Carbon Utilization Infrastructure, Markets, and Research and Development: A Final Report (2024)

Chapter: Summary

Summary

CARBON UTILIZATION AND THE TRANSITION TO NET-ZERO EMISSIONS

Carbon is an essential component of molecules and materials that are integral to life-sustaining atmospheric, geologic, biologic, and economic systems. Exploitation of fossil fuels has thrown the natural system of carbon flows out of balance, with ongoing and accelerating accumulation of waste carbon dioxide (CO2) and other greenhouse gases (GHGs) in the atmosphere, causing global warming. Returning to a safer climate will require that atmospheric GHG concentrations be stabilized, and eventually lowered, primarily by ending the largest source of GHG flows into the atmosphere: CO2 emissions from fossil fuel combustion. Some carbon-based systems that cannot be “decarbonized” with zero-carbon-emission substitutes will remain. For these systems, carbon will need to be managed, rather than eliminated. Examples include carbon-based molecules and materials associated with agriculture and consumer products; some fossil combustion emissions of CO2 into the atmosphere that cannot or will not be ended; and removal of some CO2 already in the atmosphere. Carbon management will be needed to establish a negative balance of GHG flows into and out of the atmosphere (i.e., net-negative emissions) during the decarbonization transition, and to maintain an even balance of GHG flows (i.e., net-zero emissions) once safe atmospheric concentrations of GHGs are reached.1 In a net-zero future, CO2 utilization—the conversion of CO2 into marketable products—can operate at a global annual scale of multiple gigatonnes to provide an alternative, circular-carbon feedstock2 for necessary carbon-based products and generate products that durably store carbon. Coal waste could also serve as a source of raw materials in a net-zero future, via conversion of carbon components to durable carbon-derived products or extraction of critical minerals and materials.

STUDY MANDATE

This study, sponsored by the Department of Energy (DOE), examines markets; infrastructure; and research, development, and demonstration (RD&D) needs for CO2 and coal waste utilization in a net-zero emissions future, as requested by Congress in the Energy Act of 2020. The committee focused on regional and national market opportunities,

___________________

1 For this report, net-zero emissions is the assumed final state of a safe climate system, although during and after the transition to net zero, periods of net-positive and net-negative emissions are both likely.

2 A circular-carbon feedstock is a raw material that can participate in a circular carbon economy, where materials and energy are reused and recycled to prevent net emissions to the atmosphere.

infrastructure needs, and RD&D needs for technologies that transform CO2 or coal waste3 into products that will contribute to a net-zero emission future. It analyzed challenges in expanding infrastructure, mitigating environmental impacts, accessing capital, overcoming technical hurdles, and addressing geographic, community, and equity issues for carbon utilization. In a first report, the committee assessed the state of and opportunities to improve and expand on infrastructure for CO2 utilization. The first report highlighted priority products that could be made from CO2; discussed needs for enabling infrastructure; and overviewed policy, regulatory, and environmental justice considerations for utilization infrastructure.

For this second and final report from the study, the committee was tasked to identify potential market opportunities for CO2 utilization; identify opportunities for federal support of small businesses; examine infrastructure for CO2 utilization and the economic, climate, and environmental impacts of any well-integrated national CO2 pipeline system applied for CO2 utilization; assess current and emerging technologies and approaches for CO2 utilization, identify their research needs, and develop a comprehensive research agenda to advance CO2 utilization; and determine the feasibility of and opportunities for commercializing coal waste–derived products.

PRIORITY OPPORTUNITIES FOR CO2- OR COAL WASTE–DERIVED PRODUCTS IN A NET-ZERO EMISSIONS FUTURE

CO2 can be converted to products that could serve critical markets for carbon-based materials in a circular carbon economy, for durable carbon storage, or both. Priority product classes identified were fuels, construction materials, polymers, agrochemicals, chemicals and chemical intermediates, food and animal feed, and elemental carbon materials, at potential global scales of megatonnes to gigatonnes for individual products. Coal waste utilization market opportunities include long-lived products like construction materials and elemental carbon materials, as well as metals and minerals. The carbon feedstock (e.g., CO2 from fossil or nonfossil sources, coal waste) and the product lifetime are important for assessing the climate impact and sustainability of different market opportunities. The committee considered product-specific market questions and examined factors that influence CO2 utilization market development, including cost, competing feedstocks, technology and infrastructure development, supply chains, consumer demand, the regulatory environment, financial risks, and environmental and equity impacts. The committee recommends that DOE prioritize research on co-located capture and conversion, particularly for long-lived products that contribute to carbon sequestration (Recommendation 2-1); close information gaps on environmental, market, resource, and jobs impacts of CO2 conversion (Recommendation 2-3); and support efforts to inform the public about carbon management (Recommendation 2-4).

LIFE CYCLE, TECHNO-ECONOMIC, AND SOCIETAL/EQUITY ASSESSMENTS OF CO2 UTILIZATION PROCESSES, TECHNOLOGIES, AND SYSTEMS

CO2 utilization is intimately tied to environmental, economic, and societal needs, and cannot be understood without the assessment of its life cycle, societal impact, and techno-economic status. The committee evaluated technology assessment approaches, focusing on capabilities, use, and critical issues for improvement. Technoeconomic assessment (TEA) addresses economic questions such as cost or profitability of a developing technology or process, compared to competing solutions. Life cycle assessment (LCA) informs on the sustainability of technologies and processes by quantifying the environmental burdens from materials extraction through end of life. Critical issues for both TEA and LCA of CO2 utilization technologies include transparency and consistency of system boundaries, incorporating CO2 purity and source information, geographic and temporal relevance, and addressing uncertainty, especially for early-stage technologies. Equity assessments, including social LCA, seek to minimize negative outcomes and maximize positive outcomes from policies, programs, or processes, particularly for those facing inequality or disparities. In the federal government, equity assessment guidelines for the goal, scope, and system boundaries are still being developed, as are available data and localized information.

___________________

3 Coal waste streams considered in this report are coal combustion residuals (fly ash, bottom ash, boiler slag, and flue gas desulfurization products), impoundment waste (coarse and fine refuse), and acid mine drainage (as a source of critical minerals).

TEA, LCA, and equity assessment can be applied throughout technology development, helping to inform design and RD&D priorities at early stages and informing deployment decisions at later stages. DOE’s requirements for TEA and LCA are inconsistent, and there is a need to integrate TEA and LCA for decision support to avoid conflicting outcomes. Circular uses of carbon are poorly incorporated into existing methods for TEA, LCA, and equity assessments, and technical challenges need to be overcome to improve such methodologies. The committee recommends that federal research agencies make consistent TEA and LCA requirements for applied research for all but early-stage technologies (Recommendation 3-1) and that TEA and LCA be facilitated for mid-to-late-stage technologies via guidance and improved tools (Recommendation 3-3). DOE should require life cycle thinking for equity assessments to identify hotspots and integrate risk and societal assessments (Recommendation 3-5) and support research into assessment approaches that address circularity of CO2-derived products and develop methods and tools for carbon traceability and custody (Recommendation 3-6).

POLICY AND REGULATORY FRAMEWORKS NEEDED FOR SUSTAINABLE CO2 UTILIZATION

Realizing the climate change and market benefits of CO2 utilization technology and infrastructure will require fundamental changes to current policy, economic, and regulatory structures. This report assumes a transition to a net-zero emissions future, which would require a price or limit on GHG emissions for technology competitiveness. CO2 utilization has important equity and justice implications that need to be addressed during development and deployment.

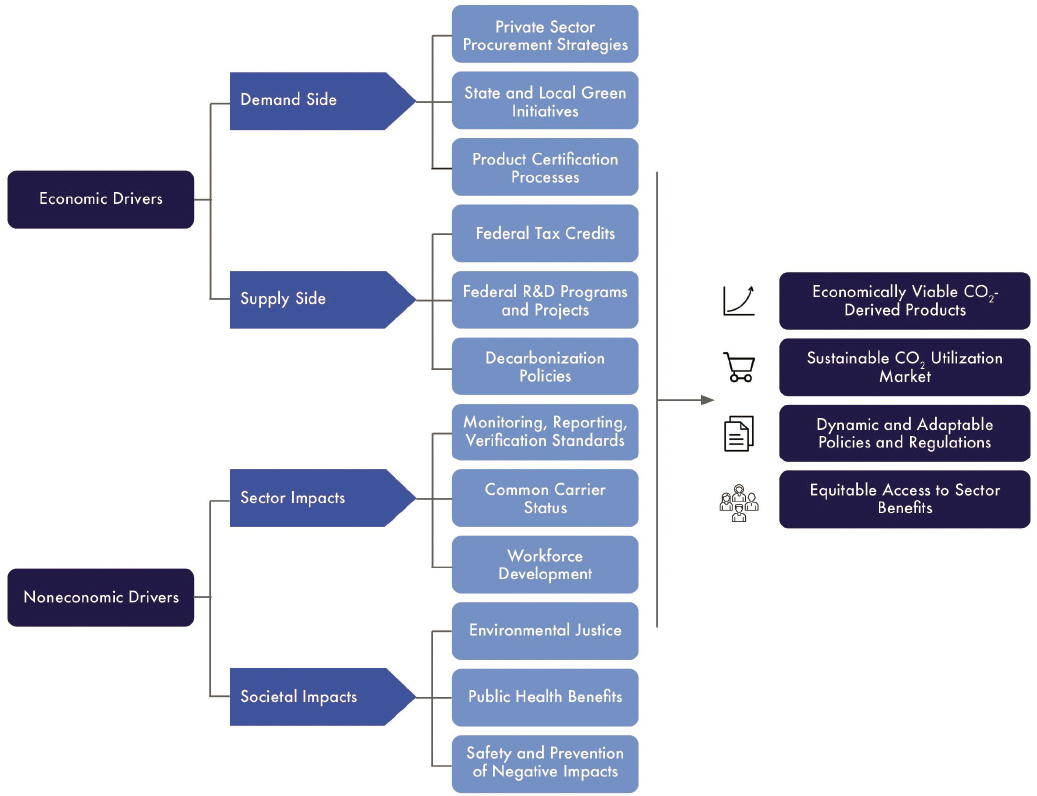

Existing incentives stem from tax credits, permitting and regulatory frameworks, and federal legislation. The committee examined potential demand- and supply-side policy tools, such as procurement and deployment support, and noneconomic tools, such as common carrier status, clarity of standards and codes, and workforce development. It evaluated business development mechanisms, especially for small businesses. It emphasized that a better understanding and intentional focus on environmental justice is needed for CO2 utilization to benefit impacted communities. In particular, environmental justice needs to be a focus during project development, infrastructure siting, and project selection. Principles of environmental justice are also useful in public discourse, community engagement, and policy development. Drivers, policies, and impacts for economically viable and sustainable carbon utilization are presented in Figure S-1.

The committee recommends that the General Services Administration and DOE develop upscaling opportunities for small businesses (Recommendation 4-4). DOE should work in partnership with community-centered councils and agencies to define, track, and measure impacts of CO2 utilization projects and infrastructure, determine equity of distribution, and communicate outcomes (Recommendation 4-5). To better understand public perception of CO2 utilization, nongovernmental organizations and research-conducting entities should identify gaps in knowledge about societal acceptance of or opposition to the sector (Recommendation 4-6). To improve community engagement, DOE should prioritize projects that incorporate meaningful community engagement frameworks into decision-making (Recommendation 4-7). To improve tangible benefits to surrounding communities, new CO2 utilization infrastructure development should apply justice principles during the planning and design process (Recommendation 4-8).

CO2 AND COAL WASTE UTILIZATION RESEARCH STATUS AND NEEDS

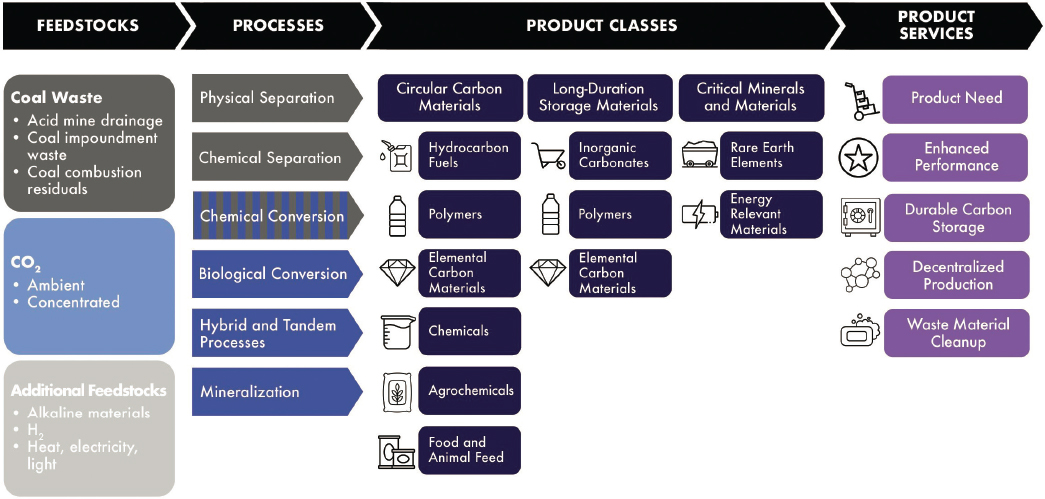

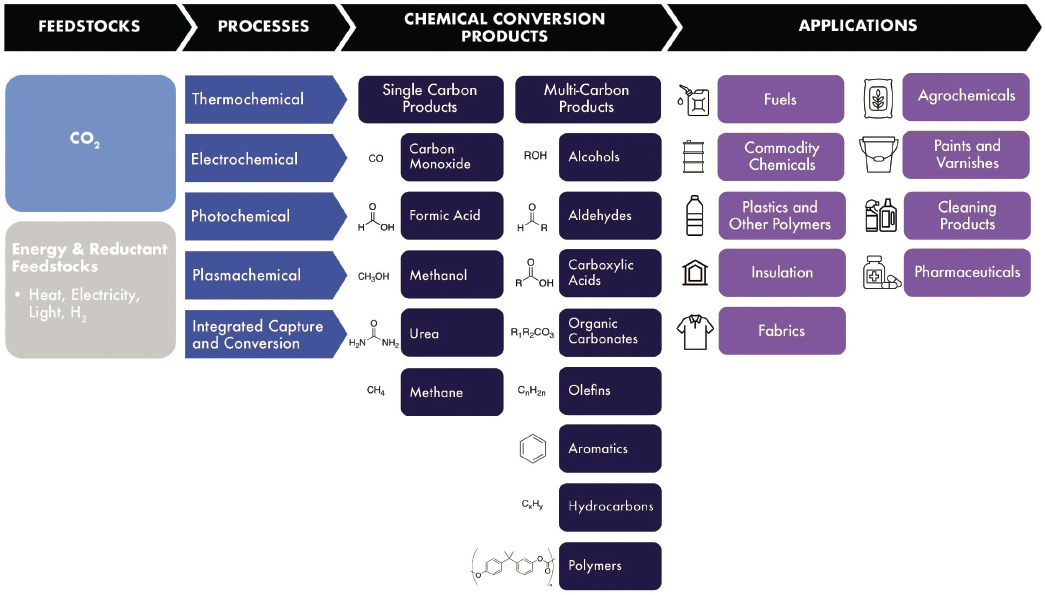

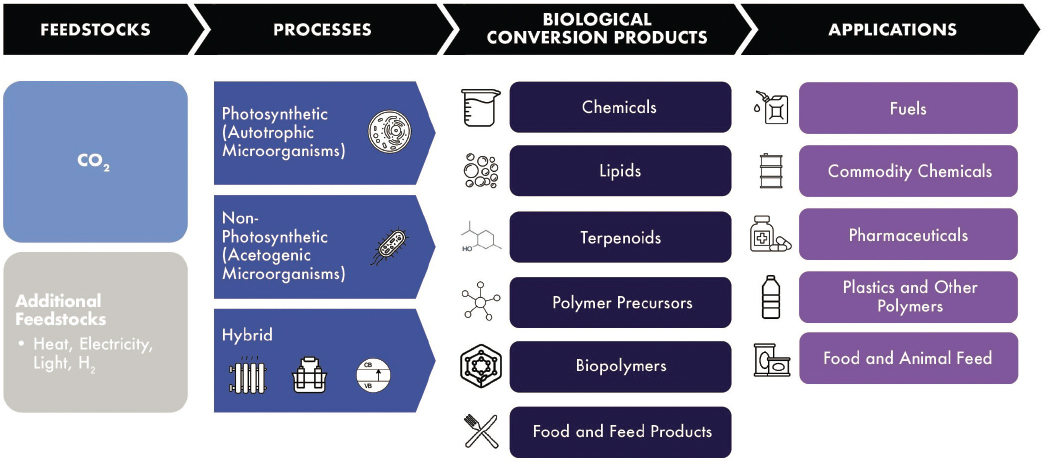

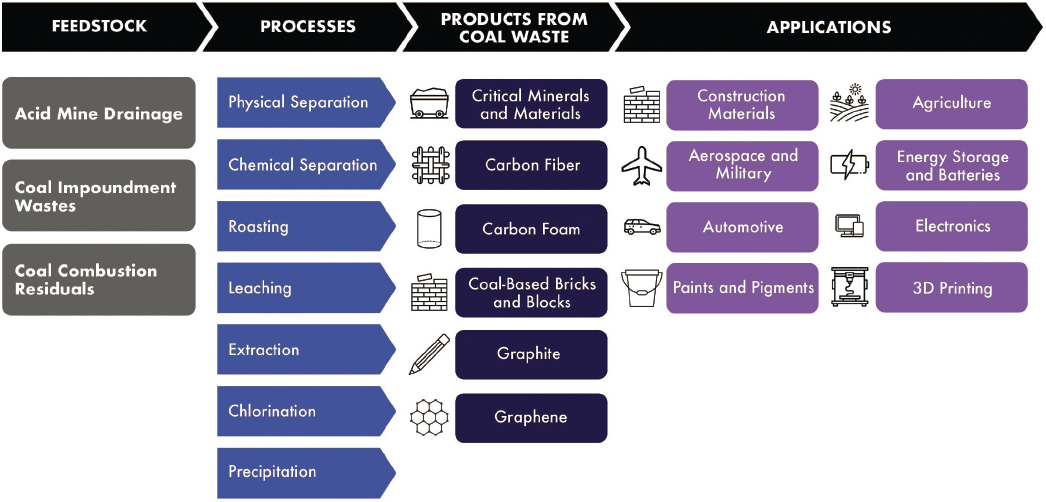

The committee described the status of RD&D efforts for CO2 utilization, assessed current and emerging technologies and approaches, identified research needs, and developed a comprehensive research agenda to advance CO2 utilization. This report updates a 2019 National Academies research agenda for gaseous carbon waste streams utilization (NASEM 2019). The committee identified research needs for coal waste utilization as part of examining commercialization feasibility and opportunities. The committee examined four approaches to CO2 utilization RD&D: (1) mineralization of CO2 into inorganic carbonates, (2) conversion of CO2 into elemental carbon materials, and (3) chemical and (4) biological pathways for CO2 conversion into organic chemicals and fuels. Coal waste utilization included use of carbon, rare earth elements, critical minerals, and other energy-relevant minerals. Chapters on each technology pathway describe existing and emerging products and processes, challenges, and RD&D opportunities. They conclude with overall RD&D needs and recommendations to address those needs. Figure S-2 summarizes the major feedstocks, processes, products, and applications for carbon utilization that are discussed in Chapters 5–9.

SOURCE: Icons from the Noun Project, https://thenounproject.com. CC BY 3.0.

SOURCE: Icons from the Noun Project, https://thenounproject.com. CC BY 3.0.

SOURCE: Icons from the Noun Project, https://thenounproject.com. CC BY 3.0.

Mineralization of CO2 to Inorganic Carbonates

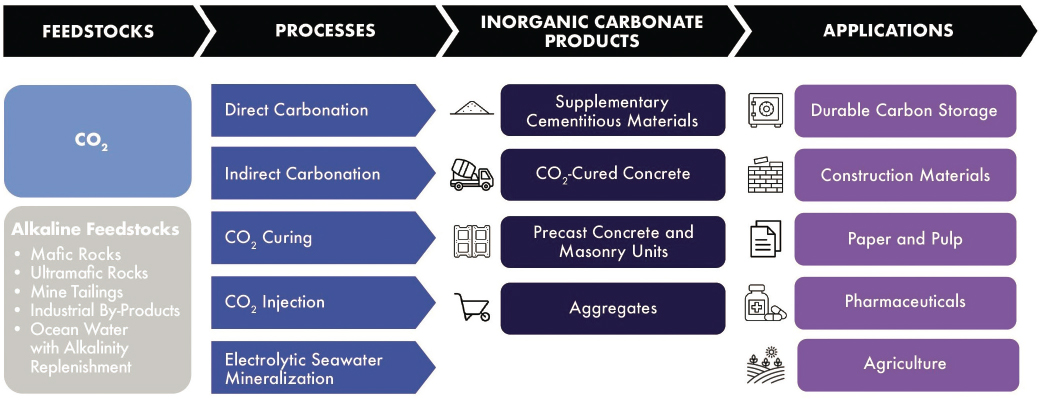

Reaction of CO2 with calcium- and magnesium-bearing minerals or alkaline industrial wastes forms inorganic carbonates: thermodynamically stable, solid materials with durable carbon storage capability and tens of gigatonnes annual global market potential. Inorganic carbonates have applications as supplementary cementitious material, in concrete cured with CO2, and as aggregates, all used primarily for construction materials. Technologies under development include carbonation of natural minerals or alkaline industrial wastes, enhanced carbon uptake by construction materials, electrolytic or biologically enhanced mineralization of brine and seawater, alternative cementitious materials and mineralization pathways (e.g., magnesium-based materials, pathways involving organic acids), and integrated processes. Current technical bottlenecks include large energy requirements for mining and processing of minerals, slow mineral dissolution and carbonation rates, managing feedstock impurities, and, for ocean-based processes, ensuring minimal environmental and ecosystem impacts. Testing and property validation of new materials for user and regulator acceptance are barriers to adoption. Figure S-3 presents the major features of mineral carbon utilization, including feedstocks, processes, products, and applications.

The committee identified mineralization RD&D needs and recommended actions in five areas. Cross-technology needs include evaluating and expanding mapping of alkaline resources; fundamental and translational research to improve energy efficiency, process efficiency, product selectivity, and scalability; and multimodal optimization of infrastructure to link feedstocks, mineralization sites, and product markets (Recommendation 5-1). Ocean-based CO2 mineralization needs include understanding local environmental impacts; developing a protocol to assess and mitigate impacts from pH changes; and developing a testing platform for ocean-based concepts (Recommendation 5-2). Electrochemical CO2 mineralization requires a full spectrum of RD&D activities, including catalyst development, cell design, membrane materials, and systems engineering/integration (Recommendation 5-3). Integration of carbon mineralization with metal recovery should be explored, including establishing university–industry–national laboratory collaborations for rapid scale up (Recommendation 5-4). Testing, standardization, and certification is required for construction materials produced from CO2; materials discovery and characterization of new forms of mineral carbonates are required to enable new processes such as 3D-printed concrete (Recommendation 5-5).

Chemical Conversion to Elemental Carbon Materials

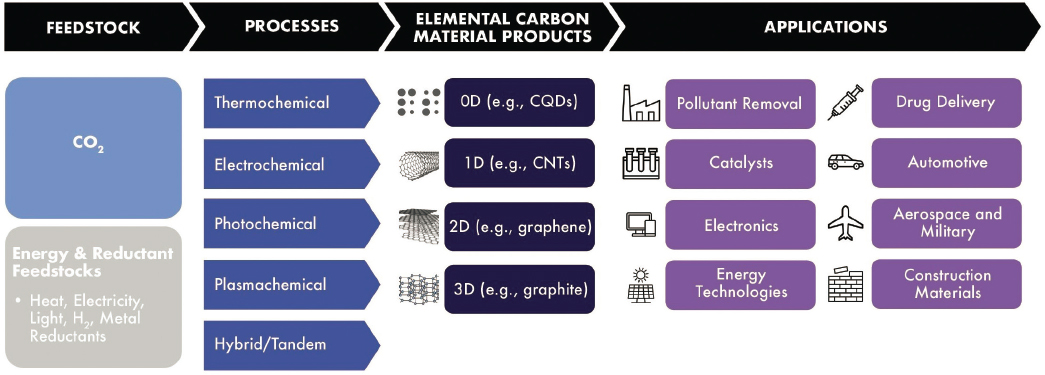

Elemental carbon materials are zero-, one-, two-, or three-dimensional (0D, 1D, 2D, or 3D) structures composed of carbon alone, and include products such as carbon dots, carbon nanotubes, graphene, carbon fibers, graphite, and carbon-carbon composites. These materials and their derivatives have elemental and bulk structures

SOURCE: Icons from the Noun Project, https://thenounproject.com. CC BY 3.0.

that yield properties like high conductivity, high mechanical strength, and active sites for catalysis. Markets for elemental carbon materials are growing as their novel structural and electronic properties are discovered and applications are found in the built environment, industry, health care, and environmental protection. Figure S-4 shows the major features of the input feedstock, processes, products, and applications associated with producing carbon materials from CO2.

CO2 can be reduced to elemental carbon via four major pathways: thermochemical, photochemical, electrochemical, and plasmachemical. Thermochemical reduction is the most mature but suffers from high energy requirements and low rates or deactivation through coking. Electrochemical reduction has relatively high selectivity and mild conditions, but slow rates owing to mass transfer, and high catalyst and separation costs. Photochemical and plasmachemical reduction have not been explored in depth. Directly derived products include fullerenes, hollow carbon spheres, carbon nanofiber and nanotubes, graphene, and graphite. Indirectly derived materials include carbon fiber and carbon-carbon composites.

Processes converting CO2 to elemental carbon materials have several common challenges, including limited research to date, difficulty comparing across approaches, substantial energy requirements, and limited understanding of system stability and selectivity. Research needs include developing foundational knowledge across the four conversion types (Recommendation 6-1), discovery and development of catalysts and low-energy processes for morphologically selective production (Recommendation 6-2), discovery and development of catalysts that are active, morphologically selective, and robust for production of diverse elemental carbon materials from CO2 (Recommendation 6-3), development of hybrid or tandem processes for CO2 conversion to elemental carbon materials (Recommendation 6-4), and development of integrated CO2 capture and conversion to elemental carbon materials (Recommendation 6-5).

Chemical Processes for CO2 Conversion to Fuels, Chemicals, and Polymers

Chemical conversion of CO2 can produce organic products, including fuels, chemicals and chemical intermediates, and polymers. Priority products include single-carbon compounds such as carbon monoxide, methanol, formic acid, urea, and methane; multicarbon compounds such as oxygenates, olefins, aromatics, and hydrocarbons; and polymers such as polycarbonates. Products can be generated via thermochemical, electrochemical, photochemical, plasmachemical, or integrated conversion routes, which each have their own challenges and RD&D opportunities. Figure S-5 shows the major feedstocks, processes, products, and applications for CO2 conversion to fuels, chemicals, and polymers.

SOURCE: Icons from the Noun Project, https://thenounproject.com. CC BY 3.0.

Challenges associated with high-temperature thermochemical CO2 conversion include controlling catalyst selectivity and stability, and the need for carbon-neutral energy, hydrogen, or other reductants. Significant amounts of carbon-neutral energy also will be needed for the other conversion pathways—electrochemical, photo(electro)chemical, and plasmachemical. Additional challenges for electrochemical CO2 conversion include long-term catalyst stability and robustness to impurities. Photo(electro)chemical and plasmachemical technologies require improved fundamental understanding of the steps from light absorption to reduction of CO2 and of plasma-catalyst interactions, and improved reactor design and reaction engineering. Tandem catalysis and integrated capture and conversion of CO2 could allow access to new products and improve energy efficiency, respectively.

The research agenda and recommendations offer guidance to address challenges with each chemical conversion pathway. Recommendations for thermochemical CO2 conversion include RD&D on catalytic selectivity and stability, alternative reaction heating methods, production of low-carbon hydrogen and other reductants, and integration with renewable energy and energy storage (Recommendations 7-1 and 7-2). For electrochemical CO2 conversion, RD&D needs include discovering and developing selective, active, and stable catalysts from abundant metals for diverse products; discovering and developing efficient, inexpensive, robust electrocatalysts for anodic reactions that enable CO2 utilization; and developing membrane materials with improved properties, cost, and efficiency (Recommendation 7-3). Advancing photo(electro)chemical and plasmachemical CO2 conversion requires gaining fundamental understanding of processes and interactions, materials discovery, and research to improve devices, reactor design, and reaction engineering (Recommendation 7-4). The committee recommends research on tandem catalysis to improve product portfolio options and integrated CO2 capture and utilization to improve system efficiency (Recommendations 7-5 and 7-6). It also recommends design and development of catalysts for rapid, stereoselective polymerization with a broader class of monomers (Recommendation 7-7).

Biological CO2 Conversion to Chemical, Fuel, and Polymer Products

Biological systems can convert CO2 to fuels, chemicals, and polymers via photosynthetic, nonphotosynthetic, and hybrid (e.g., electro-bio and cell-free biochemical) pathways. This report considers direct conversion of CO2 through autotrophic microorganisms, acetogenic microbes, or hybrid systems. Biological CO2 conversion focuses on discovery and engineering of microbes or hybrid processes, rather than on products, as often multiple products are accessible with each system. Photosynthetic systems (i.e., microalgae and cyanobacteria) use light energy and water to fix CO2 into products such as fuels, polymer precursors, and commodity chemicals. Nonphotosynthetic chemolithotrophic systems (e.g., acetogens) use the potential energy in inorganic compounds, such as H2 or CO, to form biological reducing agents that can fix CO2 under anaerobic conditions. Hybrid systems combine microorganism-based bioconversion with chemical catalysis (e.g., electro-, thermal-, plasma-, or photo-catalysis) or attempt biological conversions outside of the microbes themselves. Production of biopolymer precursors (e.g., butanediols, succinic acid, and isoprene) from CO2 could enable a circular carbon economy for plastics and other polymeric materials. Figure S-6 shows the feedstocks, processes, products, and applications for direct biological conversion of CO2.

Major challenges for photosynthetic production of chemicals from CO2 include inefficient photosynthesis and CO2 fixation; photorespiration of O2 rather than utilization of CO2, and cell shading inhibiting photosynthesis at high cell densities. Areas of opportunity include exploration of fast-growing cyanobacteria and eukaryotic algae, improved tools for genome and metabolic engineering, and development of large-scale cultivation strategies. Major challenges for nonphotosynthetic production include optimizing acetogen use of CO2 and forming commercially advantageous products; multiple substances and complex physiochemical environments; and need for improving electron donors. Opportunities include developing photomixotrophic approaches that combine photosynthesis with chemolithotrophy, including in co-cultured conditions; enhancing acetogenic fermentation, including finding product targets beyond acetate; and discovering and scaling up processes. Major challenges for hybrid systems include providing suitable electron donors; discovering or engineering bioconversion systems capable of high-rate conversion to single-carbon compounds; and improving scalability, economic viability, and process integration to facilitate commercialization. Opportunities for hybrid systems include operating in ambient conditions, converting biocompatible two- and three-carbon chemically produced intermediates, and utilizing cell-free systems to avoid competing pathways while accelerating the discovery process. Understanding the carbon flux control

SOURCE: Icons from the Noun Project, https://thenounproject.com. CC BY 3.0.

and bioenergetics of precursor production will help identify new pathways and improve productivity, conversion efficiency, and titer.

Biological CO2 conversion requires both basic and applied research to discover and improve systems. Research needs include more sophisticated understanding of metabolism design principles; development of more efficient genetic manipulation tools; and better integration of carbon capture and conversion for photosynthetic systems. Experimental and computational approaches to enhance enzyme stability and efficiency can improve commercial viability by optimizing system efficiency, by-product titer, and productivity (Recommendation 8-2). Applied research needs for polymer precursors include improving reactor design and processes and integrating carbon capture technologies with biological reactors. For hybrid systems, improving the scalability of electrolytic technology remains a key hurdle. Additionally, electrocatalyst design should be explored to improve biocompatibility and develop microorganism and cell-free systems that efficiently produce target chemicals from catalysis-derived intermediates under conditions amenable to electrocatalysis (Recommendations 8-3 and 8-4). Reactor design improvements are also needed for hybrid systems, optimizing them to use specific intermediates and produce desired final products (Recommendation 8-5).

Coal Waste

Although production and consumption of coal have fallen substantially in the United States—trends that are expected to continue4—current and past use for power generation and industrial processes has resulted in voluminous waste material. Coal waste is both an environmental contaminant in need of remediation and a material containing potentially useful components. This report considers opportunities for beneficial reuse of coal wastes, including acid mine drainage (as a source of critical minerals), coal impoundment wastes, and coal combustion residuals, focusing especially on legacy waste streams. Wastes are generated during coal mining, preparation, and combustion, and are located predominantly in Appalachia and the Intermountain West.

Materials derived from acid mine drainage include pigments and critical minerals; from impoundment wastes include materials for use in construction, energy storage, and 3D printing, carbon fiber, and carbon foam; and from coal combustion residuals include materials for use in cement, concrete blocks, asphalt, drywall, and critical minerals. Coal waste contains hazardous components such as heavy metals and volatile organic compounds, necessitating risk assessments for materials with the potential to leach hazardous components, health assessment of occupational and user exposures, and product performance evaluation for applications in construction, manufacturing, and industry. Figure S-7 shows the major features of coal waste utilization to produce long-lived, solid carbon products and extract critical minerals and materials, including feedstocks, processes, products, and applications.

The committee identified RD&D needs for coal waste utilization in five areas. Facilitating the use of coal wastes to produce solid carbon products or critical minerals and materials will require evaluation and mapping of coal waste resources, development of strategies and infrastructure to link coal waste sites to markets, and improvements to physical and chemical methods for separating mineral matter from carbon in coal wastes (Recommendation 9-1). Improved transformation of coal waste requires applied research into production of long-lived solid carbon products; basic research to understand coal waste conversions; development of 3D printing media from coal wastes; performance evaluation of coal waste–derived materials in their desired application; establishment of standards to address environmental exposures and product safety; and data and tools to conduct LCA and TEA of coal waste utilization processes (Recommendations 9-2 and 9-3). Improved characterization and separations of coal wastes and its components are needed (Recommendation 9-4). Novel methods for extracting lithium, rare earth elements, and other energy-relevant critical materials from both solid and liquid waste streams need to be developed, as do techniques to separate individual elements from each other, especially separation of nickel from cobalt (Recommendation 9-5).

___________________

4 In contrast, global production and consumption of coal are not in decline, so global markets for coal waste utilization technologies will likely exist even as U.S. coal waste volumes decrease.

SOURCE: Icons from the Noun Project, https://thenounproject.com. CC BY 3.0.

CO2 UTILIZATION INFRASTRUCTURE

CO2 utilization requires extensive infrastructure for CO2 capture, purification, transportation, and conversion, and for enabling systems to provide hydrogen, electricity, water, CO2 sequestration, and product transport. The first report of this committee (NASEM 2023) assessed the state of existing infrastructure for CO2 transportation, use, and storage and identified priority opportunities for future development of such infrastructure. This report identifies opportunities and challenges for CO2 utilization infrastructure planning at the regional or national scale and evaluates potential economic, climate, environmental, health, safety, justice, and societal impacts of CO2 utilization infrastructure.

Existing infrastructure for CO2 utilization includes 20 megatonnes (Mt) per year of CO2 point source capture and a minimal amount of direct air capture, ~5,000 miles of CO2 pipelines, ~400 gigawatts of carbon-free electricity, about half a Mt per year of low-carbon hydrogen capacity, and ~2 Mt per year of injection capacity for CO2 storage. Regional and national assessments of infrastructure capacity indicate one or more orders of magnitude increased need CO2 utilization and related systems. Extensive development and demonstration of CO2 utilization infrastructure is under way, in part because of federal government investments authorized in the Infrastructure Investment and Jobs Act. Additionally, private developers are proposing CO2 pipeline infrastructure, particularly in the Midwest associated with capture of ethanol and fertilizer plant emissions. The planned pipelines have faced opposition owing to health and safety concerns, and the potential to indirectly or directly enable continued fossil fuel use.

The need to access CO2, other enabling inputs like H2 and electricity, and product markets will generally result in a need to transport one or more of the inputs to or from a CO2 utilization site. Multimodal, regional transportation can benefit from mathematical optimization models, which can address a variety of circumstances, such as distributed small- and medium-scale emitters, industrial clusters associated with large volumes of CO2, and shared pipeline networks serving both CO2 storage and utilization. In some cases, existing infrastructure can be retrofitted to accommodate CO2 utilization, but technical, safety, and societal factors have to be considered. For instance, although some examples exist, there are significant economic and technical

challenges with retrofitting liquid petroleum or natural gas pipelines to transport high pressure CO2 or H2, as they were originally designed for lower pressures and different material reactivities. The large infrastructure requirements across the value chain for CO2 utilization could delay its growth if supporting infrastructure is slow to develop.

The committee examined economic, climate, environmental, health, safety, justice, and societal impacts of infrastructure for CO2 utilization, especially a well-integrated regional or national CO2 pipeline system applied for utilization. By enabling low-cost transportation of large volumes of CO2, a pipeline system would likely incentivize greater build-out of carbon management technologies and infrastructure across the value chain. This would enable more CO2 utilization, opening the CO2 marketplace up to traditional market demand dynamics, and could be further bolstered by regulations and policies to support the dual use of CO2 pipelines for both sequestration and utilization (Recommendation 10-3). Environmental impacts of CO2 utilization are associated with energy used for capture, transport, and utilization; leaks of CO2 or H2; and land and water requirements. Health and safety implications of CO2 pipeline systems include those associated with the value chain for utilization, especially CO2 capture, such as increased or decreased facility pollutant emissions. CO2 pipelines have significant risks that need to be addressed through proper planning, design, and public consultation in regulation, siting, construction, operation, and decommissioning. In particular, the Pipeline and Hazardous Materials Safety Administration needs to fund research into dispersion modeling and propagating brittle and ductile fractures, as well as realistic-scale test facilities (Recommendation 10-5) and to hold proactive, open-forum consultations with the public for updating its pipeline safety standards (Recommendation 10-1).

RESEARCH AGENDA

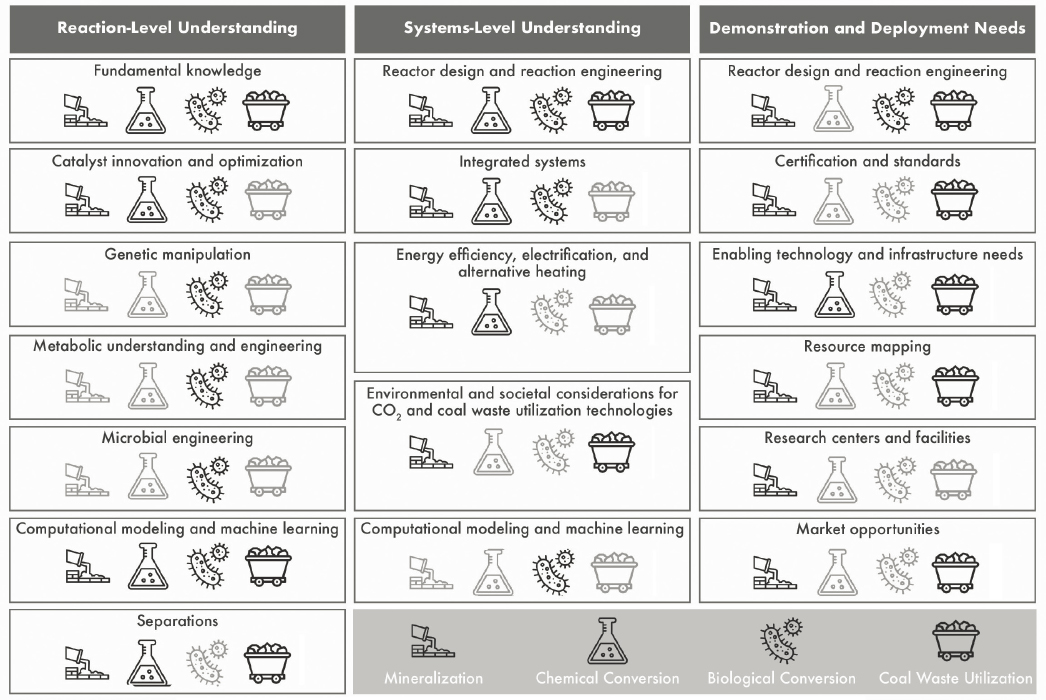

The committee developed a research agenda that identifies priority RD&D needs and recommended actions to be taken by government, industry, and academia to enable CO2 and coal waste utilization in a net-zero future. Basic research, applied research, demonstrations, and enabling technology developments are needed across all CO2 conversion and coal waste utilization pathways. Enabling needs were identified for markets, technology assessments, policy/equity, and infrastructure. Out of these research needs, three broad categories emerged—reaction-level understanding, systems-level understanding, and demonstration and deployment needs—further separated into 16 research themes. Figure S-8 illustrates the overlap in research themes among the different conversion pathways. Focus on reaction- and systems-level understanding will be most important for advancing chemical and biological CO2 conversion, while mineralization and coal waste utilization require increased support for demonstration and deployment efforts. Research to support markets, technology assessments, policy/equity, and infrastructure includes identifying market opportunities for CO2- and coal waste–derived products, developing tools to assess economic, societal, and environmental impacts of CO2 utilization processes, understanding public perception of CO2 utilization, and designing modeling and tools to support safe, efficient infrastructure development.

The full research agenda is presented in Chapter 11 (Table 11-1), supplemented by content in Appendix E. Research needs and recommended actions were developed in Chapters 2–10 based on the analysis of the status, barriers, and opportunities in each topical chapter, especially the technology pathway Chapters 5–9. All 71 research needs with their associated 35 recommendations are assembled in Table 11-1, classified by conversion pathway or enabling opportunity. Each research need identifies relevant funding agencies or other actors; specifies basic research, applied research, technology demonstration, or enabling technologies and processes; and denotes into which of the 16 research themes the research need falls. Each need indicates the relevant research area (mineralization, chemical, biological, coal waste utilization, LCA/TEA, markets, infrastructure, and societal impacts) and product class (construction materials, elemental carbon materials, chemicals, polymers, coal waste-derived carbon products, and critical material coal waste by-products), and whether the product is long- or short-lived. Finally, it notes the finding, recommendation, and/or chapter section associated with each research need to direct interested readers to more information on the topic. The research agenda indicates where DOE, other federal funding agencies, industry, and the research community can focus their efforts to improve CO2 and coal waste utilization for a net-zero emissions future.

NOTE: Icons in black (see legend lower right) indicate which process(es)—mineralization, chemical conversion, biological conversion, and/or coal waste utilization—have RD&D needs in each theme.

SOURCE: Icons from the Noun Project, https://thenounproject.com. CC BY 3.0.

REFERENCES

NASEM (National Academies of Sciences, Engineering, and Medicine). 2019. Gaseous Carbon Waste Streams Utilization: Status and Research Needs. Washington, DC: The National Academies Press. https://doi.org/10.17226/25232.

NASEM. 2023. Carbon Dioxide Utilization Markets and Infrastructure: Status and Opportunities: A First Report. Washington, DC: The National Academies Press. https://doi.org/10.17226/26703.