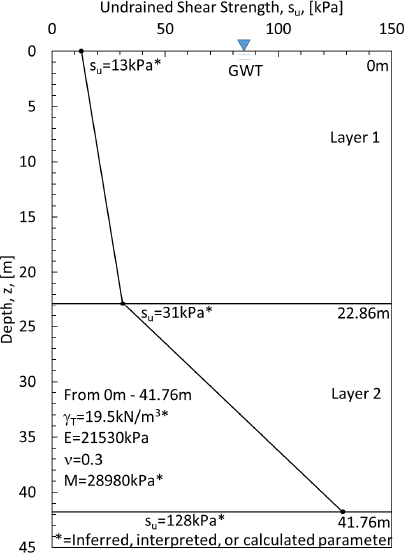

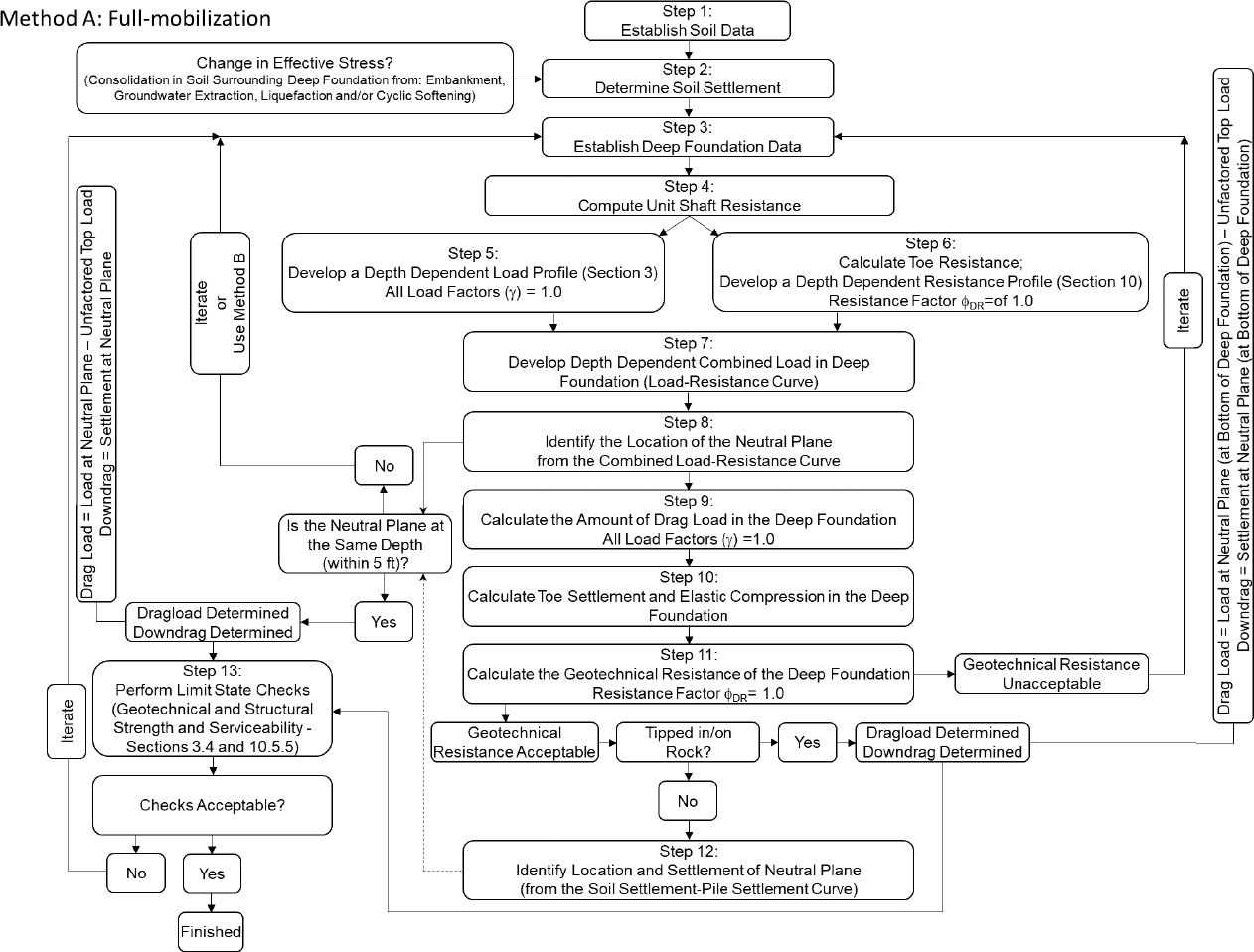

Design Example 3 is a continuation of Design Example 1. Like Design Example 1, the design data that were used for Design Example 3 were acquired from Briaud and Tucker (1997). The focus of Design Example 3 was on the determining the influence of strength gain resulting from consolidation of the soil stratigraphy as the result of an increase in stress within the soil from an applied embankment. The same initial soil stratigraphy that was used for Design Example 1 was used for Design Example 3 (Figure E1). The Stress History and Normalized Soil Parameters (SHANSEP) method that was developed by Ladd and Foote (1992) and refined by Ladd and DeGroot (2006) was used to determine the increase in shear strength resulting from consolidation of the soil stratigraphy. The approach was similar to that used by Coffman et al. (2010) and Steudlein et al. (2020). Existing equations within the Geotechnical Circular 5 (Loehr et al. 2016) allow for the use of this approach for highway projects. The revised stratigraphy, as developed from a SHANSEP analysis, was used to determine the location of the neutral plane, and magnitudes of the drag load and downdrag are demonstrated using 1) Load-Resistance profiles and 2) Pile-Soil Settlement profiles by means of the Method A (full

Table E1. Briaud and Tucker (1997) Example Problem 1 PILENEG Program input data.

| Pile Material | Concrete |

| Pile Shape | Octagonal |

| Pile Face [mm] | 174* |

| Pile Perimeter [m] | 1.39 |

| Pile Area [m2] | 0.145 |

| Pile Embedded Length [m] | 41.76 |

| Pile Modulus [kN/m2] | 2.41 x 107 |

| Top Load on Pile [kN] | 2225 |

| Number of Pile Increments | 50 |

| Soil Young’s Modulus [kN/m2] | 21531 |

| Soil Poisson’s Ratio | 0.3 |

| Soil Ultimate Bearing Capacity [kN/m2] | 7097 |

| Ground Water Table Depth [m] | 0* |

| * Inferred or interpolated parameters using correlations contained in Briaud and Tucker (1997). | |

mobilization) procedures proposed by the NCHRP12-116A project team. The flowchart proposed by the NCHRP12-116A was followed.

Step 1: Establish soil data

The pile parameters that were required were obtained from Briaud and Tucker (1997). These parameters are listed in Table E1. As with Design Example 1, the soil modulus (M) presented in Figure E1 was calculated using Equation 1 based on the Young’s modulus (E) and Poisson’s ratio (ν) values for the soil as provided in Briaud and Tucker (1997). The initial pre-consolidation undrained shear strength values were determined by converting the provided Briaud and Tucker (1997) friction data to undrained shear strength data (Figure E2).

| Eqn. 1 |

Step 2: Determine soil settlement

The soil profile shown in Figure E1 was discretized into sublayers (50 sublayers, each 0.835m thick) and then the effective stress at the center of each sublayer was calculated using a submerged unit weight of 9.69 kN/m3 below the ground water table for the two-layer clay soil profile. The effective stress (σz′) was determined using Terzaghi’s effective stress equation with the ground water table assumed to be at the original ground surface as shown previously in Figure E1. The settlement profile shown in Figure E3 was created by using the aforementioned sublayers and then calculating the amount of settlement within each sublayer resulting from a 6m thick, 8m crest, 32m base embankment fill, with a unit weight of 19.5kN/m3, being placed on top of the two-layer clay soil profile (Figure E4).

The settlement profile presented in Figure E3 was developed for points below the center of the embankment using the Osterberg embankment stress distribution which used a symmetric geometry and provided half of the actual stress influence (Figure E4 and Equations 2 through 4).

| Eqn. 2 |

| Eqn. 3 |

| Eqn. 4 |

For the geometry shown in Figure E4, the embankment was symmetric about the central axis, and the amount of settlement (δ) was determined at different depths along this line of symmetry. Therefore, the influence factor (I), as computed using Equation 2 was multiplied by two (2) to account for

both halves of the embankment about the line of symmetry. The increase in stress (∆σ) at each sublayer depth (z) was then calculated as the product of the influence factor and the bearing pressure (q=γfillHfill=117kPa) resulting from the embankment. The α1 and α2 parameters from Figure E4, along with the Σ(I), ∆σ, and δ values that were calculated for each sublayer are included as Table E2. The consolidation strain (εz) presented in Table E2 was calculated by dividing the change in stress (∆σ) by the constrained modulus (M). The vertical settlement was determined as the product of the consolidation strain and the sublayer thickness.

SHANSEP Analysis

A SHANSEP analysis was performed to determine the amount of increase in the shear strength of the soil resulting from consolidation of the soil being subjected to the embankment loading. A modified form of the SHANSEP equation is presented as Equation 5. The S and m parameters found in Equation 5 are curve-fitting parameters. Minimum values of S (0.14) and m (0.7) were selected for use. The initial undrained shear strength (su,o) profile as a function of depth, as shown previously in Figure E1, and the initial vertical effective stress () from Table E2 were used to determine the ratio prior to placement of the embankment load. Equation 5 was rearranged to determine the over-consolidation ratio prior to placement of the embankment (OCRpre−embankment) as shown in Equation 6. As calculated in Equation 7, the post-embankment vertical effective stress () within each sublayer was equal to the sum of the initial vertical effective stress () and the change in stress within each sublayer that was shown in Table E2. The pre-embankment over-consolidation ratio was then used to determine the maximum past pressure (Equation 8). As calculated in Equation 8, the maximum past pressure () was taken as the maximum value of the post-embankment vertical effective stress () or the calculated maximum past pressure that was determined as the product of the OCRpre−embankment and the pre-embankment vertical effective stress. Minimum values of S (0.14) and m (0.7) were also used in Equation 10 to determine the ratio. Using Equation 11, the ratio was then used with the final vertical effective stress () to determine the resultant final undrained shear strength (su,f). The results of the calculations performed using Equations 5 through 11 are contained in Table E3. The initial undrained shear strength and final undrained shear strength are compared in Figure E5.

Table E2. Calculated soil settlement parameters.

| Layer Depth [m] | z [m] | Thickness [m] | σz,o′ [kPa] | α1 [rad] | α2 [rad] | Σ(I) | ∆σ [kPa] | εz | δ [m] | ||

| 0 | - | 0.8352 | 0.4176 | 0.8352 | 4.0465 | 1.4668 | 0.0779 | 0.9999 | 116.9912 | 0.0040 | 0.0034 |

| 0.8352 | - | 1.6704 | 1.2528 | 0.8352 | 12.1396 | 1.2673 | 0.2254 | 0.9981 | 116.7756 | 0.0040 | 0.0034 |

| 1.6704 | - | 2.5056 | 2.088 | 0.8352 | 20.2327 | 1.0897 | 0.3513 | 0.9919 | 116.0572 | 0.0040 | 0.0033 |

| 2.5056 | - | 3.3408 | 2.9232 | 0.8352 | 28.3258 | 0.9397 | 0.4504 | 0.9805 | 114.7226 | 0.0040 | 0.0033 |

| 3.3408 | - | 4.176 | 3.7584 | 0.8352 | 36.4189 | 0.8165 | 0.5236 | 0.9642 | 112.8139 | 0.0039 | 0.0033 |

| 4.176 | - | 5.0112 | 4.5936 | 0.8352 | 44.5120 | 0.7164 | 0.5748 | 0.9440 | 110.4464 | 0.0038 | 0.0032 |

| 5.0112 | - | 5.8464 | 5.4288 | 0.8352 | 52.6051 | 0.6350 | 0.6087 | 0.9209 | 107.7477 | 0.0037 | 0.0031 |

| 5.8464 | - | 6.6816 | 6.264 | 0.8352 | 60.6982 | 0.5683 | 0.6293 | 0.8960 | 104.8309 | 0.0036 | 0.0030 |

| 6.6816 | - | 7.5168 | 7.0992 | 0.8352 | 68.7912 | 0.5131 | 0.6401 | 0.8700 | 101.7873 | 0.0035 | 0.0029 |

| 7.5168 | - | 8.352 | 7.9344 | 0.8352 | 76.8843 | 0.4669 | 0.6435 | 0.8435 | 98.6867 | 0.0034 | 0.0028 |

| 8.352 | - | 9.1872 | 8.7696 | 0.8352 | 84.9774 | 0.4279 | 0.6415 | 0.8169 | 95.5815 | 0.0033 | 0.0028 |

| 9.1872 | - | 10.0224 | 9.6048 | 0.8352 | 93.0705 | 0.3946 | 0.6355 | 0.7907 | 92.5100 | 0.0032 | 0.0027 |

| 10.0224 | - | 10.8576 | 10.44 | 0.8352 | 101.1636 | 0.3659 | 0.6268 | 0.7650 | 89.4999 | 0.0031 | 0.0026 |

| 10.8576 | - | 11.6928 | 11.2752 | 0.8352 | 109.2567 | 0.3409 | 0.6160 | 0.7399 | 86.5704 | 0.0030 | 0.0025 |

| 11.6928 | - | 12.528 | 12.1104 | 0.8352 | 117.3498 | 0.3190 | 0.6039 | 0.7157 | 83.7345 | 0.0029 | 0.0024 |

| 12.528 | - | 13.3632 | 12.9456 | 0.8352 | 125.4429 | 0.2997 | 0.5909 | 0.6923 | 81.0005 | 0.0028 | 0.0023 |

| 13.3632 | - | 14.1984 | 13.7808 | 0.8352 | 133.5360 | 0.2825 | 0.5773 | 0.6699 | 78.3730 | 0.0027 | 0.0023 |

| 14.1984 | - | 15.0336 | 14.616 | 0.8352 | 141.6290 | 0.2671 | 0.5634 | 0.6483 | 75.8540 | 0.0026 | 0.0022 |

| 15.0336 | - | 15.8688 | 15.4512 | 0.8352 | 149.7221 | 0.2533 | 0.5495 | 0.6277 | 73.4433 | 0.0025 | 0.0021 |

| 15.8688 | - | 16.704 | 16.2864 | 0.8352 | 157.8152 | 0.2408 | 0.5357 | 0.6080 | 71.1395 | 0.0025 | 0.0021 |

| 16.704 | - | 17.5392 | 17.1216 | 0.8352 | 165.9083 | 0.2295 | 0.5220 | 0.5892 | 68.9400 | 0.0024 | 0.0020 |

| 17.5392 | - | 18.3744 | 17.9568 | 0.8352 | 174.0014 | 0.2192 | 0.5087 | 0.5713 | 66.8415 | 0.0023 | 0.0019 |

| 18.3744 | - | 19.2096 | 18.792 | 0.8352 | 182.0945 | 0.2097 | 0.4956 | 0.5542 | 64.8402 | 0.0022 | 0.0019 |

| 19.2096 | - | 20.0448 | 19.6272 | 0.8352 | 190.1876 | 0.2010 | 0.4829 | 0.5379 | 62.9321 | 0.0022 | 0.0018 |

| 20.0448 | - | 20.88 | 20.4624 | 0.8352 | 198.2807 | 0.1930 | 0.4706 | 0.5223 | 61.1129 | 0.0021 | 0.0018 |

| 20.88 | - | 21.7152 | 21.2976 | 0.8352 | 206.3737 | 0.1857 | 0.4587 | 0.5075 | 59.3784 | 0.0020 | 0.0017 |

| 21.7152 | - | 22.5504 | 22.1328 | 0.8352 | 214.4668 | 0.1788 | 0.4471 | 0.4934 | 57.7242 | 0.0020 | 0.0017 |

| 22.5504 | - | 23.3856 | 22.968 | 0.8352 | 222.5599 | 0.1724 | 0.4360 | 0.4799 | 56.1463 | 0.0019 | 0.0016 |

| 23.3856 | - | 24.2208 | 23.8032 | 0.8352 | 230.6530 | 0.1665 | 0.4253 | 0.4670 | 54.6405 | 0.0019 | 0.0016 |

| 24.2208 | - | 25.056 | 24.6384 | 0.8352 | 238.7461 | 0.1609 | 0.4150 | 0.4547 | 53.2030 | 0.0018 | 0.0015 |

| 25.056 | - | 25.8912 | 25.4736 | 0.8352 | 246.8392 | 0.1558 | 0.4051 | 0.4430 | 51.8301 | 0.0018 | 0.0015 |

| 25.8912 | - | 26.7264 | 26.3088 | 0.8352 | 254.9323 | 0.1509 | 0.3955 | 0.4318 | 50.5182 | 0.0017 | 0.0015 |

| 26.7264 | - | 27.5616 | 27.144 | 0.8352 | 263.0254 | 0.1463 | 0.3863 | 0.4211 | 49.2638 | 0.0017 | 0.0014 |

| 27.5616 | - | 28.3968 | 27.9792 | 0.8352 | 271.1184 | 0.1420 | 0.3775 | 0.4108 | 48.0640 | 0.0017 | 0.0014 |

| 28.3968 | - | 29.232 | 28.8144 | 0.8352 | 279.2115 | 0.1379 | 0.3689 | 0.4010 | 46.9155 | 0.0016 | 0.0014 |

| 29.232 | - | 30.0672 | 29.6496 | 0.8352 | 287.3046 | 0.1341 | 0.3608 | 0.3916 | 45.8156 | 0.0016 | 0.0013 |

| 30.0672 | - | 30.9024 | 30.4848 | 0.8352 | 295.3977 | 0.1305 | 0.3529 | 0.3826 | 44.7616 | 0.0015 | 0.0013 |

| 30.9024 | - | 31.7376 | 31.32 | 0.8352 | 303.4908 | 0.1270 | 0.3453 | 0.3739 | 43.7510 | 0.0015 | 0.0013 |

| 31.7376 | - | 32.5728 | 32.1552 | 0.8352 | 311.5839 | 0.1238 | 0.3380 | 0.3657 | 42.7814 | 0.0015 | 0.0012 |

| 32.5728 | - | 33.408 | 32.9904 | 0.8352 | 319.6770 | 0.1207 | 0.3309 | 0.3577 | 41.8506 | 0.0014 | 0.0012 |

| 33.408 | - | 34.2432 | 33.8256 | 0.8352 | 327.7701 | 0.1177 | 0.3241 | 0.3501 | 40.9566 | 0.0014 | 0.0012 |

| 34.2432 | - | 35.0784 | 34.6608 | 0.8352 | 335.8632 | 0.1149 | 0.3176 | 0.3427 | 40.0973 | 0.0014 | 0.0012 |

| 35.0784 | - | 35.9136 | 35.496 | 0.8352 | 343.9562 | 0.1122 | 0.3113 | 0.3356 | 39.2710 | 0.0014 | 0.0011 |

| 35.9136 | - | 36.7488 | 36.3312 | 0.8352 | 352.0493 | 0.1097 | 0.3052 | 0.3289 | 38.4759 | 0.0013 | 0.0011 |

| 36.7488 | - | 37.584 | 37.1664 | 0.8352 | 360.1424 | 0.1072 | 0.2993 | 0.3223 | 37.7104 | 0.0013 | 0.0011 |

| 37.584 | - | 38.4192 | 38.0016 | 0.8352 | 368.2355 | 0.1049 | 0.2936 | 0.3160 | 36.9730 | 0.0013 | 0.0011 |

| 38.4192 | - | 39.2544 | 38.8368 | 0.8352 | 376.3286 | 0.1026 | 0.2882 | 0.3099 | 36.2624 | 0.0013 | 0.0010 |

| 39.2544 | - | 40.0896 | 39.672 | 0.8352 | 384.4217 | 0.1005 | 0.2829 | 0.3041 | 35.5770 | 0.0012 | 0.0010 |

| 40.0896 | - | 40.9248 | 40.5072 | 0.8352 | 392.5148 | 0.0984 | 0.2778 | 0.2984 | 34.9158 | 0.0012 | 0.0010 |

| 40.9248 | - | 41.76 | 41.3424 | 0.8352 | 400.6079 | 0.0965 | 0.2728 | 0.2930 | 34.2774 | 0.0012 | 0.0010 |

| z = layer midpoint depth, |

|||||||||||

| Eqn. 5 |

| Eqn. 6 |

| Eqn. 7 |

| Eqn. 8 |

| Eqn. 9 |

| Eqn. 10 |

| Eqn. 11 |

The final undrained shear strength values that were obtained from the SHANSEP analysis were then used to determine the unit side resistance acting along the pile. Like Design Example 1, the unit side shear was determined by using the total stress analysis “α method”. Specifically, the procedure and equations (Equations 12 and 13) recommended in Randolph and Murphy (1985) were used.

For :

| Eqn. 12 |

For :

| Eqn. 13 |

with

Step 3: Establish pile data

The pile data required to determine the drag load and downdrag include 1) the unit side resistance acting on the pile(s), 2) the end bearing resistance provided by the pile(s), 3) the unfactored pile head deadload, and 3) the elastic compression of the pile(s). Multiple pile types or pile geometries may be considered to determine the magnitude of downdrag/drag load on the pile(s). To compute the drag load for a given design scenario, the following pile data is required: pile material, pile diameter or pile perimeter, pile cross-sectional area, and pile modulus. The pile considered for this design example was an octagonal pile; the pile diameter was therefore not required. The pile material (pre-stressed concrete), perimeter (1.39m), cross-sectional area (0.145m2), and pile modulus (2.41x107 kN/m2) were considered in this example.

Step 4: Compute incremental side resistance

The nominal unit side resistance (fn) for each sublayer was calculated by multiplying the calculated α factor by the final post-consolidation undrained shear strength using Equation 14. Likewise, the side resistance (Fs) for each sublayer was determined by multiplying the nominal side resistance by the area of the pile in contact with the soil within the given sublayer (Equation 15). The total side resistance for the pile was determined by summing the side resistance from each sublayer. The calculated values for each sublayer, including the final vertical effective stress (σz,f′), final undrained shear strength (su,f), alpha value (α), nominal unit side resistance (fn), and side resistance (Fs) are presented in Table E4.

| Eqn. 14 |

| Eqn. 15 |

Steps 5 and 6: Develop the depth-dependent load profile, compute end bearing and a depth-dependent resistance profile

The load and resistance profile graphs were developed by determining the cumulative load in the pile, as a function of depth, from the top of the pile to the bottom of the pile for the load curve and from the bottom of the pile to the top of the pile for the resistance curve. The unfactored top load (2225 kN) was added to the cumulative load in the pile for the load curve. The end bearing resistance, as calculated using Equations 16 and 17, was added to the cumulative load in the pile for the resistance curve. For the clay profile that was investigated, the end bearing resistance (Rt) was calculated using the final undrained shear strength at the toe of the pile (su,f) and the cross-sectional area at the end of the pile (At). The values of load and resistance for each sublayer are included in Table E5. Also included in Table E5 are the segmental elastic compression and cumulative elastic compression (as measured from the bottom to the pile to the top of the pile). The elastic compression was calculated using Equations 17 and 18.

| Eqn. 16 |

| Eqn. 17 |

| Eqn. 18 |

| Eqn. 19 |

Table E3. SHANSEP calculated parameters.

| Layer Depth [m] | σz,o′ [kPa] | su,o [kPa] | su,o/σz,o′ | OCRpre | σz,f′ [kPa] | σ′max [kPa] | OCRpost | su,f/σz,f′ | su,f [kPa] | ||

| 0 | - | 0.8352 | 4.0465 | 13.2882 | 3.2838 | 90.6788 | 121.0378 | 366.9358 | 3.0316 | 0.3043 | 36.8313 |

| 0.8352 | - | 1.6704 | 12.1396 | 13.9549 | 1.1495 | 20.2430 | 128.9152 | 245.7423 | 1.9062 | 0.2199 | 28.3501 |

| 1.6704 | - | 2.5056 | 20.2327 | 14.6215 | 0.7227 | 10.4304 | 136.2899 | 211.0351 | 1.5484 | 0.1901 | 25.9129 |

| 2.5056 | - | 3.3408 | 28.3258 | 15.2882 | 0.5397 | 6.8740 | 143.0484 | 194.7108 | 1.3612 | 0.1737 | 24.8511 |

| 3.3408 | - | 4.176 | 36.4189 | 15.9548 | 0.4381 | 5.1023 | 149.2328 | 185.8210 | 1.2452 | 0.1632 | 24.3587 |

| 4.176 | - | 5.0112 | 44.5120 | 16.6215 | 0.3734 | 4.0613 | 154.9584 | 180.7763 | 1.1666 | 0.1559 | 24.1653 |

| 5.0112 | - | 5.8464 | 52.6051 | 17.2882 | 0.3286 | 3.3839 | 160.3528 | 178.0108 | 1.1101 | 0.1506 | 24.1526 |

| 5.8464 | - | 6.6816 | 60.6982 | 17.9548 | 0.2958 | 2.9115 | 165.5291 | 176.7201 | 1.0676 | 0.1466 | 24.2600 |

| 6.6816 | - | 7.5168 | 68.7912 | 18.6215 | 0.2707 | 2.5649 | 170.5785 | 176.4447 | 1.0344 | 0.1434 | 24.4530 |

| 7.5168 | - | 8.352 | 76.8843 | 19.2881 | 0.2509 | 2.3009 | 175.5710 | 176.9007 | 1.0076 | 0.1407 | 24.7101 |

| 8.352 | - | 9.1872 | 84.9774 | 19.9548 | 0.2348 | 2.0935 | 180.5589 | 180.5589 | 1.0000 | 0.1400 | 25.2782 |

| 9.1872 | - | 10.0224 | 93.0705 | 20.6214 | 0.2216 | 1.9268 | 185.5806 | 185.5806 | 1.0000 | 0.1400 | 25.9813 |

| 10.0224 | - | 10.8576 | 101.1636 | 21.2881 | 0.2104 | 1.7899 | 190.6635 | 190.6635 | 1.0000 | 0.1400 | 26.6929 |

| 10.8576 | - | 11.6928 | 109.2567 | 21.9548 | 0.2009 | 1.6758 | 195.8271 | 195.8271 | 1.0000 | 0.1400 | 27.4158 |

| 11.6928 | - | 12.528 | 117.3498 | 22.6214 | 0.1928 | 1.5792 | 201.0843 | 201.0843 | 1.0000 | 0.1400 | 28.1518 |

| 12.528 | - | 13.3632 | 125.4429 | 23.2881 | 0.1856 | 1.4965 | 206.4434 | 206.4434 | 1.0000 | 0.1400 | 28.9021 |

| 13.3632 | - | 14.1984 | 133.5360 | 23.9547 | 0.1794 | 1.4250 | 211.9090 | 211.9090 | 1.0000 | 0.1400 | 29.6673 |

| 14.1984 | - | 15.0336 | 141.6290 | 24.6214 | 0.1738 | 1.3625 | 217.4830 | 217.4830 | 1.0000 | 0.1400 | 30.4476 |

| 15.0336 | - | 15.8688 | 149.7221 | 25.2881 | 0.1689 | 1.3075 | 223.1655 | 223.1655 | 1.0000 | 0.1400 | 31.2432 |

| 15.8688 | - | 16.704 | 157.8152 | 25.9547 | 0.1645 | 1.2587 | 228.9547 | 228.9547 | 1.0000 | 0.1400 | 32.0537 |

| 16.704 | - | 17.5392 | 165.9083 | 26.6214 | 0.1605 | 1.2151 | 234.8483 | 234.8483 | 1.0000 | 0.1400 | 32.8788 |

| 17.5392 | - | 18.3744 | 174.0014 | 27.2880 | 0.1568 | 1.1760 | 240.8429 | 240.8429 | 1.0000 | 0.1400 | 33.7180 |

| 18.3744 | - | 19.2096 | 182.0945 | 27.9547 | 0.1535 | 1.1407 | 246.9347 | 246.9347 | 1.0000 | 0.1400 | 34.5709 |

| 19.2096 | - | 20.0448 | 190.1876 | 28.6213 | 0.1505 | 1.1087 | 253.1197 | 253.1197 | 1.0000 | 0.1400 | 35.4368 |

| 20.0448 | - | 20.88 | 198.2807 | 29.2880 | 0.1477 | 1.0796 | 259.3936 | 259.3936 | 1.0000 | 0.1400 | 36.3151 |

| 20.88 | - | 21.7152 | 206.3737 | 29.9547 | 0.1451 | 1.0529 | 265.7521 | 265.7521 | 1.0000 | 0.1400 | 37.2053 |

| 21.7152 | - | 22.5504 | 214.4668 | 30.6213 | 0.1428 | 1.0285 | 272.1910 | 272.1910 | 1.0000 | 0.1400 | 38.1067 |

| 22.5504 | - | 23.3856 | 222.5599 | 31.7574 | 0.1427 | 1.0276 | 278.7062 | 278.7062 | 1.0000 | 0.1400 | 39.0189 |

| 23.3856 | - | 24.2208 | 230.6530 | 36.0542 | 0.1563 | 1.1705 | 285.2935 | 285.2935 | 1.0000 | 0.1400 | 39.9411 |

| 24.2208 | - | 25.056 | 238.7461 | 40.3510 | 0.1690 | 1.3087 | 291.9491 | 312.4493 | 1.0702 | 0.1468 | 42.8614 |

| 25.056 | - | 25.8912 | 246.8392 | 44.6478 | 0.1809 | 1.4419 | 298.6693 | 355.9218 | 1.1917 | 0.1583 | 47.2752 |

| 25.8912 | - | 26.7264 | 254.9323 | 48.9447 | 0.1920 | 1.5701 | 305.4504 | 400.2735 | 1.3104 | 0.1692 | 51.6726 |

| 26.7264 | - | 27.5616 | 263.0254 | 53.2415 | 0.2024 | 1.6934 | 312.2892 | 445.3964 | 1.4262 | 0.1795 | 56.0554 |

| 27.5616 | - | 28.3968 | 271.1184 | 57.5383 | 0.2122 | 1.8118 | 319.1824 | 491.2005 | 1.5389 | 0.1893 | 60.4256 |

| 28.3968 | - | 29.232 | 279.2115 | 61.8351 | 0.2215 | 1.9255 | 326.1270 | 537.6098 | 1.6485 | 0.1986 | 64.7845 |

| 29.232 | - | 30.0672 | 287.3046 | 66.1319 | 0.2302 | 2.0346 | 333.1202 | 584.5598 | 1.7548 | 0.2075 | 69.1335 |

| 30.0672 | - | 30.9024 | 295.3977 | 70.4287 | 0.2384 | 2.1395 | 340.1593 | 631.9952 | 1.8579 | 0.2160 | 73.4738 |

| 30.9024 | - | 31.7376 | 303.4908 | 74.7255 | 0.2462 | 2.2402 | 347.2418 | 679.8683 | 1.9579 | 0.2241 | 77.8063 |

| 31.7376 | - | 32.5728 | 311.5839 | 79.0224 | 0.2536 | 2.3369 | 354.3653 | 728.1376 | 2.0548 | 0.2318 | 82.1321 |

| 32.5728 | - | 33.408 | 319.6770 | 83.3192 | 0.2606 | 2.4298 | 361.5276 | 776.7668 | 2.1486 | 0.2391 | 86.4518 |

| 33.408 | - | 34.2432 | 327.7701 | 87.6160 | 0.2673 | 2.5192 | 368.7267 | 825.7242 | 2.2394 | 0.2462 | 90.7661 |

| 34.2432 | - | 35.0784 | 335.8632 | 91.9128 | 0.2737 | 2.6052 | 375.9605 | 874.9815 | 2.3273 | 0.2529 | 95.0758 |

| 35.0784 | - | 35.9136 | 343.9562 | 96.2096 | 0.2797 | 2.6879 | 383.2272 | 924.5140 | 2.4124 | 0.2593 | 99.3812 |

| 35.9136 | - | 36.7488 | 352.0493 | 100.5064 | 0.2855 | 2.7675 | 390.5252 | 974.2995 | 2.4948 | 0.2655 | 103.6830 |

| 36.7488 | - | 37.584 | 360.1424 | 104.8032 | 0.2910 | 2.8442 | 397.8528 | 1024.3180 | 2.5746 | 0.2714 | 107.9814 |

| 37.584 | - | 38.4192 | 368.2355 | 109.1000 | 0.2963 | 2.9181 | 405.2085 | 1074.5520 | 2.6518 | 0.2771 | 112.2770 |

| 38.4192 | - | 39.2544 | 376.3286 | 113.3969 | 0.3013 | 2.9894 | 412.5909 | 1124.9855 | 2.7266 | 0.2825 | 116.5700 |

| 39.2544 | - | 40.0896 | 384.4217 | 117.6937 | 0.3062 | 3.0581 | 419.9987 | 1175.6040 | 2.7991 | 0.2878 | 120.8607 |

| 40.0896 | - | 40.9248 | 392.5148 | 121.9905 | 0.3108 | 3.1245 | 427.4305 | 1226.3945 | 2.8692 | 0.2928 | 125.1494 |

| 40.9248 | - | 41.76 | 400.6079 | 126.2873 | 0.3152 | 3.1885 | 434.8853 | 1277.3453 | 2.9372 | 0.2976 | 129.4364 |

Table E4. Calculated pile side resistance parameters.

| Layer Depth [m] | z [m] | Thickness [m] | σz,f′ [kPa] | su,f [kPa] | α | fn [kPa] | Fs [kN] | ||

| 0 | - | 0.8352 | 0.4176 | 0.8352 | 121.0378 | 36.83 | 0.85 | 0.00 | 0.00 |

| 0.8352 | - | 1.6704 | 1.2528 | 0.8352 | 128.9152 | 28.35 | 1.00 | 28.36 | 32.92 |

| 1.6704 | - | 2.5056 | 2.088 | 0.8352 | 136.2899 | 25.91 | 1.08 | 27.87 | 32.36 |

| 2.5056 | - | 3.3408 | 2.9232 | 0.8352 | 143.0484 | 24.85 | 1.13 | 27.97 | 32.47 |

| 3.3408 | - | 4.176 | 3.7584 | 0.8352 | 149.2328 | 24.36 | 1.16 | 28.28 | 32.83 |

| 4.176 | - | 5.0112 | 4.5936 | 0.8352 | 154.9584 | 24.17 | 1.19 | 28.70 | 33.32 |

| 5.0112 | - | 5.8464 | 5.4288 | 0.8352 | 160.3528 | 24.15 | 1.21 | 29.19 | 33.89 |

| 5.8464 | - | 6.6816 | 6.264 | 0.8352 | 165.5291 | 24.26 | 1.23 | 29.72 | 34.51 |

| 6.6816 | - | 7.5168 | 7.0992 | 0.8352 | 170.5785 | 24.45 | 1.24 | 30.29 | 35.17 |

| 7.5168 | - | 8.352 | 7.9344 | 0.8352 | 175.5710 | 24.71 | 1.25 | 30.89 | 35.87 |

| 8.352 | - | 9.1872 | 8.7696 | 0.8352 | 180.5589 | 25.28 | 1.25 | 31.69 | 36.79 |

| 9.1872 | - | 10.0224 | 9.6048 | 0.8352 | 185.5806 | 25.98 | 1.25 | 32.57 | 37.81 |

| 10.0224 | - | 10.8576 | 10.44 | 0.8352 | 190.6635 | 26.69 | 1.25 | 33.46 | 38.85 |

| 10.8576 | - | 11.6928 | 11.2752 | 0.8352 | 195.8271 | 27.42 | 1.25 | 34.37 | 39.90 |

| 11.6928 | - | 12.528 | 12.1104 | 0.8352 | 201.0843 | 28.15 | 1.25 | 35.29 | 40.97 |

| 12.528 | - | 13.3632 | 12.9456 | 0.8352 | 206.4434 | 28.90 | 1.25 | 36.23 | 42.06 |

| 13.3632 | - | 14.1984 | 13.7808 | 0.8352 | 211.9090 | 29.67 | 1.25 | 37.19 | 43.17 |

| 14.1984 | - | 15.0336 | 14.616 | 0.8352 | 217.4830 | 30.45 | 1.25 | 38.17 | 44.31 |

| 15.0336 | - | 15.8688 | 15.4512 | 0.8352 | 223.1655 | 31.24 | 1.25 | 39.17 | 45.47 |

| 15.8688 | - | 16.704 | 16.2864 | 0.8352 | 228.9547 | 32.05 | 1.25 | 40.18 | 46.65 |

| 16.704 | - | 17.5392 | 17.1216 | 0.8352 | 234.8483 | 32.88 | 1.25 | 41.22 | 47.85 |

| 17.5392 | - | 18.3744 | 17.9568 | 0.8352 | 240.8429 | 33.72 | 1.25 | 42.27 | 49.07 |

| 18.3744 | - | 19.2096 | 18.792 | 0.8352 | 246.9347 | 34.57 | 1.25 | 43.34 | 50.31 |

| 19.2096 | - | 20.0448 | 19.6272 | 0.8352 | 253.1197 | 35.44 | 1.25 | 44.42 | 51.57 |

| 20.0448 | - | 20.88 | 20.4624 | 0.8352 | 259.3936 | 36.32 | 1.25 | 45.52 | 52.85 |

| 20.88 | - | 21.7152 | 21.2976 | 0.8352 | 265.7521 | 37.21 | 1.25 | 46.64 | 54.14 |

| 21.7152 | - | 22.5504 | 22.1328 | 0.8352 | 272.1910 | 38.11 | 1.25 | 47.77 | 55.46 |

| 22.5504 | - | 23.3856 | 22.968 | 0.8352 | 278.7062 | 39.02 | 1.25 | 48.91 | 56.78 |

| 23.3856 | - | 24.2208 | 23.8032 | 0.8352 | 285.2935 | 39.94 | 1.25 | 50.07 | 58.13 |

| 24.2208 | - | 25.056 | 24.6384 | 0.8352 | 291.9491 | 42.86 | 1.22 | 52.47 | 60.91 |

| 25.056 | - | 25.8912 | 25.4736 | 0.8352 | 298.6693 | 47.28 | 1.18 | 55.73 | 64.70 |

| 25.8912 | - | 26.7264 | 26.3088 | 0.8352 | 305.4504 | 51.67 | 1.14 | 58.93 | 68.41 |

| 26.7264 | - | 27.5616 | 27.144 | 0.8352 | 312.2892 | 56.06 | 1.11 | 62.06 | 72.05 |

| 27.5616 | - | 28.3968 | 27.9792 | 0.8352 | 319.1824 | 60.43 | 1.08 | 65.14 | 75.62 |

| 28.3968 | - | 29.232 | 28.8144 | 0.8352 | 326.1270 | 64.78 | 1.05 | 68.18 | 79.15 |

| 29.232 | - | 30.0672 | 29.6496 | 0.8352 | 333.1202 | 69.13 | 1.03 | 71.18 | 82.63 |

| 30.0672 | - | 30.9024 | 30.4848 | 0.8352 | 340.1593 | 73.47 | 1.01 | 74.15 | 86.08 |

| 30.9024 | - | 31.7376 | 31.32 | 0.8352 | 347.2418 | 77.81 | 0.99 | 77.10 | 89.50 |

| 31.7376 | - | 32.5728 | 32.1552 | 0.8352 | 354.3653 | 82.13 | 0.97 | 80.02 | 92.90 |

| 32.5728 | - | 33.408 | 32.9904 | 0.8352 | 361.5276 | 86.45 | 0.96 | 82.92 | 96.27 |

| 33.408 | - | 34.2432 | 33.8256 | 0.8352 | 368.7267 | 90.77 | 0.95 | 85.81 | 99.62 |

| 34.2432 | - | 35.0784 | 34.6608 | 0.8352 | 375.9605 | 95.08 | 0.93 | 88.68 | 102.95 |

| 35.0784 | - | 35.9136 | 35.496 | 0.8352 | 383.2272 | 99.38 | 0.92 | 91.54 | 106.27 |

| 35.9136 | - | 36.7488 | 36.3312 | 0.8352 | 390.5252 | 103.68 | 0.91 | 94.38 | 109.57 |

| 36.7488 | - | 37.584 | 37.1664 | 0.8352 | 397.8528 | 107.98 | 0.90 | 97.22 | 112.86 |

| 37.584 | - | 38.4192 | 38.0016 | 0.8352 | 405.2085 | 112.28 | 0.89 | 100.05 | 116.15 |

| 38.4192 | - | 39.2544 | 38.8368 | 0.8352 | 412.5909 | 116.57 | 0.88 | 102.86 | 119.42 |

| 39.2544 | - | 40.0896 | 39.672 | 0.8352 | 419.9987 | 120.86 | 0.87 | 105.68 | 122.68 |

| 40.0896 | - | 40.9248 | 40.5072 | 0.8352 | 427.4305 | 125.15 | 0.87 | 108.48 | 125.94 |

| 40.9248 | - | 41.76 | 41.3424 | 0.8352 | 434.8853 | 129.44 | 0.86 | 111.28 | 129.19 |

| z = layer midpoint depth, |

|||||||||

Steps 7 through 12: Develop a depth-dependent combined load profile for the pile (Step 7) to: identify the location of the neutral plane (Step 8), calculate the amount of drag load (Step 9), calculate the toe settlement and elastic compression (Step 10), calculate the geotechnical resistance (Step 11), and identify the locations of the neutral plane from the soil settlement-pile settlement curve (Step 12)

A combined load and resistance curve, comprised of the minimum value of load or resistance for each sublayer, is presented in Figure E6a. Also included in Figure E6a, and used for comparison, is the combined load-resistance curve that was developed in Design Example 1. The soil settlement-pile settlement curve is presented in Figure E6b; this curve was developed using the elastic compression values presented in Table E5. The tip movement obtained using the DeCock (2009) method based on Chin’s Hyperbolic Model in Step 11 of Design Example 1 was also reused for this design example.

The neutral plane location that was determined from the combined load and resistance curve (14.20m) was different than the neutral plane location that was identified with the soil settlement-pile settlement curve (11.27m). Although a difference in the location of the neutral plane should not be observed when evaluating based on the combined load and resistance curve or based on the soil settlement-pile settlement curve, a difference was also observed for the case presented in Design Example 1. In Design Example 1, the neutral plane location that was determined from the combined load and resistance curve was 13.36m while the neutral plane location that was identified with the soil settlement-pile settlement curve was 12.11m. Therefore, the calculated depths for the location of the neutral plane in Design Example 3 were lower and higher than the corresponding depths that were obtained when not accounting for strength gain as obtained from the combined load and resistance curve or based on the soil settlement-pile settlement curve, respectively.

The amount of calculated drag load in the pile almost doubled (from 286kN in Design Example 1 to 582kN in Design Example 3) due to the strength gain associated with consolidation of the soil surrounding the pile. Although the drag load almost doubled, the depth of the neutral plane, as predicted using the combined load-settlement curve, did not change significantly (the location of the neutral plane moved downward by approximately 0.5m between Design Example 1 and Design Example 3 when evaluating based on the combined load and resistance curve). The amount of settlement at the neutral plane (downdrag) was 0.0576m. This calculated downdrag was slightly greater than the 0.0550m that was calculated for Design Example 1. The increased shear strength in the soil surrounding the pile and the additional amount of pile compression were observed to contribute to the increase in calculated drag load.

When comparing the locations of the neutral plane obtained during Step 8 (14.20m) and Step 12 (11.27m), the neutral plane locations were not within the required 5ft (1.5m). The additional elastic compression in the pile resulting from the increase in drag load in the pile caused the location of the neutral plane to move up from (12.11m in Design Example 1 to 11.27m in Design Example 3). Because the locations of the neutral planes obtained from Steps 8 and 12 were greater than 5ft (1.5m), the geometry of the pile should be changed (length increased or diameter increased) and the design process iterated (Step 3 through Step 12).

Table E5. Calculated load as a function of depth.

| Layer Depth | z | Q | R | δEC,s | δEC | Comments: z=depth, Q=load, R=resistance, δEC,s=segmental elastic compression, δEC=cumulative elastic compression (from bottom to top), A=pile cross-sectional area=0.145[m2] Ep=pile elastic modulus=2.41E+07[kPa] Ls=length of each pile segment=0.8532[m] |

|||

| [m] | [m] | [kN] | [kN] | [kN] | [m] | [m] | |||

| 0 | - | 0.8352 | 0.4176 | 2225.00 | 3377.24 | 2225.00 | 0.0005 | 0.0242 | |

| 0.8352 | - | 1.6704 | 1.2528 | 2257.92 | 3377.24 | 2257.92 | 0.0005 | 0.0236 | |

| 1.6704 | - | 2.5056 | 2.088 | 2290.28 | 3344.32 | 2290.28 | 0.0005 | 0.0231 | |

| 2.5056 | - | 3.3408 | 2.9232 | 2322.74 | 3311.96 | 2322.74 | 0.0006 | 0.0226 | |

| 3.3408 | - | 4.176 | 3.7584 | 2355.58 | 3279.50 | 2355.58 | 0.0006 | 0.0220 | |

| 4.176 | - | 5.0112 | 4.5936 | 2388.90 | 3246.67 | 2388.90 | 0.0006 | 0.0214 | |

| 5.0112 | - | 5.8464 | 5.4288 | 2422.78 | 3213.35 | 2422.78 | 0.0006 | 0.0209 | |

| 5.8464 | - | 6.6816 | 6.264 | 2457.29 | 3179.46 | 2457.29 | 0.0006 | 0.0203 | |

| 6.6816 | - | 7.5168 | 7.0992 | 2492.46 | 3144.95 | 2492.46 | 0.0006 | 0.0197 | |

| 7.5168 | - | 8.352 | 7.9344 | 2528.32 | 3109.79 | 2528.32 | 0.0006 | 0.0191 | |

| 8.352 | - | 9.1872 | 8.7696 | 2565.11 | 3073.92 | 2565.11 | 0.0006 | 0.0185 | |

| 9.1872 | - | 10.0224 | 9.6048 | 2602.92 | 3037.13 | 2602.92 | 0.0006 | 0.0179 | |

| 10.0224 | - | 10.8576 | 10.44 | 2641.77 | 2999.32 | 2641.77 | 0.0006 | 0.0173 | |

| 10.8576 | - | 11.6928 | 11.2752 | 2681.67 | 2960.48 | 2681.67 | 0.0006 | 0.0166 | |

| 11.6928 | - | 12.528 | 12.1104 | 2722.64 | 2920.58 | 2722.64 | 0.0007 | 0.0160 | |

| 12.528 | - | 13.3632 | 12.9456 | 2764.70 | 2879.61 | 2764.70 | 0.0007 | 0.0153 | |

| 13.3632 | - | 14.1984 | 13.7808 | 2807.87 | 2837.55 | 2807.87 | 0.0007 | 0.0147 | |

| 14.1984 | - | 15.0336 | 14.616 | 2852.18 | 2794.37 | 2794.37 | 0.0007 | 0.0140 | |

| 15.0336 | - | 15.8688 | 15.4512 | 2897.65 | 2750.06 | 2750.06 | 0.0007 | 0.0133 | |

| 15.8688 | - | 16.704 | 16.2864 | 2944.30 | 2704.59 | 2704.59 | 0.0006 | 0.0127 | |

| 16.704 | - | 17.5392 | 17.1216 | 2992.15 | 2657.95 | 2657.95 | 0.0006 | 0.0120 | |

| 17.5392 | - | 18.3744 | 17.9568 | 3041.22 | 2610.10 | 2610.10 | 0.0006 | 0.0114 | |

| 18.3744 | - | 19.2096 | 18.792 | 3091.53 | 2561.03 | 2561.03 | 0.0006 | 0.0108 | |

| 19.2096 | - | 20.0448 | 19.6272 | 3143.10 | 2510.72 | 2510.72 | 0.0006 | 0.0102 | |

| 20.0448 | - | 20.88 | 20.4624 | 3195.95 | 2459.15 | 2459.15 | 0.0006 | 0.0096 | |

| 20.88 | - | 21.7152 | 21.2976 | 3250.09 | 2406.30 | 2406.30 | 0.0006 | 0.0090 | |

| 21.7152 | - | 22.5504 | 22.1328 | 3305.55 | 2352.15 | 2352.15 | 0.0006 | 0.0084 | |

| 22.5504 | - | 23.3856 | 22.968 | 3362.33 | 2296.69 | 2296.69 | 0.0005 | 0.0078 | |

| 23.3856 | - | 24.2208 | 23.8032 | 3420.46 | 2239.91 | 2239.91 | 0.0005 | 0.0073 | |

| 24.2208 | - | 25.056 | 24.6384 | 3481.37 | 2181.78 | 2181.78 | 0.0005 | 0.0068 | |

| 25.056 | - | 25.8912 | 25.4736 | 3546.08 | 2120.87 | 2120.87 | 0.0005 | 0.0062 | |

| 25.8912 | - | 26.7264 | 26.3088 | 3614.48 | 2056.17 | 2056.17 | 0.0005 | 0.0057 | |

| 26.7264 | - | 27.5616 | 27.144 | 3686.53 | 1987.76 | 1987.76 | 0.0005 | 0.0052 | |

| 27.5616 | - | 28.3968 | 27.9792 | 3762.15 | 1915.71 | 1915.71 | 0.0005 | 0.0048 | |

| 28.3968 | - | 29.232 | 28.8144 | 3841.30 | 1840.09 | 1840.09 | 0.0004 | 0.0043 | |

| 29.232 | - | 30.0672 | 29.6496 | 3923.94 | 1760.94 | 1760.94 | 0.0004 | 0.0039 | |

| 30.0672 | - | 30.9024 | 30.4848 | 4010.02 | 1678.31 | 1678.31 | 0.0004 | 0.0035 | |

| 30.9024 | - | 31.7376 | 31.32 | 4099.52 | 1592.22 | 1592.22 | 0.0004 | 0.0030 | |

| 31.7376 | - | 32.5728 | 32.1552 | 4192.42 | 1502.72 | 1502.72 | 0.0004 | 0.0027 | |

| 32.5728 | - | 33.408 | 32.9904 | 4288.69 | 1409.82 | 1409.82 | 0.0003 | 0.0023 | |

| 33.408 | - | 34.2432 | 33.8256 | 4388.30 | 1313.56 | 1313.56 | 0.0003 | 0.0020 | |

| 34.2432 | - | 35.0784 | 34.6608 | 4491.25 | 1213.94 | 1213.94 | 0.0003 | 0.0017 | |

| 35.0784 | - | 35.9136 | 35.496 | 4597.52 | 1110.99 | 1110.99 | 0.0003 | 0.0014 | |

| 35.9136 | - | 36.7488 | 36.3312 | 4707.09 | 1004.73 | 1004.73 | 0.0002 | 0.0011 | |

| 36.7488 | - | 37.584 | 37.1664 | 4819.95 | 895.15 | 895.15 | 0.0002 | 0.0009 | |

| 37.584 | - | 38.4192 | 38.0016 | 4936.10 | 782.29 | 782.29 | 0.0002 | 0.0006 | |

| 38.4192 | - | 39.2544 | 38.8368 | 5055.51 | 666.15 | 666.15 | 0.0002 | 0.0005 | |

| 39.2544 | - | 40.0896 | 39.672 | 5178.20 | 546.73 | 546.73 | 0.0001 | 0.0003 | |

| 40.0896 | - | 40.9248 | 40.5072 | 5304.14 | 424.05 | 424.05 | 0.0001 | 0.0002 | |

| 40.9248 | - | 41.76 | 41.3424 | 5433.33 | 298.11 | 298.11 | 0.0001 | 0.0001 | |

Step 13: Perform limit state checks

The comparisons of the locations of the neutral planes obtained from Step 8 and Step 12 yielded unsatisfactory results and the design process should have been iterated prior to proceeding with step 13. However, for the sake of brevity, limit state checks were performed to determine if the pile size was suitable for the design loads. For the structural strength limit state, the determined drag load (582kN) was multiplied by the drag load factor (γDR=1.1) to obtain a factored load of drag load 640kN. The unfactored top load (2225kN) placed on the top of the pile was multiplied by the deadload factor (γD=1.25) to obtain a factored deadload of 2781kN. The combined total factored load was 3422kN. The concrete compressive strength for the pre-stressed concrete pile was assumed to be 5000psi (34474kPa) resulting in a factored structural stress of 25856kPa (0.75*34474kPa) and a factored structural strength of 3749kN when the stress was multiplied by the cross-sectional area of the pile (0.145m2). If a concrete compressive strength of 5000psi (34474kPa), was used for the pre-stressed pile then the pile is adequately sized because the factored structural strength (3749kN) was determined to be greater than the combined total factored load (3096kN). If a lower-strength concrete was used for the pre-stressed concrete pile, then the pile would need to be larger in cross-sectional area or lengthened. Either modification to the pile would result in a change in the amount of drag load on the pile; Steps 3 through 13 of the NCHRP12-116A flowchart would need to be repeated to ensure the factored structural strength was greater than the total factored load.

Conclusion:

The SHANSEP method was used in this design example to determine the influence of an increase in shear strength of the soil, resulting from reconsolidation, on the downdrag and drag load within a pile foundation. In this analysis, both the drag load and the downdrag were observed to increase. This increase in drag load resulted in a change in the location of the neutral plane when obtained from the soil settlement-pile settlement curve. The geometry of the pile should have been modified to ensure the locations of the neutral plane that were obtained in Steps 8 and 12 were within 5ft (1.5m). Although the drag load increased and the locations of the neutral planes were not within 5ft (1.5m), the factored structural strength calculated in Step 13 was sufficient to support the total factored load.

References:

Briaud, J.L., and Tucker, L. (1997). NCHRP Report 393: Design and Construction Guidelines for Downdrag on Uncoated and Bitumen-Coated Piles. TRB, National Research Council, Washington, DC.

Coffman, R.A., Bowders, J.J., and Burton, P.M. (2010). “Use of SHANSEP Design Parameters in Landfill Design: A Cost/Benefit Case Study.” ASCE Geotechnical Special Publication No. 199, Proc. GeoFlorida 2010: Advances in Analysis, Modeling and Design, West Palm Beach, Florida. 2859–2866.

DeCock, F.A. (2009). “Sense and Sensitivity of Pile Load-Deformation Behavior.” Deep Foundation on Board and Auger Piles. Taylor and Francis. 22 pp.

Ladd, C.C., and Foott, R., (1974) “New Design Procedure for Stability of Soft Clays,” Journal of Geotechnical Engineering Division, Vol. 100, No. GT7, July.

Ladd, C.C., and D.J. DeGroot. (2003). “Recommended Practice for Soft Ground Characterization.” Proceedings of Soil and Rock America 2003, 12th Pan-American Conference on Soil Mechanics and Geotechnical Engineering and 39th U.S. Rock Mechanics Symposium 1: 3–57

Loehr, J.E., Lutenegger, A., Rosenblad, B., and Bowckmann, A. (2016). Geotechnical Site Characterization Geotechnical Engineering Circular No. 5. Report No. FHWA NHI-16-072. Washington, DC. 688 pp.

Randolph, M.F., Murphy, B.S. (1985). “Shaft Capacity of Driven Piles in Clay.” Proceedings of the 1985 Offshore Technology Conference. Paper No. OTC-4883-MS. May 6-9. Houston, TX.

Stuedlein, A.W., Saye, S.R., and Kumm, B.P. (2020). “SHANSEP-Based Side Resistance of Driven Pipe Piles in Plastic Soils: Revision and LRFD Calibration.” Journal of Geotechnical and Geoenvironmental Engineering 146 (8): 06020010.