Pile Design for Downdrag: Examples and Supporting Materials (2024)

Chapter: Appendix G: Design Example 5 - Liquefaction in Sand (H-Pile) Using ALLCPT and TZPILE

APPENDIX G

Design Example 5 — Liquefaction in Sand (H-Pile) Using ALLCPT and TZPILE

The Boulanger and Idriss (2014) cone penetration test (CPT)-based liquefaction-triggering method, coupled with the Yoshimine et al. (2006) post-liquefaction settlement estimation method as adapted by Idriss and Boulanger (2008), is presented in this CPT-based example calculation of liquefaction-induced settlement. After calculating the liquefaction-induced settlement, the soil settlement was then used to obtain the magnitude of downdrag and drag load by means of the Laboratories des Ponts et Chaussess method (Bustamante and Gianeselli 1982). The estimate of post-liquefaction reconsolidation settlement is driven by the factor of safety against liquefaction triggering, FSL. Deterministic liquefaction-triggering calculation methods commonly link initial liquefaction to an excess pore pressure ratio of 100% (and/or cyclic shear strain of 3%) corresponding to FSL = 1.0. However, it is critical to recognize that FSL > 1.0 does not mean that excess pore pressures have not been generated under strong ground motion. Volumetric strains can accumulate within a soil deposit for FSL up to 2.0 as shaking generated excess pore pressures dissipate. Thus, seismic design scenario-based liquefaction-triggering calculations, which indicate that liquefaction will not be triggered (i.e., FSL > 1.0), do not justify the omission of reconsolidation settlement calculations when considering adverse effects to transportation infrastructure.

Discussion of liquefaction susceptibility for CPT-based analyses

The calculation procedure for 1D reconsolidation settlement is directly linked to FSL for soils that are susceptible to liquefaction. Soils that are not susceptible to liquefaction will need to be evaluated for the potential of cyclic softening, as very soft to medium stiff plastic soils may generate excess pore pressures in the design seismic scenario to result in volumetric strain upon dissipation of excess pore pressures (e.g., Jana and Stuedlein 2021, Dadashiserej et al. 2024). The design engineer must decide how to judge liquefaction susceptibility, which may include selection of a threshold soil behavior type index, Ic, or by comparison of stratigraphic units and the results of laboratory tests from samples retrieved from nearby borings, or both (the preferred methodology). For CPT-based liquefaction-triggering analyses, it is common to select a threshold Ic for which soil is assumed susceptible to liquefaction. Historically (Youd et al. 2001, Zhang et al. 2002), the threshold suggested for use in identifying liquefaction-susceptible soils has been Ic < 2.6, with caution given that soils with Ic ≥ 2.6 can often be sampled in an intact state and as such, should be sampled for cyclic laboratory testing and assessment of the potential for liquefaction or cyclic softening under seismic loading and corresponding volumetric strain potential. It is increasingly being recognized that Ic = 2.6 represents the median of a statistical distribution of Ic for which soils should be screened for liquefaction susceptibility (Stuedlein et al. 2023). Thus, it is recommended that CPTs be paired with nearby boreholes so that samples can be inspected and tested in the laboratory to develop

site-specific fines content-Ic correlations and select appropriate Ic thresholds for use with liquefaction-triggering analyses and the consequences of liquefaction (e.g., reconsolidation settlement). Discussions of contemporary views and recent research on the subject of liquefaction susceptibility were presented at a workshop sponsored by the Pacific Earthquake Engineering Research Center and are described in Stuedlein et al. (2023).

Prior to determining Ic, the effective overburden pressure must be calculated to stress-normalize the cone tip and sleeve friction resistance values. In the absence of laboratory-derived unit weights, γ, the effective overburden pressure (σ′vo ) can be calculated using a correlated unit weight from CPT measurements (Equation 1), using (Robertson and Cabal 2015).

| Equation 1 |

In Equation 1, Rf is the friction ratio, defined as the ratio of sleeve resistance to corrected cone resistance, (fs/qt) x 100%, γw is unit weight of water, and Pa is atmospheric pressure in the same units as qt (the cone tip resistance).

The soil behavior type index is computed iteratively using Equation 2.

| Equation 2 |

In Equation 2, Qt is the normalized, corrected net cone penetration resistance, given by (qt − σvo)/σ′vo and Fr is the normalized friction ratio in percent. The initial Ic value is then recomputed iteratively with an updated, normalized corrected net cone tip resistance, Qtn, using Equation 3. The initial stress normalization exponent (n) is presented in Equation 4.

| Equation 3 |

| Equation 4 |

The calculation of Ic, n, and Qtn is iterated until ∆n ≤ 0.01. Once n has converged, Ic is considered final.

Liquefaction triggering

The factor of safety against liquefaction is computed as the ratio of resistance (i.e., capacity) to demand (loading), in which resistance is represented by the cyclic resistance ratio, CRR, and loading is represented using the cyclic stress ratio, CSR. Owing to the inability to reliably sample many liquefaction-susceptible soils, the triggering calculations typically rely on CRR, which are correlated to penetration resistance or shear wave velocity. Penetration resistance must be corrected to account for the effects of fines content and overburden stresses. For liquefaction-triggering evaluations using the CPT and the Boulanger and Idriss (2014) method, the procedure to correct cone tip resistance is an iterative calculation readily accomplished using spreadsheet solutions. However, the option to perform iterative calculations must be enabled within the spreadsheet. First, the overburden stress-corrected cone tip resistance, qc1N, is computed using Equation 5.

| Equation 5 |

Within Equation 5, CN is the overburden correction factor and qcis the unequal area-corrected cone tip resistance (using the area ratio and excess pore pressure measured behind the cone tip). For this analysis, the overburden correction factor for qc1N is different than the CN used to calculate Ic (Equation 6). In Equation 6, σ′v0 is the vertical effective stress at the depth of interest and the exponent m captures the dependence of relative density on the overburden stress-corrected cone tip resistance. The qc1Ncs is the clean sand and overburden stress-corrected cone tip resistance, to be computed subsequently as part of the iterative calculation. Boulanger and Idriss (2014) state that qc1Ncs must be limited to the range 21-254 in these computations.

| Equation 6 |

| Equation 7 |

The increment in cone tip resistance, ∆qc1N, stemming from nonzero nonplastic silty fines, which are more compressible than clean sands and yield lower cone tip resistances at a given relative density as a result, is obtained using Equation 8. FC in Equation 8 is the fines content in percent. Here, it is critical to ascertain the plasticity of fines from split-spoon or intact tube samples, as plasticity serves to increase the cyclic resistance of the material. For nonplastic silty fines and the CPT-based liquefaction-triggering assessment, the fines content may be correlated to the soil behavior type index, Ic, using a site-specific correlation (preferred) or the global correlation proposed by Boulanger and Idriss (2014) that is presented as Equation 9. The final step in the iteration is to compute the clean sand and overburden stress-corrected cone tip resistance using Equation 10. The standardized cyclic resistance corresponding to a moment magnitude, Mw, earthquake of 7.5, with 15 uniform shear stress cycles, N = 15, and one atmosphere of pressure may then be computed using Equation 11.

| Equation 8 |

| Equation 9 |

| Equation 10 |

| Equation 11 |

The standardized cyclic resistance must then be scaled to vertical effective overburden stresses which exist at the depth where the cone tip resistance was measured and to the design scenario earthquake magnitude. Magnitude scaling essentially accounts for the duration of seismic loading and thus the number of uniform shear stress cycles assumed to be contained within the design ground motion. The correction to CRR effectively results in an increase in resistance for earthquake magnitudes smaller than 7.5, and a decrease in CRR for earthquake magnitudes larger than 7.5. The magnitude scaling factor, MSF, for sandy soils is computed using Equation 12.

| Equation 12 |

The upper bound on magnitude scaling, MSFmax in Equation 12 represents the small-magnitude earthquakes for which the loading may be represented by a fraction of one cycle or one cycle of loading

(i.e., a single pulse). The relationship between CRR and N depends on the relative density of sands. Therefore, Boulanger and Idriss (2014) extended the Idriss (1999) magnitude scaling relationship to include qc1Ncs, which is captured in MSFmax (Equation 13). The correction to cyclic resistance for overburden stress is provided in Equation 14. The Cσ in Equation 14 is determined using Equation 15.

| Equation 13 |

| Equation 14 |

| Equation 15 |

The cyclic resistance for a given magnitude earthquake and overburden stress (i.e., depth) is then scaled from the standardized cyclic resistance using Equation 16. In the “Simplified Method” for liquefaction-triggering evaluation, the effective loading imposed by shear waves is taken equal to 65 percent of the maximum shear stress, τmax, and is provided in Equation 17. In Equation 17, σv0 is the total vertical overburden stress, amax/g is the peak ground acceleration at the ground surface as a fraction of the gravitational constant, and rd is the shear stress reduction coefficient to account for “flexibility” of the soil column relative to the rigid block model adopted by Seed and Idriss (1971), as determined using Equation 18.

| Equation 16 |

| Equation 17 |

| Equation 18 |

The α(z) and β(z) terms are determined using Equations 19 and 20, respectively, with z being the depth in meters, and the elements encapsulated within the parenthesis are in radians. The factor of safety against liquefaction triggering (i.e., ru = 100%) may then be determined for the depth of interest using Equation 21.

| Equation 19 |

| Equation 20 |

| Equation 21 |

In addition to those described above, other corrections to cyclic resistance also exist. One such example includes corrections to account for soil aging (Andrus et al. 2009); these corrections are particularly useful in Pleistocene deposits. Other potential corrections may be used to account for partial saturation (e.g., Hossein et al. 2013). These corrections are particularly useful in silty sands and nonplastic silts which may exhibit partial saturation below the static groundwater table. Further, efforts to use thin layer-corrected cone tip resistances (e.g., Boulanger and DeJong 2018), corrections for partial saturation, and site-specific CPT-based fines content (FC) correlations have been shown to result in more accurate (and smaller) post--

liquefaction reconsolidation settlements when computed for the Avondale Playground case history site in Christchurch, New Zealand (Cary et al. 2022).

Post-liquefaction reconsolidation settlement

Settlement of the ground surface following seismic loading can result from two distinct phenomena: (1) seismic compression of dry and partially-saturated soils (e.g., Duku et al. 2008), and (2) settlement associated with dissipation of excess pore pressures generated in near-saturated and saturated soils (Lee and Albaisa 1974, Ishihara and Yoshimine 1992). For example, seismic compression has been observed to produce settlement in compacted fills following the 1994 Northridge earthquake (Stewart et al. 2002). The resulting ground movements may impact pile foundations through transfer of drag loads during shaking, depending on the relative density and depth of the soil, hypocentral distance, and intensity and duration of loading. Seismic compression is not considered in the example of earthquake-induced settlement described below, which focuses solely on one-dimensional reconsolidation settlement. When computing one-dimensional reconsolidation settlement for a given exploration, it must be recognized that the estimate pertains only to the location of the exploration considered. Care must be taken to place the computed estimate within the context of spatial variability of the stratigraphy (i.e., azimuthal extent and thickness) and the properties within a given unit (Bong and Stuedlein 2018). Furthermore, as noted above, it must be emphasized that reconsolidation settlement occurs as a result of the dissipation of excess pore pressures and as such must be estimated even when FSL > 1.0.

Several methods are available to estimate seismically-induced reconsolidation settlement (Zhang et al. 2002; Yoshimine et al. 2006). This example considers the Yoshimine et al. (2006) methodology as implemented by Idriss and Boulanger (2008), which uses a correlation between relative density and qc1Ncs for ease of use with CPT data. The amount of volumetric strain in cyclic laboratory test specimens has been linked to the relative density of the specimen and the magnitude of excess pore pressure generated during cyclic loading. The excess pore pressure generated is in turn related to the maximum shear strain imposed upon the specimen during loading. Hence, the procedure to estimate reconsolidation settlement from volumetric strain includes the calculation of the limiting and maximum shear strain anticipated for a given soil deposit and seismic event, respectively. The limiting shear strain, γlim, is determined using Equation 22. As shown in Equation 23, the maximum shear strain, γmax, anticipated under a given design loading scenario, is assumed smaller than the shear strain necessary to trigger excess pore pressures if FSL ≥ 2.0. The maximum shear strain is assumed equal to γlim if FSL ≤ FSα. The maximum shear strain is calculated using Equation 23 if 2 > FSL > FSα, with FSα being calculated in Equation 24. The value of qc1Ncs is limited to 69 (qc1Ncs ≥ 69) when calculating FSα.

| Equation 22 |

| Equation 23 |

| Equation 23 |

The volumetric strain at a given depth, for a given soil layer depth interval, can then be computed using Equation 25. The increment of settlement associated with the volumetric strain at a given depth, z, may then be computed using Equation 26.

| Equation 25 |

| Equation 26 |

In Equation 26, ∆z is the increment in depth pertaining to the measured penetration resistance at a given depth. Thereafter, the cumulative settlement representing the one-dimensional reconsolidation settlement at the ground surface is computed as the sum of incremental settlements from the base of the exploration, zmax, using Equation 27.

| Equation 27 |

Drag load and downdrag determination

The magnitude of the drag load and downdrag can be computed following the determination of the post-liquefaction reconsolidation soil settlement. In keeping with the Boulanger and Idriss (2014) CPT-based liquefaction-triggering method, a CPT-based drag load and downdrag interpretation method is suggested for use. Specifically, the CPT-based LCPC Method that was developed by Laboratories des Ponts et Chaussess is proposed. As documented in Bustamante and Gianeselli (1982), the LCPC Method is an empirical approach developed from an analysis of static load tests in France. Other researchers (Briaud et al. 1986, Rollins et al. 1999) have used the LCPC Method and have suggested modifications or revisions based on other full-scale load tests. For the problems associated with this NCHRP 12-116A project, the piles are considered as Group II – Driven Piles for determination of end bearing resistance. Likewise, for the side resistance, the piles are considered as Category II A (driven concrete piles) or Category II B (driven steel piles).

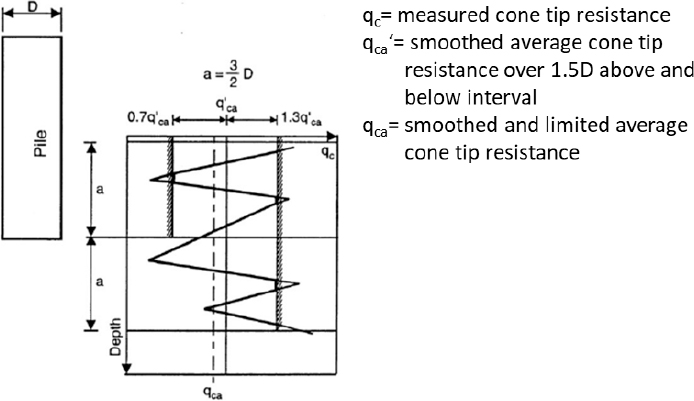

According to Bustamante and Gianeselli (1982), the smoothed average of the CPT tip resistance values are used to determine the limit resistance under the point of the pile (QLP). To determine the limit resistance under the point of the pile, the bearing capacity factor (kc) must be selected from Table G1, and the cross-sectional area of the tip of the pile must be known. An equivalent cone resistance at the level of the pile point (qca) must be determined (Equation 28).

| Equation 28 |

The procedure for determining the equivalent cone resistance at the level of the pile point is presented in Figure G1. Values between 1.5D above and 1.5D below the pile tip are averaged to determine the smoothed tip resistance profile (qca′) within this interval. Then limits are placed on the CPT tip resistance values within this region. If the CPT tip resistance value is larger than 1.3 times the smoothed value at a given depth, the CPT tip resistance value is limited to 1.3 times the smoothed value. Likewise, if the CPT tip resistance value is smaller than 0.7 times the smoothed value at a given depth, the CPT tip resistance value is limited to 0.7 times the smoothed value for depths between the pile tip and 1.5D above the pile tip. No lower limit is placed on the values between the pile tip and 1.5D below the pile tip. After determining the limited average values (qc,lim) at each depth, the equivalent cone resistance at the level of the pile point (qca) is the average of all of the qca′ or qc,lim values from 1.5D above to 1.5D below the pile tip.

Table G1. Bearing capacity factor (kc) for various soil types, pile groups, and cone penetration tip resistance (after Bustamante and Gianeselli, 1982). Units of tons per square foot are also included.

| kc Factor | |||

| Soil Type | CPT Tip Resistance, qc | Group I | Group II |

| Soft clay and mud | <10 MPa (<9.3 tsf) | 0.40 | 0.5 |

| Moderately compact clay | 10 to 50 MPa (9.3 to 46.6 tsf) | 0.35 | 0.45 |

| Silt and loose sand | <50 MPa (<46.6 tsf) | 0.40 | 0.5 |

| Compact to stiff clay and compact silt | >50 MPa (>46.6 tsf) | 0.45 | 0.55 |

| Soft chalk | <50 MPa (<46.6 tsf) | 0.20 | 0.3 |

| Moderately compact sand and gravel | 50 to 120 MPa (46.6 to 111.9 tsf) | 0.4 | 0.5 |

| Weathered to fragmented chalk | >50 MPa (>46.6 tsf) | 0.2 | 0.4 |

| Compact to very compact sand and gravel | >120 MPa (>111.9 tsf) | 0.3 | 0.4 |

When using the LCPC method, the determination of the side friction resistance also requires parameter selection from a table (Table G2). The determination of the unit skin friction is much easier than the aforementioned determination of the equivalent cone resistance at the level of the pile point. The measured CPT tip resistance at each depth (qc) is used in conjunction with the aLCPC coefficient from Table G2, for the given soil type and category, to determine the unit side resistance (fn). No averaging or limits are required when determining the unit skin resistance (Equation 29). Instead, limiting values (like the fs,max shown in Table G2) are placed on the unit skin resistance after determination of the unit skin resistance.

| Equation 29 |

Table G2. Side resistance factors for the LCPC method (after Bustamante and Gianeselli, 1982).

| Soil Type | qc [MPa] | aLCPC | Limiting value of fs,max [MPa] | ||||||||

| Category | |||||||||||

| I | II | I | II | III | |||||||

| IA | IB | IIA | IIB | IA | IB | IIA | IIB | IIIA | IIIB | ||

| Soft clay and mud | <1 | 30 | 30 | 30 | 30 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | |

| Moderately compact clay | 1 to 5 | 40 | 80 | 40 | 80 | 0.08 to 0.035 | 0.08 to 0.035 | 0.08 to 0.035 | 0.035 | 0.08 | >0.120 |

| Silt and loose sand | <5 | 60 | 150 | 60 | 120 | 0.035 | 0.035 | 0.035 | 0.035 | 0.08 | |

| Compact to stiff clay and compact silt | >5 | 60 | 120 | 60 | 120 | 0.08 to 0.035 | 0.08 to 0.035 | 0.08 to 0.035 | 0.035 | 0.08 | >0.2 |

| Soft chalk | <5 | 100 | 120 | 100 | 120 | 0.035 | 0.035 | 0.035 | 0.035 | 0.08 | |

| Moderately compact sand and gravel | 5 to 12 | 100 | 200 | 100 | 200 | 0.12 to 0.08 | 0.08 to 0.035 | 0.12 to 0.08 | 0.08 | 0.12 | >0.2 |

| Weathered to fragmented chalk | >5 | 60 | 80 | 60 | 80 | 0.15 to 0.12 | 0.12 to 0.08 | 0.15 to 0.12 | 0.12 | 0.15 | >0.2 |

| Compact to very compact sand and gravel | >12 | 150 | 300 | 150 | 200 | 0.15 to 0.12 | 0.12 to 0.08 | 0.15 to 0.12 | 0.12 | 0.15 | >0.2 |

The procedure for calculating the amount of drag load after determining the end bearing resistance and side resistance is similar to the approach presented in the later steps of the previous three examples. Like Steps 5, 6, and 7 of Design Example 1, the depth-varying load profile for the pile, the depth-varying resistance profile for the pile, and the combined load and resistance graphs are developed. As previously shown, these graphs are developed by summing the side resistance from the top of the pile to the bottom of the pile (load profile) and by summing the side resistance from the bottom of the pile to the top of the pile (resistance profile). For the load profile, the amount of unfactored top load is added to all of the values of load. Likewise, for the resistance profile, the amount of unfactored end bearing resistance is added to all values of resistance. The combined load and resistance profile is developed by taking the minimum value of load or resistance, at each depth, for all depths. The amount of drag load in the pile is determined by subtracting the unfactored top load from the maximum value of the combined load and resistance curve. The amount of elastic compression in the pile is calculated using the load within the pile (Q above the neutral plane and R below the neutral plane), the cross-sectional area of the pile (A), the elastic modulus of the pile (E), and the segmental length of the pile (Ls). Specifically, the elastic compression for each segment (δEC,s) of the pile is determined using Equation 30. The cumulative elastic compression in the pile is then determined by accumulating each of the elastic compression values from the bottom of the pile to the top of the pile (Equation 31). As with Design Example 1, the amount of tip movement of the pile and the nominal compression resistance of the pile can be determined using the DeCock (2009) method based on Chin’s Hyperbolic Model and the Davisson Method (Davisson, 1972), respectively.

| Eqn. 30 |

| Eqn. 31 |

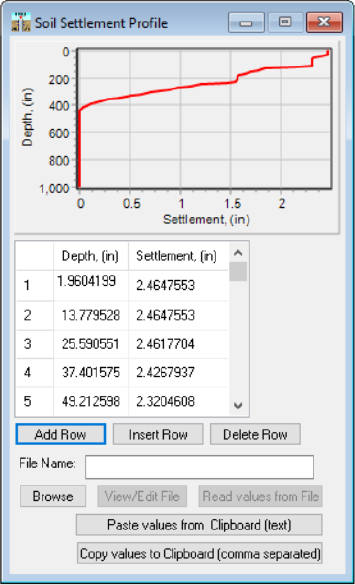

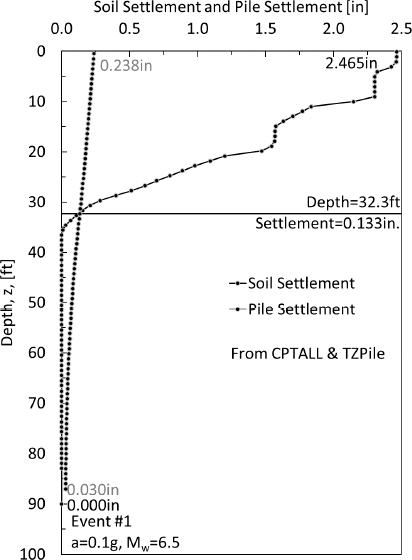

After determining the amount of tip movement and the amount of elastic compression, the pile settlement profile can be developed. The location of the neutral plane can then be determined by plotting the pile settlement profile and the soil settlement profile on the same plot. The location where the pile settlement profile and the soil settlement profile intersect is the location of the neutral plane. Moreover, the amount of movement of the pile and soil at the location of the neutral plane is the amount of downdrag expected for the pile.

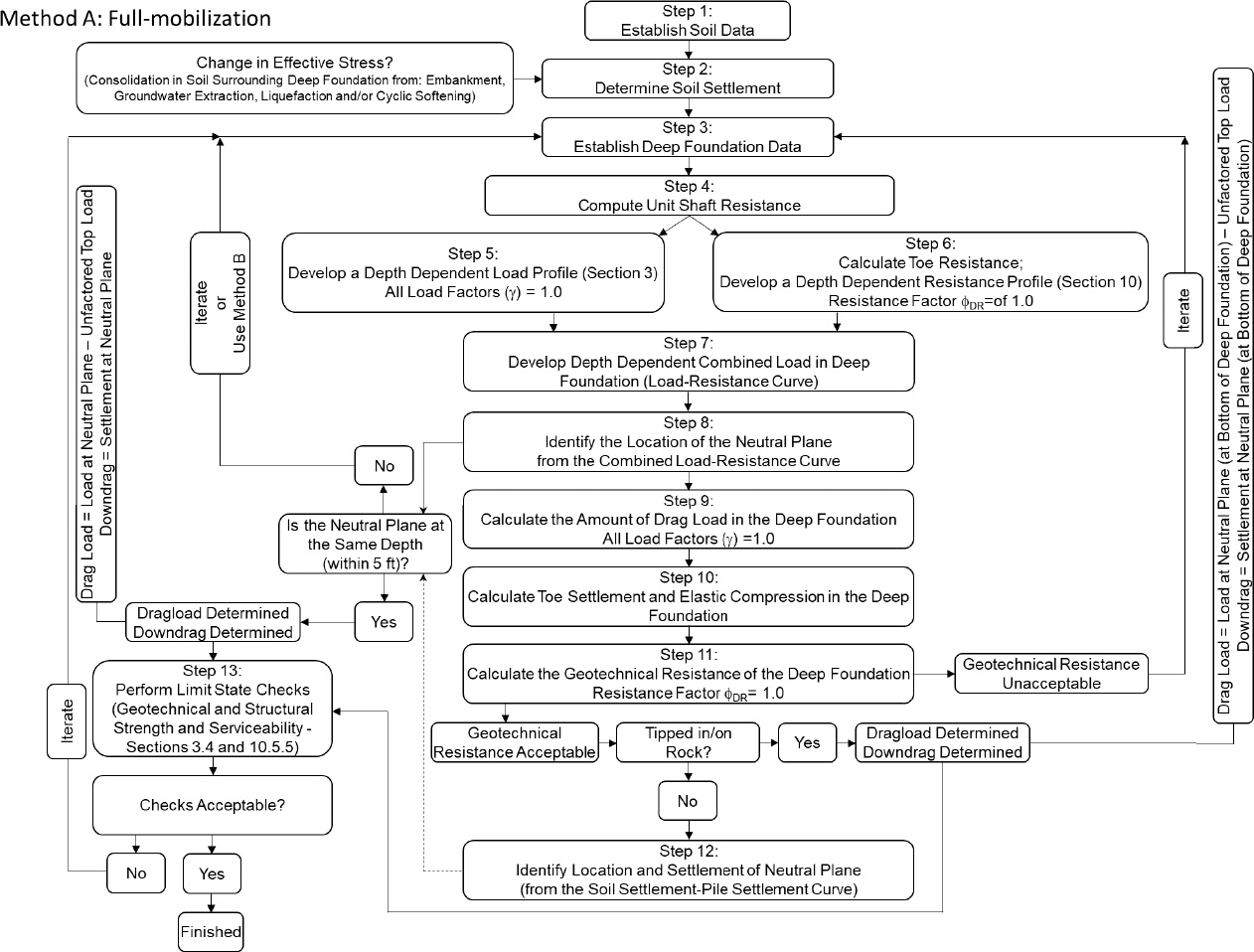

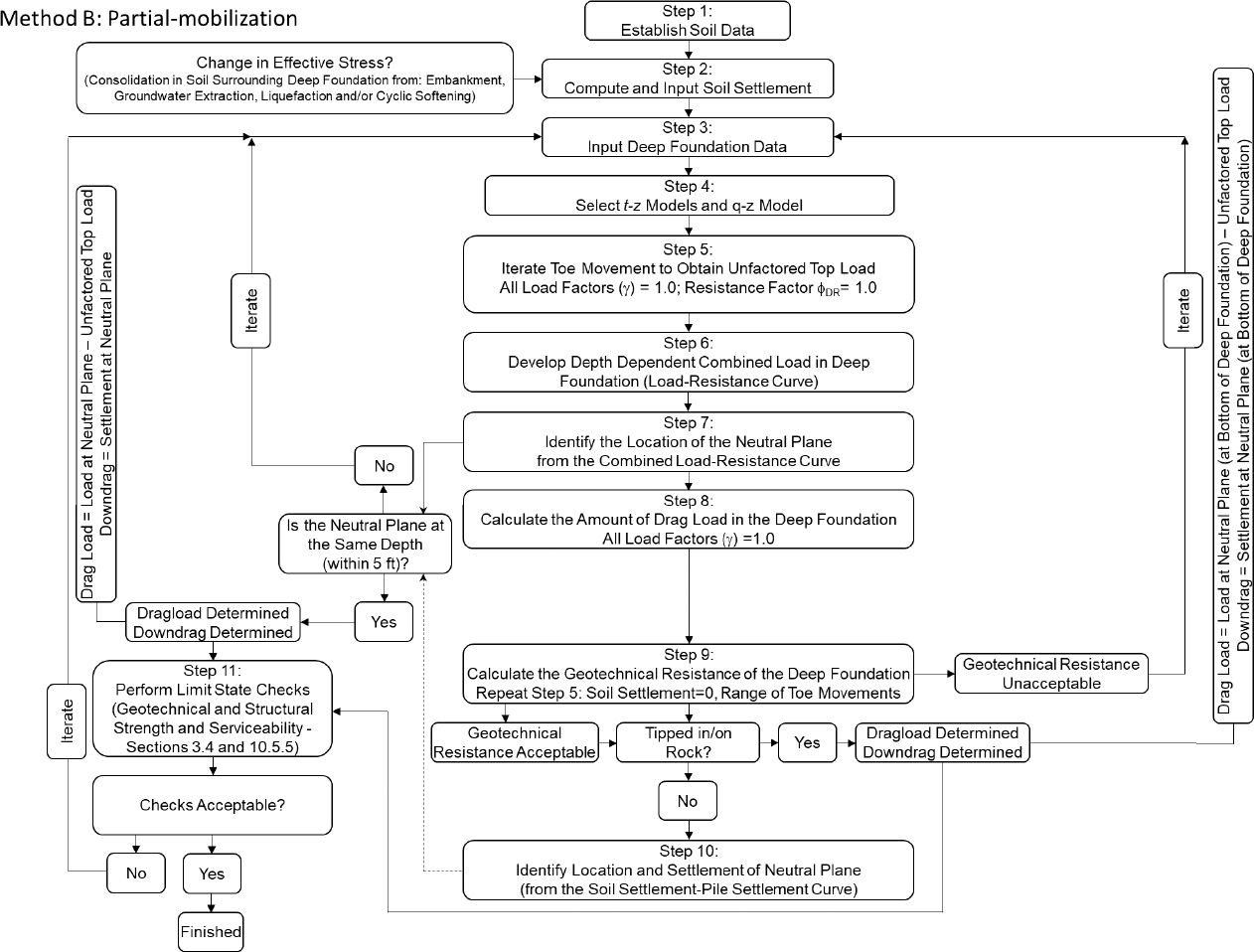

The aforementioned methodology can be completed using hand calculations in a manner similar to Design Examples 1 and 3 or through the use of the Ensoft TZPILE program, as used for Design Example 4. Other software programs can also aid in the completion of the aforementioned LCPC Method. Use of the Innovative Geotechnics ALLCPT software program for performing the LCPC Method was utilized herein. Specifically, design calculations and a program tutorial for using the ALLCPT program (NCHRP12-116A Method A) along with the TZPILE program (NCHRP 12-116A Method B) are included in the worked example that is included in the next section. The Method A and Method B flowcharts are provided on the next two pages for completeness.

Worked Example

Step 1: Establish soil data

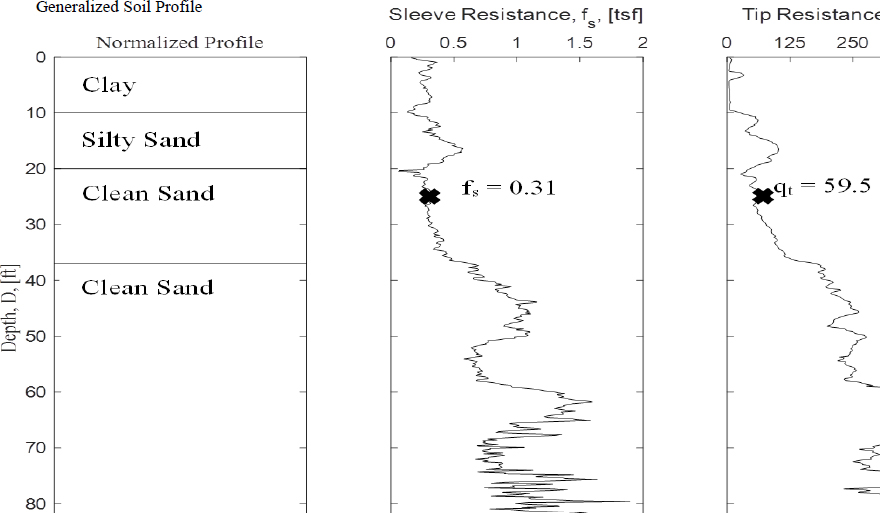

The following calculation of post-seismic reconsolidation settlement, downdrag determination, and drag load determination was completed for a site along the Mississippi River in Blytheville, Arkansas. The subsurface at this site consists of soft to medium stiff fine-grained soils overlying medium dense to very dense coarse-grained soils. Specifically, the stratigraphy includes 10 feet of soft clay overlying 10 to 15 feet of interbedded, medium-dense, clean and silty sand, overlying 10 feet of medium-dense clean sand, underlain by a thick stratum of dense to very dense sand. The water table was observed to range from a depth of 0 to 10 feet over the course of a year, with a depth of one foot below the ground surface being inferred from the CPT u2 measurements at the time of the sounding. The average CPT data from the site (based on five CPT soundings) are provided in Table G3; the interpreted subsurface conditions encountered at the site are presented in Figure G2. For simplicity in reporting, only every sixth line of the CPT data is presented. The CPT data were scalped using the OFFSET command in Microsoft Excel to obtain every sixth line. Therefore, the interval shown is every 0.984 feet (0.30m) instead of every 0.164 feet (0.05m).

Step 2: Determine soil settlement

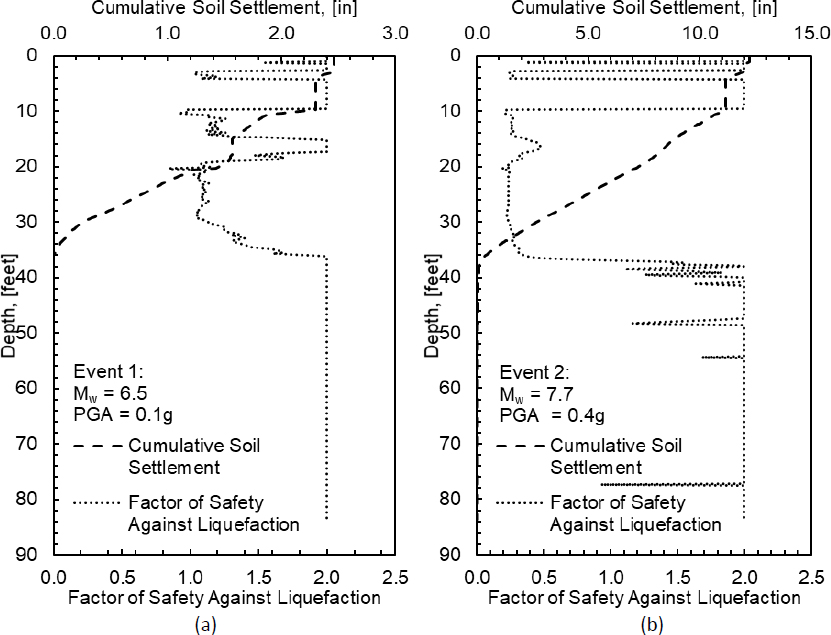

The seismic hazards for the design centers on two design events: (1) Event 1, PGA = 0.1g and Mw = 6.5; and (2) Event 2, PGA = 0.4g and Mw = 7.7. Detailed calculations of the factor of safety against liquefaction and 1D reconsolidation settlement for both events are presented for a depth of approximately 25 ft (24.93 ft) below the ground surface. At this location, σv0 = 2,758 psf, σ′v0 = 1,263 psf, and CPT outputs used for the example calculations are presented in Figure G2.

Table G3. Average CPT sounding record for the Blytheville, AR Test Site.

| z | fs | qt | u2 | Comments: z=Depth [ft], fs=Sleeve friction [tsf], qt=Tip resistance [tsf], u2=Pore pressure [psi] Values collected every |

| 0.163 | 0.163 | 5.990 | -0.080 | |

| 1.148 | 0.343 | 6.644 | -4.346 | |

| 2.133 | 0.321 | 5.024 | -3.507 | |

| 3.117 | 0.232 | 30.509 | -0.474 | |

| 4.101 | 0.283 | 8.452 | 0.052 | |

| 5.085 | 0.259 | 3.602 | 1.817 | |

| 6.070 | 0.279 | 4.583 | 2.308 | |

| 7.054 | 0.321 | 5.619 | 3.310 | |

| 8.038 | 0.314 | 7.221 | 3.799 | |

| 9.022 | 0.178 | 4.880 | 4.400 | |

| 10.007 | 0.153 | 26.554 | 4.783 | |

| 10.991 | 0.283 | 55.585 | 4.052 | |

| 11.975 | 0.380 | 57.579 | 3.349 | |

| 12.959 | 0.299 | 41.164 | 3.934 | |

| 13.944 | 0.332 | 44.718 | 1.888 | |

| 14.928 | 0.412 | 80.277 | 0.862 | |

| 15.912 | 0.485 | 99.291 | 1.548 | |

| 16.896 | 0.549 | 102.243 | 3.270 | |

| 17.881 | 0.435 | 82.030 | 3.717 | |

| 18.865 | 0.413 | 81.470 | 3.345 | |

| 19.849 | 0.259 | 50.410 | 3.707 | |

| 20.833 | 0.233 | 30.238 | 3.041 | |

| 21.818 | 0.294 | 56.976 | 4.014 | |

| 22.802 | 0.274 | 48.270 | 7.523 | |

| 23.786 | 0.306 | 58.057 | 7.823 | |

| 24.770 | 0.316 | 59.929 | 8.438 | |

| 25.755 | 0.303 | 59.692 | 9.553 | |

| 26.739 | 0.271 | 53.975 | 11.429 | |

| 27.723 | 0.290 | 60.599 | 11.954 | |

| 28.707 | 0.307 | 68.630 | 12.150 | |

| 29.692 | 0.328 | 76.193 | 13.576 | |

| 30.676 | 0.350 | 86.086 | 13.470 | |

| 31.660 | 0.336 | 89.231 | 14.176 | |

| 32.644 | 0.419 | 98.042 | 15.180 | |

| 33.629 | 0.396 | 96.314 | 15.467 | |

| 34.613 | 0.372 | 107.343 | 15.953 | |

| 35.597 | 0.410 | 113.077 | 16.297 | |

| 36.581 | 0.508 | 143.899 | 16.744 | |

| 37.566 | 0.666 | 185.609 | 16.821 | |

| 38.550 | 0.608 | 179.809 | 17.287 | |

| 39.561 | 0.656 | 185.487 | 17.292 | |

| 40.546 | 0.840 | 206.957 | 17.771 | |

| 41.530 | 0.866 | 205.632 | 16.569 | |

| 42.569 | 0.925 | 210.830 | 18.586 | |

| 43.553 | 0.995 | 232.122 | 18.903 | |

| 44.537 | 1.028 | 245.359 | 19.529 | |

| 45.549 | 1.077 | 259.473 | 19.777 | |

| 46.533 | 1.035 | 227.953 | 20.100 | |

| 47.517 | 1.000 | 211.495 | 20.318 | |

| 48.529 | 0.967 | 220.913 | 20.881 | |

| 49.513 | 1.070 | 253.789 | 20.833 | |

| 50.498 | 0.895 | 268.331 | 21.315 | |

| 51.482 | 0.757 | 256.276 | 21.870 | |

| 52.466 | 0.680 | 247.751 | 22.581 |

| z | fs | qt | u2 | Comments: z=Depth [ft], fs=Sleeve friction [tsf], qt=Tip resistance [tsf], u2=Pore pressure [psi] Values collected every |

| 53.450 | 0.717 | 240.933 | 22.914 | |

| 54.435 | 0.653 | 219.256 | 23.600 | |

| 55.474 | 0.648 | 245.683 | 24.005 | |

| 56.458 | 0.688 | 250.659 | 24.232 | |

| 57.442 | 0.767 | 245.872 | 24.346 | |

| 58.481 | 0.847 | 268.145 | 25.168 | |

| 59.465 | 1.130 | 329.023 | 25.588 | |

| 60.449 | 1.317 | 379.164 | 25.735 | |

| 61.488 | 1.457 | 392.789 | 24.920 | |

| 62.473 | 1.366 | 378.497 | 26.585 | |

| 63.457 | 1.462 | 393.080 | 26.816 | |

| 64.469 | 1.218 | 375.347 | 27.283 | |

| 65.518 | 1.017 | 343.502 | 27.677 | |

| 66.503 | 1.156 | 355.590 | 28.325 | |

| 67.626 | 1.355 | 342.052 | 29.154 | |

| 68.611 | 0.844 | 311.256 | 29.417 | |

| 69.595 | 0.687 | 298.517 | 29.799 | |

| 70.579 | 0.727 | 290.580 | 30.460 | |

| 71.563 | 0.842 | 289.159 | 30.683 | |

| 72.548 | 0.729 | 249.830 | 31.720 | |

| 73.710 | 0.863 | 273.813 | 31.332 | |

| 74.694 | 0.901 | 348.687 | 31.865 | |

| 75.678 | 1.635 | 376.848 | 31.968 | |

| 77.018 | 0.980 | 322.823 | 32.031 | |

| 78.002 | 0.885 | 260.040 | 28.425 | |

| 78.986 | 1.091 | 375.017 | 32.978 | |

| 79.970 | 0.986 | 345.087 | 32.455 | |

| 80.955 | 0.788 | 374.134 | 33.192 | |

| 81.939 | 1.274 | 374.530 | 34.805 | |

| 82.923 | 1.856 | 404.210 | 33.297 | |

| 83.661 | 1.557 | 351.657 | 29.414 |

Soils with Ic ≥ 2.6 were assumed to not be susceptible to liquefaction for demonstration purposes only, and FSL was set equal to 2.0. Additionally, any soil above the ground water table was assumed to not liquefy. Given that materials with Ic ≥ 2.6 at this site are soft to medium stiff, the potential for cyclic softening and post-shaking reconsolidation strains requires consideration. A sampling and laboratory testing program would be recommended to assess cyclic resistance and reconsolidation strain potential (see Section 2.6 of the NCHRP12-116A Phase IV report).

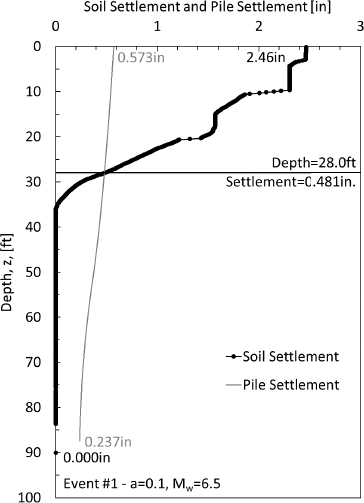

The results of the liquefaction settlement analysis for Event 1 and Event 2 are presented in Figure G3a and Figure G3b, respectively. For Event 1, liquefaction triggering was not indicated with FSL > 1.0 for all depths, but 2.5 inches of reconsolidation settlement was predicted due to the dissipation of excess pore pressures which are presumed to have been generated by shaking. For Event 2, liquefaction was indicated for depths ranging from 10 to 37 ft, and reconsolidation settlement of 12.2 inches was calculated. For both events, soil settlements extended to the depth of the dense sand layer (37 ft). As discussed in the next section, these settlement profiles were then used as input parameters to determine the location of the neutral plane and the amount of drag load developed. Detailed procedures and computations for determining the post-liquefaction reconsolidation settlement at a depth of 24.93 ft are provided in Table G4. The post-liquefaction reconsolidation settlement calculations and the amount of cumulative soil settlement, as a function of depth, for all depths are reported in Tables G5 through G7.

Table G4. Detailed calculations for determining post-liquefaction soil settlement.

| Event 1 | ||

| Equation | Worked Example at Depth of 24.93ft | Comment |

| Calculate the cyclic resistance ratio, CRR | ||

| Qtn replaces Qt in Ic equation following initial calculation. Following iteration (x4): Ic=1.86, n = 0.585, and Qtn=74.3 |

||

| FC = 80Ic − 137 | FC = 80 ∙ 1.86 − 137 = 11.5% | |

|

|

m = 1.338 − 0.249(85)0.264 = 0.53 qc1Ncs = 74.0 + 11.0 = 85.0 |

Iterative calculation required. Accomplished using the Enable Iterative Calculations option in Excel. To enable the iterative calculations option in Excel, click File > Options > Formulas. Limit qc1Ncs to the range of [21, 254] |

| Calculate the cyclic stress ratio, CSR | ||

| Calculate the factor of safety against liquefaction, FSL | ||

| See Figure G3; FSL ≤ 2.0 triggers calculation of volumetric strain and corresponding settlement | ||

| Calculate reconsolidation settlement | ||

| Limit qc1Ncs ≥ 69 | ||

| This is arithmetic strain, equal to γlim = 44% and associated with low relative density | ||

| This is arithmetic strain, equal to γmax = 1.8% and associated with low PGA | ||

| This is arithmetic strain, equal to εv = 0.8% | ||

| S1D = 2.5 inches | See Figure G3. | |

Table G5. Results from calculations to find corrected tip resistance.

| z | Ic | n | Qtn | qc1N | CN | m | qc1Ncs | Comments: For Event #1 – amax=0.1, Mw=6.5, z=Depth [ft], Ic=Soil behavior type index, n=stress normalization exponent, Qtn=Normalized corrected net cone tip resistance, qc1N=Overburden stress-corrected cone tip resistance [tsf], CN=Overburden correction factor, m=Overburden correction factor exponent, qc1Ncs=Clean sand and overburden stress-corrected cone tip resistance [tsf]. Values collected every |

|||

| 0.163 | 120.822 | 19.738 | 2.190 | 0.683 | 137.351 | 9.624 | 1.700 | 0.628 | 43.214 | 52.837 | |

| 1.148 | 107.801 | 125.255 | 2.543 | 0.819 | 67.872 | 10.674 | 1.700 | 0.592 | 53.081 | 63.755 | |

| 2.133 | 105.991 | 229.496 | 2.720 | 0.887 | 46.606 | 8.071 | 1.700 | 0.596 | 54.513 | 62.584 | |

| 3.117 | 113.182 | 338.402 | 1.837 | 0.553 | 104.314 | 49.018 | 1.700 | 0.620 | 6.153 | 55.171 | |

| 4.101 | 110.548 | 453.651 | 2.539 | 0.821 | 43.669 | 13.580 | 1.700 | 0.581 | 53.853 | 67.433 | |

| 5.085 | 103.417 | 555.312 | 2.996 | 0.996 | 22.063 | 5.786 | 1.700 | 0.599 | 55.730 | 61.516 | |

| 6.070 | 105.630 | 658.756 | 2.924 | 0.969 | 23.599 | 7.363 | 1.700 | 0.594 | 55.970 | 63.333 | |

| 7.054 | 106.426 | 762.746 | 2.882 | 0.954 | 25.261 | 9.027 | 1.700 | 0.588 | 56.185 | 65.212 | |

| 8.038 | 107.520 | 867.675 | 2.769 | 0.912 | 27.638 | 11.602 | 1.700 | 0.580 | 56.046 | 67.648 | |

| 9.022 | 101.243 | 969.769 | 2.880 | 0.955 | 17.579 | 7.841 | 1.700 | 0.593 | 55.809 | 63.649 | |

| 10.007 | 114.235 | 1074.550 | 1.971 | 0.611 | 58.582 | 42.662 | 1.700 | 0.565 | 30.473 | 73.136 | |

| 10.991 | 113.878 | 1188.052 | 1.729 | 0.520 | 103.531 | 89.305 | 1.700 | 0.523 | 0.000 | 89.305 | |

| 11.975 | 113.888 | 1299.143 | 1.785 | 0.543 | 105.468 | 92.510 | 1.700 | 0.514 | 0.488 | 92.998 | |

| 12.959 | 112.948 | 1411.400 | 1.925 | 0.597 | 76.425 | 66.136 | 1.700 | 0.518 | 25.361 | 91.497 | |

| 13.944 | 115.292 | 1522.129 | 1.917 | 0.595 | 79.401 | 71.846 | 1.700 | 0.507 | 24.349 | 96.195 | |

| 14.928 | 114.023 | 1635.068 | 1.662 | 0.500 | 124.908 | 120.641 | 1.590 | 0.456 | 0.000 | 120.641 | |

| 15.912 | 116.185 | 1748.957 | 1.593 | 0.475 | 146.144 | 139.982 | 1.492 | 0.420 | 0.000 | 139.982 | |

| 16.896 | 117.133 | 1864.281 | 1.614 | 0.484 | 147.175 | 140.264 | 1.452 | 0.420 | 0.000 | 140.264 | |

| 17.881 | 115.266 | 1978.696 | 1.693 | 0.515 | 117.381 | 114.269 | 1.474 | 0.468 | 0.000 | 114.269 | |

| 18.865 | 114.686 | 2091.573 | 1.694 | 0.517 | 113.434 | 111.183 | 1.444 | 0.474 | 0.000 | 111.183 | |

| 19.849 | 110.400 | 2201.933 | 1.871 | 0.585 | 71.261 | 70.255 | 1.475 | 0.535 | 14.012 | 84.267 | |

| 20.833 | 107.996 | 2306.491 | 2.144 | 0.690 | 44.084 | 40.910 | 1.432 | 0.524 | 47.842 | 88.752 | |

| 21.818 | 111.073 | 2414.187 | 1.845 | 0.578 | 76.371 | 75.895 | 1.409 | 0.535 | 8.632 | 84.527 | |

| 22.802 | 109.488 | 2522.566 | 1.933 | 0.612 | 64.164 | 62.479 | 1.370 | 0.524 | 26.522 | 89.002 | |

| 23.786 | 110.799 | 2630.505 | 1.860 | 0.585 | 74.492 | 73.952 | 1.348 | 0.532 | 11.743 | 85.695 | |

| 24.770 | 111.341 | 2740.067 | 1.857 | 0.585 | 75.134 | 74.755 | 1.320 | 0.531 | 11.049 | 85.804 | |

| 25.755 | 110.547 | 2849.221 | 1.858 | 0.587 | 73.204 | 73.119 | 1.296 | 0.535 | 11.296 | 84.415 | |

| 26.739 | 110.086 | 2957.878 | 1.901 | 0.604 | 65.096 | 64.819 | 1.271 | 0.533 | 20.286 | 85.105 | |

| 27.723 | 110.588 | 3067.169 | 1.856 | 0.588 | 71.248 | 71.631 | 1.251 | 0.540 | 10.844 | 82.475 | |

| 28.707 | 111.897 | 3176.704 | 1.804 | 0.570 | 78.705 | 79.730 | 1.229 | 0.542 | 1.790 | 81.520 | |

| 29.692 | 112.653 | 3286.978 | 1.764 | 0.556 | 85.465 | 86.551 | 1.202 | 0.530 | 0.026 | 86.577 | |

| 30.676 | 113.638 | 3397.761 | 1.713 | 0.538 | 94.472 | 95.483 | 1.174 | 0.508 | 0.000 | 95.483 | |

| 31.660 | 113.003 | 3509.623 | 1.691 | 0.530 | 96.059 | 97.256 | 1.153 | 0.504 | 0.000 | 97.256 | |

| 32.644 | 115.062 | 3621.893 | 1.688 | 0.530 | 103.928 | 104.746 | 1.130 | 0.488 | 0.000 | 104.746 | |

| 33.629 | 114.899 | 3734.786 | 1.693 | 0.533 | 100.416 | 101.522 | 1.115 | 0.495 | 0.000 | 101.522 | |

| 34.613 | 114.591 | 3847.326 | 1.622 | 0.508 | 109.784 | 111.068 | 1.095 | 0.475 | 0.000 | 111.068 | |

| 35.597 | 115.863 | 3961.458 | 1.618 | 0.507 | 113.953 | 115.207 | 1.078 | 0.466 | 0.000 | 115.207 | |

| 36.581 | 117.757 | 4076.590 | 1.526 | 0.474 | 142.725 | 143.622 | 1.056 | 0.414 | 0.000 | 143.622 | |

| 37.566 | 120.242 | 4194.474 | 1.440 | 0.443 | 181.446 | 181.864 | 1.037 | 0.355 | 0.000 | 181.864 | |

| 38.550 | 119.499 | 4312.741 | 1.444 | 0.445 | 173.422 | 174.495 | 1.027 | 0.365 | 0.000 | 174.495 | |

| 39.561 | 120.083 | 4434.628 | 1.447 | 0.448 | 176.598 | 178.041 | 1.016 | 0.360 | 0.000 | 178.041 | |

| 40.546 | 121.871 | 4553.866 | 1.445 | 0.448 | 194.761 | 196.572 | 1.005 | 0.334 | 0.000 | 196.572 | |

| 41.530 | 122.199 | 4674.384 | 1.461 | 0.456 | 191.015 | 193.487 | 0.996 | 0.338 | 0.000 | 193.487 | |

| 42.569 | 123.445 | 4802.070 | 1.468 | 0.460 | 193.243 | 196.480 | 0.986 | 0.334 | 0.000 | 196.480 | |

| 43.553 | 123.941 | 4923.348 | 1.432 | 0.448 | 210.501 | 214.749 | 0.979 | 0.310 | 0.000 | 214.749 | |

| 44.537 | 123.910 | 5045.827 | 1.410 | 0.441 | 220.087 | 225.413 | 0.972 | 0.297 | 0.000 | 225.413 | |

| 45.549 | 124.236 | 5171.284 | 1.392 | 0.435 | 230.278 | 236.911 | 0.966 | 0.283 | 0.000 | 236.911 | |

| 46.533 | 123.506 | 5293.349 | 1.467 | 0.465 | 198.903 | 205.483 | 0.954 | 0.322 | 0.000 | 205.483 | |

| 47.517 | 124.343 | 5415.452 | 1.509 | 0.483 | 181.689 | 188.407 | 0.943 | 0.345 | 0.000 | 188.407 | |

| 48.529 | 123.000 | 5540.488 | 1.477 | 0.472 | 188.003 | 195.521 | 0.936 | 0.336 | 0.000 | 195.521 | |

| 49.513 | 123.547 | 5662.041 | 1.420 | 0.452 | 214.886 | 224.721 | 0.937 | 0.298 | 0.000 | 224.721 | |

| 50.498 | 122.997 | 5783.748 | 1.342 | 0.424 | 226.501 | 236.827 | 0.934 | 0.283 | 0.000 | 236.827 | |

| 51.482 | 121.750 | 5903.794 | 1.335 | 0.422 | 214.291 | 223.896 | 0.924 | 0.299 | 0.000 | 223.896 | |

| 52.466 | 121.018 | 6022.677 | 1.335 | 0.424 | 205.151 | 214.395 | 0.916 | 0.311 | 0.000 | 214.395 |

| z | Ic | n | Qtn | qc1N | CN | m | qc1Ncs | Comments: See definition of variables on previous page. Values collected every ∆z=0.164ft but reported herein every ∆z=0.984ft (except for first and last values). |

|||

| 53.450 | 121.375 | 6141.791 | 1.368 | 0.438 | 196.831 | 206.549 | 0.907 | 0.321 | 0.000 | 206.549 | |

| 54.435 | 120.474 | 6260.247 | 1.410 | 0.455 | 176.321 | 185.030 | 0.893 | 0.350 | 0.000 | 185.030 | |

| 55.474 | 120.556 | 6385.614 | 1.341 | 0.430 | 197.683 | 208.063 | 0.896 | 0.319 | 0.000 | 208.063 | |

| 56.458 | 120.924 | 6504.888 | 1.345 | 0.433 | 199.820 | 211.300 | 0.892 | 0.315 | 0.000 | 211.300 | |

| 57.442 | 121.561 | 6624.140 | 1.386 | 0.450 | 193.053 | 205.445 | 0.884 | 0.322 | 0.000 | 205.445 | |

| 58.481 | 122.479 | 6750.393 | 1.358 | 0.441 | 209.641 | 224.845 | 0.887 | 0.298 | 0.000 | 224.845 | |

| 59.465 | 124.887 | 6872.280 | 1.304 | 0.421 | 257.745 | 278.294 | 0.895 | 0.264 | 0.000 | 254.000 | |

| 60.449 | 126.740 | 6996.671 | 1.257 | 0.405 | 297.100 | 319.071 | 0.890 | 0.264 | 0.000 | 254.000 | |

| 61.488 | 127.600 | 7128.689 | 1.266 | 0.410 | 304.597 | 328.776 | 0.886 | 0.264 | 0.000 | 254.000 | |

| 62.473 | 126.950 | 7254.346 | 1.275 | 0.415 | 290.399 | 315.231 | 0.881 | 0.264 | 0.000 | 254.000 | |

| 63.457 | 127.479 | 7379.282 | 1.272 | 0.416 | 299.257 | 325.789 | 0.877 | 0.264 | 0.000 | 254.000 | |

| 64.469 | 125.938 | 7507.147 | 1.255 | 0.411 | 284.171 | 309.583 | 0.873 | 0.264 | 0.000 | 254.000 | |

| 65.518 | 124.651 | 7640.161 | 1.269 | 0.417 | 256.807 | 281.911 | 0.868 | 0.264 | 0.000 | 254.000 | |

| 66.503 | 125.502 | 7762.766 | 1.283 | 0.424 | 263.053 | 290.541 | 0.865 | 0.264 | 0.000 | 254.000 | |

| 67.626 | 126.212 | 7902.300 | 1.356 | 0.454 | 246.692 | 278.103 | 0.860 | 0.264 | 0.000 | 254.000 | |

| 68.611 | 122.403 | 8024.086 | 1.297 | 0.433 | 225.304 | 251.602 | 0.855 | 0.267 | 0.000 | 251.602 | |

| 69.595 | 121.499 | 8144.146 | 1.280 | 0.428 | 215.142 | 238.091 | 0.844 | 0.282 | 0.000 | 238.091 | |

| 70.579 | 121.793 | 8264.421 | 1.314 | 0.442 | 206.152 | 229.293 | 0.835 | 0.292 | 0.000 | 229.293 | |

| 71.563 | 122.231 | 8385.033 | 1.355 | 0.459 | 201.555 | 226.729 | 0.830 | 0.296 | 0.000 | 226.729 | |

| 72.548 | 122.618 | 8505.017 | 1.421 | 0.485 | 169.611 | 188.973 | 0.800 | 0.344 | 0.000 | 188.973 | |

| 73.710 | 123.440 | 8649.010 | 1.404 | 0.481 | 185.100 | 209.681 | 0.810 | 0.317 | 0.000 | 209.681 | |

| 74.694 | 123.754 | 8770.369 | 1.257 | 0.426 | 243.712 | 275.531 | 0.836 | 0.264 | 0.000 | 254.000 | |

| 75.678 | 128.338 | 8895.132 | 1.371 | 0.471 | 253.916 | 296.602 | 0.833 | 0.264 | 0.000 | 254.000 | |

| 77.018 | 124.661 | 9061.838 | 1.337 | 0.460 | 216.689 | 252.473 | 0.828 | 0.266 | 0.000 | 252.473 | |

| 78.002 | 124.108 | 9185.051 | 1.461 | 0.509 | 166.798 | 191.854 | 0.781 | 0.341 | 0.000 | 191.854 | |

| 78.986 | 125.660 | 9307.667 | 1.270 | 0.438 | 253.122 | 291.482 | 0.822 | 0.264 | 0.000 | 254.000 | |

| 79.970 | 124.876 | 9432.607 | 1.304 | 0.452 | 228.713 | 267.216 | 0.819 | 0.264 | 0.000 | 254.000 | |

| 80.955 | 124.062 | 9556.417 | 1.198 | 0.413 | 254.053 | 288.658 | 0.816 | 0.264 | 0.000 | 254.000 | |

| 81.939 | 126.667 | 9681.199 | 1.322 | 0.462 | 243.412 | 287.915 | 0.813 | 0.264 | 0.000 | 254.000 | |

| 82.923 | 130.206 | 9805.708 | 1.384 | 0.487 | 256.159 | 309.623 | 0.811 | 0.264 | 0.000 | 254.000 | |

| 83.661 | 127.812 | 10859.659 | 1.430 | 0.505 | 217.688 | 268.635 | 0.808 | 0.264 | 0.000 | 254.000 |

Table G6. Results from CRR, cyclic stress ratio, and factor of safety calculations.

| z | rd | K |

C |

MSFmax | MSF | CRR7.5,1atm | CRRM, |

CSRM, |

Comments: For Event #1 – amax=0.1, Mw=6.5, z=Depth [ft], rd=Shear stress reduction coefficient, |

||

| 0.163 | 1.00 | 0.01 | 0.00 | 1.10 | 0.07 | 1.12 | 1.04 | 0.09 | 0.11 | 0.07 | |

| 1.148 | 1.00 | 0.00 | 0.00 | 1.10 | 0.08 | 1.13 | 1.05 | 0.10 | 0.12 | 0.07 | |

| 2.133 | 1.00 | -0.01 | 0.00 | 1.10 | 0.08 | 1.13 | 1.05 | 0.10 | 0.12 | 0.09 | |

| 3.117 | 1.00 | -0.02 | 0.00 | 1.10 | 0.07 | 1.12 | 1.04 | 0.10 | 0.11 | 0.11 | |

| 4.101 | 0.99 | -0.04 | 0.00 | 1.10 | 0.08 | 1.14 | 1.05 | 0.11 | 0.12 | 0.11 | |

| 5.085 | 0.99 | -0.05 | 0.01 | 1.10 | 0.08 | 1.13 | 1.05 | 0.10 | 0.12 | 0.12 | |

| 6.070 | 0.98 | -0.07 | 0.01 | 1.10 | 0.08 | 1.13 | 1.05 | 0.10 | 0.12 | 0.12 | |

| 7.054 | 0.98 | -0.09 | 0.01 | 1.10 | 0.08 | 1.14 | 1.05 | 0.10 | 0.12 | 0.13 | |

| 8.038 | 0.98 | -0.10 | 0.01 | 1.10 | 0.08 | 1.14 | 1.05 | 0.11 | 0.12 | 0.13 | |

| 9.022 | 0.97 | -0.12 | 0.01 | 1.10 | 0.08 | 1.13 | 1.05 | 0.10 | 0.12 | 0.13 | |

| 10.007 | 0.97 | -0.14 | 0.02 | 1.10 | 0.09 | 1.16 | 1.06 | 0.11 | 0.13 | 0.13 | |

| 10.991 | 0.96 | -0.16 | 0.02 | 1.10 | 0.10 | 1.21 | 1.08 | 0.12 | 0.15 | 0.13 | |

| 11.975 | 0.96 | -0.17 | 0.02 | 1.10 | 0.10 | 1.23 | 1.09 | 0.13 | 0.15 | 0.13 | |

| 12.959 | 0.95 | -0.19 | 0.02 | 1.10 | 0.10 | 1.22 | 1.08 | 0.13 | 0.15 | 0.13 | |

| 13.944 | 0.95 | -0.21 | 0.02 | 1.10 | 0.10 | 1.24 | 1.09 | 0.13 | 0.16 | 0.13 | |

| 14.928 | 0.94 | -0.23 | 0.03 | 1.10 | 0.13 | 1.39 | 1.15 | 0.17 | 0.22 | 0.13 | |

| 15.912 | 0.94 | -0.26 | 0.03 | 1.10 | 0.15 | 1.56 | 1.21 | 0.23 | 0.31 | 0.13 | |

| 16.896 | 0.93 | -0.28 | 0.03 | 1.10 | 0.15 | 1.56 | 1.21 | 0.24 | 0.31 | 0.13 | |

| 17.881 | 0.92 | -0.30 | 0.03 | 1.10 | 0.12 | 1.35 | 1.13 | 0.16 | 0.20 | 0.13 | |

| 18.865 | 0.92 | -0.32 | 0.04 | 1.09 | 0.12 | 1.33 | 1.12 | 0.15 | 0.19 | 0.13 | |

| 19.849 | 0.91 | -0.34 | 0.04 | 1.07 | 0.09 | 1.19 | 1.07 | 0.12 | 0.14 | 0.13 | |

| 20.833 | 0.91 | -0.37 | 0.04 | 1.07 | 0.10 | 1.21 | 1.08 | 0.12 | 0.14 | 0.13 | |

| 21.818 | 0.90 | -0.39 | 0.04 | 1.06 | 0.09 | 1.19 | 1.07 | 0.12 | 0.14 | 0.13 | |

| 22.802 | 0.89 | -0.42 | 0.05 | 1.06 | 0.10 | 1.21 | 1.08 | 0.12 | 0.14 | 0.13 | |

| 23.786 | 0.89 | -0.44 | 0.05 | 1.05 | 0.10 | 1.20 | 1.07 | 0.12 | 0.14 | 0.13 | |

| 24.770 | 0.88 | -0.47 | 0.05 | 1.05 | 0.10 | 1.20 | 1.07 | 0.12 | 0.14 | 0.13 | |

| 25.755 | 0.88 | -0.49 | 0.06 | 1.05 | 0.09 | 1.19 | 1.07 | 0.12 | 0.13 | 0.12 | |

| 26.739 | 0.87 | -0.52 | 0.06 | 1.04 | 0.09 | 1.20 | 1.07 | 0.12 | 0.13 | 0.12 | |

| 27.723 | 0.86 | -0.54 | 0.06 | 1.04 | 0.09 | 1.19 | 1.07 | 0.12 | 0.13 | 0.12 | |

| 28.707 | 0.86 | -0.57 | 0.06 | 1.04 | 0.09 | 1.18 | 1.07 | 0.12 | 0.13 | 0.12 | |

| 29.692 | 0.85 | -0.60 | 0.07 | 1.03 | 0.10 | 1.20 | 1.08 | 0.12 | 0.14 | 0.12 | |

| 30.676 | 0.84 | -0.62 | 0.07 | 1.03 | 0.10 | 1.24 | 1.09 | 0.13 | 0.15 | 0.12 | |

| 31.660 | 0.84 | -0.65 | 0.07 | 1.03 | 0.10 | 1.25 | 1.09 | 0.13 | 0.15 | 0.12 | |

| 32.644 | 0.83 | -0.68 | 0.08 | 1.03 | 0.11 | 1.29 | 1.11 | 0.14 | 0.16 | 0.12 | |

| 33.629 | 0.82 | -0.70 | 0.08 | 1.02 | 0.11 | 1.27 | 1.10 | 0.14 | 0.16 | 0.12 | |

| 34.613 | 0.82 | -0.73 | 0.08 | 1.02 | 0.12 | 1.32 | 1.12 | 0.15 | 0.18 | 0.12 | |

| 35.597 | 0.81 | -0.76 | 0.08 | 1.02 | 0.12 | 1.35 | 1.13 | 0.16 | 0.19 | 0.12 | |

| 36.581 | 0.81 | -0.79 | 0.09 | 1.02 | 0.15 | 1.60 | 1.23 | 0.25 | 0.31 | 0.12 | |

| 37.566 | 0.80 | -0.82 | 0.09 | 1.02 | 0.22 | 2.12 | 1.42 | 0.78 | 1.14 | 0.11 | |

| 38.550 | 0.79 | -0.85 | 0.09 | 1.01 | 0.20 | 2.00 | 1.38 | 0.59 | 0.82 | 0.11 | |

| 39.561 | 0.79 | -0.87 | 0.10 | 1.01 | 0.21 | 2.06 | 1.40 | 0.67 | 0.95 | 0.11 | |

| 40.546 | 0.78 | -0.90 | 0.10 | 1.00 | 0.25 | 2.20 | 1.45 | 1.57 | 2.28 | 0.11 | |

| 41.530 | 0.77 | -0.93 | 0.10 | 1.00 | 0.24 | 2.20 | 1.45 | 1.33 | 1.93 | 0.11 | |

| 42.569 | 0.77 | -0.96 | 0.11 | 0.99 | 0.25 | 2.20 | 1.45 | 1.56 | 2.24 | 0.11 | |

| 43.553 | 0.76 | -0.99 | 0.11 | 0.98 | 0.30 | 2.20 | 1.45 | 2.00 | 2.84 | 0.11 | |

| 44.537 | 0.75 | -1.02 | 0.11 | 0.97 | 0.30 | 2.20 | 1.45 | 2.00 | 2.82 | 0.11 | |

| 45.549 | 0.75 | -1.05 | 0.12 | 0.96 | 0.30 | 2.20 | 1.45 | 2.00 | 2.80 | 0.11 | |

| 46.533 | 0.74 | -1.08 | 0.12 | 0.96 | 0.28 | 2.20 | 1.45 | 2.00 | 2.78 | 0.10 | |

| 47.517 | 0.73 | -1.11 | 0.12 | 0.96 | 0.23 | 2.20 | 1.45 | 1.04 | 1.45 | 0.10 | |

| 48.529 | 0.73 | -1.14 | 0.13 | 0.95 | 0.25 | 2.20 | 1.45 | 1.48 | 2.05 | 0.10 | |

| 49.513 | 0.72 | -1.17 | 0.13 | 0.93 | 0.30 | 2.20 | 1.45 | 2.00 | 2.71 | 0.10 | |

| 50.498 | 0.72 | -1.19 | 0.13 | 0.93 | 0.30 | 2.20 | 1.45 | 2.00 | 2.69 | 0.10 | |

| 51.482 | 0.71 | -1.22 | 0.14 | 0.92 | 0.30 | 2.20 | 1.45 | 2.00 | 2.67 | 0.10 | |

| 52.466 | 0.70 | -1.25 | 0.14 | 0.91 | 0.30 | 2.20 | 1.45 | 2.00 | 2.66 | 0.10 |

| z | rd | K |

C |

MSFmax | MSF | CRR7.5,1atm | CRRM, |

CSRM, |

Comments: See definition of variables on previous page. Values collected every ∆z=0.164ft but reported herein every ∆z=0.984ft (except for first and last values). |

||

| 53.450 | 0.70 | -1.28 | 0.14 | 0.91 | 0.28 | 2.20 | 1.45 | 2.00 | 2.65 | 0.10 | |

| 54.435 | 0.69 | -1.31 | 0.14 | 0.93 | 0.22 | 2.18 | 1.44 | 0.90 | 1.20 | 0.10 | |

| 55.474 | 0.69 | -1.34 | 0.15 | 0.90 | 0.29 | 2.20 | 1.45 | 2.00 | 2.61 | 0.10 | |

| 56.458 | 0.68 | -1.36 | 0.15 | 0.89 | 0.30 | 2.20 | 1.45 | 2.00 | 2.59 | 0.09 | |

| 57.442 | 0.67 | -1.39 | 0.15 | 0.89 | 0.28 | 2.20 | 1.45 | 2.00 | 2.59 | 0.09 | |

| 58.481 | 0.67 | -1.42 | 0.16 | 0.88 | 0.30 | 2.20 | 1.45 | 2.00 | 2.55 | 0.09 | |

| 59.465 | 0.66 | -1.45 | 0.16 | 0.87 | 0.30 | 2.20 | 1.45 | 2.00 | 2.54 | 0.09 | |

| 60.449 | 0.66 | -1.47 | 0.16 | 0.87 | 0.30 | 2.20 | 1.45 | 2.00 | 2.52 | 0.09 | |

| 61.488 | 0.65 | -1.50 | 0.16 | 0.86 | 0.30 | 2.20 | 1.45 | 2.00 | 2.50 | 0.09 | |

| 62.473 | 0.65 | -1.53 | 0.17 | 0.86 | 0.30 | 2.20 | 1.45 | 2.00 | 2.49 | 0.09 | |

| 63.457 | 0.64 | -1.55 | 0.17 | 0.85 | 0.30 | 2.20 | 1.45 | 2.00 | 2.47 | 0.09 | |

| 64.469 | 0.64 | -1.58 | 0.17 | 0.85 | 0.30 | 2.20 | 1.45 | 2.00 | 2.45 | 0.09 | |

| 65.518 | 0.63 | -1.60 | 0.18 | 0.84 | 0.30 | 2.20 | 1.45 | 2.00 | 2.44 | 0.09 | |

| 66.503 | 0.62 | -1.63 | 0.18 | 0.83 | 0.30 | 2.20 | 1.45 | 2.00 | 2.42 | 0.09 | |

| 67.626 | 0.62 | -1.65 | 0.18 | 0.83 | 0.30 | 2.20 | 1.45 | 2.00 | 2.41 | 0.08 | |

| 68.611 | 0.61 | -1.68 | 0.18 | 0.82 | 0.30 | 2.20 | 1.45 | 2.00 | 2.39 | 0.08 | |

| 69.595 | 0.61 | -1.70 | 0.19 | 0.82 | 0.30 | 2.20 | 1.45 | 2.00 | 2.38 | 0.08 | |

| 70.579 | 0.60 | -1.72 | 0.19 | 0.81 | 0.30 | 2.20 | 1.45 | 2.00 | 2.37 | 0.08 | |

| 71.563 | 0.60 | -1.75 | 0.19 | 0.81 | 0.30 | 2.20 | 1.45 | 2.00 | 2.35 | 0.08 | |

| 72.548 | 0.60 | -1.77 | 0.19 | 0.85 | 0.23 | 2.20 | 1.45 | 1.07 | 1.32 | 0.08 | |

| 73.710 | 0.59 | -1.79 | 0.19 | 0.80 | 0.30 | 2.20 | 1.45 | 2.00 | 2.33 | 0.08 | |

| 74.694 | 0.59 | -1.81 | 0.20 | 0.80 | 0.30 | 2.20 | 1.45 | 2.00 | 2.31 | 0.08 | |

| 75.678 | 0.58 | -1.83 | 0.20 | 0.79 | 0.30 | 2.20 | 1.45 | 2.00 | 2.30 | 0.08 | |

| 77.018 | 0.58 | -1.86 | 0.20 | 0.79 | 0.30 | 2.20 | 1.45 | 2.00 | 2.28 | 0.08 | |

| 78.002 | 0.57 | -1.88 | 0.20 | 0.83 | 0.24 | 2.20 | 1.45 | 1.23 | 1.47 | 0.08 | |

| 78.986 | 0.57 | -1.90 | 0.20 | 0.78 | 0.30 | 2.20 | 1.45 | 2.00 | 2.26 | 0.08 | |

| 79.970 | 0.57 | -1.91 | 0.21 | 0.77 | 0.30 | 2.20 | 1.45 | 2.00 | 2.25 | 0.08 | |

| 80.955 | 0.56 | -1.93 | 0.21 | 0.77 | 0.30 | 2.20 | 1.45 | 2.00 | 2.23 | 0.08 | |

| 81.939 | 0.56 | -1.95 | 0.21 | 0.77 | 0.30 | 2.20 | 1.45 | 2.00 | 2.22 | 0.08 | |

| 82.923 | 0.55 | -1.96 | 0.21 | 0.76 | 0.30 | 2.20 | 1.45 | 2.00 | 2.21 | 0.08 | |

| 83.661 | 0.55 | -1.97 | 0.21 | 0.76 | 0.30 | 2.20 | 1.45 | 2.00 | 2.20 | 0.08 |

Table G7. Results from Yoshimine et al. (2006) and Idriss and Boulanger (2008) calculations.

| z | FS |

Comments: For Event #1 – amax=0.1, Mw=6.5, z=Depth [ft], FS Values collected every |

|||||

| 0.163 | 0.94 | 0.95 | 0.00 | 0.00 | 0.00 | 2.46 | |

| 1.148 | 0.94 | 0.73 | 0.00 | 0.00 | 0.00 | 2.46 | |

| 2.133 | 0.94 | 0.75 | 0.00 | 0.00 | 0.00 | 2.46 | |

| 3.117 | 0.94 | 0.90 | 0.02 | 0.02 | 0.03 | 2.43 | |

| 4.101 | 0.94 | 0.67 | 0.01 | 0.01 | 0.02 | 2.32 | |

| 5.085 | 0.94 | 0.77 | 0.00 | 0.00 | 0.00 | 2.30 | |

| 6.070 | 0.94 | 0.73 | 0.00 | 0.00 | 0.00 | 2.30 | |

| 7.054 | 0.94 | 0.70 | 0.00 | 0.00 | 0.00 | 2.30 | |

| 8.038 | 0.94 | 0.66 | 0.00 | 0.00 | 0.00 | 2.30 | |

| 9.022 | 0.94 | 0.73 | 0.00 | 0.00 | 0.00 | 2.30 | |

| 10.007 | 0.94 | 0.58 | 0.07 | 0.04 | 0.08 | 2.15 | |

| 10.991 | 0.87 | 0.40 | 0.02 | 0.01 | 0.01 | 1.84 | |

| 11.975 | 0.85 | 0.37 | 0.01 | 0.01 | 0.01 | 1.77 | |

| 12.959 | 0.86 | 0.38 | 0.01 | 0.01 | 0.01 | 1.70 | |

| 13.944 | 0.82 | 0.34 | 0.01 | 0.01 | 0.01 | 1.63 | |

| 14.928 | 0.60 | 0.19 | 0.00 | 0.00 | 0.00 | 1.58 | |

| 15.912 | 0.37 | 0.12 | 0.00 | 0.00 | 0.00 | 1.57 | |

| 16.896 | 0.37 | 0.12 | 0.00 | 0.00 | 0.00 | 1.57 | |

| 17.881 | 0.66 | 0.22 | 0.01 | 0.00 | 0.00 | 1.57 | |

| 18.865 | 0.69 | 0.24 | 0.01 | 0.00 | 0.01 | 1.54 | |

| 19.849 | 0.90 | 0.45 | 0.02 | 0.01 | 0.02 | 1.47 | |

| 20.833 | 0.87 | 0.40 | 0.02 | 0.01 | 0.01 | 1.20 | |

| 21.818 | 0.90 | 0.44 | 0.02 | 0.01 | 0.02 | 1.09 | |

| 22.802 | 0.87 | 0.40 | 0.02 | 0.01 | 0.01 | 0.98 | |

| 23.786 | 0.89 | 0.43 | 0.02 | 0.01 | 0.02 | 0.89 | |

| 24.770 | 0.89 | 0.43 | 0.02 | 0.01 | 0.02 | 0.80 | |

| 25.755 | 0.90 | 0.45 | 0.02 | 0.01 | 0.02 | 0.70 | |

| 26.739 | 0.89 | 0.44 | 0.02 | 0.01 | 0.02 | 0.61 | |

| 27.723 | 0.91 | 0.47 | 0.02 | 0.01 | 0.02 | 0.51 | |

| 28.707 | 0.91 | 0.48 | 0.02 | 0.01 | 0.02 | 0.40 | |

| 29.692 | 0.89 | 0.42 | 0.02 | 0.01 | 0.01 | 0.28 | |

| 30.676 | 0.83 | 0.34 | 0.01 | 0.00 | 0.01 | 0.21 | |

| 31.660 | 0.81 | 0.33 | 0.01 | 0.00 | 0.01 | 0.15 | |

| 32.644 | 0.75 | 0.28 | 0.01 | 0.00 | 0.01 | 0.11 | |

| 33.629 | 0.78 | 0.30 | 0.01 | 0.00 | 0.01 | 0.07 | |

| 34.613 | 0.69 | 0.24 | 0.01 | 0.00 | 0.00 | 0.03 | |

| 35.597 | 0.65 | 0.22 | 0.01 | 0.00 | 0.00 | 0.01 | |

| 36.581 | 0.33 | 0.11 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 37.566 | -0.19 | 0.04 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 38.550 | -0.08 | 0.05 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 39.561 | -0.13 | 0.04 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 40.546 | -0.40 | 0.02 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 41.530 | -0.36 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 42.569 | -0.40 | 0.02 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 43.553 | -0.67 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 44.537 | -0.83 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 45.549 | -1.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 46.533 | -0.53 | 0.02 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 47.517 | -0.28 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 48.529 | -0.39 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 49.513 | -0.82 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 50.498 | -1.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 51.482 | -0.81 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 52.466 | -0.67 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 |

| z | FS |

Comments: See definition of variables on previous page. Values collected every 0.164ft but reported herein every 0.984ft (except for first and last values). |

|||||

| 53.450 | -0.55 | 0.02 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 54.435 | -0.23 | 0.04 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 55.474 | -0.57 | 0.02 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 56.458 | -0.62 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 57.442 | -0.53 | 0.02 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 58.481 | -0.83 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 59.465 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 60.449 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 61.488 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 62.473 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 63.457 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 64.469 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 65.518 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 66.503 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 67.626 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 68.611 | -1.24 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 69.595 | -1.03 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 70.579 | -0.89 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 71.563 | -0.85 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 72.548 | -0.29 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 73.710 | -0.60 | 0.02 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 74.694 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 75.678 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 77.018 | -1.25 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 78.002 | -0.33 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 78.986 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 79.970 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 80.955 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 81.939 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 82.923 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| 83.661 | -1.28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

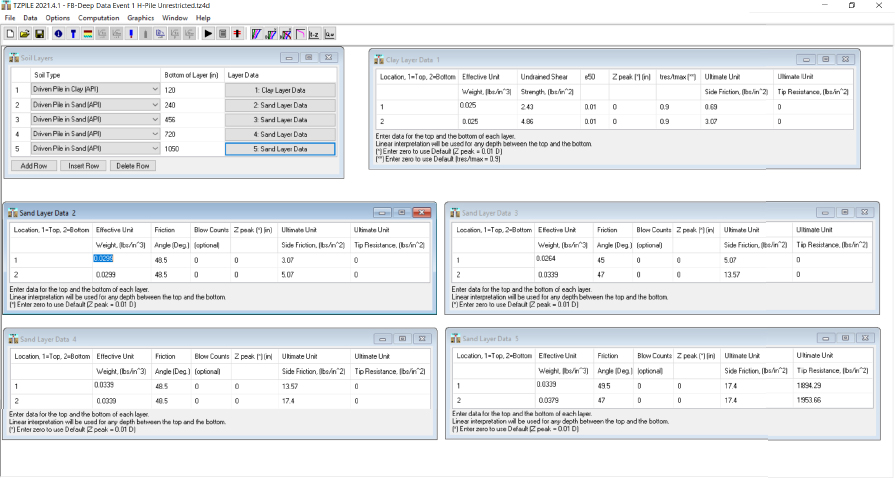

Hand calculations have been performed and reported for the previous examples (Examples 1, 3, and 4). The calculations can also be performed using design software. For example, the Bridge Software Institute FB-Deep Version 3.1.10 (2022) software program and the Innovative Geotechnics ALLCPT Version 2.5 (2023) or PileAXL Version 2.5 (2023) software programs are a user friendly way to perform similar calculations to those completed using an Excel spreadsheet in the previous design examples. The FB-Deep software program was developed at the University of Florida for the Florida Department of Transportation. For the design example that is included herein (Design Example 5), the LCPC CPT-based pile design methodology within the FB-Deep program will be used but the FB-Deep program is also capable of using standard penetration test (SPT) results to calculate pile resistance. Likewise, the PileAXL program can be used to perform a LCPC CPT- or SPT-based pile design. However, the ALLCPT program can only be used to perform a LCPC CPT-based design, as included herein; the ALLCPT program can only be used with CPT data and cannot be used if only standard penetration data are available.

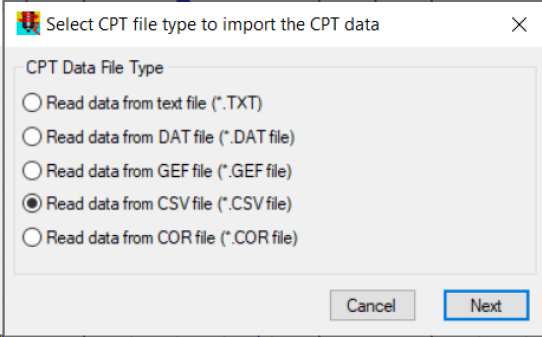

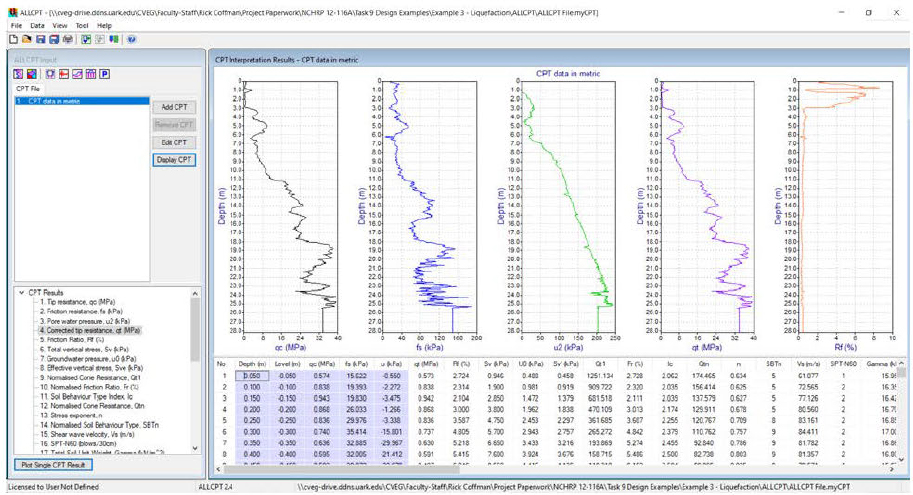

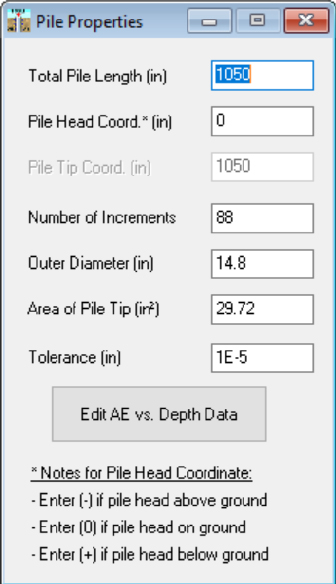

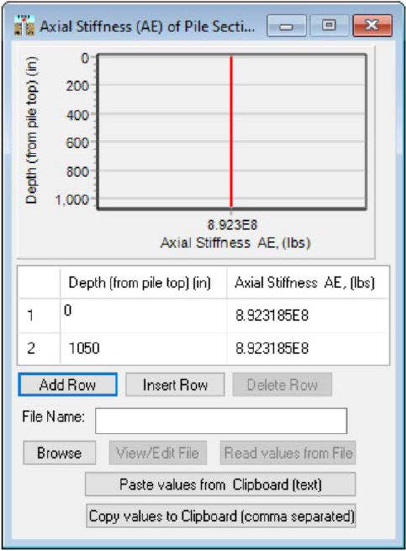

Step 3: Establish pile data

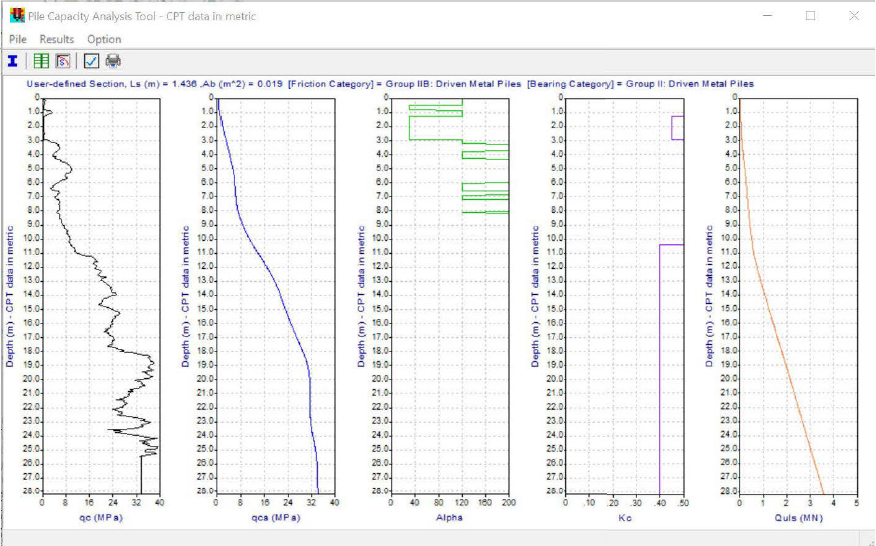

The Innovative Geotechnics ALLCPT program was used for raw CPT processing and axial pile resistance computations using the LCPC method. Only metric units can be imported and reported using the current version of ALLCPT (Version 2.5). Therefore, the unscalped, raw, CPT data that were shown previously in Figure G2 and tabulated in Table G3 were converted from imperial units to metric units and imported into the ALLCPT program using the Data – Add CPT tab in the main window. Specifically, the CPT data that were contained in a .CSV file were imported using the Read data from CSV file (*.CSV file) toggle (Figure G4).

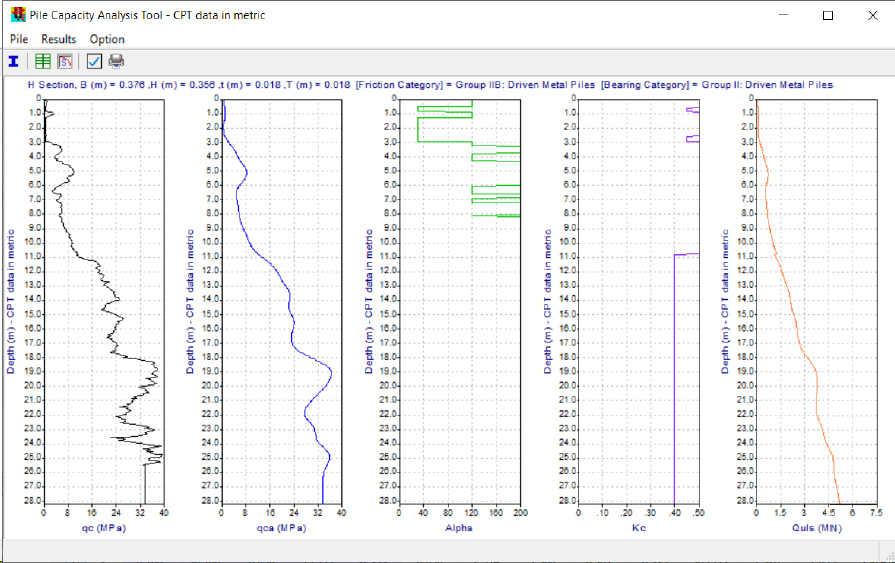

After uploading the data, the predominant CPT parameters (qc, fs, u2, qt, Rf) are graphically displayed in the upper right hand side of the main window (Figure 5). All of the correlated values that were obtained from the ALLCPT calculations are also tabulated in the lower right of the main window. Pop-out windows with graphs for any variable can be obtained by selecting on the variable of interest in the bottom left of the main window.

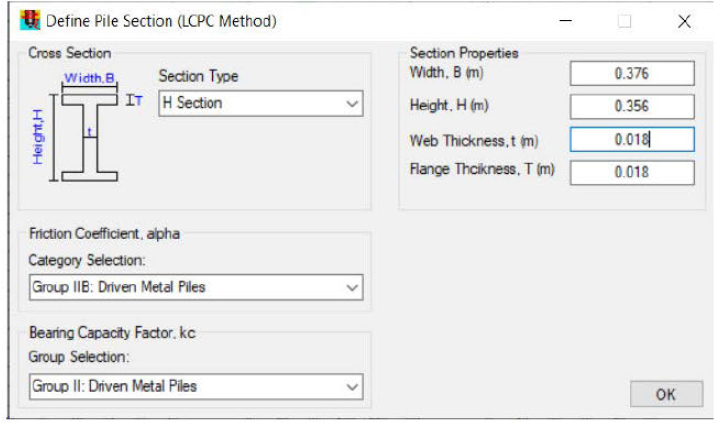

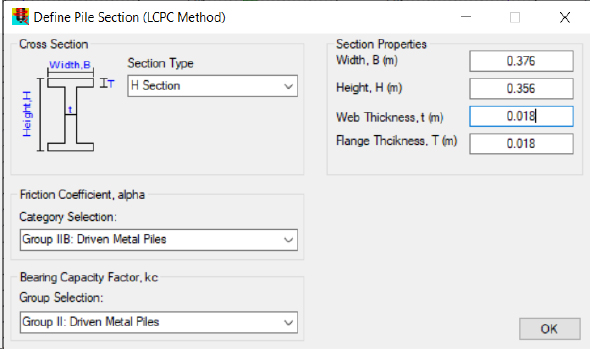

H-pile pile section

Axial pile resistance computations were performed by selecting Tool – Pile Axial Capacity Tool from the ALLCPT ribbon. The results that were shown in the pop-out window were for the default pile type. To obtain the correct design calculations, the pile information was required. The pile information, including the: cross section, friction coefficient, bearing capacity factor, width, height, web thickness and flange thickness were input into the Define Pile Section (LCPC Method) pop-out window that was obtained by selecting on Pile – Pile Section within the Pile Capacity Analysis Tool (Figure G6). The Options – Advanced Settings feature was used to select the design approach and establish proper factors of safety. A working load design methodology and factors of safety of unity were selected (Figure G7).

Step 4: Compute the incemental side resistance

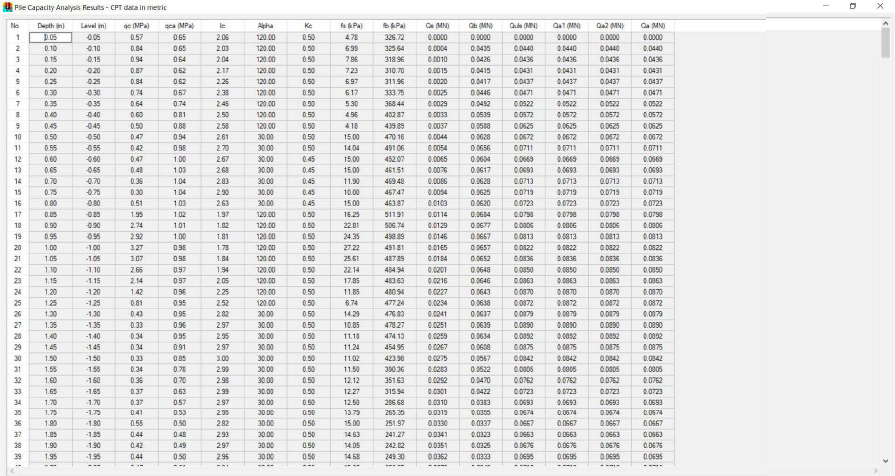

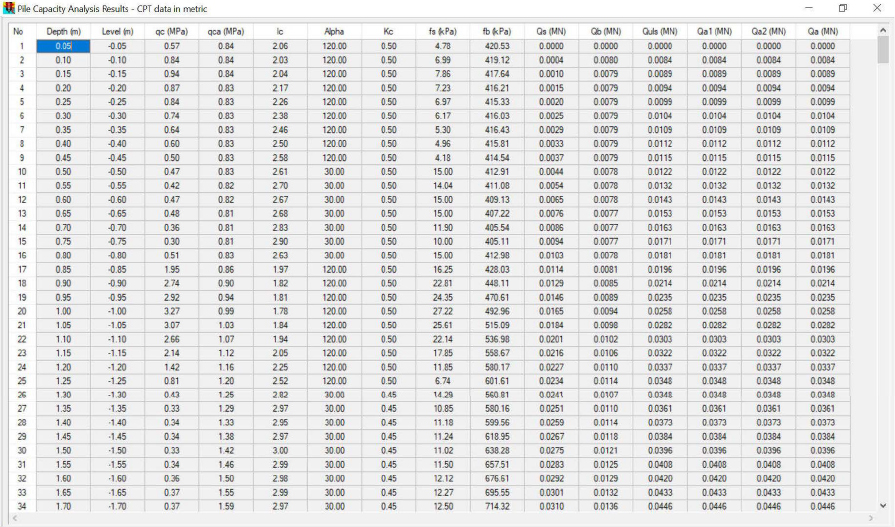

After inputting the correct pile and design information, the desired pile resistance output was obtained (Figure G8). Unlike the FB-Deep program, the LCPC computations from the ALLCPT Pile Capacity Analysis Tool were not limited based on by using weakest values for each soil type. The tabulated values from the Pile Capacity Analysis Tool were obtained by selecting Results – Results Table from the ribbon in the Pile Capacity Analysis Tool window (Figure G9). The results were also exported to a .CSV file for additional processing. The unit side resistance is identified as the fs (kPa) term Results – Results Table shown in Figure G9. These unit side resistance values are also provided in Table G8 for completeness.

The ALLCPT output: Depth (m), fs (kPa), fb (kPa), Qs (kN), and Qb (kN) parameters that were shown previously in Figure G9, were exported to Microsoft Excel for additional processing including unit conversion (Table G8, with each variable being defined in the table). The processing required a correction to the ALLCPT Qb data because the ALLCPT program used the gross pile area (0.134m2) in the Qb calculation instead of the pile tip area (0.019m2). The change in side resistance per increment of depth (∆Q), total load in the pile (Q), including the unfactored top load and total resistance (R) in the pile were obtained following calculations that were similar to the calculations used in Design Example 2 and presented herein as Equations 32 through 35. The load, resistance, and combined load and resistance plots obtained from the ALLCPT Pile Capacity Analysis Tool output and additional processing are presented as Figure G10.

| Eqn. 32 |

| Eqn. 33 |

| Eqn. 34 |

| Eqn. 35 |

Table G8. Results from ALLCPT Pile Capacity Analysis and calculations (reported in imperial units).

| z | Qs | Qb | ∆Qs | QwUTL | R | Min(Q,R) | Comments: z=Depth [ft], Qs=Summation of side resistance from ALLCPT pile capacity analysis [tons], Qb=End resistance from ALLCPT pile capacity analysis [tons], ∆Q=Incremental side resistance [tons], QwUTL=Load in pile with unfactored top load [tons], R=Resistance in pile [tons], Min(Q,R)=Load [tons] used to develop combination curve to identify the location of the neutral plane. Values calculated every ∆z=0.164ft but reported herein every ∆z=0.984ft (except for first and last values). |

| 0.164 | 0.000 | 0.000 | 0.000 | 107.000 | 378.116 | 107.000 | |

| 1.148 | 0.326 | 5.530 | 0.045 | 107.326 | 377.835 | 107.326 | |

| 2.133 | 0.854 | 6.935 | 0.124 | 107.854 | 377.385 | 107.854 | |

| 3.117 | 1.641 | 7.497 | 0.191 | 108.641 | 376.666 | 108.641 | |

| 4.101 | 2.630 | 7.171 | 0.079 | 109.630 | 375.564 | 109.630 | |

| 5.085 | 3.181 | 5.868 | 0.090 | 110.181 | 375.024 | 110.181 | |

| 6.070 | 3.833 | 3.631 | 0.124 | 110.833 | 374.406 | 110.833 | |

| 7.054 | 4.564 | 4.069 | 0.124 | 111.564 | 373.676 | 111.564 | |

| 8.038 | 5.294 | 5.418 | 0.124 | 112.294 | 372.945 | 112.294 | |

| 9.022 | 6.036 | 10.094 | 0.124 | 113.036 | 372.203 | 113.036 | |

| 10.007 | 6.789 | 18.749 | 0.157 | 113.789 | 371.484 | 113.789 | |

| 10.991 | 8.194 | 26.977 | 0.225 | 115.194 | 370.146 | 115.194 | |

| 11.975 | 9.611 | 33.778 | 0.225 | 116.611 | 368.730 | 116.611 | |

| 12.959 | 11.139 | 38.959 | 0.270 | 118.139 | 367.246 | 118.139 | |

| 13.944 | 12.735 | 45.344 | 0.281 | 119.735 | 365.661 | 119.735 | |

| 14.928 | 14.298 | 52.763 | 0.303 | 121.298 | 364.121 | 121.298 | |

| 15.912 | 16.456 | 59.934 | 0.393 | 123.456 | 362.053 | 123.456 | |

| 16.896 | 18.850 | 62.182 | 0.393 | 125.850 | 359.659 | 125.850 | |

| 17.881 | 21.065 | 58.462 | 0.326 | 128.065 | 357.377 | 128.065 | |

| 18.865 | 23.077 | 51.054 | 0.337 | 130.077 | 355.376 | 130.077 | |

| 19.849 | 24.605 | 42.039 | 0.247 | 131.605 | 353.758 | 131.605 | |

| 20.833 | 26.157 | 36.498 | 0.225 | 133.157 | 352.184 | 133.157 | |

| 21.818 | 27.494 | 35.205 | 0.225 | 134.494 | 350.846 | 134.494 | |

| 22.802 | 28.933 | 36.486 | 0.292 | 135.933 | 349.475 | 135.933 | |

| 23.786 | 30.563 | 39.162 | 0.225 | 137.563 | 347.778 | 137.563 | |

| 24.770 | 31.968 | 41.039 | 0.236 | 138.968 | 346.384 | 138.968 | |

| 25.755 | 33.395 | 42.095 | 0.236 | 140.395 | 344.956 | 140.395 | |

| 26.739 | 34.800 | 43.624 | 0.259 | 141.800 | 343.574 | 141.800 | |

| 27.723 | 36.205 | 46.153 | 0.247 | 143.205 | 342.157 | 143.205 | |

| 28.707 | 37.723 | 49.874 | 0.270 | 144.723 | 340.662 | 144.723 | |

| 29.692 | 39.387 | 54.617 | 0.303 | 146.387 | 339.033 | 146.387 | |

| 30.676 | 41.275 | 59.608 | 0.337 | 148.275 | 337.178 | 148.275 | |

| 31.660 | 43.354 | 64.262 | 0.348 | 150.354 | 335.110 | 150.354 | |

| 32.644 | 45.580 | 68.724 | 0.382 | 152.580 | 332.918 | 152.580 | |

| 33.629 | 47.862 | 73.951 | 0.371 | 154.862 | 330.625 | 154.862 | |

| 34.613 | 50.267 | 82.280 | 0.416 | 157.267 | 328.264 | 157.267 | |

| 35.597 | 52.943 | 74.783 | 0.450 | 159.943 | 325.623 | 159.943 | |

| 36.581 | 55.888 | 85.675 | 0.540 | 162.888 | 322.768 | 162.888 | |

| 37.566 | 59.990 | 96.713 | 0.731 | 166.990 | 318.856 | 166.990 | |

| 38.550 | 64.441 | 105.143 | 0.708 | 171.441 | 314.382 | 171.441 | |

| 39.567 | 69.039 | 111.483 | 0.742 | 176.039 | 309.819 | 176.039 | |

| 40.551 | 73.782 | 116.024 | 0.821 | 180.782 | 305.154 | 180.782 | |

| 41.535 | 78.515 | 120.824 | 0.798 | 185.515 | 300.399 | 185.515 | |

| 42.585 | 83.865 | 127.545 | 0.821 | 190.865 | 295.071 | 190.865 | |

| 43.570 | 89.148 | 133.019 | 0.910 | 196.148 | 289.878 | 196.148 | |

| 44.554 | 94.847 | 135.526 | 0.955 | 201.847 | 284.224 | 201.847 | |

| 45.538 | 100.849 | 135.616 | 0.978 | 207.849 | 278.244 | 207.849 | |

| 46.522 | 106.616 | 134.121 | 0.899 | 213.616 | 272.399 | 213.616 |

| z | Qs | Qb | ∆Qs | QwUTL | R | Min(Q,R) | Comments: See definition of variables on previous page. |

| 47.507 | s 111.719 | 133.626 | s 0.832 | 218.719 | 267.229 | , 218.719 | |

| 48.524 | 116.755 | 135.919 | 0.843 | 223.755 | 262.204 | 223.755 | |

| 49.508 | 122.431 | 140.202 | 0.978 | 229.431 | 256.663 | 229.431 | |

| 50.492 | 128.355 | 143.687 | 0.989 | 235.355 | 250.750 | 235.355 | |

| 51.476 | 134.278 | 144.091 | 0.989 | 241.278 | 244.826 | 241.278 | |

| 52.461 | 140.135 | 142.237 | 0.967 | 247.135 | 238.948 | 238.948 | |

| 53.445 | 145.912 | 139.899 | 0.944 | 252.912 | 233.148 | 233.148 | |

| 54.429 | 151.364 | 138.606 | 0.877 | 258.364 | 227.629 | 227.629 | |

| 55.479 | 157.220 | 139.955 | 0.955 | 264.220 | 221.851 | 221.851 | |

| 56.463 | 163.133 | 143.777 | 0.989 | 270.133 | 215.972 | 215.972 | |

| 57.448 | 168.978 | 152.364 | 0.978 | 275.978 | 210.116 | 210.116 | |

| 58.465 | 174.991 | 168.966 | 0.978 | 281.991 | 204.102 | 204.102 | |

| 59.449 | 180.915 | 185.962 | 0.989 | 287.915 | 198.190 | 198.190 | |

| 60.433 | 186.839 | 201.328 | 0.989 | 293.839 | 192.266 | 192.266 | |

| 61.483 | 193.088 | 214.479 | 0.989 | 300.088 | 186.016 | 186.016 | |

| 62.467 | 199.001 | 218.896 | 0.978 | 306.001 | 180.093 | 180.093 | |

| 63.451 | 204.925 | 217.424 | 0.989 | 311.925 | 174.180 | 174.180 | |

| 64.469 | 211.006 | 214.119 | 0.978 | 318.006 | 168.088 | 168.088 | |

| 65.518 | 217.323 | 207.409 | 1.383 | 324.323 | 162.175 | 162.175 | |

| 66.503 | 223.247 | 199.833 | 0.989 | 330.247 | 155.858 | 155.858 | |

| 67.618 | 230.002 | 190.042 | 0.989 | 337.002 | 149.103 | 149.103 | |

| 68.602 | 235.926 | 181.117 | 0.989 | 342.926 | 143.179 | 143.179 | |

| 69.587 | 241.838 | 174.148 | 0.978 | 348.838 | 137.255 | 137.255 | |

| 70.571 | 247.762 | 167.809 | 0.989 | 354.762 | 131.343 | 131.343 | |

| 71.555 | 253.686 | 165.066 | 0.989 | 360.686 | 125.419 | 125.419 | |

| 72.539 | 259.598 | 167.033 | 0.978 | 366.598 | 119.495 | 119.495 | |

| 73.720 | 266.590 | 175.486 | 0.989 | 373.590 | 112.515 | 112.515 | |

| 74.705 | 272.513 | 182.140 | 0.989 | 379.513 | 106.591 | 106.591 | |

| 75.689 | 278.426 | 185.614 | 0.978 | 385.426 | 100.668 | 100.668 | |

| 77.001 | 286.485 | 187.828 | 0.989 | 393.485 | 92.619 | 92.619 | |

| 77.986 | 292.330 | 190.481 | 0.989 | 399.330 | 86.774 | 86.774 | |

| 78.970 | 298.254 | 198.034 | 0.989 | 405.254 | 80.851 | 80.851 | |

| 79.987 | 304.178 | 206.712 | 0.989 | 411.178 | 74.927 | 74.927 | |

| 80.971 | 310.090 | 213.748 | 0.989 | 417.090 | 69.015 | 69.015 | |

| 81.923 | 316.014 | 216.120 | 0.989 | 423.014 | 63.091 | 63.091 | |

| 82.907 | 321.938 | 213.692 | 0.989 | 428.938 | 57.167 | 57.167 | |

| 83.825 | 327.356 | 209.612 | 0.978 | 434.356 | 51.738 | 51.738 | |

| 84.810 | 333.279 | 205.846 | 0.989 | 440.279 | 45.826 | 45.826 | |

| 85.794 | 339.192 | 203.531 | 0.978 | 446.192 | 39.902 | 39.902 | |

| 86.778 | 345.115 | 202.418 | 0.989 | 452.115 | 33.989 | 33.989 | |

| 87.434 | 349.061 | 202.384 | 0.989 | 456.061 | 30.044 | 30.044 |

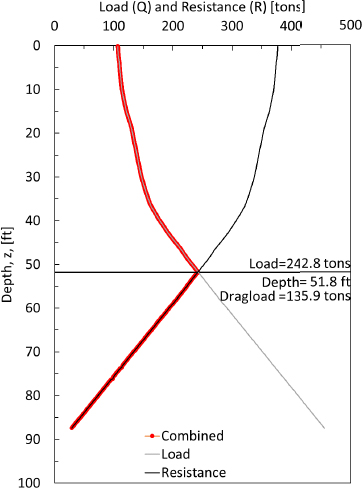

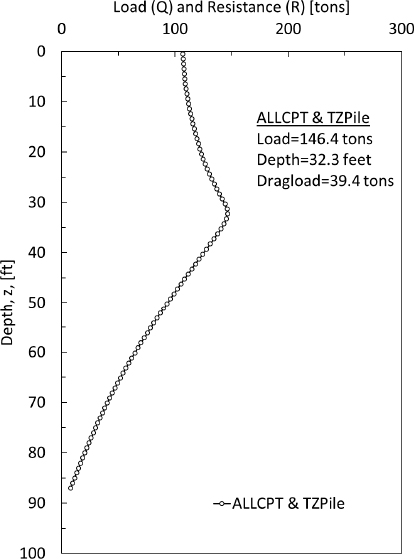

Step 5: Develop a depth-dependent load profile

The depth-dependent load in the pile is reported in Table G8. Specifically, the QwUTL term that represents the load in pile with the unfactored top load in units of tons is the term of interest. A standalone plot of the QwUTL term as a function of depth can be generated to observe how the load develops as a function of depth. However, this plot has been included as the “Load” curve in Figure G10.

Step 6: Calculate the end bearing resistance; develop the depth-dependent resistance profile

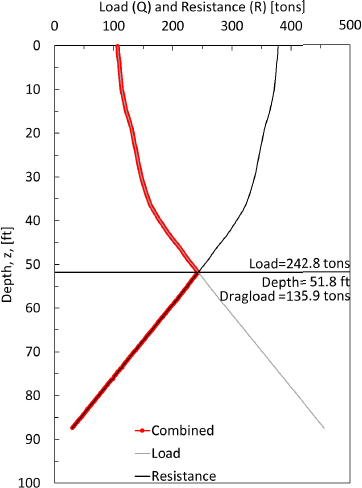

The end bearing resistance and the depth-dependent resistance profile are also included in Table G8. The end bearing resistance was taken as the Qb value at a depth of 26.65m (87.43ft); a depth of 26.65m was the closest depth to the actual length of the pile (26.67m=87.5ft). A end bearing resistance of 30.04 tons was obtained after using the aforementioned pile tip area 0.019m2 instead of the gross pile area 0.134m2.

The depth-dependent resistance in the pile (R) is reported in Table G8. A standalone plot of the R term as a function of depth can be generated to observe how the resistance develops as a function of depth. However, this plot has been included as the “Resistance” curve in Figure G10.

Step 7: Develop the depth-dependent combined load-resistance curve

The combined load-resistance curve is also presented in Figure G10. This curve was obtained by selecting the minimum value of load and resistance at each given depth. The depth-dependent values of the combined load-resistance curve are presented in the Min(Q,R) column in Table G8.

Step 8: Identify the location of the neutral plane from the combined load-resistance curve

As shown previously in Figure G10, the neutral plane was identified at a depth of 51.8ft. This depth corresponded with the intersection of the “Load’ and “Resistance” curves that were developed in Steps 5 and 6, respectively. The depth also corresponded with the largest load observed for the depth depended combined load-resistance curve.

Step 9: Calculate the amount of drag load in the pile

From the depth-dependent combined load-resistance curve (Figure G10), the maximum load was 282.8 tons. This load results in an observed drag load of 135.9 tons. As expected, the drag load was observed to be the largest at the location of the neutral plane.

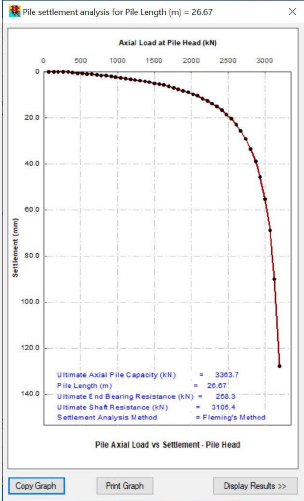

Step 10: Calculate the toe settlement and elastic compression in the pile

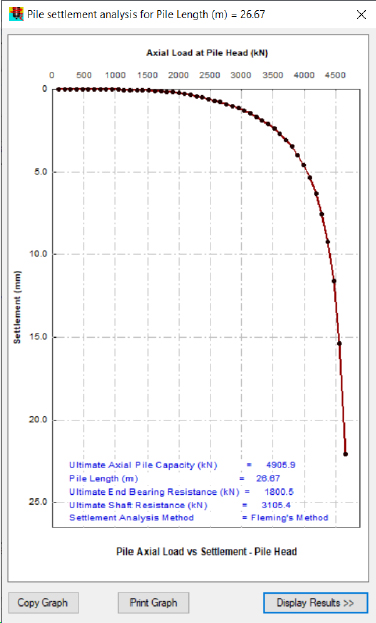

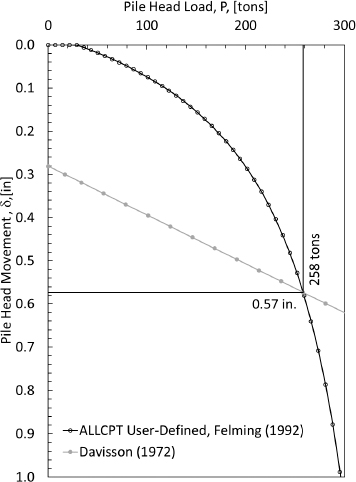

A settlement analysis was also performed using the Fleming (1992) approach. Key parameters for the Fleming approach were input into the Pile Capacity Analysis Option pop-out window obtained by selecting Option – Advanced Setting within the Pile Capacity Analysis Tool window. The values that were used for the advanced settings are presented in Figure G7 (the same figure that was referenced previously for input of the design approach). The value for the soil stiffness at the pile base, Eb (kPa) parameter, that is shown in Figure G7 was obtained from row 527 of the Es (MPa) column of the table shown in the bottom right corner of Figure G5 (Es=148.714 Mpa). This row corresponded with the depth of the pile tip. The pile settlement graph (Figure G11) was then obtained by selecting on the Pile Settlement Analysis tab in the Pile Capacity Analysis Tool ribbon after the Pile Capacity Analysis Option window was closed. The values were exported to Microsoft Excel after selecting on Display Results >>.

The aforementioned limitation associated with the ALLCPT program of using the pile gross area instead of the pile tip adversely impacts the pile settlement curve. Unlike the ALLCPT output (depth, fs, fb, Qs, and Qb) where the data can be manipulated to correct for the use of the incorrect area, the use of the wrong area cannot be corrected in the load-settlement curve. Innovative Geotechnics, the creators of the software, have suggested use of the User Defined pile section rather than the H-pile pile section until the next release of the software enables either gross area or tip area to be considered.

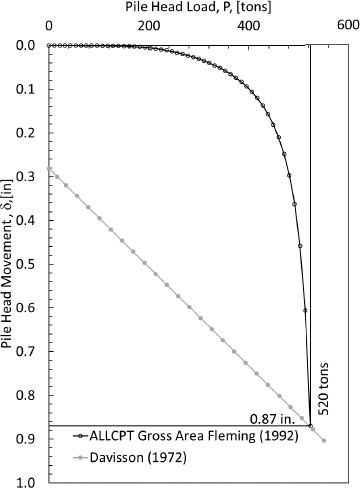

The Davisson (1972) method was used in conjunction with the settlement curve presented in Figure G11 to determine the pile tip movement. This pile tip movement was used in association with the elastic compression data to determine the predicted location of the neutral plane using a soil settlement-pile settlement plot. The pile head settlement was obtained by using the Davisson (1972) method along with the developed Fleming (1992) curve.

Step 11: Calculate the geotechnical resistance of the pile

The geotechnical resistance was also obtained by using the Davisson (1972) method along with the developed Fleming (1992) curve. Specifically, the pile head load value obtained from the intersection of the Davisson (1972) curve and the Fleming (1992) curve was the geotechnical resistance. The observed

geotechnical resistance of the pile was 520 tons. However, it must be noted that this resistance was obtained by using the gross area pile instead of the end area of the pile.

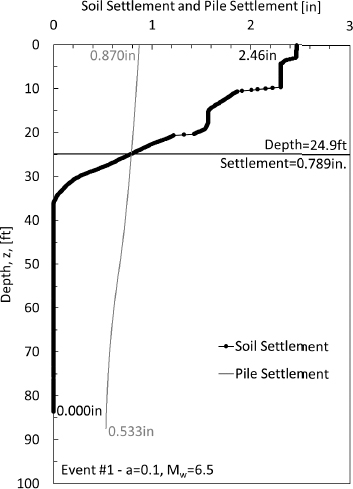

Step 12: Identify the location and the settlement of the neutral plane (from the soil settlement-pile settlement curve)

The elastic compression in the pile was also computed (Equations 30 and 31 as previously presented). The cumulative elastic compression was subtracted from the pile head movement (determined in Step 11), as a function of depth, to determine the amount of settlement of the pile. As shown in Figure G13, the pile head settled by 0.870in and the pile toe settled by 0.533in. The soil settlement shown in Figure G13 was obtained previously in Step 2. From the soil settlement-pile settlement curve, the neutral plane was observed to occur at a depth of 24.9ft. The settlement of the neutral plane was 0.789in.

The location of the neutral plane (51.8ft) that was determined from the load-resistance curve was not within 5 feet of the location of the neutral plane (24.9ft) that was determined from the soil settlement-pile settlement curve. The use of the gross cross-sectional area instead of the pile tip area may have contributed to the difference in the locations of the neutral plane. The size of the pile (length and diameter) and type of pile (elastic compression) may have also contributed to the difference in the

locations of the neutral planes. Moreover, the fully-mobilized conditions may not be reached resulting in a need to perform and analysis on partially-mobilized conditions.

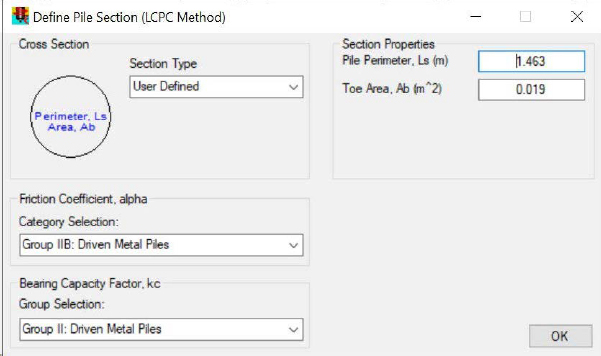

“User Defined” pile section

When using the User Defined selection within the Pile–Pile Section pop-out of the Pile Capacity Analysis Tool, the pile perimeter and toe area are required inputs (Figure G14). An equivalent H-pile selection that only considered the tip area rather than the gross area for the bearing capacity calculations was created. The Pile Perimeter was set to 1.436m, and the Toe Area was set to 0.019m2.

The working load design methodology and factors of safety of unity that were previously selected for the H-pile case (as shown previously Figure G6) were also used for the user defined case. After the correct pile and design information was input, the desired pile resistance output was obtained (Figure G15). The tabulated values from the Pile Capacity Analysis Tool were obtained by selecting Results – Results Table from the ribbon in the Pile Capacity Analysis Tool window (Figure G16). The results were also exported to a .CSV file for additional processing.

The ALLCPT output: Depth (m), fs (kPa), fb (kPa), Qs (kN), and Qb (kN) parameters that were shown previously in Figure G16, were exported to Microsoft Excel for additional processing including unit conversion (Table G9, with each variable being defined in the table). Like with the H-pile pile section, a neutral plane location was determined as the intersection of the load and resistance curves developed from the processed data for the user defined pile section. The load within the pile, as a function of depth, is presented in Figure G17.

The pile settlement graph (Figure G18) was obtained by selecting on the Pile Settlement Analysis tab in the Pile Capacity Analysis Tool ribbon after the Pile Capacity Analysis Option window was closed. The values were exported to Microsoft Excel after selecting on Display Results >>. The Davisson (1972) method was used in conjunction with the pile settlement curve (Figure G19) to determine the pile tip movement. This pile tip movement was used in association with the elastic compression data to determine the predicted location of the neutral plane via the soil settlement-pile settlement plot. By combining the pile settlement analysis and the soil settlement analysis, the neutral plane was predicted to occur at a depth of 28.0ft (Figure G20).

Table G9. Results from ALLCPT Pile Capacity Analysis and calculations (reported in imperial units).

| z | Qs | Qb | ∆Qs | QwUTL | R | Min(Q,R) | Comments: z=Depth [ft], Qs=Summation of side resistance from ALLCPT pile capacity analysis [tons], Qb=End resistance from ALLCPT pile capacity analysis [tons], ∆Q=Incremental side resistance [tons], QwUTL=Load in pile with unfactored top load [tons], R=Resistance in pile [tons], Min(Q,R)=Load [tons] used to develop combination curve to identify the location of the neutral plane. Values calculated every ∆z=0.164ft but reported herein every ∆z=0.984ft (except for first and last values). See definition of variables on previous page. |

| 0.164 | 0.000 | 0.000 | 0.000 | 107.000 | 378.116 | 107.000 | |

| 1.148 | 0.326 | 5.530 | 0.045 | 107.326 | 377.835 | 107.326 | |

| 2.133 | 0.854 | 6.935 | 0.124 | 107.854 | 377.385 | 107.854 | |

| 3.117 | 1.641 | 7.497 | 0.191 | 108.641 | 376.666 | 108.641 | |

| 4.101 | 2.630 | 7.171 | 0.079 | 109.630 | 375.564 | 109.630 | |

| 5.085 | 3.181 | 5.868 | 0.090 | 110.181 | 375.024 | 110.181 | |

| 6.070 | 3.833 | 3.631 | 0.124 | 110.833 | 374.406 | 110.833 | |

| 7.054 | 4.564 | 4.069 | 0.124 | 111.564 | 373.676 | 111.564 | |

| 8.038 | 5.294 | 5.418 | 0.124 | 112.294 | 372.945 | 112.294 | |

| 9.022 | 6.036 | 10.094 | 0.124 | 113.036 | 372.203 | 113.036 | |